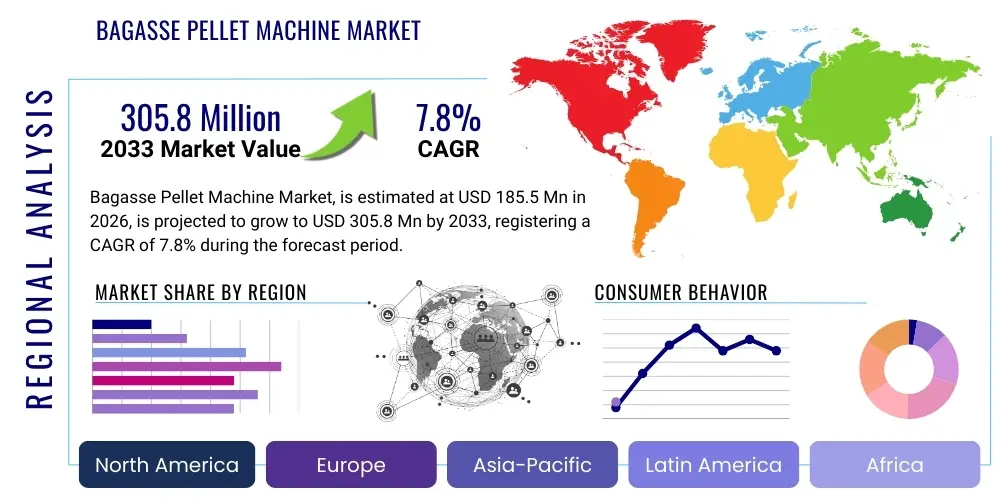

Bagasse Pellet Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438862 | Date : Dec, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Bagasse Pellet Machine Market Size

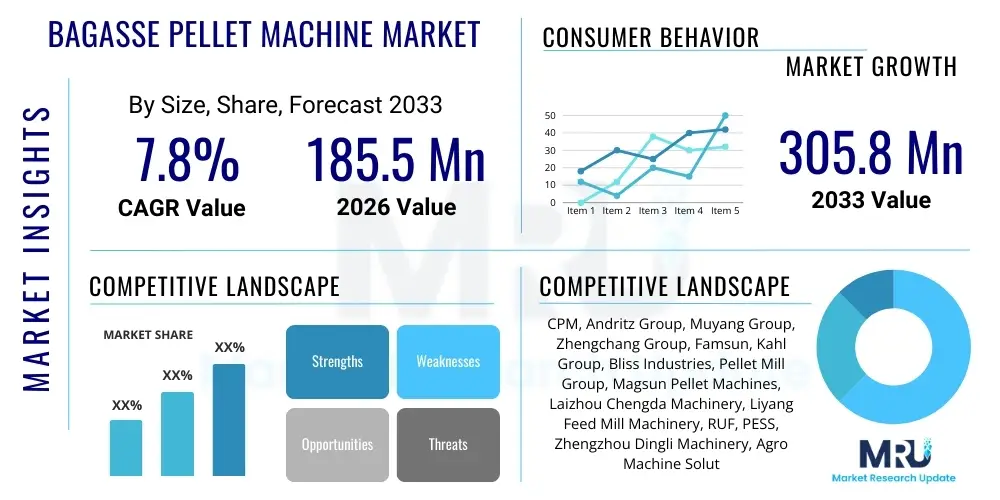

The Bagasse Pellet Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 185.5 million in 2026 and is projected to reach USD 305.8 million by the end of the forecast period in 2033.

Bagasse Pellet Machine Market introduction

The Bagasse Pellet Machine Market encompasses the manufacturing, distribution, and utilization of specialized machinery designed to compress bagasse—the fibrous residue remaining after crushing sugarcane stalks—into dense, uniform biomass pellets. These pellets serve as an eco-friendly alternative to fossil fuels, primarily utilized in industrial boilers, power generation facilities, and heating systems. The increasing global focus on sustainable energy sources, coupled with the substantial agricultural waste generated by the sugar industry worldwide, positions bagasse pelletization as a critical component of the bio-energy supply chain. These machines typically employ high-pressure compression technology, such as flat die or ring die mechanisms, to achieve the necessary density and durability for efficient transport and combustion.

The primary applications of bagasse pellets span across various sectors, demonstrating their versatility as a solid biofuel. In large-scale power plants, bagasse pellets are increasingly co-fired with coal, significantly reducing greenhouse gas emissions and reliance on conventional fuels. Industrially, they are used as boiler fuel in textiles, food processing, and chemical plants, offering cost savings and environmental compliance benefits, especially in regions with high sugar production. Furthermore, smaller-scale applications include residential and commercial heating, where the standardized size and low ash content of the pellets provide efficient and clean combustion.

Driving factors for this market include stringent governmental regulations promoting renewable energy adoption, favorable subsidies and incentives for biomass utilization, and the need for efficient waste management solutions within the sugar industry. The inherent benefits of bagasse pellets—high calorific value, low sulfur content, and carbon neutrality—further accelerate market demand. Key challenges involve managing the moisture content of raw bagasse and ensuring the operational efficiency and durability of the pelletizing equipment under continuous industrial loads, requiring continuous innovation in machine design and material science.

Bagasse Pellet Machine Market Executive Summary

The Bagasse Pellet Machine Market is characterized by robust growth, driven primarily by the global transition towards biomass energy and circular economy principles within the agricultural sector. Current business trends indicate a strong move towards integrated solutions, where manufacturers offer not just the pelletizer but also pre-processing equipment (shredders, dryers) and automated packaging systems. This vertical integration allows sugar mills and biomass aggregators to achieve higher efficiency and better quality control over the final pellet product. Technological advancement focuses on increasing energy efficiency, reducing operational downtime, and developing highly wear-resistant dies and rollers to handle the abrasive nature of bagasse feedstock, thereby lowering long-term maintenance costs for end-users.

Regional trends highlight the Asia Pacific (APAC) as the dominant and fastest-growing region, specifically driven by major sugar-producing countries like India, Thailand, Brazil, and China. These countries face immense pressure to sustainably manage agricultural residues and meet rapidly growing energy demands. North America and Europe, while slower in growth rate due to established mature energy markets, show significant adoption due to strict carbon reduction targets and the availability of substantial feedstock from global sugar trade. Latin America is also emerging strongly, capitalizing on its vast sugarcane plantations to establish robust bio-energy infrastructures, often supported by government-backed renewable energy schemes.

Segment trends reveal that the ring die pellet machine segment, preferred for high-volume industrial production due to its superior efficiency and ability to produce high-density pellets, maintains the largest market share. However, the flat die segment is gaining traction in smaller and decentralized operations due to its lower initial investment and simpler maintenance profile. In terms of application, industrial boiler fuel and power generation remain the largest segments, though the market is seeing increased specialization for torrefied bagasse pellets, which offer higher energy density and improved hydrophobicity, catering to long-distance export markets and advanced co-firing applications.

AI Impact Analysis on Bagasse Pellet Machine Market

User inquiries regarding the intersection of Artificial Intelligence (AI) and the Bagasse Pellet Machine market primarily revolve around optimizing operational efficiency, predicting equipment failures, and enhancing raw material quality control. Users are keen to understand how machine learning can interpret real-time sensor data—such as temperature, pressure, vibration, and moisture content—to dynamically adjust machine settings for optimal pellet density and energy consumption. Key concerns include the feasibility of integrating expensive AI systems into existing legacy machinery, the need for specialized data scientists in agricultural contexts, and ensuring the accuracy of predictive maintenance models given the variable nature of agricultural waste feedstock. Expectations center on leveraging AI to reduce energy costs by up to 15-20% and significantly minimize unexpected downtime through highly accurate failure prediction models for high-wear components like dies and rollers.

- AI optimizes machine operational parameters (pressure, speed, temperature) in real-time based on feedstock variability.

- Predictive maintenance algorithms use vibration and thermal data to forecast imminent failure of critical components (dies, rollers, gearboxes).

- Machine Vision (AI-driven cameras) performs high-speed quality control of finished pellets, ensuring uniform size and density.

- AI-powered supply chain logistics optimize bagasse collection, drying, and storage processes, minimizing moisture content variation.

- Automated fault diagnosis reduces troubleshooting time and improves technician efficiency.

DRO & Impact Forces Of Bagasse Pellet Machine Market

The market for Bagasse Pellet Machines is subject to various forces that shape its growth trajectory, categorized as Drivers (D), Restraints (R), and Opportunities (O). A primary driver is the global mandate for decarbonization, which necessitates the replacement of fossil fuels with carbon-neutral alternatives like biomass. Furthermore, the massive waste volume generated by the global sugar industry (estimated at hundreds of millions of tons annually) provides an extremely large and localized raw material source, eliminating significant logistical challenges faced by other biomass types. The financial viability of pelletization is further enhanced by regulatory credits and favorable power purchase agreements for bio-energy projects in key developing economies.

Restraints, however, pose significant challenges. The high initial capital investment required for industrial-scale pelletizing plants, including the necessary pre-treatment stages (drying, grinding), can deter smaller investors. Additionally, the highly abrasive nature of dried bagasse, attributed to its silica content, leads to rapid wear and tear of machine components, resulting in high maintenance costs and frequent component replacement. Consistency in feedstock supply quality, particularly managing moisture content variation during wet seasons, is a persistent operational hurdle that directly impacts pellet quality and machine throughput.

Opportunities for growth are concentrated in advanced processing technologies, such as torrefaction and steam explosion, which enhance the energy density and durability of bagasse pellets, opening up profitable international export markets. Furthermore, the integration of automation and smart monitoring systems, utilizing IoT and AI, presents a chance to overcome maintenance and efficiency challenges. The expanding decentralized energy generation model, particularly in rural sugar-producing regions, creates demand for small to medium-scale, modular pelletizing units, diversifying the market beyond large industrial plants.

Segmentation Analysis

The Bagasse Pellet Machine Market is comprehensively segmented based on machine type, technology employed, and end-user application, providing a granular view of demand characteristics across different operational scales. This segmentation is crucial for understanding specific technological preferences, investment strategies, and the dominant end-use sectors driving revenue. Analyzing these segments reveals shifting preferences toward higher capacity machines for established industrial users and simpler, more robust models for emerging decentralized biomass operations. The dominance of ring die technology reflects the high-density requirements of industrial power generation, which remains the largest application segment globally.

Geographically, the market segmentation highlights pronounced differences in adoption rates and machine capacity needs between regions. Asia Pacific leads the segment demand across all categories due to the sheer volume of sugarcane harvested. Conversely, established markets like Europe prioritize high-efficiency, low-emission models, often favoring integrated drying and pelletizing solutions to meet stringent quality standards for co-firing applications. Understanding these segment dynamics allows manufacturers to tailor their product offerings, focusing on modularity, scalability, or specialized post-processing features depending on the target region and application.

- By Machine Type:

- Small Scale (Under 1 Ton/Hour)

- Medium Scale (1 – 3 Tons/Hour)

- Large Scale (Above 3 Tons/Hour)

- By Technology:

- Ring Die Pellet Machines

- Flat Die Pellet Machines

- Hydraulic/Piston Pellet Presses

- By Application:

- Industrial Boiler Fuel

- Power Generation (Co-firing and Dedicated Plants)

- Commercial and Residential Heating

- Animal Bedding/Other Industrial Uses

Value Chain Analysis For Bagasse Pellet Machine Market

The value chain for the Bagasse Pellet Machine Market starts with the upstream segment, primarily involving the raw material suppliers and machinery component manufacturers. Upstream activities include the sourcing of high-grade steel and alloys necessary for manufacturing wear-resistant dies, rollers, and critical transmission parts. Key suppliers here are heavy engineering component providers and specialized metallurgy firms who must guarantee material quality to withstand the abrasive nature of bagasse processing. The reliance on durable materials significantly influences the final machine cost and the long-term total cost of ownership (TCO) for end-users.

The core of the value chain involves the manufacturing and assembly of the pelletizing equipment, including R&D efforts focused on optimizing compression ratios, thermal management, and automation features. Downstream activities encompass the distribution and deployment phases. Distribution channels are typically a mix of direct sales to large sugar conglomerates or integrated power plants, and indirect sales through regional distributors, engineering procurement and construction (EPC) contractors, and specialized biomass technology integrators. Post-sales services, including maintenance contracts, spare parts supply, and operational training, constitute a vital part of the downstream value proposition, ensuring high equipment utilization rates.

The final stage involves the utilization of the machines by end-users (sugar mills, biomass power producers) to create bagasse pellets, followed by the logistics network for pellet transport and sale to consumption points (industrial boilers, co-firing power plants). Direct distribution often occurs when the sugar mill utilizes the pellets internally or sells them directly to a nearby industrial park. Indirect distribution involves aggregators or commodity traders who purchase pellets, manage export logistics, and supply them to international markets, relying heavily on standardized quality certification to facilitate global trade.

Bagasse Pellet Machine Market Potential Customers

Potential customers for Bagasse Pellet Machines are diverse yet highly concentrated within the agricultural and industrial energy sectors. The most significant end-users are large sugar mills and integrated sugar production complexes. These entities possess a localized and enormous source of raw bagasse feedstock, making the investment in pelletization a natural extension of their waste management and energy generation strategy. By converting their waste into valuable energy assets, they achieve self-sufficiency in power and steam generation, often selling surplus power back to the grid, thus transforming a cost center (waste disposal) into a revenue stream.

Another major customer segment includes independent biomass power producers (IPPs) and co-firing power plants. These operators specialize exclusively in energy generation and source their bagasse feedstock from multiple sugar mills or via commodity traders. Their demand is specifically focused on high-capacity, highly efficient ring die machines capable of continuous 24/7 operation and producing pellets that meet stringent technical specifications for combustion efficiency and emission control. Furthermore, heavy industrial facilities, such as textile dyeing houses, chemical processing plants, and cement kilns located near sugarcane regions, constitute a growing market, utilizing bagasse pellets as a sustainable replacement for natural gas or fuel oil in their thermal processes.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 185.5 Million |

| Market Forecast in 2033 | USD 305.8 Million |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | CPM, Andritz Group, Muyang Group, Zhengchang Group, Famsun, Kahl Group, Bliss Industries, Pellet Mill Group, Magsun Pellet Machines, Laizhou Chengda Machinery, Liyang Feed Mill Machinery, RUF, PESS, Zhengzhou Dingli Machinery, Agro Machine Solutions, Gungzhou Kingwood Group, VYNTEC, Promill Stolz, Teknomatik, ABC Machinery |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Bagasse Pellet Machine Market Key Technology Landscape

The Bagasse Pellet Machine market is dominated by two primary mechanical technologies: the Ring Die and the Flat Die pellet mills, each optimized for different production scales and feedstock characteristics. Ring Die technology is characterized by a rotating die and fixed rollers, offering superior capacity and consistency for large industrial applications. This technology achieves higher compression ratios, crucial for producing durable, high-density bagasse pellets suitable for demanding processes like co-firing in coal power plants and for international shipping. Recent technological enhancements in ring die systems focus on optimizing the die structure and material composition (e.g., high chromium steel alloys) to mitigate the severe wear caused by the high silica content in bagasse, thereby extending the lifespan of the most critical component.

Flat Die technology, featuring a vertical axis and rotating rollers pressing material through a stationary horizontal die, is favored in small to medium-scale operations due to its simpler construction and lower maintenance profile. While generally yielding lower output than ring die machines, flat die presses offer better accessibility for repairs and are more forgiving with highly variable feedstock. Innovation in the flat die sector centers on enhanced gearbox designs to handle high torque requirements and automated moisture sensing systems integrated directly into the feeding mechanism to ensure consistent pre-treatment quality, which is vital for efficient pelletization.

Beyond the core mechanical press, crucial supplementary technologies define the current landscape. High-efficiency rotary drum dryers are essential for reducing bagasse moisture content from typical post-milling levels (45-55%) down to the optimal 10-15% range required for pelletization. Furthermore, advanced automation, utilizing PLC controls and Variable Frequency Drives (VFDs), allows for precise regulation of feeding, compression speed, and thermal output, optimizing energy consumption and improving pellet quality uniformity. Emerging technologies include torrefaction, a mild pyrolysis process applied to finished bagasse pellets to create "bio-coal," significantly increasing energy density and making the product water-resistant for improved storage and long-distance transportation.

Regional Highlights

The regional analysis of the Bagasse Pellet Machine Market reveals distinct growth drivers and technological adoption patterns across different continents, highly correlated with local sugar production volumes and governmental renewable energy policies. Asia Pacific (APAC) holds the largest market share globally due to concentrated sugarcane cultivation in countries such as India, Thailand, and China, which generate enormous quantities of bagasse waste. Rapid industrialization and government mandates for sustainable waste management and energy security further propel demand in APAC, leading to significant investment in large-scale, automated pelletizing facilities, often deployed directly within sugar mill premises to minimize logistical costs.

Latin America, particularly Brazil, is positioned as a powerhouse in this market. Brazil is the world's largest sugar producer and has well-established bio-energy policies utilizing sugarcane derivatives (ethanol and biomass). The region is characterized by integrated, large-scale milling operations that demand the highest capacity bagasse pelletizing systems for internal power generation and, increasingly, for export. The market in Latin America is driven by economic feasibility, leveraging bagasse to stabilize energy costs and reduce reliance on volatile hydro or fossil fuel power sources, attracting substantial foreign direct investment into biomass infrastructure.

Europe and North America represent mature markets, where growth is driven by regulatory compliance and high value-added applications. European demand is fueled by stringent EU emissions targets, requiring co-firing power plants to utilize certified sustainable biomass pellets. While local bagasse production is limited, demand focuses on premium, imported pellets (often torrefied) and highly efficient, low-emission machinery capable of processing imported feedstock. North America, especially the U.S. Gulf Coast, sees localized demand linked to regional sugar production, with an emphasis on using pellets for combined heat and power (CHP) applications in industrial clusters, demanding robust and technologically advanced equipment built for reliability and high throughput.

- Asia Pacific (APAC): Dominant market share and fastest growth; driven by massive sugar production (India, China, Thailand) and urgent waste-to-energy initiatives.

- Latin America: High growth driven by Brazil (world's largest producer); emphasis on large-scale, integrated bio-energy projects and energy independence.

- Europe: Growth driven by strict decarbonization mandates and demand for high-quality, certified imported pellets for co-firing applications.

- North America: Steady market relying on localized sugar production areas and demand for industrial CHP and boiler fuel replacement.

- Middle East & Africa (MEA): Emerging market potential, focused on utilizing sugar production waste to address severe energy deficits in localized areas.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Bagasse Pellet Machine Market.- CPM (California Pellet Mill)

- Andritz Group

- Muyang Group (Famsun)

- Zhengchang Group

- KAHL Group

- Bliss Industries

- Laizhou Chengda Machinery Co., Ltd.

- Liyang Feed Mill Machinery Co., Ltd.

- ABC Machinery

- Zhengzhou Dingli Machinery Co., Ltd.

- Gungzhou Kingwood Group

- Pellet Mill Group

- Promill Stolz

- Rye Pellet Solutions

- PESS Energy Equipment

- VYNTEC

- Teknomatik

- Magsun Pellet Machines

- Agro Machine Solutions

Frequently Asked Questions

Analyze common user questions about the Bagasse Pellet Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the typical return on investment (ROI) period for a Bagasse Pellet Plant?

The typical ROI period ranges from 3 to 5 years, highly dependent on the scale of the operation, local energy tariffs, and the availability and cost of raw bagasse feedstock. Utilizing self-generated bagasse and selling surplus power significantly accelerates the payback timeline.

What are the key challenges in processing bagasse compared to wood biomass?

Bagasse poses challenges primarily due to its high moisture content post-milling (requiring extensive pre-drying) and its abrasive silica content, which causes faster wear on pellet machine dies and rollers, necessitating more frequent maintenance and replacement of specialized components.

Which technology, Ring Die or Flat Die, is preferred for large-scale industrial use?

The Ring Die technology is overwhelmingly preferred for large-scale industrial use (over 3 tons/hour capacity) because it offers superior efficiency, higher compression ratios, and the ability to produce denser, more durable pellets suitable for continuous power generation and export logistics.

How does the quality of bagasse pellets affect combustion efficiency?

High-quality bagasse pellets, characterized by low moisture content (10-15%), uniform density, and low ash fusion temperature, maximize combustion efficiency, reduce slagging in boilers, and minimize particulate matter emissions, resulting in better energy yield and reduced maintenance.

What role do government policies play in driving market growth?

Government policies are crucial drivers, primarily through implementing Renewable Energy Standards (RES), offering production tax credits or subsidies for biomass energy projects, and mandating sustainable waste management practices for major agricultural producers, thereby creating a financial incentive for pelletizing operations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager