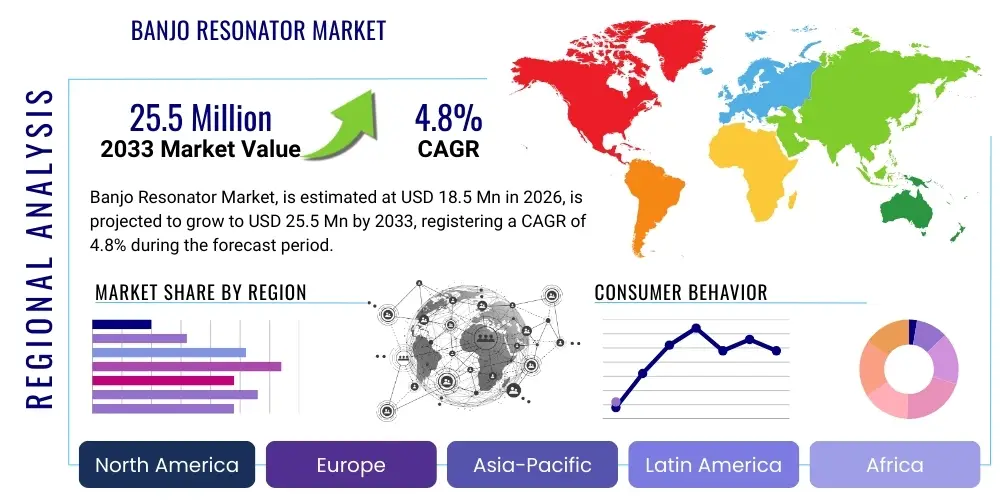

Banjo Resonator Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437869 | Date : Dec, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Banjo Resonator Market Size

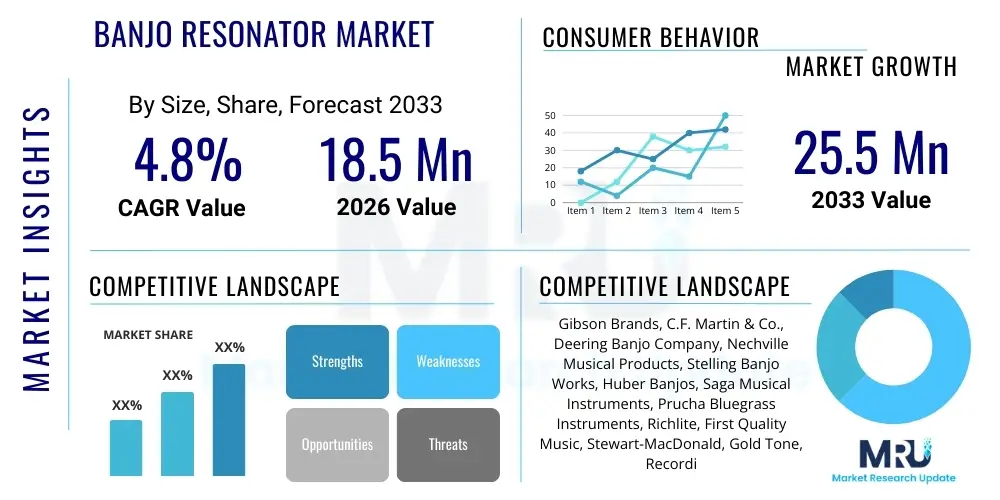

The Banjo Resonator Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at $18.5 Million in 2026 and is projected to reach $25.5 Million by the end of the forecast period in 2033.

Banjo Resonator Market introduction

The Banjo Resonator Market encompasses the specialized segment within the broader musical instruments accessories industry focused on the detachable or fixed wooden back component designed to enhance the projection and tonal quality of a five-string banjo. A resonator, typically utilized on Bluegrass or Scruggs-style banjos, functions primarily by reflecting sound waves generated by the pot assembly and head, forcing the sound outward rather than allowing it to dissipate equally in all directions. This structural element is crucial for achieving the characteristic loud, punchy, and highly articulate tone required for ensemble playing, distinguishing resonator banjos from open-back counterparts used predominantly for clawhammer or frailing styles. The demand in this market is intrinsically linked to the performance needs of professional musicians and serious hobbyists seeking superior acoustic performance and material customization.

The primary materials driving innovation within this market include premium woods such as mahogany, maple, and walnut, each imparting distinct tonal characteristics—maple for bright projection, mahogany for warmth, and walnut offering a balanced middle ground. The manufacturing process involves high-precision craftsmanship, often utilizing CNC machinery alongside traditional woodworking techniques to ensure perfect fit and optimal acoustic properties. Major applications extend beyond professional stage performance to recording studios, educational settings teaching traditional American folk and Bluegrass music, and the burgeoning custom instrument building industry. Resonators are essential for any player needing significant volume or specific tonal colorations in amplified or acoustic settings, thereby positioning them as high-value, non-commodity components.

Key benefits derived from high-quality banjo resonators include increased volume, improved sustain, and enhanced clarity across the tonal spectrum, allowing the instrument to cut through dense musical arrangements without distortion. The driving factors sustaining market growth include the global resurgence of interest in traditional acoustic music, particularly Bluegrass and related genres, necessitating instruments capable of professional-grade performance. Furthermore, the increasing consumer desire for customized instruments, where players select specific resonator woods and finishes to match aesthetic and acoustic preferences, fuels specialized manufacturing and material innovation, elevating the average selling price and market valuation. The market is characterized by a strong emphasis on brand reputation, material provenance, and meticulous construction standards, all contributing to the overall market dynamic.

Banjo Resonator Market Executive Summary

The Banjo Resonator Market exhibits steady growth, primarily fueled by robust business trends centered on customization, high-precision manufacturing, and direct-to-consumer sales strategies implemented by niche manufacturers. Business trends indicate a movement away from standardized, mass-produced components toward specialized, bespoke resonators crafted from select acoustic-grade timbers, often featuring unique inlay work or finishing techniques. Manufacturers are leveraging technological advancements, particularly in drying and curing wood, and utilizing advanced acoustic modeling software to optimize the internal geometry of the resonator, maximizing sound efficiency and consistency. The competitive landscape is characterized by a mix of established legacy banjo brands and smaller, high-end independent luthiers, creating a dual market structure where volume stability coexists with high-margin specialty components, maintaining overall market buoyancy despite the niche nature of the product.

Regional trends significantly underscore the dominance of North America, specifically the United States, which remains the central hub for Bluegrass music performance, education, and instrument manufacturing, thereby generating the highest demand for high-quality resonators. Europe follows as a crucial secondary market, driven by the popularity of folk and traditional music festivals and strong communities dedicated to American roots music, particularly in the UK, Ireland, and Scandinavian countries. Emerging regional growth is noted in parts of Asia Pacific, although this demand is generally focused on imported high-end US or Japanese instruments, rather than localized manufacturing. Infrastructure supporting acoustic music education and performance directly correlates with regional market maturity and consumption patterns for premium banjo components.

Segment trends highlight the critical role of material choice, with premium-grade maple and mahogany resonators capturing the largest revenue share due to their proven acoustic performance in Bluegrass settings. Furthermore, segmentation by end-user reflects a strong bifurcation between professional musicians seeking the absolute highest quality and advanced hobbyists prioritizing value and durability, impacting pricing strategies and production volumes across the market. The retail segment is increasingly migrating towards specialized online platforms and direct sales models, reducing reliance on traditional brick-and-mortar music stores, especially for high-value custom parts. This shift necessitates streamlined logistics and robust digital content showcasing the acoustic properties of the different resonator options available to the global consumer base.

AI Impact Analysis on Banjo Resonator Market

User inquiries regarding the integration of Artificial Intelligence (AI) in the Banjo Resonator Market primarily revolve around three core themes: optimization of manufacturing processes, predictive modeling for material sourcing, and the potential for AI-driven personalized sound design. Users frequently question how AI can ensure consistency in the inherently variable material (wood) and whether AI-powered acoustics modeling can supersede traditional luthier expertise in determining optimal resonator geometry and finish characteristics. There is also significant interest in using AI to analyze vast databases of historical banjo tones and player preferences, potentially leading to the development of "perfectly voiced" resonators tailored to individual musical styles or specific tonal goals. While AI’s direct impact on the craftsmanship of the final component remains limited, its application in reducing waste, enhancing quality control during drying, and optimizing complex supply chains is rapidly gaining traction among leading manufacturers.

- AI-driven acoustic modeling software optimizes internal resonator dimensions for maximum sound projection and clarity based on predictive simulations.

- Predictive supply chain analytics enhance raw material procurement, forecasting demand for specific high-grade timber species and minimizing inventory holding costs.

- AI algorithms analyze manufacturing data (temperature, humidity, cutting tolerance) to ensure precise quality control and consistency across production batches.

- Personalized marketing and recommendation engines use player data to match custom banjo builders and consumers with the ideal resonator wood and finish combinations.

- Robotics and automated finishing systems, managed by AI, improve the efficiency and uniformity of lacquering and polishing processes, reducing human error.

DRO & Impact Forces Of Banjo Resonator Market

The Banjo Resonator Market dynamic is defined by a nuanced interplay of Drivers (D), Restraints (R), and Opportunities (O), shaped by internal industry forces and external market influences. A primary driver is the ongoing revival and steady global growth of acoustic music genres, particularly Bluegrass, which mandates the use of instruments equipped with high-performance resonators for sonic projection and tonal purity in both live and recorded settings. Conversely, the market faces significant restraints, notably the reliance on scarce, high-quality, aged acoustic-grade hardwoods, which leads to volatile raw material costs and extended production lead times. Furthermore, the specialized nature of banjo components means demand elasticity is low, limiting the potential for significant market size expansion beyond the established enthusiast base. The interplay of these forces ensures a stable but specialized market environment, emphasizing quality over mass volume.

The core opportunities available to market participants include leveraging globalization to penetrate emerging markets in Asia and Latin America, where interest in American folk instruments is slowly gaining momentum, and focusing heavily on product diversification through material science. Innovations in composite materials that can mimic or surpass the acoustic properties of traditional hardwoods, offering supply chain stability and price predictability, represent a substantial opportunity for future revenue streams. Additionally, the increasing adoption of personalized purchasing experiences, often facilitated by digital configurators allowing customers to select every component detail, provides a pathway for manufacturers to capture premium pricing and enhance brand loyalty within the highly engaged consumer base. Strategic marketing efforts focused on the legacy and craftsmanship inherent in high-quality resonators further solidify brand positioning.

Impact forces within the market are predominantly driven by technological evolution in luthier techniques and material handling, alongside shifting consumer preferences toward sustainability and ethical sourcing. The technological force includes the adoption of advanced CNC machining and 3D scanning to ensure resonators fit the corresponding banjo pot perfectly, a critical factor for acoustic performance. The social impact force centers on the authenticity of the product; consumers often prefer traditionally crafted, ethically sourced woods, sometimes resulting in higher prices. The competitive impact force is high among specialized small workshops, where differentiation is achieved through unique inlay work, proprietary finishing processes, and established relationships with professional musicians, often overshadowing larger factory production scales. These forces collectively dictate pricing structure, production methodology, and distribution strategies across the entire value chain.

Segmentation Analysis

The Banjo Resonator Market is primarily segmented based on the material utilized for construction, the construction style (type), the end-user application, and the primary distribution channel employed for sales. Material segmentation is paramount as the choice of wood—primarily maple, mahogany, or walnut—directly determines the acoustic properties and final cost of the component, allowing manufacturers to target specific tonal preferences within the Bluegrass community. Segmentation by type differentiates between flange-integrated resonators and separate components, impacting installation methods and compatibility with various banjo pot assemblies. End-user segmentation distinguishes between Original Equipment Manufacturers (OEMs) who integrate the resonators into new instruments and the Aftermarket segment, consisting of custom builders and repair shops purchasing components for upgrades and repairs, often the highest margin segment. Understanding these segmentations is critical for market participants optimizing inventory and strategic pricing.

- By Material:

- Maple Resonators

- Mahogany Resonators

- Walnut Resonators

- Exotic Wood Resonators (e.g., Koa, Rosewood)

- Composite/Synthetic Resonators

- By Type/Construction:

- Traditional Archtop Resonators

- Flathead Resonators

- Integrated Resonator Systems

- By End-User:

- Original Equipment Manufacturers (OEMs)

- Custom Builders/Luthiers

- Hobbyists and Individual Upgraders

- Repair and Maintenance Shops

- By Distribution Channel:

- Direct Sales (Manufacturer Websites, Custom Shops)

- Specialized Music Retail Stores

- E-commerce Platforms (Amazon, Reverb)

- Wholesale Distribution (Supplying OEMs)

Value Chain Analysis For Banjo Resonator Market

The value chain for the Banjo Resonator Market begins with the upstream segment, which is dominated by the sourcing and preliminary processing of specialized acoustic timbers. This involves complex processes such as sustainable forestry, meticulous selection of highly figured or dense wood billets, and the critical stage of air-drying or kiln-drying the wood over extended periods to achieve optimal density and moisture content for stability and acoustic resonance. Upstream suppliers are often highly specialized wood mills or brokers who understand the unique requirements of instrument manufacturing, ensuring the wood is quarter-sawn and free of defects that could compromise sound quality. The quality and cost of raw materials at this stage dictate a significant portion of the final component cost and strongly influence overall market profitability, making robust supply chain management a core competence for manufacturers.

The midstream processing stage involves core manufacturing, where raw wood is machined using precision tools, often including advanced CNC systems, to cut the resonator rim and backplate to exacting specifications, followed by complex finishing and binding application. This stage requires significant investment in capital equipment and highly skilled labor—luthiers and finish specialists—who ensure that the acoustic integrity is maintained throughout the process. Downstream activities involve distribution channels, which are characterized by a strong presence of both direct and indirect sales models. Direct sales, facilitated by manufacturer websites and custom luthier shops, allow for high margins and personalized customer engagement, particularly for high-end, custom-order resonators, fostering a strong brand connection and technical consultation.

Indirect distribution relies on a network of specialized musical instrument retailers and e-commerce platforms, providing broader market access and standardized product availability. These channels cater primarily to the standardized replacement or upgrade market. The ultimate end-users/buyers include professional touring musicians, recording artists, serious amateur players, and custom instrument builders who require components meeting stringent quality standards. The efficiency of the distribution channel is measured by its ability to deliver delicate, high-value wooden components without damage, often necessitating specialized packaging and expedited logistics, reinforcing the importance of reliable, specialized distributors rather than general mass-market retailers.

Banjo Resonator Market Potential Customers

The core customer base for the Banjo Resonator Market is highly defined, consisting primarily of specialized musical professionals and dedicated amateur musicians who recognize the critical acoustic contribution of the resonator to the banjo’s overall tone and projection. Professional musicians, particularly those specializing in high-volume genres like Bluegrass, are the most discerning buyers, often seeking premium materials, custom specifications, and specific acoustic characteristics to differentiate their sound on stage and in the studio. These customers prioritize flawless craftsmanship, specific tonal woods (e.g., highly figured hard rock maple), and components that are compatible with specific vintage or contemporary banjo designs, often purchasing resonators as high-value upgrades rather than replacements.

A secondary, yet significant, segment comprises custom banjo builders and luthiers who purchase resonators in bulk or on a project-by-project basis to integrate into their bespoke instrument creations. These professional instrument makers act as key influencers and volume buyers, relying heavily on manufacturers to provide consistently high-quality components with precise dimensional tolerances, ensuring ease of assembly and acoustic optimization. Their purchasing decisions are driven by reliability of supply, the reputation of the resonator manufacturer, and the ability to offer their clients unique wood species or finishing options, contributing significantly to the aftermarket segment's revenue stream and shaping material trends.

Furthermore, educational institutions focusing on folk music programs, musical instrument repair shops, and advanced hobbyists constitute the tertiary market segment. Hobbyists often engage in the upgrade market, seeking to improve the sound of mid-range instruments through a resonator replacement, balancing quality with affordability. Educational customers typically seek durable, standardized components suitable for rigorous student use. This segmentation demands that manufacturers offer a tiered product line, ranging from high-cost, premium components for professional and custom markets down to more cost-effective, durable options for the student and repair segments, ensuring comprehensive market coverage and maximizing total addressable market penetration across all experience levels.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $18.5 Million |

| Market Forecast in 2033 | $25.5 Million |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Gibson Brands, C.F. Martin & Co., Deering Banjo Company, Nechville Musical Products, Stelling Banjo Works, Huber Banjos, Saga Musical Instruments, Prucha Bluegrass Instruments, Richlite, First Quality Music, Stewart-MacDonald, Gold Tone, Recording King, Banjos by Prucha, Ome Banjos, Wildwood Banjos, Bishline Banjos, Yates Banjo Company, Arthur E. Smith Banjos, Crafters of Tennessee. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Banjo Resonator Market Key Technology Landscape

The technology landscape governing the Banjo Resonator Market is characterized by a synergistic blend of traditional luthier techniques and advanced digital manufacturing processes aimed at optimizing precision and acoustic performance. Central to production is the application of high-precision Computer Numerical Control (CNC) machining. CNC technology allows manufacturers to achieve tolerances measured in microns, critical for ensuring that the resonator fits the banjo pot with zero gaps, which is paramount for maximizing acoustic coupling and sound transmission. Furthermore, sophisticated 3D scanning and computer-aided design (CAD) software are utilized to reverse-engineer vintage resonator geometries or to design proprietary internal channeling that influences the reflection and projection of sound waves. This digital precision enhances consistency, especially for high-volume orders for OEM clients, overcoming the natural variability inherent in manual woodworking.

Material science and specialized wood treatment technologies form another essential pillar of the technological landscape. Advancements in thermal modification (torrefaction or baking) of acoustic timbers are increasingly being adopted. This process alters the wood's cellular structure, reducing internal dampening and mimicking the acoustic properties of wood that has naturally aged for decades, resulting in enhanced tone and increased stability against environmental changes (humidity, temperature). Manufacturers utilizing such proprietary wood treatment processes gain a significant competitive advantage by offering high-performance, stable components without the lengthy lead times associated with traditional natural aging methods. The integration of advanced hygrometers and climate-controlled drying facilities further minimizes waste and ensures materials meet rigorous acoustic standards before machining.

Finally, the finishing technology applied to resonators, which involves specialized lacquers and polishing processes, is critical not only for aesthetics but also for acoustic impedance. Modern technologies include electrostatic painting and UV-cured finishes, which provide a thin, hard, and durable coating that minimizes mass while maximizing surface hardness, ensuring the finish does not dampen the wood’s vibration. The development of proprietary thin-skin finishes, sometimes utilizing nano-technology coatings, is a key area of research, focused on protecting the wood without stifling its natural resonance. Overall, the technological focus remains on minimizing variables associated with natural materials while maximizing the precision required for acoustic excellence, thereby bridging the gap between traditional craft and modern engineering.

Regional Highlights

North America, particularly the United States, represents the epicenter of the Banjo Resonator Market, driven by deep cultural roots in Bluegrass, Country, and American Folk music. The region boasts the highest concentration of professional banjo players, major manufacturers (like Gibson, Deering, and Nechville), custom luthiers, and dedicated music education institutions focusing on traditional acoustic genres. The regional market is characterized by a strong demand for premium, historically accurate components, with sales concentrated in the Southeast and Appalachian regions where Bluegrass culture is most dominant. High disposable income among serious hobbyists and professional musicians allows for robust sales of high-margin, custom resonators, making North America the primary revenue generator and trendsetter for component innovation.

Europe serves as the second most vital market, sustained by vibrant folk music scenes and increasing adoption of Bluegrass styles, particularly within the United Kingdom, Ireland, Germany, and Scandinavia. European demand is often met through imports from North American manufacturers, although niche European custom builders are gaining recognition. The market here focuses slightly more on versatility, with customers seeking high-quality components for both traditional five-string and tenor banjos used in different folk styles. Market growth is supported by large, international music festivals and a network of specialized importers and retailers catering to acoustic instrument enthusiasts who appreciate finely crafted components.

The Asia Pacific (APAC) region, while smaller in absolute terms, is emerging as a growth opportunity, driven by increasing awareness and interest in Western acoustic instruments among affluent consumers, particularly in Japan, South Korea, and Australia. Demand is heavily concentrated on high-end imported components, reflecting a preference for established American brands associated with quality and heritage. Latin America, the Middle East, and Africa (MEA) currently represent marginal markets, characterized primarily by scattered individual enthusiasts and specific regional cultural music programs that sometimes incorporate banjo styles, requiring specialized, low-volume distribution strategies focused on online and direct-import sales models.

- North America (NA): Dominant market share; driven by Bluegrass cultural heritage, high concentration of OEMs and custom builders, focus on premium, historically accurate components (e.g., specific pre-war specifications).

- Europe: Key growth market; strong folk music infrastructure, significant import volume, and growing presence of localized custom luthiers focusing on component quality and aesthetic customization.

- Asia Pacific (APAC): Emerging high-potential market; demand centered on high-end imports, driven by disposable income and cultural curiosity in Western acoustic instruments, particularly in developed economies like Japan.

- Latin America & MEA: Niche markets; characterized by low-volume, specialized demand met largely through e-commerce and direct international shipping, focusing on durability and necessary repair components.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Banjo Resonator Market.- Gibson Brands

- C.F. Martin & Co.

- Deering Banjo Company

- Nechville Musical Products

- Stelling Banjo Works

- Huber Banjos

- Saga Musical Instruments

- Prucha Bluegrass Instruments

- Richlite (Material Supplier)

- First Quality Music

- Stewart-MacDonald (Component Supplier/Distributor)

- Gold Tone

- Recording King

- Banjos by Prucha

- Ome Banjos

- Wildwood Banjos

- Bishline Banjos

- Yates Banjo Company

- Arthur E. Smith Banjos

- Crafters of Tennessee

Frequently Asked Questions

Analyze common user questions about the Banjo Resonator market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of a banjo resonator?

The primary function of a banjo resonator is to increase sound projection and enhance the tonal volume and clarity of the instrument by reflecting sound waves outward. This component is essential for instruments used in Bluegrass and ensemble settings, providing the characteristic punch and articulation necessary to cut through other instruments.

Which wood material is acoustically superior for banjo resonators?

There is no single "superior" material; the best choice depends on the desired tone. Maple is typically preferred for bright, clear projection, Mahogany for warm, focused tone, and Walnut offers a balanced sound. Premium acoustic-grade woods, often thermally modified, are valued above composite materials for professional-grade performance.

How does the Banjo Resonator Market compare in size to the overall musical instrument industry?

The Banjo Resonator Market constitutes a highly specialized, niche segment within the broader musical instrument accessory industry. While small in absolute valuation, it commands high margins due to the need for precision craftsmanship, specialized raw materials, and its essential role in professional-level acoustic performance instruments.

Are CNC-machined banjo resonators better than hand-carved resonators?

CNC machining offers unparalleled consistency and precision in achieving critical dimensions necessary for optimal acoustic coupling, often surpassing the repeatable tolerances of hand carving. While luthier expertise remains vital for material selection and finishing, CNC technology ensures the structural uniformity required for predictable high-performance sound characteristics across production batches.

What are the current major drivers of market growth?

The market is primarily driven by the sustained global revival of traditional acoustic music genres, increasing consumer demand for custom-built instruments that allow component specification, and ongoing technological advancements in wood treatment and precision manufacturing enhancing component quality and stability.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager