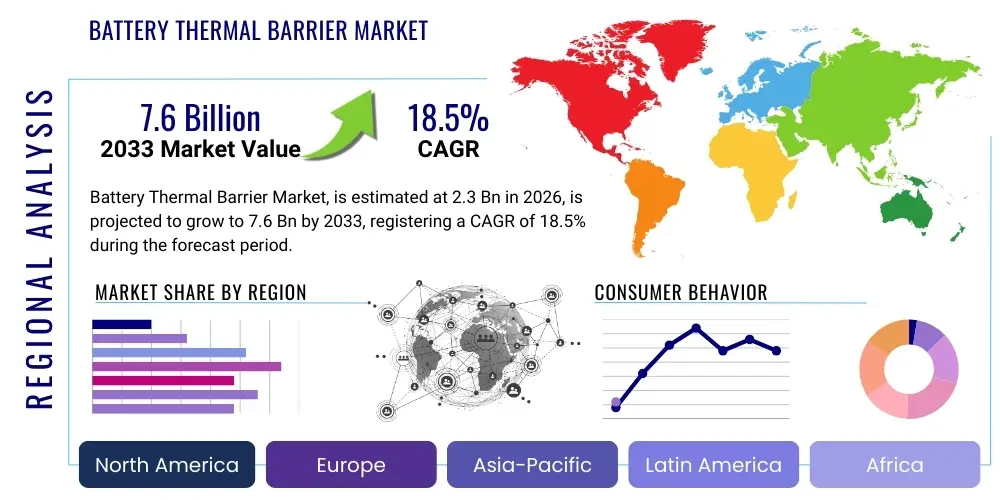

Battery Thermal Barrier Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440556 | Date : Jan, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Battery Thermal Barrier Market Size

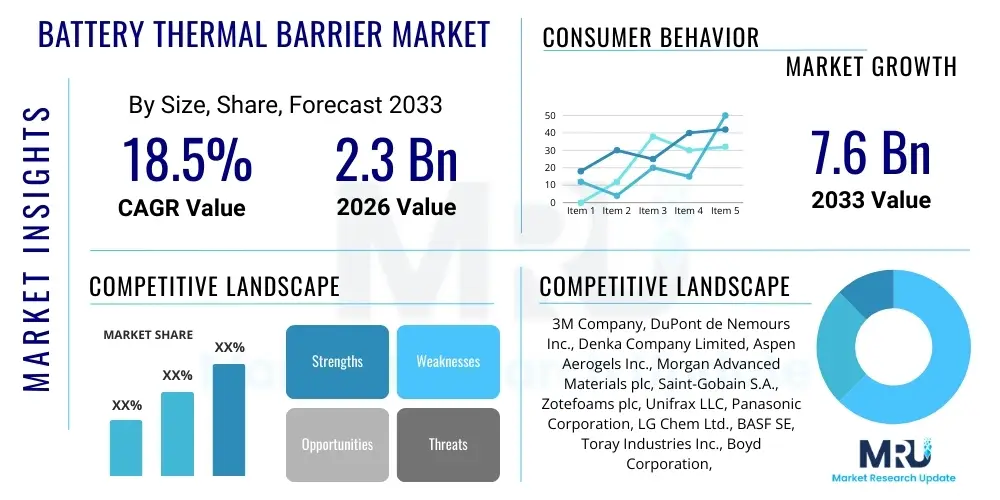

The Battery Thermal Barrier Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 18.5% between 2026 and 2033. The market is estimated at USD 2.3 billion in 2026 and is projected to reach USD 7.6 billion by the end of the forecast period in 2033.

Battery Thermal Barrier Market introduction

The Battery Thermal Barrier Market is a critical and rapidly evolving segment within the broader advanced materials industry, driven primarily by the escalating demand for safer and more efficient energy storage solutions, particularly in electric vehicles (EVs) and grid-scale applications. Battery thermal barriers are specialized materials or systems designed to prevent or mitigate thermal runaway events in battery packs by impeding the propagation of heat from one cell to adjacent cells, thereby enhancing safety and extending the operational life of the battery system. These barriers are essential components for improving the overall reliability and performance of lithium-ion batteries, which are susceptible to significant heat generation during charge/discharge cycles and potential internal short circuits.

The primary application areas for battery thermal barriers include electric vehicles, hybrid electric vehicles, stationary energy storage systems (ESS), and portable electronic devices. In EVs, thermal barriers are integral to battery module design, offering crucial protection against cell-to-cell thermal propagation, a key safety concern for automotive manufacturers. For stationary energy storage, which often involves large battery installations, these barriers help maintain system stability and prevent catastrophic failures. The increasing energy density of modern batteries, while beneficial for performance, also amplifies the risk of thermal events, making advanced thermal management solutions indispensable for market growth.

The core benefits derived from integrating battery thermal barriers are manifold, encompassing enhanced safety, extended battery life, and improved system reliability. By isolating individual battery cells or modules, these barriers effectively contain thermal events, preventing a cascading failure throughout the entire battery pack. This protection significantly reduces the risk of fires or explosions, which are major safety concerns for consumers and regulators. Moreover, by maintaining optimal operating temperatures and preventing localized overheating, thermal barriers contribute to preserving battery health, slowing degradation, and ultimately prolonging the lifespan of expensive battery systems, thereby offering significant economic and operational advantages to end-users.

Battery Thermal Barrier Market Executive Summary

The Battery Thermal Barrier Market is experiencing robust expansion, characterized by significant business trends driven by global electrification initiatives and stringent safety regulations. Key trends include a rapid increase in research and development activities focused on novel, high-performance materials such as aerogels, mica, ceramic composites, and advanced polymers that offer superior thermal insulation and flame retardancy. There is also a growing emphasis on cost-effective manufacturing processes and integration solutions to meet the scalability demands of the automotive and energy storage sectors. Strategic partnerships between material suppliers, battery manufacturers, and automotive OEMs are becoming increasingly common, fostering innovation and accelerating market penetration of new barrier technologies.

Regionally, the market exhibits dynamic growth patterns, with Asia Pacific emerging as the dominant region, primarily fueled by the substantial presence of major EV and battery manufacturers in countries like China, South Korea, and Japan. Europe and North America are also witnessing strong growth, propelled by ambitious decarbonization goals, significant investments in EV infrastructure, and evolving regulatory frameworks that mandate enhanced battery safety. Government incentives and subsidies for EV adoption and renewable energy deployment in these regions further stimulate the demand for advanced battery thermal management solutions. Latin America, the Middle East, and Africa are showing nascent but promising growth, driven by increasing awareness and initial investments in electric mobility and decentralized energy solutions.

From a segmentation perspective, the market's growth is largely bifurcated by material type and application. Materials like mica, ceramic, and aerogels are gaining traction due to their excellent thermal resistance and lightweight properties, while polymer-based solutions continue to hold a significant share due to their flexibility and cost-effectiveness. In terms of applications, electric vehicles remain the largest segment, with battery electric vehicles (BEVs) and plug-in hybrid electric vehicles (PHEVs) representing the primary demand drivers. The stationary energy storage segment is also experiencing accelerated growth, propelled by the increasing integration of renewable energy sources into power grids and the need for reliable backup power solutions. The diverse requirements across these segments are fostering a rich ecosystem of specialized products and tailored thermal barrier solutions.

AI Impact Analysis on Battery Thermal Barrier Market

User inquiries regarding the impact of AI on the Battery Thermal Barrier Market often revolve around its potential to revolutionize material discovery, optimize design and manufacturing processes, and enhance predictive safety protocols. Common questions include how AI can accelerate the identification of new, more efficient thermal barrier materials, whether AI-driven simulations can reduce development costs and time, and if AI will play a role in real-time thermal management and fault prediction within battery systems. There is also significant interest in AI's capacity to integrate disparate data points from material science, engineering, and operational analytics to create smarter, more adaptive thermal barrier solutions. Users are looking for insights into how AI will move the industry beyond traditional trial-and-error methods towards a more data-driven, predictive, and optimized approach to battery safety.

- AI-driven material discovery: Accelerates the identification and synthesis of novel thermal barrier materials with enhanced properties, reducing research cycles.

- Optimized design and simulation: Enables rapid prototyping and virtual testing of thermal barrier designs, predicting performance under extreme conditions and minimizing physical iterations.

- Predictive thermal management: AI algorithms can analyze real-time battery data to anticipate potential thermal runaway events, allowing for proactive intervention and dynamic adjustment of cooling strategies or barrier activation.

- Enhanced manufacturing efficiency: AI can optimize production processes for thermal barrier materials, improving yield, reducing waste, and ensuring consistent quality through automated inspection.

- Personalized safety solutions: AI may enable the development of adaptive thermal barrier systems that adjust their properties or deployment based on specific battery usage patterns and environmental conditions.

- Data-driven failure analysis: AI models can pinpoint root causes of thermal incidents, providing valuable feedback for future material development and system design improvements.

- Supply chain optimization: AI can predict demand fluctuations for thermal barrier components, optimizing inventory management and logistics for manufacturers.

DRO & Impact Forces Of Battery Thermal Barrier Market

The Battery Thermal Barrier Market is significantly influenced by a confluence of drivers, restraints, and opportunities, all contributing to its dynamic growth trajectory. A primary driver is the accelerating global adoption of electric vehicles (EVs) and hybrid electric vehicles (HEVs), which necessitates increasingly sophisticated battery thermal management and safety solutions. Concurrently, stringent safety regulations and evolving industry standards for battery packs, particularly in the automotive and energy storage sectors, are compelling manufacturers to integrate advanced thermal barriers. The continuous pursuit of higher energy density in batteries, while enhancing performance, simultaneously escalates the risk of thermal runaway, thereby creating an indispensable need for effective thermal isolation. Moreover, the growing demand for grid-scale energy storage systems (ESS) for renewable energy integration further amplifies the need for robust battery safety features, including thermal barriers.

Despite these powerful drivers, the market faces several restraining factors. The high cost associated with advanced thermal barrier materials, such as aerogels and specialized ceramic composites, can be a significant barrier to widespread adoption, particularly for budget-sensitive applications. The complexity involved in integrating these materials into compact battery pack designs, often requiring sophisticated manufacturing processes and precision engineering, adds to the overall system cost and can present design challenges. Additionally, the limited availability of certain raw materials and the intricate supply chains required for specialized thermal barrier components can lead to supply chain vulnerabilities and price volatility. Ensuring the long-term durability and consistent performance of thermal barriers under diverse operating conditions also presents an ongoing research and development challenge.

Nevertheless, the market is rife with substantial opportunities that are poised to drive future innovation and growth. The ongoing development of novel, cost-effective thermal barrier materials with improved performance characteristics, such as enhanced flame retardancy, thinner profiles, and lighter weights, presents a significant avenue for market expansion. The emergence of solid-state batteries, which promise higher energy density and improved safety, will still require robust thermal management solutions, albeit potentially different in nature, opening new design and material opportunities. Furthermore, the increasing focus on sustainable manufacturing practices and the demand for recyclable thermal barrier materials align with global environmental goals and can create competitive advantages. The expansion into emerging applications like electric aircraft, marine vessels, and advanced robotics also represents untapped potential for thermal barrier technologies, diversifying the market's revenue streams.

Segmentation Analysis

The Battery Thermal Barrier Market is comprehensively segmented to provide granular insights into its diverse components and growth drivers. These segmentations are critical for understanding market dynamics, identifying niche opportunities, and formulating targeted business strategies. The market can be broadly categorized by material type, which dictates the performance characteristics and cost structure of the barriers; by application, which highlights the primary end-use sectors driving demand; by battery type, reflecting specific safety needs for different electrochemical chemistries; and by form factor, detailing how these barriers are physically integrated into battery systems. Each segment possesses unique requirements and growth potentials, shaped by technological advancements, regulatory pressures, and evolving consumer preferences. This structured approach to segmentation allows for a detailed analysis of market trends and competitive landscapes across various dimensions of the industry.

- By Material Type:

- Mica-based Barriers

- Ceramic-based Barriers

- Aerogel-based Barriers

- Polymer-based Barriers (e.g., Polyimide, Polypropylene)

- Fiber-based Barriers (e.g., Glass Fiber, Aramid Fiber)

- Composite Materials

- By Application:

- Electric Vehicles (EVs)

- Battery Electric Vehicles (BEVs)

- Plug-in Hybrid Electric Vehicles (PHEVs)

- Hybrid Electric Vehicles (HEVs)

- Stationary Energy Storage Systems (ESS)

- Portable Electronics

- Industrial Equipment

- Aerospace and Defense

- Electric Vehicles (EVs)

- By Battery Type:

- Lithium-ion Batteries

- NMC (Nickel Manganese Cobalt)

- LFP (Lithium Iron Phosphate)

- NCA (Nickel Cobalt Aluminum)

- Solid-State Batteries

- Other Advanced Battery Chemistries

- Lithium-ion Batteries

- By Form Factor:

- Sheets/Films

- Coating/Gels

- Pads/Insulators

- Encapsulants

Value Chain Analysis For Battery Thermal Barrier Market

The value chain for the Battery Thermal Barrier Market is intricate, involving several distinct stages from raw material procurement to end-use integration, each adding specialized value. The upstream segment commences with the extraction and processing of fundamental raw materials such as silica for aerogels, various mineral ores for mica and ceramics, and petrochemicals for advanced polymers. This stage also includes the manufacturing of specialized chemicals and additives crucial for enhancing the thermal and flame-retardant properties of the barrier materials. Key players at this stage focus on securing reliable supplies, optimizing material purity, and developing sustainable sourcing strategies to meet the growing demand from downstream processors. Innovations in eco-friendly material synthesis and recycling are gaining prominence within this initial phase of the value chain.

Moving downstream, the value chain encompasses the sophisticated manufacturing and conversion of these raw materials into functional thermal barrier products. This involves processes such as fiber spinning, composite layering, coating application, and precision cutting to create sheets, films, pads, or gels specifically engineered for battery thermal management. Specialized material processors and component manufacturers play a crucial role, often employing advanced techniques to achieve desired thermal conductivity, mechanical strength, and electrical insulation properties. These companies invest heavily in R&D to develop proprietary formulations and production methods that can meet the stringent performance and safety standards required by battery manufacturers and OEMs. Quality control and customization capabilities are paramount in this transformative stage.

The distribution channel for battery thermal barriers is multifaceted, involving both direct and indirect routes to market. Direct distribution typically occurs when thermal barrier manufacturers supply their products directly to large-scale battery manufacturers, automotive OEMs, or major energy storage system integrators. This direct approach often involves bespoke solutions, technical collaboration, and long-term supply agreements. Indirect channels involve a network of specialized distributors, value-added resellers, and industrial suppliers who serve a broader range of smaller battery assemblers, aftermarket providers, and diverse industrial clients. These intermediaries often provide inventory management, technical support, and localized logistics, enhancing market reach. The effectiveness of the distribution network is crucial for ensuring timely delivery and widespread availability of these critical safety components across the global market.

Battery Thermal Barrier Market Potential Customers

The primary potential customers and end-users of battery thermal barrier products are diverse, reflecting the broad application spectrum of modern battery technologies. At the forefront are original equipment manufacturers (OEMs) in the automotive industry, particularly those involved in the production of electric vehicles (BEVs, PHEVs, and HEVs). These OEMs integrate thermal barriers directly into their battery modules and packs to meet rigorous safety standards and enhance vehicle performance and reliability. Their demand is driven by rapid electrification trends, consumer safety expectations, and regulatory mandates, making them a cornerstone of the market. Battery manufacturers, who supply cells and modules to these OEMs and other sectors, also represent a significant customer base, often working closely with thermal barrier suppliers to optimize their pack designs.

Beyond the automotive sector, developers and integrators of stationary energy storage systems (ESS) constitute a rapidly expanding customer segment. These systems, ranging from residential backup solutions to large-scale grid stabilization projects, rely on thermal barriers to ensure the safe and stable operation of extensive battery arrays. Companies specializing in renewable energy integration, utilities, and industrial facilities requiring reliable power backup are key buyers in this segment. The increasing deployment of renewable energy sources like solar and wind, coupled with the need for energy independence, is fueling significant demand from these customers for robust and safe battery solutions that incorporate advanced thermal protection.

Furthermore, manufacturers of portable electronics, power tools, and various industrial equipment also represent important end-users. While their individual unit demand for thermal barriers might be smaller than that of EVs or ESS, the sheer volume of products across these categories creates substantial cumulative demand. Aerospace and defense contractors also procure highly specialized thermal barrier solutions for critical applications where extreme reliability and safety are paramount. These diverse customer groups all share a common need for enhanced battery safety, performance longevity, and adherence to evolving regulatory requirements, driving continuous innovation and demand within the Battery Thermal Barrier Market. The tailored needs of each customer segment necessitate a diverse product portfolio and adaptable material solutions from thermal barrier suppliers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 2.3 billion |

| Market Forecast in 2033 | USD 7.6 billion |

| Growth Rate | 18.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | 3M Company, DuPont de Nemours Inc., Denka Company Limited, Aspen Aerogels Inc., Morgan Advanced Materials plc, Saint-Gobain S.A., Zotefoams plc, Unifrax LLC, Panasonic Corporation, LG Chem Ltd., BASF SE, Toray Industries Inc., Boyd Corporation, NITTO DENKO CORPORATION, Sekisui Chemical Co. Ltd., Rogers Corporation, Trelleborg AB, Sumitomo Bakelite Co. Ltd., Hitachi Chemical Co. Ltd., SABIC |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Battery Thermal Barrier Market Key Technology Landscape

The technology landscape for the Battery Thermal Barrier Market is characterized by continuous innovation aimed at developing materials and designs that offer superior thermal isolation, improved flame retardancy, reduced weight, and enhanced manufacturability. Current key technologies revolve around advanced material science, utilizing various chemistries and structures to achieve optimal thermal performance. This includes the development of thin, flexible mica-based sheets and papers known for their excellent dielectric strength and high-temperature resistance, providing robust protection against thermal runaway. Ceramic-based solutions, often incorporating ceramic fibers or coatings, leverage their inherently high melting points and non-combustible properties to create durable and effective barriers. These materials are crucial for withstanding extreme temperatures during thermal events and preventing direct flame propagation.

Aerogel-based technologies represent another significant advancement, offering unparalleled thermal insulation due to their highly porous, lightweight structure. Silica aerogels, in particular, are being engineered into flexible blankets, films, or composites that provide superior insulation with minimal weight penalty, making them ideal for space-constrained applications like electric vehicle battery packs. Polymer-based solutions, such as polyimide films and specialized flame-retardant polypropylene, are also vital, offering a balance of flexibility, mechanical strength, and electrical insulation properties. These polymers are often enhanced with intumescent additives that expand upon heating, forming a protective char layer that further insulates and slows thermal propagation. The synergistic use of these different material types in multi-layer composites is a growing trend, combining the best properties of each to create highly effective and robust thermal barriers.

Beyond material composition, the technology landscape also encompasses advanced manufacturing processes and integration techniques. This includes precision cutting and shaping of barrier materials to fit complex battery module geometries, as well as innovative assembly methods that ensure reliable and consistent performance across thousands of cells. The development of direct-to-cell coatings and encapsulants that intimately surround individual battery cells is also gaining traction, offering localized protection and simplifying module assembly. Furthermore, smart thermal barriers incorporating embedded sensors or responsive materials capable of dynamically changing their properties in response to temperature fluctuations are emerging as future technologies, promising even more proactive and adaptive thermal management. The integration of these materials with passive and active cooling systems further enhances overall battery safety and performance, creating a holistic thermal management ecosystem.

Regional Highlights

- Asia Pacific: This region stands as the dominant market for battery thermal barriers, primarily driven by the colossal manufacturing base for electric vehicles and lithium-ion batteries in countries such as China, South Korea, and Japan. Robust government support for EV adoption, extensive R&D investments in battery technology, and the presence of leading battery cell manufacturers like CATL, LG Energy Solution, and Panasonic, create a highly concentrated demand. The region also leads in stationary energy storage deployments, further amplifying the need for advanced thermal management solutions. Strict safety standards in regional markets continue to push innovation and adoption.

- Europe: Europe represents a significant and rapidly growing market, fueled by ambitious decarbonization targets, stringent emissions regulations, and substantial investments in gigafactories for EV battery production. Countries like Germany, France, and the UK are at the forefront of EV adoption and battery innovation, with a strong focus on enhancing battery safety and sustainability. The European Union's regulatory framework, including initiatives like the Battery Regulation, is driving demand for high-performance and environmentally responsible thermal barrier solutions.

- North America: The North American market is experiencing robust growth, primarily spurred by increasing EV sales, significant investments in charging infrastructure, and government incentives like the Inflation Reduction Act. The United States and Canada are witnessing a surge in domestic battery manufacturing capacity, driving demand for locally sourced and innovative thermal barrier materials. Regulatory bodies such as NHTSA are increasingly scrutinizing battery safety, compelling automakers to integrate advanced thermal management technologies.

- Latin America: This emerging market shows promising growth, albeit from a smaller base, driven by increasing awareness and initial investments in electric mobility, particularly in countries like Brazil and Mexico. Government initiatives to promote sustainable transportation and expand public charging infrastructure are gradually stimulating demand for battery-related components, including thermal barriers. Economic development and urbanization are key factors contributing to the slow but steady adoption of EVs and stationary storage solutions in the region.

- Middle East and Africa (MEA): The MEA region is at an early stage of battery thermal barrier adoption, with growth primarily concentrated in areas making strategic investments in renewable energy projects and developing EV charging networks. Countries in the Gulf Cooperation Council (GCC) are exploring diversification from fossil fuels, leading to investments in large-scale energy storage and nascent EV markets. As infrastructure develops and EV penetration increases, the demand for advanced battery safety solutions is expected to grow, focusing initially on commercial and public transport applications.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Battery Thermal Barrier Market.- 3M Company

- DuPont de Nemours Inc.

- Denka Company Limited

- Aspen Aerogels Inc.

- Morgan Advanced Materials plc

- Saint-Gobain S.A.

- Zotefoams plc

- Unifrax LLC

- Panasonic Corporation

- LG Chem Ltd.

- BASF SE

- Toray Industries Inc.

- Boyd Corporation

- NITTO DENKO CORPORATION

- Sekisui Chemical Co. Ltd.

- Rogers Corporation

- Trelleborg AB

- Sumitomo Bakelite Co. Ltd.

- Hitachi Chemical Co. Ltd.

- SABIC

Frequently Asked Questions

Analyze common user questions about the Battery Thermal Barrier market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is a battery thermal barrier and why is it important?

A battery thermal barrier is a specialized material or system designed to prevent or slow the propagation of heat between battery cells, particularly during a thermal runaway event. Its importance lies in significantly enhancing battery safety by containing thermal incidents, preventing catastrophic failures, extending battery lifespan, and improving overall system reliability, especially in electric vehicles and energy storage systems.

What are the primary materials used in battery thermal barriers?

The primary materials include mica-based solutions (known for high-temperature resistance and dielectric strength), ceramic-based materials (offering high melting points and non-combustibility), aerogel-based technologies (providing superior lightweight insulation), and various polymer-based composites (offering flexibility, mechanical strength, and often enhanced with flame retardants). Often, multi-layer composites combine these materials for optimal performance.

How do battery thermal barriers contribute to the safety of electric vehicles (EVs)?

In EVs, thermal barriers are critical for preventing cell-to-cell thermal propagation, which can lead to a cascading failure across the entire battery pack during a thermal runaway. By isolating individual cells or modules, they contain heat, reduce the risk of fire or explosion, and provide crucial time for vehicle occupants to egress, thereby significantly improving passenger safety and vehicle integrity.

What are the key drivers for the growth of the Battery Thermal Barrier Market?

Key drivers include the rapid global adoption of electric vehicles, increasingly stringent battery safety regulations, the continuous demand for higher energy density in batteries (which elevates thermal risks), and the significant expansion of stationary energy storage systems for renewable energy integration. These factors collectively push for advanced thermal management solutions.

What are the future trends and opportunities in battery thermal barrier technology?

Future trends include the development of novel, thinner, and lighter materials with enhanced thermal and flame-retardant properties, advancements in AI-driven material discovery and design optimization, and the integration of smart, responsive thermal barrier systems. Opportunities arise from the growth of solid-state batteries, expansion into new applications like electric aircraft, and a growing emphasis on sustainable and recyclable barrier solutions.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager