Belt Drying System Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 431355 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Belt Drying System Market Size

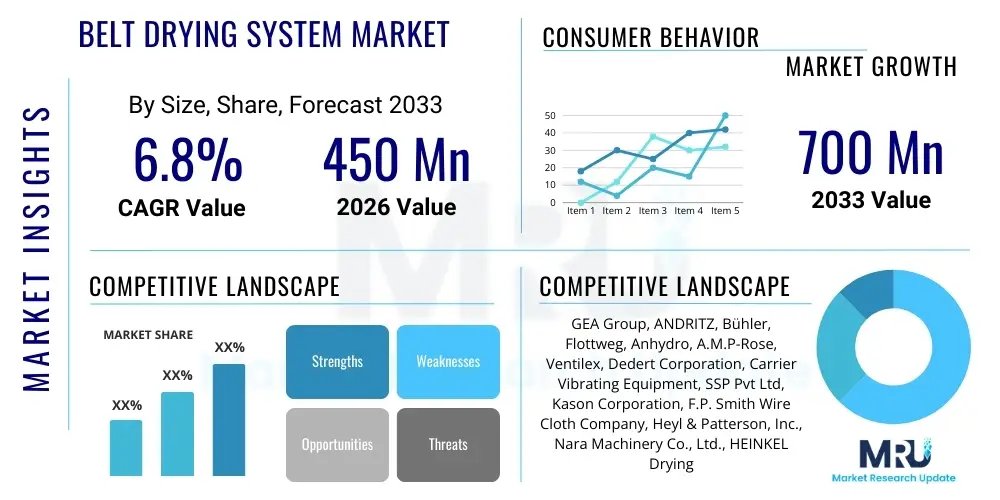

The Belt Drying System Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 700 Million by the end of the forecast period in 2033.

Belt Drying System Market introduction

The Belt Drying System Market encompasses industrial equipment designed for continuous, gentle drying of various materials, including food products, biomass, chemicals, and pharmaceuticals. These systems operate by conveying material on a perforated belt through enclosed chambers where hot air, infrared radiation, or other heating mediums circulate to remove moisture. The fundamental mechanism ensures precise control over temperature and residence time, making belt dryers indispensable for preserving the structural integrity and nutritional value of sensitive products. They are particularly valued in high-volume production environments due to their continuous operation and scalability, contrasting sharply with batch-based drying methods in terms of throughput and operational efficiency.

Major applications of belt drying systems span several critical industrial sectors. In the Food and Beverage industry, they are essential for drying grains, fruits, vegetables, snacks, and pet food, ensuring extended shelf life and consistent quality. Chemical and pharmaceutical manufacturers utilize these systems for solvent removal, granulation drying, and processing delicate powders. Furthermore, the rising focus on environmental sustainability has positioned belt dryers as key components in wastewater treatment (sludge drying) and biomass processing (pellet production), optimizing waste reduction and energy recovery processes.

The key driving factors propelling the adoption of belt drying systems include stringent food safety regulations requiring precise moisture control, the necessity for energy-efficient drying solutions in high-energy consumption industries, and the increasing global demand for processed and convenient food products. Benefits associated with these systems include high thermal efficiency, reduced product damage due to gentle handling, operational flexibility (handling pastes, granules, or extruded products), and lower maintenance requirements compared to complex fluidized bed or spray drying technologies. The market expansion is intrinsically linked to industrial growth, especially in emerging economies focusing on advanced manufacturing and agricultural processing.

Belt Drying System Market Executive Summary

The Belt Drying System Market is witnessing robust expansion, driven primarily by evolving regulatory standards emphasizing product consistency and sanitation across the food and pharmaceutical sectors. Current business trends indicate a strong move towards modular system designs and integration capabilities, allowing for easier scaling and retrofitting into existing manufacturing lines. Manufacturers are concentrating on optimizing heat recovery mechanisms, such as implementing sophisticated heat exchangers and recirculation loops, to minimize operational costs associated with high energy input. The competitive landscape is characterized by a mix of established industrial machinery giants offering customized large-scale solutions and specialized niche players focusing on specific applications like low-temperature vacuum belt drying, which caters to highly sensitive or volatile materials.

Regionally, Asia Pacific (APAC) stands out as the primary growth engine, fueled by rapid industrialization, large-scale investment in food processing infrastructure, and significant governmental support for waste management projects, particularly sludge drying. North America and Europe maintain a mature market status, where growth is predominantly driven by replacement demand, modernization of legacy systems, and the adoption of advanced automation features (Industry 4.0 integration) to enhance quality control and reduce labor dependency. These developed markets show a higher inclination toward specialized, high-efficiency hybrid drying systems that combine belt technology with microwave or radio frequency assistance to speed up processing times while maintaining product integrity.

Segment trends highlight the dominance of continuous belt dryers due to their inherent suitability for mass production environments. By application, the Food and Beverage sector remains the largest segment, demanding equipment capable of meeting high hygiene standards (e.g., easy-clean designs and CIP compatibility). However, the Waste Management and Chemical segments are registering the highest growth rates, spurred by regulatory pressures to reduce sludge volume and recover valuable materials from chemical processes. Furthermore, there is a distinct trend within the technology segment toward multi-stage drying systems that utilize different temperatures and airflows across sequential zones on the belt, maximizing efficiency and minimizing the risk of product overheating.

AI Impact Analysis on Belt Drying System Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Belt Drying System Market commonly center on predictive maintenance, optimization of energy usage, and real-time quality control. Users express concerns about the complexity of integrating AI algorithms with legacy PLC and SCADA systems, along with expectations that AI should significantly reduce the margin of error in moisture content (MC) prediction, which directly affects product quality and waste generation. Key themes emerging from these questions involve determining the Return on Investment (ROI) for AI-driven process optimization versus traditional PID control loops, and the feasibility of creating digital twins of complex drying processes to simulate various input variables before implementation.

The core promise of AI in this domain lies in transforming industrial drying from a reactive, empirical process into a proactive, data-driven operation. By analyzing sensor data streams—including temperature, humidity, airflow, vibration, and energy consumption—AI models can establish complex non-linear relationships that traditional control systems cannot capture. This allows for anticipatory adjustments to drying parameters, preventing suboptimal drying conditions before they impact the final product. For instance, AI can predict when specific maintenance is required on air handlers or heat exchangers based on slight deviations in efficiency metrics, thereby minimizing costly unplanned downtime and maximizing the operational lifespan of the equipment.

Furthermore, AI facilitates superior energy management. Since thermal drying is one of the most energy-intensive steps in industrial processing, AI models can learn the energy consumption profile of the dryer under various load and material characteristics. This knowledge enables the system to dynamically adjust fan speeds, burner modulation, and recirculation rates to achieve target moisture content using the least amount of energy possible. This shift towards AI-enhanced thermal efficiency is critical for manufacturers aiming to meet increasingly ambitious sustainability targets and reduce carbon footprints associated with their production processes.

- Enhanced Predictive Maintenance: AI algorithms analyze vibration and temperature data to forecast component failure, reducing unplanned downtime by up to 30%.

- Real-Time Moisture Content Prediction: Utilizing machine learning on NIR (Near-Infrared) sensor data for precise, non-destructive, and continuous quality assurance.

- Energy Consumption Optimization: Dynamic adjustment of thermal and airflow parameters based on predictive models of current material load and external environmental factors.

- Digital Twin Simulation: Creation of virtual models to test new product recipes or operational strategies without disrupting live production.

- Automated Fault Diagnosis: Rapid identification and isolation of processing anomalies, improving operator response time and reducing material waste.

DRO & Impact Forces Of Belt Drying System Market

The market for belt drying systems is governed by a robust interplay of driving forces, restraining factors, and significant opportunities, collectively shaping its trajectory. The primary driver is the global expansion of food processing industries, particularly in Asia and Latin America, necessitating continuous, high-capacity drying solutions for grains, prepared meals, and animal feed. Concurrently, strict environmental regulations concerning sludge disposal and waste reduction are boosting demand for industrial belt dryers within municipal and industrial wastewater treatment plants. These market dynamics are further amplified by continuous technological advancements aimed at improving thermal efficiency and ensuring compliance with rising hygiene standards, such as 3-A Sanitary Standards and FDA guidelines.

However, market growth faces considerable restraints. The initial capital investment required for high-capacity, automated belt drying systems is substantial, posing a barrier to entry, especially for small and medium-sized enterprises (SMEs). Operational complexity, particularly in achieving uniform drying for heterogeneous materials, requires skilled labor for monitoring and calibration, adding to operational expenditure (OPEX). Furthermore, competition from alternative drying technologies, such as spray drying (for liquid solutions) and freeze drying (for high-value, heat-sensitive materials), continues to cap the potential market share in specific specialized applications, requiring belt dryer manufacturers to continuously innovate in hybrid configurations.

Significant opportunities exist in the development of modular and containerized belt drying solutions tailored for small-scale operations or mobile use, particularly relevant in decentralized agricultural hubs. The increasing focus on biomass and biofuel production offers a lucrative, expanding segment, as these processes require large-scale, high-throughput drying of materials like wood chips and agricultural residues. The impact forces influencing the market are substantial; rising energy prices worldwide place immense pressure on manufacturers to prioritize and invest in ultra-efficient designs utilizing waste heat recovery and closed-loop systems. Additionally, global supply chain disruptions necessitate regional manufacturing capabilities and standardized component inventories to mitigate risks related to project timelines and system installation.

Segmentation Analysis

The Belt Drying System Market is extensively segmented based on several key parameters including the product type, operational mechanism, heat source, and the diverse applications across end-user industries. This stratification provides a granular view of market dynamics, revealing specific growth pockets driven by technological necessity and industrial demand. The core segmentation often distinguishes between traditional single-stage and advanced multi-stage systems, catering to simple and complex drying processes, respectively. Understanding these segments is crucial for manufacturers to tailor their product offerings, focusing on compliance, efficiency, and scale required by specific sectors like pharmaceuticals which demand stringent validation, versus municipal waste treatment which prioritizes high volume throughput and robustness.

- By Type:

- Single-Stage Belt Dryers

- Multi-Stage Belt Dryers

- Vacuum Belt Dryers

- Hybrid Belt Dryers (e.g., combining RF or Microwave heating)

- By Operation:

- Continuous

- Batch

- By Heat Source:

- Steam Heated

- Hot Water Heated

- Thermal Oil Heated

- Natural Gas/LPG Fired

- Electric/Infrared Heated

- By Application:

- Food & Beverage Processing (Fruits, Vegetables, Grains, Snacks, Pet Food)

- Chemical and Petrochemical Processing (Polymers, Pigments)

- Pharmaceuticals and Nutraceuticals (Granules, APIs)

- Wastewater and Sludge Treatment

- Biomass and Biofuel Production

- Wood and Construction Materials

Value Chain Analysis For Belt Drying System Market

The value chain for the Belt Drying System Market begins with the upstream suppliers responsible for providing essential components and raw materials. This includes manufacturers of specialized conveyor belts (often Teflon-coated or stainless steel mesh), industrial fan and blower systems, advanced heat exchangers, and precision sensors/controls (PLC systems). The quality and durability of these upstream inputs directly influence the final performance and reliability of the drying system. Key factors at this stage involve securing high-grade stainless steel for sanitary applications and establishing robust supply agreements for critical, often proprietary, electronic components necessary for modern automation and control.

The midstream stage involves the core manufacturing and assembly of the belt drying unit, including system design, fabrication, thermal modeling, and integration of heating and control units. This phase is characterized by high engineering complexity, requiring specialized knowledge in thermodynamics and fluid dynamics to ensure optimal air distribution and thermal uniformity across the belt surface. Manufacturers typically engage in direct integration of advanced components and often customize the dryer dimensions, airflow patterns, and cleaning mechanisms (e.g., CIP systems) to meet specific client requirements regarding material characteristics and hygiene standards. Quality assurance and adherence to international safety certifications (e.g., ASME, CE) are paramount at this stage.

Downstream analysis focuses on distribution, installation, commissioning, and long-term service provision. Distribution channels typically involve a mix of direct sales teams for large, highly customized projects and specialized regional distributors/agents who handle sales and initial technical support for standard or modular units. Post-sales service is a crucial revenue stream, encompassing spare parts supply, preventative maintenance contracts, and technical upgrades (e.g., adding AI-driven predictive maintenance modules). Direct client engagement, particularly with large industrial end-users like multinational food conglomerates or major municipal waterworks, is essential for maintaining market presence and gathering feedback for iterative product improvement.

Belt Drying System Market Potential Customers

Potential customers for high-capacity belt drying systems are concentrated in sectors requiring continuous, gentle, and energy-efficient moisture reduction to maintain product quality and volume throughput. The primary customer base resides within the Food and Beverage sector, including major manufacturers of breakfast cereals, dehydrated fruits and vegetables, specialty grains, and pet food processors. These end-users prioritize systems offering high sanitary design (to prevent cross-contamination and bacterial growth) and precise temperature control to preserve flavor, color, and nutritional content. The procurement decision in this sector is heavily influenced by total cost of ownership (TCO) assessments, factoring in energy efficiency and ease of cleaning.

A rapidly expanding customer segment includes municipal and industrial wastewater treatment facilities. These organizations utilize belt dryers for sludge volume reduction, minimizing disposal costs, and often converting sludge into reusable materials (biosolids). The buying criteria in this segment focus on robustness, capacity to handle varying moisture contents, and compliance with stringent environmental regulations governing emissions and odor control. Furthermore, customers in the biomass and biofuel industries, such as pellet manufacturers and agricultural waste processors, represent significant buyers, seeking large-scale continuous systems capable of handling high moisture loads efficiently to prepare raw material for combustion or refining.

Specialized buyers are found in the Chemical and Pharmaceutical industries. Pharmaceutical companies are extremely sensitive to solvent residues and cross-contamination, demanding high-specification vacuum or closed-loop belt dryers that meet GMP (Good Manufacturing Practice) standards. Chemical manufacturers, dealing with pigments, polymers, and catalysts, seek systems that offer inert atmosphere processing or explosion protection, requiring highly customized and validated engineering solutions. These customers typically engage directly with manufacturers, utilizing detailed engineering specifications to ensure the system integrates perfectly with upstream processing equipment like filters or centrifuges.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 700 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | GEA Group, ANDRITZ, Bühler, Flottweg, Anhydro, A.M.P-Rose, Ventilex, Dedert Corporation, Carrier Vibrating Equipment, SSP Pvt Ltd, Kason Corporation, F.P. Smith Wire Cloth Company, Heyl & Patterson, Inc., Nara Machinery Co., Ltd., HEINKEL Drying and Separation Group, Witte Co., Inc., Comessa, Gouda B.V. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Belt Drying System Market Key Technology Landscape

The technological landscape of the Belt Drying System Market is rapidly evolving, moving beyond simple convection heating towards integrated, intelligent, and highly efficient thermal processing. A critical area of development is the implementation of advanced heat recovery systems. Modern belt dryers increasingly feature sophisticated air recirculation loops and air-to-air or air-to-water heat exchangers that capture waste heat from exhaust air and return it to the heating medium or pre-heat the incoming air, dramatically reducing primary energy consumption. This focus on maximizing thermal efficiency is essential for large industrial users operating under increasing pressure from utility costs and carbon emission taxes.

Another significant trend is the rise of hybrid drying technologies. To address the challenge of slow drying speeds inherent in some convection-only systems, manufacturers are integrating auxiliary heating methods. Hybrid systems often combine the gentle, continuous movement of the belt with localized heating sources such as microwave, radio frequency (RF), or infrared radiation. Microwave and RF technologies penetrate the material and heat the moisture internally, accelerating the drying process significantly and ensuring highly uniform moisture content, especially beneficial for thick or porous materials like extruded plastics or certain food products, without compromising the product surface integrity.

Furthermore, digitalization and Industry 4.0 integration are reshaping operational control. Contemporary belt dryers are equipped with extensive sensor arrays, including precise humidity, temperature, and Near-Infrared (NIR) sensors for non-contact moisture measurement. These sensors feed real-time data into sophisticated control systems utilizing predictive modeling (often AI-enhanced) to automatically adjust variables like belt speed, layer thickness, and zone temperatures. This level of automation not only ensures consistent product quality but also enables remote monitoring, rapid fault diagnosis, and optimized maintenance scheduling, significantly reducing human intervention and operational variance.

Regional Highlights

The global Belt Drying System Market exhibits distinct growth patterns across major geographical regions, influenced by varying levels of industrial maturity, regulatory frameworks, and investment in infrastructure. Asia Pacific (APAC) represents the most dynamic and fastest-growing market, primarily due to large-scale infrastructure development and rapid expansion in the food, agriculture, and waste management sectors, particularly in China, India, and Southeast Asian nations. The demand here is characterized by the need for high-capacity, robust systems to handle massive volumes of materials, often driven by government initiatives to modernize agricultural processing and manage burgeoning urban sludge output.

North America and Europe constitute the mature markets, characterized by high adoption rates of advanced, highly automated, and energy-efficient systems. Growth in these regions is less reliant on new industrial construction and more focused on replacing aging equipment with high-spec units that meet stringent environmental and sanitation standards. European demand, in particular, emphasizes systems designed for maximum energy recovery and minimum carbon footprint, often favoring closed-loop designs and high-precision vacuum belt dryers for specialized pharmaceutical applications where solvent recovery and quality validation are critical.

Latin America and the Middle East & Africa (MEA) are emerging markets showing gradual but consistent growth. Latin America's market expansion is tied to investments in mineral processing and large-scale agricultural operations. The MEA region's growth is predominantly fueled by water treatment projects and infrastructure development. Both regions present opportunities for manufacturers specializing in modular, scalable solutions that can be deployed effectively in areas with limited infrastructure or rapidly changing processing needs, often prioritizing reliability and lower maintenance costs over cutting-edge automation complexity.

- Asia Pacific (APAC): Dominates market growth; driven by food processing capacity expansion, industrialization in China and India, and major investments in municipal sludge treatment facilities.

- North America: Mature market focusing on technological upgrades, automation (Industry 4.0), and adherence to strict food safety and hygiene protocols (e.g., 3-A Sanitary Design).

- Europe: High demand for energy-efficient and highly specialized systems (vacuum belt dryers); regulatory compliance and sustainability targets are key purchasing criteria.

- Latin America: Emerging demand linked to expanding agro-processing and mining industries, seeking cost-effective and scalable drying solutions.

- Middle East & Africa (MEA): Growth centered on water infrastructure projects and petrochemical processing, prioritizing robust, high-durability equipment.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Belt Drying System Market.- GEA Group

- ANDRITZ

- Bühler

- Flottweg

- Anhydro

- A.M.P-Rose

- Ventilex

- Dedert Corporation

- Carrier Vibrating Equipment

- SSP Pvt Ltd

- Kason Corporation

- F.P. Smith Wire Cloth Company

- Heyl & Patterson, Inc.

- Nara Machinery Co., Ltd.

- HEINKEL Drying and Separation Group

- Witte Co., Inc.

- Comessa

- Gouda B.V.

- Hosokawa Alpine

- Jinan Tonsen Equipment Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Belt Drying System market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of a multi-stage belt dryer over a single-stage system?

Multi-stage belt dryers offer superior thermal efficiency and product quality control by allowing different drying parameters (temperature, humidity, airflow) in sequential zones. This staged approach prevents case hardening, maximizes energy use by managing temperature profiles, and ensures uniform final moisture content, particularly for materials requiring complex drying curves.

How does the integration of AI improve the energy efficiency of belt drying systems?

AI utilizes machine learning to analyze continuous sensor data, predicting optimal operational parameters based on material load and ambient conditions. This predictive capability allows the system to dynamically adjust heat input and airflow rates in real-time, minimizing wasted energy and ensuring the lowest possible specific energy consumption (SEC) per kilogram of water evaporated.

What key factors determine the capital cost of installing a belt drying system?

Capital cost is primarily determined by system capacity (throughput requirement), the material of construction (e.g., stainless steel for sanitary use vs. carbon steel), the inclusion of advanced features like vacuum or explosion-proof designs, and the integration of sophisticated control and heat recovery peripherals. Customization requirements significantly increase the overall project expenditure.

Are belt drying systems suitable for high-value pharmaceutical products?

Yes, specialized vacuum belt dryers (VBDs) are highly suitable for pharmaceuticals. VBDs operate at low temperatures under vacuum conditions, preventing thermal degradation of active pharmaceutical ingredients (APIs), ensuring solvent recovery, and meeting stringent regulatory demands for cleanliness, validation, and controlled drying environments required by GMP guidelines.

Which application segment is expected to show the highest growth rate in the Belt Drying Market?

The Wastewater Treatment and Sludge Management segment is projected to show the highest compound annual growth rate (CAGR). This growth is driven by increasing global urbanization, stricter governmental regulations mandating volume reduction of sewage sludge, and the need to convert municipal waste into usable biosolids or environmentally compliant disposable material.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager