Battery Grade Ethyl Methyl Carbonate Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439603 | Date : Jan, 2026 | Pages : 255 | Region : Global | Publisher : MRU

Battery Grade Ethyl Methyl Carbonate Market Size

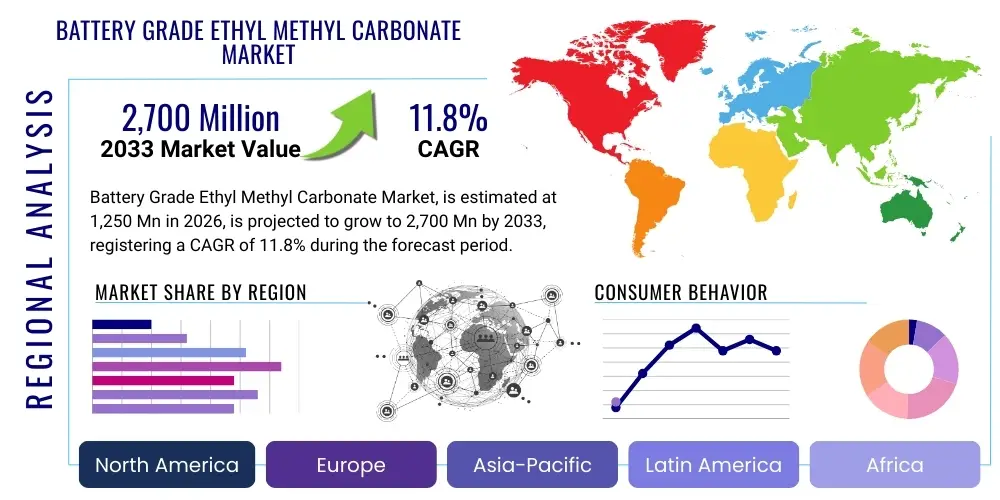

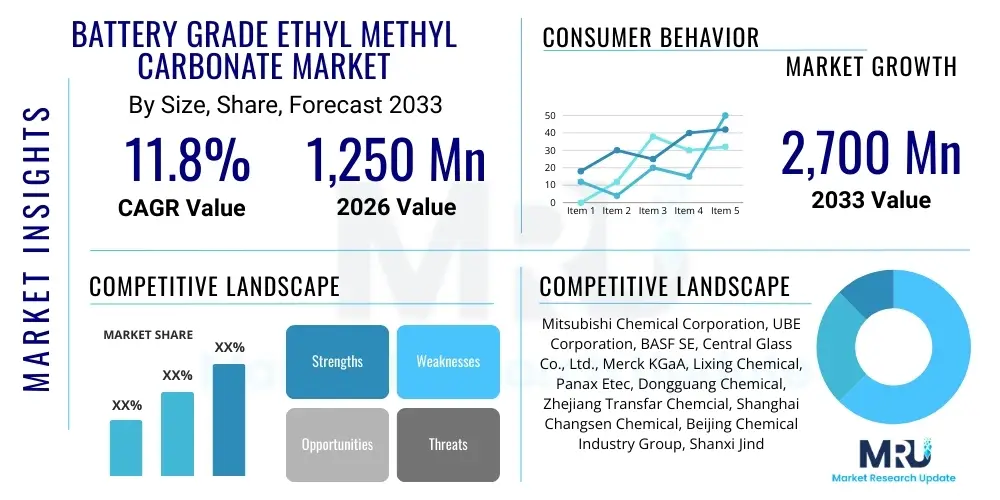

The Battery Grade Ethyl Methyl Carbonate Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 11.8% between 2026 and 2033. The market is estimated at USD 1,250 Million in 2026 and is projected to reach USD 2,700 Million by the end of the forecast period in 2033.

Battery Grade Ethyl Methyl Carbonate Market introduction

The Battery Grade Ethyl Methyl Carbonate (EMC) market plays a pivotal role in the rapidly expanding lithium-ion battery industry, serving as a critical component of electrolyte solutions. EMC, an organic carbonate solvent, is highly valued for its exceptional chemical stability, low viscosity, and high flash point, properties that are indispensable for enhancing the performance, safety, and longevity of modern rechargeable batteries. Its inclusion in electrolyte formulations helps optimize ion transport, reduce internal resistance, and improve the overall charge-discharge cycling capabilities of lithium-ion cells, making it a preferred choice over other carbonate solvents in numerous high-performance battery applications.

The primary application of Battery Grade Ethyl Methyl Carbonate lies in the production of electrolytes for lithium-ion batteries, which power a vast array of devices and systems. This includes electric vehicles (EVs), hybrid electric vehicles (HEVs), consumer electronics such as smartphones, laptops, and tablets, as well as large-scale energy storage systems (ESS) for grid stabilization and renewable energy integration. The benefits derived from using high-purity EMC are substantial, contributing to increased energy density, improved low-temperature performance, and enhanced safety features in battery packs. As technological advancements continue to push the boundaries of battery performance, the demand for ultra-pure EMC is set to intensify, driving innovation in its manufacturing and purification processes.

Key driving factors for the Battery Grade Ethyl Methyl Carbonate market are intrinsically linked to the global acceleration of electrification and the increasing adoption of sustainable energy solutions. The burgeoning electric vehicle market, propelled by stringent emission regulations and consumer preference shifts, represents the largest growth segment. Concurrently, the proliferation of portable electronic devices and the imperative for robust energy storage infrastructure further underpin market expansion. Government incentives for EV adoption and renewable energy projects worldwide also create a conducive environment for the sustained growth of the Battery Grade Ethyl Methyl Carbonate sector, ensuring its continuous evolution and increasing market footprint.

Battery Grade Ethyl Methyl Carbonate Market Executive Summary

The Battery Grade Ethyl Methyl Carbonate market is experiencing dynamic shifts influenced by several overarching business trends, reflecting a global push towards higher performance and more sustainable battery solutions. Key trends include significant investments in upstream production capacities to meet the escalating demand from battery manufacturers, particularly in Asia-Pacific. Furthermore, there is a growing emphasis on developing greener synthesis methods for EMC, reducing reliance on phosgene-based processes, and incorporating circular economy principles through recycling initiatives for spent electrolyte components. Strategic alliances and collaborations between chemical producers and battery manufacturers are also becoming more prevalent, aimed at ensuring a stable supply chain and fostering innovation in electrolyte formulations.

Regionally, the market exhibits a clear concentration of both production and consumption in Asia-Pacific, particularly China, South Korea, and Japan, which are global hubs for lithium-ion battery manufacturing. This region benefits from established supply chains, robust government support for the EV and electronics industries, and a large consumer base. However, North America and Europe are rapidly increasing their domestic battery production capabilities, driven by national energy independence strategies and environmental goals, leading to a projected surge in demand for Battery Grade Ethyl Methyl Carbonate within these regions. This geographical diversification of manufacturing is creating new investment opportunities and supply chain adjustments globally.

Segmentation trends within the Battery Grade Ethyl Methyl Carbonate market highlight a growing preference for ultra-high purity grades (>99.99%) to meet the stringent requirements of advanced battery chemistries, especially for high-energy-density EV batteries. Application-wise, the Electric Vehicle segment continues to dominate, exhibiting the fastest growth due to the immense scale of the automotive electrification transition. The energy storage systems segment is also showing robust growth, driven by renewable energy integration and grid modernization efforts. These segment-specific dynamics underscore the market's responsiveness to technological advancements and evolving end-user demands across various industrial sectors.

AI Impact Analysis on Battery Grade Ethyl Methyl Carbonate Market

Artificial intelligence is poised to significantly transform the Battery Grade Ethyl Methyl Carbonate market by optimizing various stages from research and development to production, quality control, and supply chain management. Users frequently inquire about AI's role in accelerating the discovery of novel electrolyte formulations, enhancing the purity and yield of EMC synthesis processes, and improving the efficiency of battery manufacturing lines that utilize EMC. Concerns often revolve around the initial investment costs for AI integration, the availability of skilled personnel to manage AI systems, and the data privacy implications of sharing sensitive manufacturing data. There is also a keen interest in how AI can contribute to sustainable practices, such as predicting material degradation for recycling and optimizing energy consumption in chemical synthesis, ultimately leading to more cost-effective and environmentally friendly production of Battery Grade Ethyl Methyl Carbonate.

- AI can optimize chemical synthesis parameters for Ethyl Methyl Carbonate, leading to higher purity, improved yield, and reduced energy consumption.

- Predictive analytics powered by AI can forecast demand for Battery Grade EMC, enabling better inventory management and supply chain resilience, minimizing waste and ensuring timely delivery.

- AI-driven quality control systems can monitor the purity and composition of EMC in real-time, detecting anomalies and ensuring compliance with stringent battery-grade specifications more accurately than traditional methods.

- Machine learning algorithms can accelerate the discovery and screening of new electrolyte additive combinations involving EMC, leading to more stable, higher-performing, and safer battery chemistries.

- AI can facilitate sustainable manufacturing by optimizing resource allocation, identifying opportunities for waste reduction, and potentially even contributing to the design of more recyclable battery components that utilize EMC.

DRO & Impact Forces Of Battery Grade Ethyl Methyl Carbonate Market

The Battery Grade Ethyl Methyl Carbonate market is shaped by a complex interplay of drivers, restraints, opportunities, and inherent impact forces. Key drivers include the exponential growth of the global electric vehicle market, fueled by increasing consumer adoption and supportive government policies emphasizing decarbonization. Simultaneously, the expanding demand for grid-scale energy storage systems and high-performance consumer electronics further propels the need for advanced lithium-ion batteries and, consequently, high-purity EMC. Technological advancements in battery chemistry, aimed at increasing energy density and extending cycle life, also create a continuous demand for superior electrolyte components like EMC, establishing a strong foundation for market expansion.

Conversely, the market faces several significant restraints. Volatility in raw material prices, particularly for precursors used in EMC synthesis, can directly impact production costs and market pricing. Stringent environmental regulations concerning chemical manufacturing and waste disposal impose compliance burdens, potentially increasing operational expenses for producers. Furthermore, the inherent safety concerns associated with handling highly flammable organic solvents, though mitigated by advancements, necessitate rigorous safety protocols and investments. Competition from alternative carbonate solvents or emerging electrolyte technologies, while currently limited for high-performance applications, remains a long-term restraint, pushing for continuous innovation in EMC production and application.

Opportunities for growth are abundant within the Battery Grade Ethyl Methyl Carbonate market. The development of next-generation battery technologies, such as solid-state batteries, while potentially altering electrolyte needs, may also create new niches for specialized carbonate solvents or purification techniques. Emerging markets in Southeast Asia and Latin America, with their nascent but rapidly growing EV and electronics industries, represent significant untapped potential. Furthermore, advancements in recycling technologies for spent lithium-ion batteries could create a closed-loop system for electrolyte components, offering a sustainable source of raw materials and reducing reliance on virgin production, thereby presenting a long-term opportunity for the EMC market to enhance its environmental footprint and supply chain resilience.

Segmentation Analysis

Understanding the Battery Grade Ethyl Methyl Carbonate market through segmentation analysis is crucial for discerning its intricate dynamics, identifying key growth areas, and formulating effective market strategies. The market is primarily segmented based on purity levels, application areas, and regional distribution, each offering distinct insights into supply and demand patterns. Analyzing these segments helps stakeholders—from raw material suppliers to battery manufacturers—to tailor their products, services, and investments to specific market needs, ensuring optimal resource allocation and competitive advantage. This granular view allows for a more precise assessment of market potential and the identification of high-value opportunities within the rapidly evolving battery industry landscape.

- By Purity

- >99.9% Purity (Standard Battery Grade)

- >99.99% Purity (High-Performance/Advanced Battery Grade)

- By Application

- Electric Vehicles (EVs)

- Consumer Electronics (Smartphones, Laptops, Tablets, Wearables)

- Energy Storage Systems (ESS)

- Industrial Applications (Power Tools, Forklifts, Robotics)

- Others (Medical devices, Aerospace, Defense)

- By Region

- North America (U.S., Canada, Mexico)

- Europe (Germany, France, U.K., Italy, Spain, Rest of Europe)

- Asia Pacific (China, Japan, South Korea, India, Southeast Asia, Rest of Asia Pacific)

- Latin America (Brazil, Argentina, Rest of Latin America)

- Middle East & Africa (GCC Countries, South Africa, Rest of MEA)

Value Chain Analysis For Battery Grade Ethyl Methyl Carbonate Market

The value chain for Battery Grade Ethyl Methyl Carbonate is complex and spans from raw material extraction to the integration into final battery products, involving several critical stages. Upstream activities commence with the sourcing of precursor chemicals such as methanol, ethanol, and often carbon dioxide (CO2) or dimethyl carbonate (DMC). The synthesis of EMC typically involves transesterification processes or other specialized chemical reactions to produce crude EMC. This initial stage is heavily dependent on the availability and purity of these foundational chemicals and the efficiency of chemical conversion processes, which directly impact the final product's quality and cost-effectiveness. Key players in this segment are major chemical manufacturers with advanced synthetic capabilities.

Midstream in the value chain involves the crucial purification of crude Ethyl Methyl Carbonate to achieve the stringent battery-grade specifications. This purification process often includes multi-stage distillation, filtration, and other proprietary methods to remove impurities, water content, and metallic ions, ensuring the ultra-high purity required for stable battery performance. Companies specializing in advanced chemical purification technologies play a vital role here, investing heavily in research and development to enhance purification efficiency and reduce environmental impact. Quality control and assurance at this stage are paramount, as even minute impurities can significantly degrade battery performance and safety.

Downstream, the Battery Grade Ethyl Methyl Carbonate is supplied to electrolyte manufacturers who blend it with other organic carbonate solvents (like EC, DMC, DEC), lithium salts (e.g., LiPF6), and various additives to formulate custom electrolyte solutions. These electrolyte solutions are then sold to lithium-ion battery cell manufacturers, who integrate them into their battery cells (e.g., cylindrical, prismatic, pouch cells). The distribution channels are predominantly direct, involving direct sales and long-term contracts between EMC producers, electrolyte manufacturers, and battery cell manufacturers to ensure a consistent and reliable supply. Indirect channels may involve specialized chemical distributors for smaller players or specific regional markets, but the high volume and critical nature of Battery Grade EMC typically favor direct procurement to maintain quality control and supply chain integrity.

Battery Grade Ethyl Methyl Carbonate Market Potential Customers

The primary potential customers and end-users for Battery Grade Ethyl Methyl Carbonate are predominantly within the highly specialized and rapidly evolving lithium-ion battery ecosystem. The most significant direct buyers are electrolyte solution manufacturers, who procure high-purity EMC to formulate proprietary electrolyte blends crucial for battery functionality. These manufacturers require EMC that meets rigorous specifications for purity, moisture content, and chemical stability, as these factors directly influence the performance, safety, and cycle life of the final battery product. Their purchasing decisions are driven by cost-effectiveness, consistent supply, and the ability of the EMC to enhance specific battery characteristics like low-temperature performance or high-voltage stability.

Further down the value chain, the ultimate beneficiaries and indirect customers include major lithium-ion battery cell manufacturers, who integrate these electrolyte solutions into their diverse range of battery products. These include global giants producing cells for electric vehicles (EVs), consumer electronics (smartphones, laptops, wearables), and large-scale energy storage systems (ESS). Their demand for high-quality battery components like EMC is immense and continuously growing, fueled by the accelerating adoption of EVs and the widespread proliferation of portable electronic devices. These battery manufacturers exert significant influence on the entire supply chain, dictating quality standards and often engaging in long-term strategic partnerships with electrolyte and EMC suppliers.

Beyond direct manufacturing, other potential customers include research and development institutions and specialized material science companies focused on next-generation battery technologies. These entities require Battery Grade Ethyl Methyl Carbonate for experimental purposes, testing new battery chemistries, and validating novel electrolyte formulations. While their purchase volumes might be smaller, their role is crucial for future innovations and the continuous improvement of battery performance. The consistent demand from these various customer segments underscores the foundational importance of high-purity EMC in supporting the ongoing technological advancements and commercial expansion of the global energy storage sector.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1,250 Million |

| Market Forecast in 2033 | USD 2,700 Million |

| Growth Rate | 11.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Mitsubishi Chemical Corporation, UBE Corporation, BASF SE, Central Glass Co., Ltd., Merck KGaA, Lixing Chemical, Panax Etec, Dongguang Chemical, Zhejiang Transfar Chemcial, Shanghai Changsen Chemical, Beijing Chemical Industry Group, Shanxi Jindam Chemical, Kishida Chemical, Sigma-Aldrich, Noah Technologies, Guangzhou Tinci Materials Technology Co., Ltd., Kanto Chemical Co., Inc., Thermo Fisher Scientific Inc., Honeywell International Inc., Santa Cruz Biotechnology Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Battery Grade Ethyl Methyl Carbonate Market Key Technology Landscape

The technology landscape for the Battery Grade Ethyl Methyl Carbonate market is characterized by a relentless pursuit of higher purity, enhanced production efficiency, and improved environmental sustainability. A primary technological focus revolves around advanced synthesis methods. While traditional phosgene-based routes were historically employed, there has been a significant shift towards phosgene-free processes, such as the transesterification of dimethyl carbonate with ethanol. This not only mitigates safety and environmental concerns associated with phosgene but also often yields higher quality products and better overall process economics. Research continues into catalytic improvements and novel reaction pathways to further optimize yield and reduce energy consumption during the synthesis phase, ensuring the scalability required by the booming battery market.

Beyond synthesis, the purification technologies are paramount in achieving battery-grade standards for Ethyl Methyl Carbonate. Multi-stage distillation, often involving highly efficient fractional distillation columns, is a cornerstone for separating EMC from impurities, unreacted raw materials, and other byproducts. This is frequently complemented by specialized filtration techniques, including membrane filtration and adsorption processes, designed to remove trace metallic impurities, water, and other contaminants that can negatively impact battery performance. Advanced analytical techniques, such as Gas Chromatography-Mass Spectrometry (GC-MS), Karl Fischer titration for moisture content, and Inductively Coupled Plasma-Mass Spectrometry (ICP-MS) for trace metals, are indispensable for real-time quality control and ensuring the EMC meets ultra-high purity specifications (e.g., >99.99%).

Moreover, technological advancements extend to the entire handling, storage, and transportation infrastructure for Battery Grade Ethyl Methyl Carbonate. Inert gas blanketing systems, specialized corrosion-resistant materials for tanks and piping, and controlled atmospheric conditions are crucial to prevent degradation and contamination of the high-purity product. Innovations in digital twin technology and process simulation are also gaining traction, allowing manufacturers to model and optimize their production lines, predict equipment failures, and fine-tune purification parameters without physical experimentation. These integrated technological approaches are vital for maintaining the competitive edge in a market that demands both high volume production and uncompromising quality for critical battery components.

Regional Highlights

- Asia Pacific: This region dominates the Battery Grade Ethyl Methyl Carbonate market, driven by the massive presence of lithium-ion battery manufacturers in countries like China, South Korea, and Japan. China stands as the largest producer and consumer, benefiting from extensive government support for its EV and energy storage sectors, coupled with a well-established chemical industry infrastructure. South Korea and Japan, home to leading battery and electronics companies, are significant consumers and innovators in high-purity EMC. The region's robust demand is further propelled by the booming consumer electronics market and rapidly expanding EV production facilities.

- Europe: Europe is emerging as a significant market, experiencing rapid growth in demand for Battery Grade EMC due to substantial investments in domestic Gigafactories and battery production facilities. Countries such as Germany, France, and the UK are at the forefront of this expansion, aiming to localize the battery supply chain to reduce reliance on Asian imports and meet ambitious decarbonization targets. Stringent environmental regulations in Europe are also driving innovation towards greener production processes for EMC and increased recycling efforts.

- North America: The North American market, particularly the United States, is witnessing accelerated growth, spurred by supportive government policies like the Inflation Reduction Act (IRA) and significant investments by automotive manufacturers in EV production. There's a strong push to establish a domestic battery material supply chain, reducing geopolitical risks and enhancing energy independence. This is leading to increased local production capacity for Battery Grade EMC and a surge in R&D activities focused on advanced battery chemistries.

- Latin America: While a smaller market compared to Asia Pacific, Europe, or North America, Latin America presents emerging opportunities for Battery Grade EMC, primarily driven by the nascent but growing EV market in countries like Brazil and Mexico. Investments in charging infrastructure and a shift towards electric mobility are expected to gradually increase demand for battery components in the region, attracting attention from global chemical suppliers.

- Middle East & Africa (MEA): The MEA region is at an early stage of development for the Battery Grade EMC market. However, with increasing focus on renewable energy projects and diversification away from fossil fuels, countries in the GCC are exploring investments in energy storage solutions. Additionally, South Africa is showing potential for EV adoption and related manufacturing, which could slowly contribute to the demand for battery materials in the long term, though significant growth is still on the horizon.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Battery Grade Ethyl Methyl Carbonate Market.- Mitsubishi Chemical Corporation

- UBE Corporation

- BASF SE

- Central Glass Co., Ltd.

- Merck KGaA

- Lixing Chemical

- Panax Etec

- Dongguang Chemical

- Zhejiang Transfar Chemcial

- Shanghai Changsen Chemical

- Beijing Chemical Industry Group

- Shanxi Jindam Chemical

- Kishida Chemical

- Sigma-Aldrich

- Noah Technologies

- Guangzhou Tinci Materials Technology Co., Ltd.

- Kanto Chemical Co., Inc.

- Thermo Fisher Scientific Inc.

- Honeywell International Inc.

- Santa Cruz Biotechnology Inc.

Frequently Asked Questions

What is Battery Grade Ethyl Methyl Carbonate (EMC)?

Battery Grade Ethyl Methyl Carbonate (EMC) is a high-purity organic carbonate solvent primarily used as a key component in the electrolyte solutions of lithium-ion batteries. It is valued for its low viscosity, high chemical stability, and excellent performance in facilitating ion transport, which are crucial for enhancing battery efficiency, safety, and longevity in various applications.

Why is EMC crucial for lithium-ion batteries?

EMC is crucial for lithium-ion batteries because it helps form an optimal electrolyte blend that enables efficient lithium ion movement between electrodes. Its properties contribute to improved low-temperature performance, reduced internal resistance, enhanced charge-discharge cycling stability, and increased overall safety, making it indispensable for high-performance battery systems.

What are the primary drivers of the Battery Grade EMC market?

The primary drivers of the Battery Grade EMC market include the exponential growth of the global electric vehicle (EV) industry, the increasing demand for advanced energy storage systems (ESS), and the widespread adoption of portable consumer electronics. Additionally, government incentives for sustainable energy and continuous advancements in battery technology further stimulate market expansion.

Which regions dominate the production and consumption of Battery Grade EMC?

Asia Pacific, particularly countries like China, South Korea, and Japan, overwhelmingly dominates both the production and consumption of Battery Grade EMC. This regional leadership is attributed to the presence of major lithium-ion battery manufacturing hubs, robust government support for electrification, and a well-developed chemical industry infrastructure.

What challenges does the Battery Grade EMC market face?

The Battery Grade EMC market faces challenges such as volatility in raw material prices, which can impact production costs and market stability. Additionally, stringent environmental regulations governing chemical manufacturing, the need for continuous technological innovation to meet evolving battery demands, and potential competition from alternative electrolyte components pose ongoing hurdles for market players.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager