Bag On Valve Laminates Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433385 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Bag On Valve Laminates Market Size

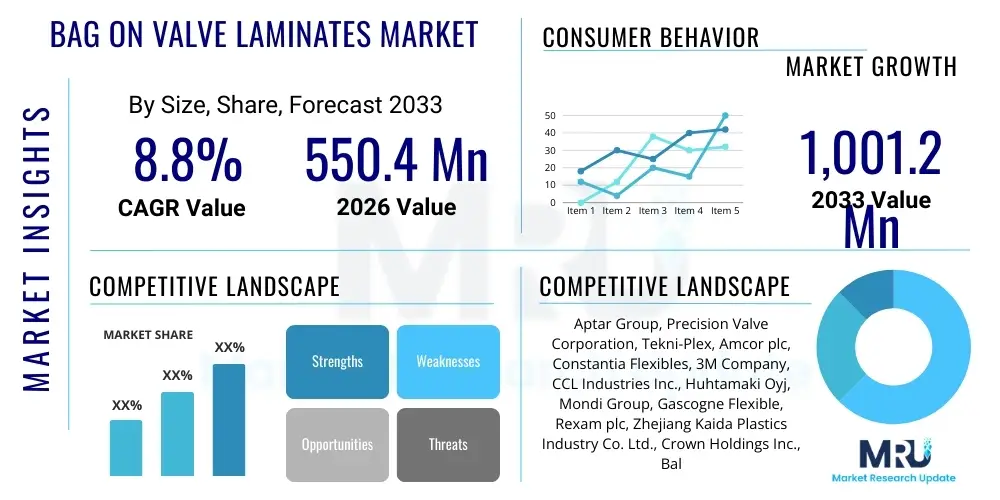

The Bag On Valve Laminates Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.8% between 2026 and 2033. The market is estimated at USD 550.4 Million in 2026 and is projected to reach USD 1,001.2 Million by the end of the forecast period in 2033.

Bag On Valve Laminates Market introduction

The Bag On Valve (BOV) Laminates Market encompasses advanced flexible packaging materials specifically designed for use in aerosol dispensing systems that separate the product from the propellant. BOV technology is a modern alternative to traditional aerosol cans, offering superior product integrity, extended shelf life, and controlled, non-aerosolized dispensing. The core product, BOV laminate, is a multi-layer flexible material—often combining materials like aluminum foil, polyethylene (PE), and polyethylene terephthalate (PET)—engineered to possess exceptionally high barrier properties against moisture, oxygen, and UV light, ensuring the contents remain sterile and uncontaminated by the surrounding pressurized gas. These laminates are crucial as they form the internal bag holding the product, which collapses as the product is dispensed, utilizing compressed air or nitrogen as the propellant outside the bag.

Major applications for BOV laminates span highly regulated industries, including pharmaceuticals, where they are used for topical medications, wound cleansers, and nasal sprays requiring sterility and precise dosage control; cosmetics, particularly for sunscreens, natural lotions, and sensitive skin formulations; and food products, such as cooking oils, condiments, and flavor sprays that benefit from zero propellant contamination. The appeal of BOV systems stems from their ability to allow near-complete product evacuation (up to 99%), consistency in spray pattern regardless of the can orientation (360-degree application), and reduced environmental impact compared to traditional hydrocarbon propellants. The inherent safety features and the ability to handle highly viscous or sensitive formulations have solidified BOV laminates as a premium packaging solution.

Driving factors in this market include stringent global regulations emphasizing the elimination of volatile organic compound (VOC) propellants in consumer goods, increasing consumer preference for clean label products free from chemical additives, and the accelerating demand for sterile and non-contaminating packaging in healthcare sectors. Furthermore, continuous technological advancements in flexible barrier film science, specifically the development of sustainable, recyclable, and bio-based laminates that maintain high barrier integrity, are opening new opportunities for BOV systems across diverse consumer goods categories. The robust growth trajectory is intrinsically linked to the expanding scope of applications where product purity and controlled dispensing are paramount market differentiators, pushing manufacturers toward advanced laminate solutions.

Bag On Valve Laminates Market Executive Summary

The Bag On Valve Laminates Market is characterized by robust growth driven by sustained demand from the personal care and pharmaceutical sectors, establishing a strong business trend toward specialized, high-barrier flexible packaging. A primary business trend involves the rapid shift towards high-performance, multilayer structures that incorporate advanced materials like EVOH (Ethylene Vinyl Alcohol) or metallized films, enhancing gas and moisture protection beyond standard aluminum foil laminates, which is essential for preserving the efficacy of sensitive medicinal and cosmetic formulations. Furthermore, consolidation among major packaging converters and raw material suppliers is shaping the competitive landscape, focusing efforts on vertical integration to control quality and supply chain resilience. The market also observes an increasing emphasis on sustainability, pushing manufacturers to invest significantly in the research and development of recyclable monomaterial BOV laminate structures that comply with emerging global plastic circular economy mandates, representing a critical long-term investment for major industry participants.

Regional trends indicate that Europe and North America currently dominate the market, primarily due to well-established regulatory environments that favor propellant-free dispensing and high consumer acceptance of premium, safe packaging solutions in the cosmetics and healthcare industries. However, the Asia Pacific (APAC) region is projected to register the highest Compound Annual Growth Rate (CAGR) throughout the forecast period. This rapid expansion in APAC is fueled by increasing healthcare expenditure, burgeoning personal hygiene awareness, rapid urbanization leading to higher demand for convenience products, and the establishment of local manufacturing hubs for personal care and pharmaceutical production, particularly in populous countries such as China and India. Middle East and Africa (MEA) and Latin America (LATAM) are emerging as significant consumption markets, primarily adopting BOV technology in insecticide, household cleaning, and specific pharmaceutical applications where portability and extended shelf life are valued attributes.

Segment trends highlight the Material type segment, where Aluminum Laminates currently hold the largest market share due to their unmatched barrier performance, especially crucial for oxygen-sensitive or sterile products. Nevertheless, the Polymers/Plastics segment (including PE, PET, and specialized films) is demonstrating faster growth, driven by cost-effectiveness, design flexibility, and the drive toward aluminum-free, transparent, or lightweight packaging solutions. Within the Application segment, the Cosmetics and Personal Care industry remains the largest revenue generator, utilizing BOV systems extensively for high-value sunscreens, deodorants, and shaving creams. Concurrently, the Pharmaceutical segment is experiencing critical growth, propelled by the strict requirement for sterile and highly controlled drug delivery systems, making it the most stringent segment in terms of material specification and regulatory compliance. The focus across all segments remains firmly fixed on developing customized laminate structures that meet specific product viscosity and barrier requirements while reducing the overall cost of ownership for fillers and brand owners.

AI Impact Analysis on Bag On Valve Laminates Market

User queries regarding AI's influence in the BOV Laminates sector often center on improving material science, enhancing manufacturing precision, and optimizing complex supply chains. Common questions include how AI can accelerate the discovery of new sustainable barrier materials, whether AI-driven quality control can reduce defects in multi-layer lamination processes, and how predictive analytics can manage inventory and demand forecasting for specialized raw materials like high-purity aluminum foil or specific polymers. The consensus expectation is that AI will primarily drive operational efficiency and product quality enhancement. Key themes involve using machine learning algorithms to model the performance of new laminate compositions under varying environmental stressors (temperature, humidity), predicting potential failure points in the sealing and forming stages of BOV production, and automating fault detection during high-speed printing and lamination, thereby minimizing waste and achieving AEO in material handling.

- AI-Driven Material Informatics: Accelerating the discovery and simulation of novel, high-barrier, mono-material, and recyclable laminates, reducing R&D cycles.

- Predictive Maintenance: Utilizing machine learning on lamination and converting equipment to forecast mechanical failures, ensuring continuous, high-precision production runs and minimizing downtime.

- Advanced Quality Control (AQC): Implementing computer vision and deep learning models for real-time defect detection (pinholes, delamination, sealing imperfections) at speeds unattainable by human operators.

- Supply Chain Optimization: Employing AI algorithms to optimize the sourcing and logistics of specialized raw materials, providing predictive demand insights to converters and fillers.

- Process Parameter Optimization: Using reinforcement learning to fine-tune heat sealing, pressure, and speed parameters in the lamination process, achieving superior bond strength and consistency.

DRO & Impact Forces Of Bag On Valve Laminates Market

The market dynamics of BOV Laminates are significantly influenced by a convergence of strong regulatory drivers favoring environmentally conscious dispensing and underlying restraints related to manufacturing complexity and cost structure, alongside substantial opportunities in emerging healthcare applications. The key drivers center on the global push towards safer, non-flammable propellants and the proven efficacy of BOV systems in maintaining product purity and stability, which is particularly critical in pharmaceutical and sterile cosmetic domains. This trend is further amplified by consumer demand for products that offer 360-degree application and near-total product evacuation, providing superior value proposition compared to conventional aerosol technologies. These driving forces create a high barrier to entry for conventional packaging methods, cementing the role of BOV systems as a superior alternative for demanding applications, thereby consistently bolstering market growth.

Conversely, the market faces notable restraints, primarily stemming from the complexity inherent in producing highly engineered, multi-layer laminates and the overall higher initial capital investment required for BOV filling equipment compared to traditional aerosol lines. Manufacturing BOV laminates demands strict control over material quality, thickness tolerances, and bond strength to prevent delamination or barrier failure during pressurization and use, leading to higher operational costs. Furthermore, the limited availability of high-pgrade, specialized raw materials like specific barrier polymers and the intellectual property surrounding high-speed lamination and valve technology present technical and economic hurdles. While sustainability is a driver, the current dominant use of multi-material laminates (e.g., aluminum and plastics) poses a restraint regarding end-of-life recycling, necessitating substantial innovation to develop functional, recyclable, mono-material structures acceptable to the market.

Opportunities for expansion are abundant, particularly in the geographic penetration into rapidly developing economies where demand for advanced personal care and healthcare solutions is skyrocketing, alongside strategic diversification into new application sectors. The development of customized BOV solutions for high-viscosity products, biological formulations, and specific industrial lubricants offers significant untapped potential. Additionally, technological opportunities lie in developing cost-effective, high-speed rotary printing and lamination techniques that can drive down unit costs, making BOV technology accessible to mid-range consumer product segments. The ongoing focus on bio-based and compostable materials represents a long-term opportunity to overcome current recycling restraints and align the technology perfectly with future sustainability goals, potentially leading to widespread regulatory adoption incentives.

Segmentation Analysis

The Bag On Valve Laminates market is rigorously segmented based on material type, structure, application, and geographical region, reflecting the highly specialized nature of the end-use requirements. Material composition is foundational, dictating the barrier performance and cost, with aluminum-based laminates dominating high-end markets requiring maximal protection, while polymer-only structures cater to cost-sensitive or transparent packaging needs. Segmentation by structure, such as 3-ply or 4-ply, signifies the level of barrier integration and mechanical strength engineered into the film, tailored specifically to the product's shelf life and dispensing pressure requirements. Analyzing these segments provides crucial insights into product development pathways and investment priorities, especially regarding the shift towards recyclable or sustainable alternatives across different end-user industries.

- By Material Type

- Aluminum Laminates (High barrier, pharmaceutical grade)

- Polymer/Plastic Laminates (PE, PET, PP, EVOH)

- Metallized Film Laminates

- By Structure

- 2-Ply Laminates

- 3-Ply Laminates (PE/Adhesive/Aluminum)

- 4-Ply Laminates (Enhanced barrier layers)

- By Application

- Cosmetics and Personal Care (Sunscreens, Shaving gels, Deodorants)

- Pharmaceuticals (Wound care, Topical sprays, Nasal applications)

- Food and Beverage (Cooking oils, Condiments, Flavored sprays)

- Home Care and Industrial (Insecticides, Lubricants, Cleaning agents)

Value Chain Analysis For Bag On Valve Laminates Market

The Value Chain for the Bag On Valve Laminates Market is complex and highly specialized, beginning with the upstream supply of sophisticated raw materials and culminating in the downstream distribution of the finished, filled product to the end consumer. Upstream analysis focuses intensely on the suppliers of high-grade raw materials, primarily specialized polymer resins (such as linear low-density polyethylene (LLDPE), PET, and barrier polymers like EVOH), high-purity aluminum foils, and specific bonding adhesives. Quality control at this stage is critical, as minor inconsistencies in resin melt flow or foil thickness can compromise the integrity of the final multi-layer laminate. Key upstream activities involve the chemical formulation of barrier compounds and the production of film rolls that are then delivered to converters for the lamination process. Strong partnerships between raw material suppliers and converters are essential for innovation and maintaining a stable supply of materials that meet stringent regulatory compliance standards, particularly for pharmaceutical use.

The core of the value chain is the converting and manufacturing stage, where the specialized multi-layer laminates are produced through processes like co-extrusion, adhesive lamination, or extrusion coating, transforming raw films into the final BOV laminate structure with specified barrier characteristics and sealability. After lamination, these materials are often supplied to specialized valve manufacturers (who produce the actual BOV assembly) and then onward to contract filling companies or brand owners who perform the final process of pouch formation, product filling, and valve crimping inside the aerosol can. Distribution channels are varied but frequently rely on highly technical B2B sales forces, often directly connecting laminate manufacturers and valve suppliers with the pharmaceutical and cosmetic brand owners who prioritize technical consulting and quality assurance. Direct sales channels are highly favored for large-volume, specialized orders, ensuring technical support and tailored logistics.

Downstream analysis involves the final product assembly and market distribution. The key players here are the aerosol filler companies, which specialize in integrating the BOV laminate pouch and valve assembly into the final aluminum or steel can, performing the pressurization, and ensuring all quality checks are met before the product is packed and shipped. The final indirect distribution flows through traditional retail channels (pharmacies, supermarkets, e-commerce) to reach the end consumer. The increasing complexity of regulatory requirements, particularly concerning pharmaceutical product traceability and integrity, often mandates robust quality assurance checks throughout the downstream chain. The efficiency of the entire value chain hinges on seamless coordination between the laminate producer and the filler, as the performance of the laminate directly affects the product's shelf life and the success of the dispensing mechanism, making integrated technical support a major competitive advantage.

Bag On Valve Laminates Market Potential Customers

The primary potential customers and end-users of Bag On Valve Laminates are large multinational corporations and specialized manufacturers operating in highly regulated consumer goods sectors that require superior packaging integrity and controlled delivery systems. The most critical segments include pharmaceutical companies specializing in dermatological treatments, over-the-counter nasal decongestants, and sterile wound care sprays, where product stability and contamination prevention are non-negotiable regulatory requirements. These customers prioritize high-barrier aluminum laminates and demand extensive documentation regarding material sourcing and purity. The decision-making process in this sector is heavily influenced by regulatory compliance, vendor auditability, and proven performance in accelerated stability testing, making them high-value but stringent customers requiring highly customized laminate specifications and dedicated technical support throughout the product lifecycle.

Another significant customer base resides within the Cosmetics and Personal Care industry, encompassing leading brands of high-SPF sunscreens, specialized hair care mousses, sensitive skin moisturizers, and natural deodorants. For these buyers, the appeal of BOV laminates lies in the ability to dispense products with propellant-free precision, offer a premium user experience (360-degree spray), and maintain the purity of natural, preservative-sensitive formulations. While cost sensitivity is higher here than in pharmaceuticals, the willingness to invest in BOV technology is driven by brand differentiation and premiumization strategies. Furthermore, the Food and Beverage sector, particularly manufacturers of high-end cooking oils (like olive oil sprays) and specific concentrated flavorings, represents a growing customer segment that values BOV's ability to extend shelf life and dispense without oxidizing propellants, ensuring the true flavor profile of the product remains intact until the last drop.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 550.4 Million |

| Market Forecast in 2033 | USD 1,001.2 Million |

| Growth Rate | 8.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Aptar Group, Precision Valve Corporation, Tekni-Plex, Amcor plc, Constantia Flexibles, 3M Company, CCL Industries Inc., Huhtamaki Oyj, Mondi Group, Gascogne Flexible, Rexam plc, Zhejiang Kaida Plastics Industry Co. Ltd., Crown Holdings Inc., Ball Corporation, Sibo Group, Toyo Seikan Group Holdings Ltd., Essel Propack (now part of Aptar), ALPLA Werke Alwin Lehner GmbH & Co KG, Winpak Ltd., Bischof + Klein SE & Co. KG |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Bag On Valve Laminates Market Key Technology Landscape

The technology landscape governing the Bag On Valve Laminates Market is highly specialized, revolving primarily around advanced flexible material science, precision manufacturing processes, and sterilization techniques crucial for maintaining product integrity. The foundational technology involves multi-layer co-extrusion and sophisticated lamination processes (such as solventless or adhesive lamination) used to bond disparate material layers—like high-barrier aluminum foil, structural polymers (e.g., PET), and sealant layers (e.g., LDPE/LLDPE)—into a single, robust laminate film. Achieving perfect adhesion across these layers while maintaining minimal thickness variation is technologically demanding and essential for preventing delamination when the package is subjected to high internal pressures and external stresses during filling and use. Current technological advancements focus heavily on integrating EVOH or specialized nylon barrier layers into the structure to create high-performance, cost-effective films that can substitute aluminum in certain applications, especially where transparency or reduced density is required, pushing the boundaries of material engineering efficiency.

Another pivotal technological development involves surface deposition and coating technologies, such as plasma-enhanced chemical vapor deposition (PECVD), used to apply ultra-thin inorganic barrier coatings (e.g., Aluminum Oxide (AlOx) or Silicon Oxide (SiOx)) onto polymer films. These high-barrier coatings enable the creation of transparent or semi-transparent flexible packaging with barrier properties approaching that of aluminum, while significantly enhancing the material’s recyclability profile. This is crucial for AEO compliance in products where visual appeal is important or metal detection is problematic. Furthermore, precision converting technology, particularly the use of laser scoring and advanced heat-sealing equipment, plays a critical role in accurately cutting and forming the laminate into the final BOV pouch geometry. Imperfections in the seal area are the most common cause of BOV failure, thus demanding highly controlled, consistent sealing technology that can accommodate varied film compositions at high production speeds.

In terms of process optimization and functional integration, key technological trends include the integration of advanced inline quality monitoring systems, often utilizing non-destructive testing methods like ultrasonic scanning or specialized visual inspection software, to detect micro-pinholes or internal bond defects during the high-speed lamination phase. The focus on sustainability has also spurred intense research into creating functional mono-material BOV laminates (e.g., all-polyethylene structures) that can be readily recycled through existing waste streams. While challenging due to inherent barrier limitations of single polymers, progress is being made through novel compatibilizer chemistries and multi-layer structural configurations that mimic the barrier performance of mixed materials. Successful deployment of these mono-material solutions represents a significant technological leap that would redefine market standards and address critical environmental restraints facing the packaging industry globally, ensuring compliance with future circular economy mandates and providing competitive advantage.

Regional Highlights

The Bag On Valve Laminates Market demonstrates distinct regional characteristics, driven by varying regulatory environments, consumer wealth, and the maturity of local manufacturing capabilities across the globe. Each region presents unique growth drivers and strategic priorities for market penetration, making localization of material specifications and application focus essential for overall market success. Strategic localization involves tailoring barrier technology to regional climate factors, such as high humidity in Southeast Asia, and adapting to local recycling infrastructure, which significantly affects the preferred laminate structure and end-of-life considerations.

- North America (US and Canada): This region is characterized by high penetration of BOV technology in premium personal care and sophisticated pharmaceutical markets. Regulatory strictness, particularly from the FDA, mandates the use of high-quality, traceable, and sterile packaging, driving demand for premium aluminum-based laminates. The U.S. remains a technological leader in BOV filling and is a major center for innovation in sustainable packaging, with a growing focus on bio-based and recyclable plastic laminates to meet consumer-driven environmental targets. Growth is robust, propelled by the medical and cosmetic sectors' willingness to adopt high-cost, high-performance solutions.

- Europe (Germany, UK, France, Italy): Europe is the largest market segment, strongly influenced by stringent environmental mandates (e.g., REACH and the European Green Deal) and strong consumer awareness regarding product safety and ecological impact. The adoption rate of BOV systems is exceptionally high across all sectors, replacing traditional aerosols aggressively due to the environmental pressure against hydrocarbon propellants. Germany and France, in particular, are centers for technological excellence in lamination and converting, focusing heavily on developing high-barrier, mono-material, and cradle-to-cradle certified BOV solutions, setting global standards for sustainable innovation.

- Asia Pacific (APAC) (China, India, Japan, South Korea): APAC is the fastest-growing region, expected to outperform other markets in CAGR due to rapid industrial expansion, increasing middle-class income, and escalating demand for imported and locally manufactured personal care and healthcare products. China and India represent massive opportunities due to burgeoning population density and urbanization, driving demand for convenient, hygienic packaging solutions like BOV. While cost sensitivity is higher than in the West, localized manufacturing capabilities are rapidly expanding, leading to competitive pricing and greater market accessibility for laminate suppliers focusing on polymer-based, cost-effective BOV structures.

- Latin America (LATAM) (Brazil, Mexico): The LATAM market is characterized by medium growth potential, driven primarily by the need for extended shelf life solutions due to long distribution chains and varied climatic conditions. BOV adoption is accelerating in the personal care and home care segments. Economic instability remains a constraint, but increasing foreign direct investment in local manufacturing plants is steadily boosting the uptake of advanced packaging materials.

- Middle East and Africa (MEA): This region is an emerging market with significant opportunities in specialized pharmaceutical and high-end cosmetic segments. Demand is largely concentrated in the Gulf Cooperation Council (GCC) countries, driven by high per capita spending on luxury goods and stringent quality requirements for imported health products. Challenges include complex logistics and the relatively small scale of local converting infrastructure, often necessitating reliance on imports for specialized BOV laminates and valves.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Bag On Valve Laminates Market.- Aptar Group

- Precision Valve Corporation

- Tekni-Plex

- Amcor plc

- Constantia Flexibles

- 3M Company

- CCL Industries Inc.

- Huhtamaki Oyj

- Mondi Group

- Gascogne Flexible

- Zhejiang Kaida Plastics Industry Co. Ltd.

- Crown Holdings Inc.

- Ball Corporation

- Sibo Group

- Toyo Seikan Group Holdings Ltd.

- Essel Propack (now part of Aptar)

- ALPLA Werke Alwin Lehner GmbH & Co KG

- Winpak Ltd.

- Bischof + Klein SE & Co. KG

- Sonoco Products Company

Frequently Asked Questions

Analyze common user questions about the Bag On Valve Laminates market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of the laminate in a Bag On Valve system?

The primary function of the BOV laminate is to create a sealed pouch that holds the product and acts as a high-integrity barrier. This barrier separates the product from the pressurized propellant (air or nitrogen) contained in the outer can, ensuring the product remains sterile, untainted, and prevents oxidation or contamination throughout its shelf life. The laminate must be highly impermeable to gas and moisture.

How do Bag On Valve laminates contribute to product sustainability?

BOV laminates enhance sustainability by eliminating the need for traditional hydrocarbon or chemical propellants, which are often classified as Volatile Organic Compounds (VOCs). They also facilitate near-total product evacuation (up to 99%), reducing product waste. Furthermore, ongoing research is focused on developing mono-material laminate structures that are fully recyclable, addressing the challenge posed by conventional multi-layer packaging.

Which application segment holds the largest share in the BOV Laminates Market?

The Cosmetics and Personal Care application segment currently holds the largest market share. This dominance is driven by the widespread use of BOV technology for premium dispensing of sunscreens, natural lotions, shaving gels, and deodorants, where controlled dosage, propellant-free delivery, and 360-degree application are key value propositions for consumers.

What types of materials are commonly used to manufacture high-barrier BOV laminates?

High-barrier BOV laminates typically utilize multi-layer structures incorporating materials such as Aluminum foil (for maximum oxygen/moisture barrier), Polyethylene (PE) as the heat-sealable inner layer, and Polyethylene Terephthalate (PET) or Nylon for structural strength. Advanced laminates may also incorporate specialized barrier polymers like EVOH (Ethylene Vinyl Alcohol) to enhance gas barrier properties for specific product formulations.

What are the main drawbacks or restraints associated with adopting Bag On Valve technology?

The main restraints include the significantly higher initial capital investment required for specialized BOV filling and crimping equipment compared to conventional aerosol lines, the complexity and high cost of manufacturing the highly precise multi-layer laminate films, and the current challenges related to the recyclability of these multi-material structures at their end-of-life stage, which is a concern in markets prioritizing circular economy initiatives.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager