Bare Thermocouple Wire Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436002 | Date : Dec, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Bare Thermocouple Wire Market Size

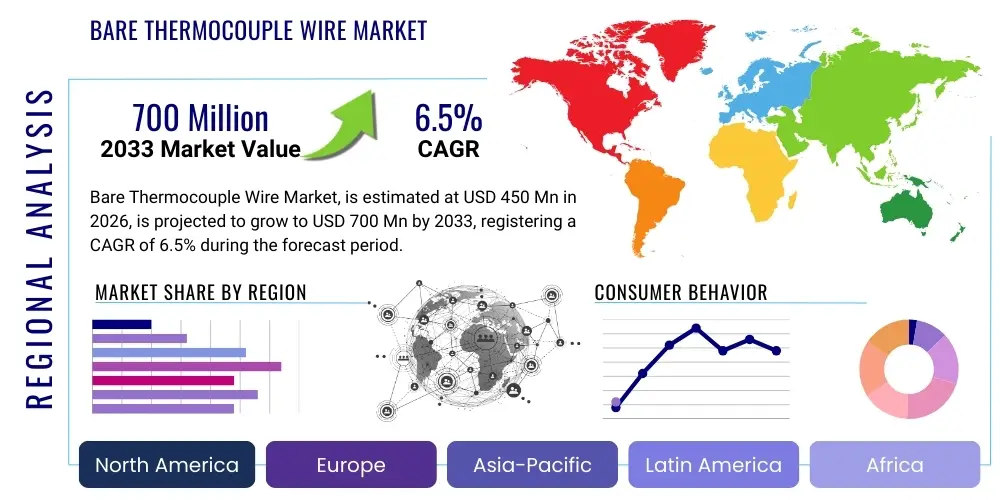

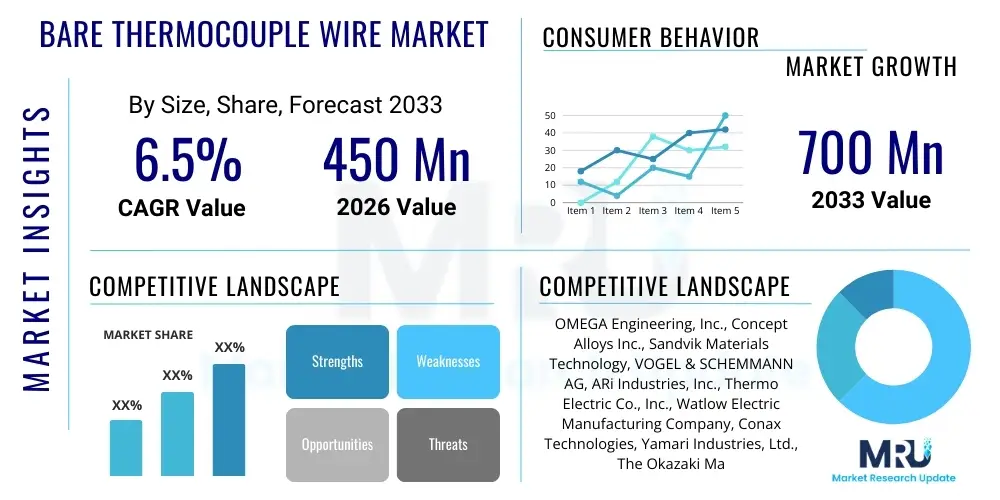

The Bare Thermocouple Wire Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.5% between 2026 and 2033. The market is estimated at $450 million in 2026 and is projected to reach $700 million by the end of the forecast period in 2033. This robust expansion is primarily fueled by the increasing demand for high-precision temperature measurement solutions across critical industrial sectors such as power generation, metallurgy, and chemical processing, where extreme temperatures and harsh operating environments necessitate the reliable performance characteristics of bare thermocouple wires.

Bare Thermocouple Wire Market introduction

The Bare Thermocouple Wire Market encompasses the production and distribution of uninsulated metallic wires used specifically for constructing thermocouples—devices pivotal in measuring temperature differentials. These wires are typically composed of two dissimilar metal alloys, which, when joined at a junction, produce a voltage (Seebeck effect) proportional to the temperature. The primary product is critical in high-temperature applications (often exceeding 1200°C) or highly corrosive environments where standard insulated sensors fail. Common types include Type K (Nickel-Chromium/Nickel-Aluminum), Type J (Iron/Constantan), and specialized noble metal types (R, S, B) crucial for extremely demanding applications in aerospace and semiconductor manufacturing.

Major applications include process control in industrial furnaces, kilns, heat treating facilities, and boiler systems within the energy sector. The benefits of using bare wire include faster thermal response time due to the lack of thermal insulation, adaptability to custom sensor configurations, and superior stability at extreme temperatures compared to mineral insulated (MI) or sheathed options, particularly when only the sensing junction needs exposure. Key driving factors involve the global push toward industrial automation (Industry 4.0), stringent quality control standards requiring precise temperature monitoring, and the continuous growth of complex manufacturing processes in the automotive and glass industries.

Bare Thermocouple Wire Market Executive Summary

The Bare Thermocouple Wire Market exhibits strong business trends marked by increased consolidation among key material suppliers and sensor manufacturers focusing on high-purity alloy development to enhance accuracy and extend lifespan under severe conditions. Technologically, there is a distinct shift towards optimizing Type N and noble metal thermocouples (R and S) for ultra-high temperature performance demanded by advanced material production and aerospace testing. Regional trends indicate that the Asia Pacific (APAC) region, driven by massive investments in infrastructure, manufacturing expansion, and energy infrastructure, is emerging as the dominant market consumer and production hub, necessitating large volumes of temperature sensors for new industrial installations. Meanwhile, mature markets like North America and Europe focus heavily on integrating these sensors with sophisticated smart factory systems, emphasizing data quality and predictive maintenance capabilities.

Segment trends confirm that Type K remains the largest segment by volume due to its cost-effectiveness and wide temperature range, suitable for general industrial use. However, the fastest growth is observed in the noble metal wire segment (Type R/S/B), propelled by the aerospace, petrochemical, and specialized laboratory sectors that require unparalleled accuracy and stability near the upper limits of temperature measurement. Furthermore, there is a growing demand for fine gauge bare wires, offering micro-second response times critical for rapid thermal cycling tests in material science research and electronics manufacturing. Supply chain resilience, particularly the sourcing of critical materials like platinum, rhodium, and specialized nickel alloys, remains a crucial competitive differentiator for leading market participants.

AI Impact Analysis on Bare Thermocouple Wire Market

User inquiries regarding the influence of Artificial Intelligence (AI) on the Bare Thermocouple Wire Market often center on how AI can enhance the utility and reliability of temperature data collected by these foundational sensors. Key themes analyzed include the use of machine learning (ML) algorithms for predictive maintenance of industrial heating elements and furnaces, optimizing energy consumption based on real-time temperature fluctuations, and ensuring sensor integrity through continuous drift detection and self-calibration. Users are particularly interested in AI's ability to process massive datasets generated by arrays of thermocouples in complex processes (e.g., semiconductor diffusion furnaces or catalytic crackers) to identify subtle anomalies that precede equipment failure, thereby reducing catastrophic downtime and improving overall process efficiency. This shift moves the thermocouple from a simple measurement tool to an integral data source within a sophisticated intelligent control loop.

- AI enables predictive failure analysis of thermocouples by monitoring degradation patterns (drift) and compensating for aging effects.

- Machine Learning optimizes thermal profiles in industrial processes (e.g., heat treatment, glass manufacturing) using thermocouple data for energy reduction and consistent product quality.

- AI-driven automated quality control systems rely on ultra-precise, real-time temperature input from bare thermocouples to adjust process parameters instantaneously.

- Integration of bare thermocouple data into Industrial Internet of Things (IIoT) platforms allows AI to provide holistic operational visibility and remote diagnostic capabilities.

- Enhanced thermal modeling and simulation, powered by AI, require highly accurate and rapidly responsive temperature data supplied by bare wire sensors for validation.

DRO & Impact Forces Of Bare Thermocouple Wire Market

The Bare Thermocouple Wire Market is fundamentally driven by the escalating requirements for precise thermal monitoring in high-stakes environments, coupled with the global expansion of industrial and power generation capacity, particularly in emerging economies. However, market growth is constrained by the volatility of raw material prices (especially nickel, chromium, and platinum group metals) and the availability of alternative, non-contact temperature measurement technologies like pyrometers, particularly in situations where physical contact is challenging or undesirable. Opportunities are abundant in the development of specialized, small-gauge bare wires for miniaturized electronics and medical devices, alongside the burgeoning demand from the hydrogen and carbon capture sectors which operate under extreme thermal stresses. These combined forces dictate market dynamics, rewarding innovation in alloy purity and stability while pressuring manufacturers on cost-efficiency.

Segmentation Analysis

The Bare Thermocouple Wire Market is segmented based primarily on the type of material (defining the temperature range and environment compatibility), the wire gauge (influencing response time and robustness), and the end-use application (determining the required accuracy and life span). This segmentation is crucial for understanding specific market needs, as different industrial processes require highly tailored temperature sensing solutions. For instance, high-purity platinum wires are mandatory for primary calibration standards and high-precision aerospace applications, while bulk industrial processes prioritize the ruggedness and lower cost of base metal wires like Type K and J. The trend toward smaller, more accurate sensors is driving growth in fine gauge wire consumption across high-tech manufacturing sectors.

- By Material Type:

- Base Metal Thermocouples (Type K, Type J, Type T, Type E, Type N)

- Noble Metal Thermocouples (Type R, Type S, Type B)

- Refractory Metal Thermocouples (Type C, Type D)

- By Gauge Size:

- Fine Gauge Wire (30 AWG and finer)

- Medium Gauge Wire (20 AWG to 28 AWG)

- Heavy Gauge Wire (18 AWG and larger)

- By Application:

- Metallurgy and Foundries

- Power Generation (Conventional and Nuclear)

- Chemical and Petrochemical Processing

- Aerospace and Defense

- Glass and Ceramics Manufacturing

- Research and Development/Calibration Laboratories

- By Regional Analysis:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East and Africa (MEA)

Value Chain Analysis For Bare Thermocouple Wire Market

The value chain for bare thermocouple wire begins with the upstream sourcing of high-purity raw materials, principally Nickel, Chromium, Iron, Platinum, and Rhodium. Material procurement involves rigorous quality checks to ensure the precise stoichiometric ratios necessary for predictable thermal electric properties, often requiring specialized smelting and alloying processes. The middle stages involve wire manufacturing, including precision drawing, annealing, and specialized coating (though the end product is bare wire, intermediate processing often involves temporary protection or lubrication), which demands tight dimensional tolerances and surface finish quality, directly impacting the final sensor accuracy. Key value addition points at this stage include minimizing impurities and achieving exceptional homogeneity across the entire wire spool.

Downstream analysis focuses on the transformation of bare wire into finished thermocouples and thermal assemblies by specialized sensor manufacturers (OEMs). These manufacturers cut, weld, calibrate, and potentially integrate the bare wire into sheaths or protection tubes as required by the end-user environment. Distribution channels are highly fragmented, involving direct sales to large-scale industrial customers (e.g., power plants, major chemical companies) and reliance on specialized technical distributors and representatives who possess deep knowledge of temperature measurement standards and application engineering. The complexity of application requirements often necessitates indirect channels through system integrators who incorporate these sensors into larger control and monitoring systems, ensuring compliance with standards like ASTM E230 and IEC 60584.

Bare Thermocouple Wire Market Potential Customers

The primary customers for bare thermocouple wire are professional sensor manufacturers, calibration laboratories, and industrial end-users requiring custom or highly specialized temperature sensing solutions. Sensor manufacturers purchase bare wire as the core component for building mineral insulated (MI) cables, protection tube assemblies, and custom fast-response probes tailored for specific processes. Industrial buyers, particularly in maintenance, repair, and operations (MRO) departments, utilize bare wire for on-site fabrication of replacement junctions, repair of existing sensors, or creation of temporary monitoring setups. This wide array of applications positions the industrial manufacturing and energy sectors as the largest consumers, driving consistent demand for standard and high-performance alloy types.

Specific end-user/buyer categories include large petrochemical complexes requiring hundreds of Type K and J sensors for catalytic reactors and distillation columns; nuclear and conventional power plants needing high-stability Type N and noble metal wires for core and turbine monitoring; and aerospace manufacturers demanding specialized, highly stable wires for engine testing and high-temperature material stress analysis. Furthermore, academic and government research institutions are significant buyers, utilizing bare thermocouple wire for fundamental material science research, high-vacuum experiments, and primary temperature scale realization, prioritizing the highest purity materials for accuracy.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $450 Million |

| Market Forecast in 2033 | $700 Million |

| Growth Rate | 6.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | OMEGA Engineering, Inc., Concept Alloys Inc., Sandvik Materials Technology, VOGEL & SCHEMMANN AG, ARi Industries, Inc., Thermo Electric Co., Inc., Watlow Electric Manufacturing Company, Conax Technologies, Yamari Industries, Ltd., The Okazaki Manufacturing Company, CCPI Inc., T&D Materials Manufacturing, Inc., Thermador Engineering, Heraeus Group, DUREX Industries, Pyromation, Inc., Tempco Electric Heater Corporation, Honeywell International Inc., ABB Ltd., Siemens AG |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Bare Thermocouple Wire Market Key Technology Landscape

Technological advancements in the Bare Thermocouple Wire Market are predominantly focused on material science, aiming to enhance the accuracy, stability, and longevity of the sensing elements, especially in extreme operational environments. A key area of innovation involves developing new high-purity alloys, such as those used in Type N (Nicrosil-Nisil) thermocouples, which offer superior resistance to oxidation and decalibration compared to traditional Type K alloys, particularly in the critical temperature range between 800°C and 1200°C. Refinements in manufacturing processes, including vacuum melting and precision drawing techniques, are essential for ensuring compositional uniformity throughout the wire, minimizing errors caused by material inhomogeneity and crystalline structure variations.

Another significant technological focus is on enhancing calibration and conformity standards. Advanced software and instrumentation are being used to map thermal characteristics more precisely, allowing manufacturers to supply bare wire with tighter tolerance limits than standard IEC/ASTM grades. For high-end applications like primary temperature measurement, technological efforts concentrate on the ultra-purification of platinum and rhodium alloys to maintain high stability over thousands of hours of operation. Furthermore, the development of smaller, flexible, and micro-gauge bare wires utilizes specialized diamond dies and processing equipment to meet the requirements of miniaturization in medical devices and complex electronics thermal management, where response time is paramount.

Regional Highlights

The global Bare Thermocouple Wire Market exhibits varied growth dynamics across major geographical regions, reflecting differences in industrial maturity, regulatory frameworks, and infrastructural investment patterns. The Asia Pacific (APAC) region stands out as the primary growth engine, fueled by the rapid expansion of industrial bases in China, India, South Korea, and Southeast Asia. These countries are seeing massive investments in sectors like power generation (including coal, nuclear, and renewables), steel production, and consumer electronics manufacturing, all of which require continuous, high-volume temperature monitoring solutions. Consequently, APAC drives the largest demand for both standard base metal and specialized noble metal bare thermocouple wires, often sourcing locally to achieve competitive pricing and fast delivery schedules. This region's focus on heavy industry and energy security ensures its market dominance throughout the forecast period.

North America and Europe represent mature markets characterized by stringent regulatory standards (e.g., environmental emissions control, nuclear safety) and a strong emphasis on automation and digital integration (Industry 4.0). Demand in these regions is less volume-driven and more quality-centric, focusing on high-accuracy, stable noble metal wires for applications in aerospace, pharmaceutical manufacturing, and high-end R&D facilities. European companies, in particular, lead in developing calibration and standardization technologies. The adoption of smart factory solutions here necessitates highly reliable sensor data, pushing manufacturers toward premium products that minimize drift and maximize operational lifespan. Furthermore, the robust presence of the automotive sector, requiring precise thermal management in both traditional and electric vehicle component manufacturing, sustains stable demand.

- Asia Pacific (APAC): Dominates market share due to rapid industrialization, expansion of the power sector (coal, nuclear, renewable energy), and high output in steel, cement, and chemical manufacturing. Focus on volume and infrastructure development.

- North America: Strong demand from the aerospace, defense, and oil & gas sectors. Emphasis on high-specification, specialized wires for critical applications and compliance with strict safety standards. Early adopter of IIoT integration.

- Europe: Characterized by high precision requirements in calibration laboratories and advanced manufacturing (pharmaceuticals, high-end automotive). Driven by strict EU regulations on process safety and environmental monitoring.

- Latin America (LATAM): Growth is tied to commodity production (mining, metals) and petrochemical refinement, leading to stable, project-based demand for rugged, heavy-gauge thermocouple wires.

- Middle East and Africa (MEA): Demand is concentrated in the burgeoning oil, gas, and power generation sectors, requiring specialized, corrosion-resistant bare wires for high-temperature process control in refineries and desalination plants.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Bare Thermocouple Wire Market.- OMEGA Engineering, Inc.

- Concept Alloys Inc.

- Sandvik Materials Technology

- VOGEL & SCHEMMANN AG

- ARi Industries, Inc.

- Thermo Electric Co., Inc.

- Watlow Electric Manufacturing Company

- Conax Technologies

- Yamari Industries, Ltd.

- The Okazaki Manufacturing Company

- CCPI Inc.

- T&D Materials Manufacturing, Inc.

- Thermador Engineering

- Heraeus Group

- DUREX Industries

- Pyromation, Inc.

- Tempco Electric Heater Corporation

- Honeywell International Inc.

- ABB Ltd.

- Siemens AG

Frequently Asked Questions

Analyze common user questions about the Bare Thermocouple Wire market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary advantage of using bare thermocouple wire over sheathed sensors?

Bare thermocouple wire offers significantly faster thermal response times because there is no insulation or sheath delay. This makes it ideal for applications requiring rapid temperature monitoring or when installing into specialized, custom assemblies in non-corrosive, high-temperature environments.

Which thermocouple wire type is most suitable for ultra-high temperature measurements, such as above 1500°C?

Noble metal thermocouple types, specifically Type B (Platinum-30% Rhodium vs. Platinum-6% Rhodium) or specialized Refractory Metal types (like Type C/D Tungsten-Rhenium), are typically required for reliable and stable temperature measurement above 1500°C, offering superior stability and resistance to grain growth.

How does raw material cost volatility impact the bare thermocouple wire market?

Raw material volatility, especially concerning Platinum Group Metals (PGMs) used in noble metal thermocouples (R, S, B), directly affects manufacturing costs and pricing strategies. Fluctuations necessitate hedging strategies and influence end-user decisions regarding sensor replacement cycles versus repair or recalibration.

What role does Industry 4.0 play in driving demand for bare thermocouple wires?

Industry 4.0 drives demand by requiring high-density, real-time data input for automated process control and predictive maintenance systems. Bare wires are crucial for providing rapid, precise thermal data that feed into AI and IIoT platforms, optimizing energy consumption and product consistency across smart factories.

Which geographical region is expected to demonstrate the highest growth rate (CAGR) in the forecast period?

The Asia Pacific (APAC) region is projected to exhibit the highest CAGR due to massive ongoing industrial expansion, particularly in power generation, metallurgy, and chemical sectors across developing economies like China and India, increasing the underlying requirement for fundamental temperature sensing components.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager