Batch Coding Machines Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433161 | Date : Dec, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Batch Coding Machines Market Size

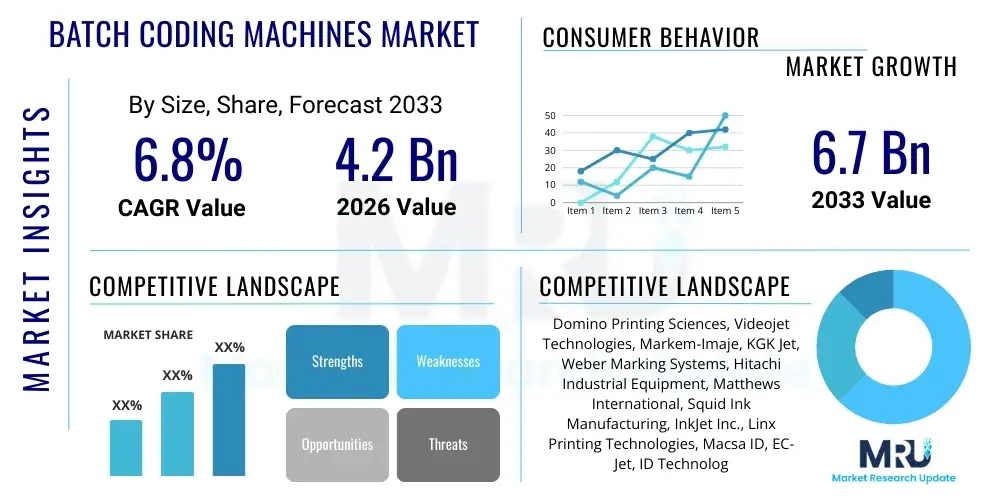

The Batch Coding Machines Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 4.2 Billion in 2026 and is projected to reach USD 6.7 Billion by the end of the forecast period in 2033.

Batch Coding Machines Market introduction

The Batch Coding Machines Market encompasses sophisticated industrial equipment essential for printing variable data such as manufacturing dates, expiration dates, lot numbers, serial numbers, and 2D barcodes directly onto primary and secondary packaging materials. These machines are crucial for product traceability, regulatory compliance, quality control, and anti-counterfeiting efforts across highly regulated industries. The technology range includes Continuous Inkjet (CIJ), Thermal Inkjet (TIJ), Laser Marking Systems, and Thermal Transfer Overprinting (TTO), each suited for different substrates, line speeds, and environmental conditions. The increasing global focus on supply chain transparency and consumer safety mandates the widespread adoption of robust batch coding solutions, driving continuous innovation in speed, print quality, and data management capabilities.

Batch coding systems serve diverse applications, primarily within the fast-moving consumer goods (FMCG), pharmaceuticals, food and beverage, and industrial manufacturing sectors. Their primary benefit lies in ensuring legal adherence, particularly concerning shelf-life labeling required by international food and drug administrations. Furthermore, these machines significantly enhance operational efficiency by integrating seamlessly into high-speed production lines, minimizing downtime, and ensuring code permanence even in harsh industrial environments. The versatility of modern coders, capable of handling materials from glass and metal to flexible films and cardboard, solidifies their position as indispensable assets in automated production facilities globally.

Key driving factors for market expansion include the stringent global regulatory landscape, especially concerning pharmaceutical serialization and food allergen labeling, which necessitates detailed and accurate batch tracking. Rapid industrialization in developing economies, coupled with the exponential growth of the packaged food and beverage sector, further fuels demand for reliable, high-throughput coding solutions. Moreover, the shift towards smart factories and Industry 4.0 initiatives is prompting manufacturers to invest in networked coding machines capable of remote diagnostics, centralized data management, and integration with Enterprise Resource Planning (ERP) systems, moving beyond simple marking toward comprehensive data control.

Batch Coding Machines Market Executive Summary

The global Batch Coding Machines Market is experiencing robust growth fueled by mandatory traceability requirements and the expansion of automated manufacturing across Asia Pacific and Latin America. Key business trends involve the increasing integration of vision inspection systems to verify code accuracy immediately after application, ensuring zero defects and compliance adherence. Furthermore, vendors are focusing intensely on developing eco-friendly consumables, such as low-VOC (Volatile Organic Compound) inks and energy-efficient laser technologies, responding to sustainability mandates from major multinational clients. The market competitive landscape is characterized by strategic mergers and acquisitions aimed at consolidating technology portfolios, particularly in advanced digital coding and cloud-based data services, enhancing value proposition beyond hardware sales.

Regionally, Asia Pacific maintains the highest growth trajectory, primarily due to massive investments in pharmaceutical manufacturing capacity, rapid urbanization leading to increased packaged food consumption, and the government implementation of strict anti-counterfeiting laws in countries like China and India. North America and Europe remain mature markets, focusing less on capacity expansion and more on technological replacement cycles, prioritizing high-resolution printing for complex barcodes, enhanced connectivity for centralized operation, and robust cybersecurity features for integrated systems. Latin America is also emerging as a high-potential market, driven by foreign direct investment in food processing and beverage bottling, requiring compliance-ready coding solutions.

Segment trends highlight the dominance of Continuous Inkjet (CIJ) technology due to its versatility and high-speed capabilities across multiple substrates, although Thermal Inkjet (TIJ) is gaining significant traction in secondary packaging and high-resolution applications due to its cleanliness and low maintenance. The laser coding segment shows the highest compound annual growth rate, favored by its permanent marking quality, absence of consumables, and suitability for highly regulated environments like medical device and rigid packaging. End-user demand is consistently shifting towards solutions offering higher uptime, faster changeover times, and user-friendly interfaces, minimizing reliance on specialized maintenance personnel and maximizing overall equipment effectiveness (OEE).

AI Impact Analysis on Batch Coding Machines Market

Users frequently inquire about how Artificial Intelligence (AI) can minimize coding errors, maximize production uptime, and streamline regulatory compliance in high-volume manufacturing environments. Common concerns revolve around the necessary infrastructure investment for AI-powered vision systems, the complexity of integrating machine learning algorithms with legacy coding hardware, and the reliability of predictive maintenance models based on operational data. Users anticipate that AI integration will revolutionize code verification by eliminating manual quality checks, ensuring 100% data integrity, and optimizing ink consumption through intelligent usage algorithms. The primary theme identified is the expectation that AI should transform batch coding from a static marking process into an intelligent, self-optimizing component of the production line.

The impact of AI is primarily felt in three domains: quality assurance, predictive maintenance, and operational optimization. AI-driven vision systems utilize deep learning to recognize and validate complex data matrices, characters, and barcodes, instantaneously flagging and rejecting products with smudged, missing, or incorrect codes, a capability far superior to traditional rule-based inspection systems. In maintenance, AI analyzes real-time sensor data—such as temperature, nozzle pressure, and ink viscosity—to predict potential hardware failures before they cause line stoppages, thereby automating scheduling for necessary preventative maintenance actions. This transition shifts maintenance from reactive or time-based schedules to highly efficient, condition-based schedules.

Furthermore, AI algorithms are being applied to optimize job scheduling and material usage. By analyzing historical production runs, AI can suggest optimal settings for ink drop velocity, printing speed, and code position based on the specific substrate and environmental conditions, leading to significant material savings and faster setup times during product changeovers. This move toward 'smart coding' integration within the broader industrial internet of things (IIoT) frameworks is making batch coding operations more efficient, reducing human error, and creating robust, verifiable audit trails essential for global compliance standards.

- AI enhances Code Verification: Deep learning models automatically verify code readability and accuracy (OCR/OCV), eliminating human inspection errors.

- Predictive Maintenance: AI algorithms analyze operational data (temperature, pressure, vibration) to forecast hardware failures, maximizing machine uptime.

- Optimized Consumable Usage: Intelligent systems regulate ink or ribbon usage based on substrate properties and speed, reducing waste and operating costs.

- Automated Job Setup: Machine learning accelerates changeover times by recommending optimal coding parameters based on previous successful production batches.

- Real-time Compliance Auditing: AI maintains immutable, verifiable digital records of every code printed, ensuring seamless traceability and regulatory compliance reporting.

DRO & Impact Forces Of Batch Coding Machines Market

The market dynamics are defined by several powerful forces: regulatory demands, technological advancements, operational restraints, and substantial new opportunities. Drivers include global regulatory mandates like the U.S. FDA’s requirement for Unique Device Identification (UDI) and similar pharmaceutical serialization mandates in Europe (EU FMD) and India, which necessitate advanced, reliable coding systems. The exponential growth of e-commerce, driving demand for efficient warehousing and track-and-trace capabilities, further accelerates adoption. Conversely, restraints include the high initial capital expenditure associated with sophisticated laser and high-speed CIJ systems, particularly challenging for small and medium-sized enterprises (SMEs), and the environmental and disposal concerns related to volatile organic compound (VOC) based inks used in traditional coding methods, pushing the industry towards cleaner alternatives.

Significant opportunities arise from the ongoing proliferation of Industry 4.0 and the Internet of Things (IoT) in manufacturing, enabling integration of coding data into broader manufacturing execution systems (MES) and supply chain visibility platforms. The rising demand for eco-friendly marking solutions, such as fiber lasers and low-migration, food-safe inks, presents a major green technology adoption avenue. Furthermore, the massive untapped potential in emerging markets in Africa and Southeast Asia, where local production and packaging operations are rapidly scaling up to meet domestic demand, offers long-term growth prospects for affordable and scalable coding technologies. Manufacturers focusing on flexible financing models and modular system designs are poised to capture these developing markets effectively.

The key impact forces shaping the market include intense competition driving down equipment prices for standard models while simultaneously pushing innovation towards premium, integrated systems. Buyer power is increasing, particularly among large multinational FMCG and pharmaceutical companies that demand global service support, guaranteed uptime, and seamless integration capabilities, favoring suppliers who can offer comprehensive, global solutions packages. Substitution threat is moderate; while permanent alternatives like molded marking exist for some plastics, most variable data requirements necessitate digital coding methods. The overall impact of these forces is an ongoing technological arms race among vendors, focused on connectivity, sustainability, and data accuracy, ensuring robust market growth driven by non-negotiable compliance needs.

Segmentation Analysis

The Batch Coding Machines Market is extensively segmented based on technology type, product type, end-user industry, and region, reflecting the diverse operational needs of the global manufacturing sector. Technology segmentation, including CIJ, TIJ, Laser, and TTO, dictates the machine's speed, substrate compatibility, and cost profile. CIJ remains the foundational segment, preferred for high-speed lines and challenging surfaces, whereas the Laser segment is rapidly accelerating due to the demand for permanent, maintenance-free coding. Product segmentation typically differentiates between fixed, portable, and integrated systems, addressing the mobility and setup flexibility required by various factory layouts.

End-user segmentation is critical, with the food and beverage industry dominating demand due to extensive labeling requirements for expiry dates, nutritional information, and batch numbers across perishable goods. The pharmaceutical and medical device sector, however, mandates the highest level of regulatory compliance, driving investment in high-precision, serialized coding and vision verification systems. Industrial manufacturing, including automotive and electronics, primarily utilizes robust laser markers for permanent identification on durable parts. The strategic differentiation across these segments allows vendors to tailor their offerings, focusing either on high throughput efficiency (F&B) or absolute data integrity (Pharma).

This granular segmentation is essential for understanding market opportunities. For instance, the transition in packaging materials—from rigid containers to flexible pouches and sustainable paper-based substrates—is specifically boosting demand for TIJ and advanced TTO technologies that excel on porous and delicate materials. Furthermore, regional market variations dictate segment concentration; mature markets focus on high-end laser and smart coding for automation upgrades, while emerging markets prioritize cost-effective, durable CIJ solutions for new production lines. Successful market strategies require precise targeting of these segment-specific requirements, especially concerning compliance standards and preferred levels of automation.

- Technology Type:

- Continuous Inkjet (CIJ)

- Thermal Inkjet (TIJ)

- Laser Coding (CO2, Fiber, UV)

- Thermal Transfer Overprinting (TTO)

- Drop-on-Demand (DOD)

- Product Type:

- Fixed/Integrated Systems

- Portable/Handheld Coders

- Semi-Automatic Systems

- End-User Industry:

- Food and Beverage (Dairy, Beverages, Confectionery)

- Pharmaceutical and Healthcare (Drug serialization, Medical devices)

- Cosmetics and Personal Care

- Industrial Manufacturing (Automotive, Electronics, Construction)

- Chemical and Petrochemical

- Code Type:

- Date and Time Codes

- Lot and Batch Numbers

- Barcodes and 2D Data Matrix Codes

- Human-Readable Codes (HRC)

Value Chain Analysis For Batch Coding Machines Market

The value chain for Batch Coding Machines begins with upstream analysis, focusing on the sourcing of critical components and specialized materials. This includes high-precision electronic components, sophisticated nozzle and printhead assemblies (especially crucial for CIJ and TIJ), specialized laser sources (for laser coders), and the complex chemical formulation of inks, solvents, and ribbons. Key suppliers in the upstream segment are highly specialized chemical companies providing high-performance, low-VOC inks and specialized OEMs manufacturing sophisticated motion control systems and advanced optical sensors. The quality and intellectual property surrounding consumable formulation, particularly compliance with food-safe and medical-grade standards, are major factors determining profitability and competitive advantage in the upstream market.

Midstream activities involve the design, manufacturing, assembly, and rigorous testing of the coding machinery. Manufacturing requires high-level precision engineering to ensure reliability at high production speeds and durability in harsh industrial environments. Vendors invest heavily in R&D to enhance print resolution, integration capabilities (Industry 4.0), and user interface design. Downstream analysis encompasses distribution, installation, customer training, and, most critically, post-sales service and maintenance, especially the recurring revenue stream generated by consumables (inks, solvents, ribbons). Direct sales channels are common for large, customized installations requiring specific integration expertise, while indirect channels (distributors and system integrators) handle smaller, standardized machine sales and localized support in emerging markets.

The distribution channel strategy is pivotal for maintaining market share and profitability. Direct channels allow for higher margins and better control over the customer experience, particularly vital for complex laser or high-end CIJ systems sold to large multinational corporations requiring comprehensive service level agreements (SLAs). Indirect channels, leveraging local distributors, are essential for penetrating geographically dispersed markets and providing rapid local support, especially for consumable supply. The long-term relationship with customers is often sustained not by the machine sale itself, but by the continuous, reliable, and compliant supply of specialized consumables and the quality of technical service provided, making the service and distribution segment the highest value-added activity downstream.

Batch Coding Machines Market Potential Customers

Potential customers for Batch Coding Machines are predominantly high-volume manufacturers and contract packers operating within industries where product identification, traceability, and regulatory compliance are non-negotiable operational requirements. The largest segment remains the food and beverage industry, including bottlers, breweries, snack food manufacturers, and frozen food processors, who require fast, reliable coding on diverse substrates under often damp or cold conditions. These buyers prioritize machine speed, durability, and low operational costs (cost per code) when making purchasing decisions, often selecting CIJ or TTO technologies for flexible packaging and bottling lines.

The pharmaceutical and medical device sector represents the most stringent customer base. Due to strict global mandates regarding serialization (unique identifiers for every saleable unit) and UDI, these customers invest in high-resolution, validated laser and TIJ systems integrated with vision inspection and robust data management software. Their purchasing criteria center on 21 CFR Part 11 compliance, integration with existing MES/ERP systems, guaranteed code accuracy, and comprehensive validation documentation, often leading to preference for top-tier global suppliers who can ensure worldwide technical and compliance support.

Furthermore, contract packaging organizations (CPOs) and third-party logistics (3PL) providers represent a growing customer segment. As outsourcing of packaging and fulfillment increases, CPOs require highly flexible, easily configurable batch coding machines capable of rapid changeovers to handle multiple product lines and substrate types for various clients simultaneously. This segment often seeks modular TIJ or flexible CIJ systems that offer quick setup and minimal maintenance. Other key buyers include manufacturers of cables, pipes, building materials, and automotive components, who require highly durable, deep, or permanent marking solutions, typically opting for advanced fiber laser technology.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.2 Billion |

| Market Forecast in 2033 | USD 6.7 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Domino Printing Sciences, Videojet Technologies, Markem-Imaje, KGK Jet, Weber Marking Systems, Hitachi Industrial Equipment, Matthews International, Squid Ink Manufacturing, InkJet Inc., Linx Printing Technologies, Macsa ID, EC-Jet, ID Technology, Allen Coding, Reiner Marking |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Batch Coding Machines Market Key Technology Landscape

The technology landscape of the Batch Coding Machines Market is dominated by four core technologies: Continuous Inkjet (CIJ), Thermal Inkjet (TIJ), Laser Marking Systems, and Thermal Transfer Overprinting (TTO). CIJ remains the workhorse of the industry, renowned for its ability to print at high speeds (up to 300 meters per minute) and on virtually any substrate, including curved, damp, or greasy surfaces, utilizing a non-contact method. Recent advancements in CIJ focus on micro-print capability for small electronics, specialized pigmented inks for dark substrates, and enhanced nozzle cleaning systems to maximize uptime. The fundamental CIJ principle involves charging and deflecting individual ink drops to form the desired code, necessitating precise fluid management systems and high-reliability printheads, which is a major area of competitive differentiation among leading vendors.

Thermal Inkjet (TIJ) technology has witnessed explosive growth, primarily driven by the increasing need for high-resolution (up to 600 dpi) codes on porous and non-porous materials, particularly in secondary packaging (boxes, cartons) and pharmaceutical unit dosing. TIJ operates by heating small resistors to vaporize ink, creating bubbles that propel ink droplets through the nozzles, offering a clean, maintenance-free operation as the print cartridge contains the printhead itself. The primary limiting factors, traditionally, were line speed and the cost of consumables, but technological breakthroughs in solvent-based inks and multi-head systems are rapidly addressing these restraints, making TIJ a compelling alternative to CIJ in many primary packaging applications that prioritize data intensity and pristine code quality.

Laser coding represents the fastest-growing segment, characterized by permanence, absence of consumables, and high environmental compliance. Laser systems (CO2 for organic materials like paper and plastics; Fiber for metals; UV for high-contrast, non-damaging marking) mark the substrate by ablating, etching, or changing the material's surface structure. The significant initial investment is often offset by extremely low operating costs and superior reliability over the machine's lifespan. The latest trend in laser technology involves dynamic field-of-view lenses and smaller, highly integrated beam steering mechanisms, enabling faster marking speeds and greater flexibility in handling varying product geometries. Connectivity, leveraging IoT platforms for remote diagnostics and centralized data integration, is now a standard feature across all technology types, moving the industry toward fully automated, self-monitoring coding ecosystems that support centralized control over global manufacturing operations.

Regional Highlights

Regional dynamics significantly influence the adoption rates and technological preferences within the Batch Coding Machines Market, shaped by regulatory frameworks, industrial maturity, and economic growth patterns. Asia Pacific (APAC) stands out as the engine of market expansion, demonstrating the highest growth rates globally. This is driven primarily by the massive scale-up of indigenous manufacturing, especially in China, India, and Southeast Asia, coupled with substantial foreign direct investment in food processing and pharmaceutical sectors. Governments in APAC are increasingly implementing strict track-and-trace mandates to combat pervasive counterfeiting, compelling local manufacturers to rapidly adopt reliable batch coding and serialization technologies. The region exhibits high demand for both cost-effective, durable CIJ machines for new production lines and advanced laser systems for high-value exports complying with Western regulatory standards.

North America and Europe constitute mature markets characterized by high saturation of existing equipment. Growth in these regions is driven by replacement cycles and the adoption of high-end, connected (Industry 4.0 compliant) coding solutions. European regulations, particularly the EU Falsified Medicines Directive (FMD) and stringent food labeling standards, mandate investment in precision coding, serialization, and integrated vision inspection systems, favoring laser and high-resolution TIJ technologies. North American manufacturers prioritize operational efficiency, looking for machines that offer minimized maintenance, superior integration with existing packaging lines, and advanced data analytics capabilities to optimize overall equipment effectiveness (OEE).

Latin America (LATAM) and the Middle East and Africa (MEA) represent emerging opportunity markets. LATAM's growth is tied to the expansion of regional food, beverage, and consumer packaged goods production, often requiring coding solutions that can handle high humidity or fluctuating power supplies, favoring rugged CIJ systems. In MEA, particularly the GCC nations and South Africa, infrastructure development and diversification away from oil economies are spurring growth in pharmaceutical and industrial manufacturing. While the market is price-sensitive, increasing regulatory harmonization and greater consumer awareness of product safety are gradually shifting demand toward standardized, compliant coding equipment, creating significant potential for vendors offering localized support and flexible business models, such as leasing agreements or pay-per-code services.

- Asia Pacific (APAC): Leading market growth due to pharmaceutical serialization mandates, vast manufacturing capacity expansion (India, China), and rising packaged food consumption.

- North America: Focus on technology replacement, Industry 4.0 integration, and demand for high-speed, verifiable codes (UDI compliance).

- Europe: Driven by strict traceability and serialization laws (EU FMD), prioritizing environmental sustainability (low-VOC inks, laser) and operational efficiency.

- Latin America (LATAM): High potential due to beverage and food industry growth; seeking durable, cost-effective CIJ and TIJ solutions.

- Middle East and Africa (MEA): Emerging market fueled by industrial diversification and increasing government focus on combating counterfeiting and ensuring food safety standards.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Batch Coding Machines Market.- Domino Printing Sciences PLC

- Videojet Technologies Inc. (Danaher Corporation)

- Markem-Imaje (Dover Corporation)

- Hitachi Industrial Equipment Systems Co., Ltd.

- Linx Printing Technologies (PFS)

- KGK Jet India Private Limited

- Matthews International Corporation

- Squid Ink Manufacturing, Inc.

- Macsa ID S.A.

- Allen Coding Systems Ltd.

- Diagraph (ITW)

- Reiner Marking GmbH

- ID Technology (ProMach)

- Web Printing Systems

- Xaar plc (Printheads focus)

- EC-Jet Inkjet Coder

- Bentsai Coding Machines

- Sunine Code Technology Co., Ltd.

- Leibinger GmbH & Co. KG

- Rottweil Codiertechnik

Frequently Asked Questions

Analyze common user questions about the Batch Coding Machines market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between Continuous Inkjet (CIJ) and Thermal Inkjet (TIJ) batch coding?

CIJ is optimal for high-speed, non-contact coding on challenging, curved, or oily surfaces, using specialized solvent-based inks for durability. TIJ is preferred for high-resolution graphics and barcodes, primarily on porous materials like cardboard and certain non-porous films, offering zero maintenance due to disposable ink cartridges, but generally operating at slightly lower maximum speeds than CIJ.

How does the implementation of serialization mandates impact the demand for batch coding machines?

Serialization mandates, especially in pharmaceuticals (e.g., EU FMD, UDI), necessitate the printing of unique, high-density 2D Data Matrix codes on every saleable unit. This drives demand for high-precision coding technologies, such as laser or high-resolution TIJ, integrated with advanced vision systems and secure, centralized data management software to ensure end-to-end traceability and compliance validation.

Which batch coding technology offers the lowest long-term operational cost?

Laser marking systems (CO2, Fiber) generally offer the lowest long-term operational cost because they eliminate the need for consumables (inks, solvents, ribbons). While the initial capital investment is high, the absence of recurring supply costs and minimal maintenance requirements over the machine's extended lifespan result in a significantly lower total cost of ownership (TCO) compared to ink-based systems.

What role does Industry 4.0 play in the evolution of batch coding systems?

Industry 4.0 integration enables batch coding machines to become smart, interconnected devices capable of bi-directional communication. This allows for centralized monitoring of operational performance, remote diagnostics, automated error correction, integration with Manufacturing Execution Systems (MES), and real-time data flow for comprehensive traceability and optimized production scheduling.

Are there environmentally friendly alternatives to traditional solvent-based coding inks?

Yes, the market is rapidly shifting toward sustainable alternatives. This includes water-based inks (common in TIJ), low-migration and low-VOC (Volatile Organic Compound) inks (for CIJ systems near food contact), and laser coding technology, which eliminates consumables entirely. Manufacturers are increasingly prioritizing solutions that meet strict environmental regulations and corporate sustainability targets.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager