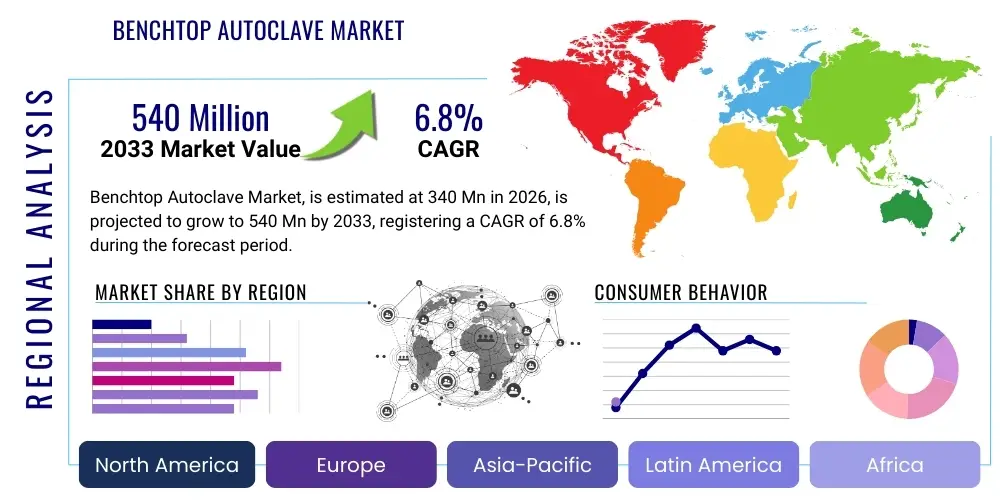

Benchtop Autoclave Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440408 | Date : Jan, 2026 | Pages : 242 | Region : Global | Publisher : MRU

Benchtop Autoclave Market Size

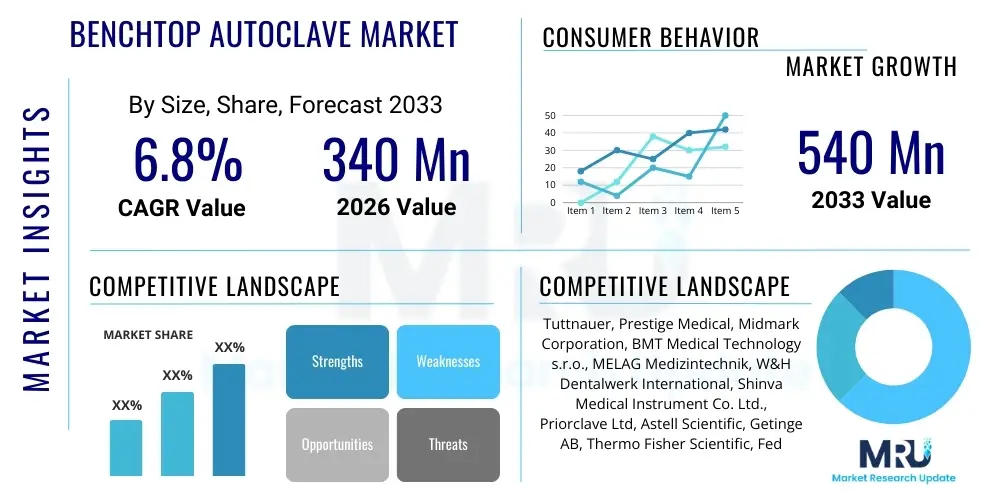

The Benchtop Autoclave Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 340 Million in 2026 and is projected to reach USD 540 Million by the end of the forecast period in 2033.

Benchtop Autoclave Market introduction

The benchtop autoclave market is experiencing robust expansion, driven by an escalating demand for sterilization solutions across various critical sectors. Benchtop autoclaves are compact, self-contained devices designed for effective sterilization using high-pressure saturated steam, primarily catering to smaller volumes of instruments and materials. These essential pieces of equipment are indispensable in settings where rapid and reliable sterilization is paramount, such as dental offices, small clinics, research laboratories, and tattoo parlors. Their design emphasizes efficiency, safety, and user-friendliness, making them a preferred choice for on-demand sterilization processes.

The product, a benchtop autoclave, functions on the principle of heat and pressure to eradicate microorganisms, including bacteria, viruses, fungi, and spores, from reusable items. Major applications span medical and dental instrument sterilization, laboratory glassware and media preparation, and general waste decontamination. These devices ensure compliance with stringent health and safety regulations, thereby preventing cross-contamination and the spread of infections. Their benefits include consistent and repeatable sterilization cycles, reduced operational costs compared to larger systems for specific applications, and adaptability to a wide range of heat and moisture-resistant materials.

Driving factors for market growth encompass the global increase in healthcare expenditure, the rising prevalence of infectious diseases necessitating rigorous sterilization protocols, the expansion of the dental and life sciences industries, and increasingly stringent regulatory guidelines for infection control. Furthermore, technological advancements leading to more efficient, user-friendly, and IoT-enabled benchtop autoclaves are significantly contributing to their adoption. The convenience, portability, and relatively lower capital investment associated with benchtop models, when compared to floor-standing industrial autoclaves, further solidify their market position and appeal to a broader base of end-users seeking localized and efficient sterilization capabilities.

Benchtop Autoclave Market Executive Summary

The executive summary highlights a dynamic and expanding benchtop autoclave market, influenced by converging business, regional, and segment trends. Business trends indicate a strong focus on innovation, with manufacturers investing in research and development to introduce advanced features such as faster cycle times, enhanced user interfaces, automatic water filling, and integrated data logging capabilities. There is a perceptible shift towards connectivity and smart functionalities, allowing for remote monitoring and improved traceability of sterilization cycles. Furthermore, strategic collaborations and mergers and acquisitions are observed as companies seek to consolidate market share, expand product portfolios, and penetrate new geographical territories, reflecting a competitive yet cooperative market landscape driven by the need for comprehensive sterilization solutions.

Regionally, the market exhibits varied growth trajectories, with established healthcare infrastructures in North America and Europe representing mature but stable markets driven by replacement demand and strict regulatory compliance. The Asia Pacific region, particularly emerging economies like China and India, is poised for significant growth due to rapidly expanding healthcare facilities, increasing medical tourism, and a growing awareness of infection control. Latin America, the Middle East, and Africa are also showing promising potential, albeit at an earlier stage of development, propelled by improving access to healthcare services and increasing investments in public health infrastructure. These regions are becoming crucial for market players looking to tap into unsaturated demand and lower operational costs, presenting both opportunities and challenges related to distribution and market penetration strategies.

Segment-wise, the market is primarily driven by the Class B autoclaves due to their superior performance in sterilizing complex, hollow, and porous instruments, meeting the highest international standards. The dental and hospital segments remain the largest end-users, with research and academic institutions showing accelerated adoption rates fueled by continuous funding in life sciences. Capacity-wise, models with less than 20 liters are highly sought after for their compact design and suitability for smaller clinics, while medium-capacity units find favor in larger dental practices and outpatient facilities. The overarching trend points towards a preference for solutions that offer both compliance and operational efficiency, underscoring the market's evolution towards more sophisticated and specialized sterilization technologies tailored to specific industry needs.

AI Impact Analysis on Benchtop Autoclave Market

User questions concerning the integration of Artificial Intelligence (AI) into benchtop autoclaves frequently revolve around expectations for enhanced automation, predictive maintenance capabilities, improved diagnostic accuracy, and ultimately, a reduction in human error during sterilization processes. Users are keen to understand how AI can optimize cycle parameters, provide real-time performance analytics, and ensure compliance with regulatory standards more efficiently than traditional systems. Concerns often include data security, the cost of implementing AI-powered features, and the learning curve associated with new, complex technologies. There's a strong desire for AI to not only streamline operations but also to proactively identify potential issues, thereby minimizing downtime and extending the lifespan of the equipment, while also facilitating more precise and documented sterilization outcomes.

- AI-driven algorithms can optimize sterilization cycles by adjusting parameters based on load characteristics, thereby reducing energy consumption and cycle times.

- Predictive maintenance through AI can monitor autoclave performance, anticipate component failures, and schedule preventative servicing, minimizing unexpected downtime and repair costs.

- Enhanced user interfaces leveraging AI can provide intuitive operation, guided troubleshooting, and personalized training, improving user experience and reducing operational errors.

- AI integration enables sophisticated data logging and analytics, offering real-time insights into sterilization efficacy, compliance reporting, and trend analysis for quality assurance.

- Advanced diagnostics powered by AI can quickly identify operational anomalies or component malfunctions, leading to faster resolution and improved overall reliability of the sterilization process.

- Remote monitoring and control capabilities, often enhanced by AI, allow for off-site management and alerts, crucial for multi-site operations or specialized facilities.

DRO & Impact Forces Of Benchtop Autoclave Market

The benchtop autoclave market is profoundly shaped by a confluence of drivers, restraints, opportunities, and external impact forces. A primary driver is the global increase in healthcare expenditure, particularly in emerging economies, which directly translates into greater investment in medical infrastructure and equipment. Coupled with this, the escalating awareness and stringent regulatory enforcement regarding infection control and patient safety, especially in hospitals, clinics, and dental practices, mandate the use of effective sterilization methods. The continuous growth of the life sciences research sector, including biotechnology and pharmaceutical companies, further fuels demand for reliable sterilization of laboratory tools and media. Additionally, the rising incidence of hospital-acquired infections (HAIs) globally places immense pressure on healthcare providers to adopt advanced and dependable sterilization technologies, significantly propelling the adoption of benchtop autoclaves for their localized and efficient capabilities.

However, the market faces notable restraints that could impede its growth trajectory. The relatively high initial capital investment required for purchasing advanced benchtop autoclaves can be a significant barrier for smaller clinics or start-up laboratories with limited budgets. This is often compounded by ongoing maintenance costs, including regular calibration, validation, and replacement of consumables, which can add to the total cost of ownership. Furthermore, the availability of alternative sterilization methods, such as chemical sterilants or dry heat sterilizers, while often not as effective or universally applicable as steam sterilization, might be considered by some facilities for specific applications or cost reasons. Concerns regarding energy consumption and the environmental footprint of these devices, although continually improving with newer models, also present a restraint, prompting users to seek more energy-efficient solutions.

Opportunities for market expansion are considerable, particularly in untapped emerging markets where healthcare infrastructure is rapidly developing and awareness of infection control is growing. Technological advancements represent a significant opportunity, with the development of "smart" autoclaves featuring IoT connectivity, cloud-based data management, and AI-driven predictive maintenance capabilities. The increasing demand for compact, portable, and energy-efficient models tailored for specialized applications, such as veterinary clinics or cosmetic surgery centers, also opens new avenues for market penetration. Moreover, the continuous expansion of the biotechnology and pharmaceutical sectors, driven by drug discovery and vaccine development, inherently increases the need for precise and sterile laboratory conditions, directly bolstering the demand for advanced benchtop autoclaves. Strategic partnerships and localized manufacturing can help address regional demands and cost sensitivities, unlocking further market potential.

Segmentation Analysis

The benchtop autoclave market is extensively segmented to reflect the diverse needs of its end-users and the varying technological specifications available. This segmentation helps in understanding specific market dynamics, identifying niche opportunities, and tailoring product development to meet precise demands across different applications and operational environments. The primary segmentation criteria typically include the type of autoclave, its capacity, the specific end-user industry, and the application for which it is intended, each offering unique insights into market preferences and growth areas.

- By Type

- Class N: Non-vacuum autoclaves designed for sterilizing unwrapped, solid, non-hollow, and non-porous instruments.

- Class S: Autoclaves with basic vacuum cycles suitable for sterilizing wrapped or unwrapped, solid instruments, and some hollow or porous items as specified by the manufacturer.

- Class B: Advanced vacuum autoclaves capable of sterilizing all types of loads, including wrapped, unwrapped, solid, hollow (Type A and B), and porous instruments, meeting the most stringent European standards.

- By Capacity

- Less than 20 Liters: Compact units ideal for small dental clinics, tattoo studios, and specific laboratory applications.

- 20-50 Liters: Medium-sized units commonly used in larger dental practices, outpatient clinics, and research laboratories.

- More than 50 Liters: Larger benchtop models suitable for high-volume sterilization needs in hospitals, pharmaceutical companies, and academic institutions.

- By End-User

- Hospitals and Clinics: Broad range of sterilization needs for surgical instruments and medical devices.

- Dental Clinics: Essential for sterilizing dental handpieces and instruments to prevent cross-contamination.

- Research and Academic Institutions: Used for sterilizing laboratory equipment, glassware, and culture media.

- Pharmaceutical and Biotechnology Companies: Critical for maintaining sterile environments in drug discovery and manufacturing.

- Veterinary Clinics: For sterilizing surgical tools and equipment used in animal care.

- Educational Institutions: For laboratory safety in science education.

- Tattoo and Piercing Studios: Crucial for sterilizing instruments to ensure client safety.

- Others: Includes beauty salons, podiatry clinics, and other niche applications requiring sterilization.

- By Application

- Medical Instrument Sterilization: Sterilization of surgical tools, diagnostic equipment, and other medical devices.

- Laboratory Equipment Sterilization: Cleaning of beakers, flasks, petri dishes, and various lab tools.

- Dental Tool Sterilization: Specific to dental instruments like handpieces, mirrors, and explorers.

- Pharmaceutical Product Sterilization: Sterilization of ingredients, containers, and finished products in drug manufacturing.

- Culture Media Sterilization: Preparation of sterile media for microbiology and cell culture.

- Waste Sterilization: Decontamination of biological waste before disposal.

Value Chain Analysis For Benchtop Autoclave Market

The value chain for the benchtop autoclave market encompasses several critical stages, beginning with upstream activities focused on raw material sourcing and component manufacturing. This initial phase involves the procurement of high-grade stainless steel for chambers, durable plastics for external casings, sophisticated electronic components for control systems, and precision mechanical parts for pumps, valves, and safety mechanisms. Suppliers in this upstream segment are crucial for ensuring the quality, reliability, and cost-effectiveness of the final product. Strong relationships with these suppliers are vital for manufacturers to manage costs, maintain consistent production schedules, and ensure the availability of components that meet stringent industry standards and certifications.

Midstream activities primarily involve the design, manufacturing, assembly, and quality control of the benchtop autoclaves. Manufacturers leverage advanced engineering capabilities to develop innovative designs that enhance efficiency, safety, and user experience. This stage includes precision fabrication of the pressure vessel, integration of sophisticated control electronics, installation of safety features, and rigorous testing to comply with international standards such as ISO 13485 and EN 13060. Research and development play a significant role here, as companies continuously strive to introduce improvements in cycle times, energy consumption, connectivity, and overall performance. The manufacturing process often involves complex supply chain management to coordinate the inflow of components and the outflow of finished goods efficiently.

Downstream activities focus on distribution, sales, after-sales service, and end-user engagement. Distribution channels are varied, including direct sales from manufacturers, networks of specialized medical and laboratory equipment distributors, and online marketplaces. Direct sales offer manufacturers greater control over customer relationships and branding, while distributors provide extensive market reach and local support, especially in diverse regional markets. After-sales service, encompassing installation, training, maintenance, calibration, and spare parts supply, is a critical component of the value chain, ensuring customer satisfaction and long-term product reliability. The effectiveness of this downstream segment directly impacts market penetration and customer loyalty, highlighting the importance of robust support networks and skilled service technicians to maintain operational continuity for end-users.

Benchtop Autoclave Market Potential Customers

Potential customers for benchtop autoclaves are diverse and span across various industries that require stringent sterilization protocols for their instruments, media, and waste. The primary end-users or buyers of these products include a vast network of healthcare facilities, encompassing hospitals, multi-specialty clinics, and specialized outpatient centers. Within these settings, benchtop autoclaves are indispensable for sterilizing a wide array of surgical instruments, medical devices, and reusable equipment to prevent nosocomial infections and ensure patient safety. The growing complexity of medical procedures and the increasing volume of patient visits continuously drive demand from this segment, making them a cornerstone of the market's customer base, emphasizing the need for reliable and high-capacity units that meet rigorous regulatory standards.

Beyond traditional healthcare, the dental industry represents a significant and rapidly expanding customer segment. Dental clinics, from small independent practices to large corporate chains, rely heavily on benchtop autoclaves for the daily sterilization of handpieces, mirrors, explorers, and a multitude of other dental instruments. The imperative to adhere to strict infection control guidelines for every patient interaction positions dental professionals as consistent and high-volume purchasers of these devices. Similarly, the burgeoning aesthetic and cosmetic surgery clinics, along with tattoo and piercing studios, also constitute vital customer groups, as they must maintain impeccable hygiene standards for their instruments to ensure client safety and comply with local health regulations, often favoring compact and efficient models.

The life sciences sector, encompassing research laboratories, academic institutions, and pharmaceutical and biotechnology companies, forms another critical segment of potential customers. These entities utilize benchtop autoclaves for sterilizing laboratory glassware, culture media, reagents, and contaminated waste, which is crucial for maintaining sterile working conditions in sensitive experiments, drug discovery, and vaccine production. The continuous funding in scientific research, coupled with an increasing focus on developing new therapies and biotechnological advancements, ensures a steady demand from this sector. Furthermore, veterinary clinics and even some educational institutions with science laboratories also represent viable customer segments, demonstrating the broad applicability and essential nature of benchtop autoclaves in any environment where microbial contamination must be rigorously controlled.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 340 Million |

| Market Forecast in 2033 | USD 540 Million |

| Growth Rate | CAGR 6.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Tuttnauer, Prestige Medical, Midmark Corporation, BMT Medical Technology s.r.o., MELAG Medizintechnik, W&H Dentalwerk International, Shinva Medical Instrument Co. Ltd., Priorclave Ltd, Astell Scientific, Getinge AB, Thermo Fisher Scientific, Fedegari Autoclavi S.p.A., Steris Corporation, Consolidated Sterilizer Systems, Sakura Seiki Co., Ltd., Belimed AG, CertoClav GmbH, Benchmark Scientific, Scican, Matachana |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Benchtop Autoclave Market Key Technology Landscape

The technology landscape for the benchtop autoclave market is characterized by a continuous evolution towards enhanced efficiency, safety, and user integration, driven by the imperative for absolute sterility and operational convenience. Modern benchtop autoclaves frequently incorporate advanced microprocessor control systems that allow for precise regulation of temperature, pressure, and cycle times, ensuring optimal sterilization conditions for various types of loads. This includes programmable cycles tailored for different materials, automatic pre-vacuum and post-vacuum drying phases for efficient removal of air and moisture, and sophisticated alarm systems to alert users to any deviations or malfunctions. Manufacturers are also focusing on robust chamber construction, often utilizing high-grade stainless steel to ensure durability and resistance to corrosive steam environments, alongside advanced sealing technologies for long-term reliability.

Beyond core sterilization functionalities, connectivity and smart features are becoming increasingly prevalent, transforming traditional autoclaves into intelligent, interconnected devices. Many contemporary models now offer USB ports for cycle data logging, Ethernet connections for network integration, and even Wi-Fi capabilities for cloud-based data storage and remote monitoring. This integration allows for comprehensive documentation of sterilization parameters, crucial for regulatory compliance and quality assurance in healthcare and research settings. Furthermore, touch-screen interfaces with intuitive graphical user experiences are replacing conventional button controls, simplifying operation and training. These technological advancements not only streamline workflows but also provide invaluable traceability for every sterilization cycle, which is a critical aspect of modern infection control protocols.

The latest innovations in the benchtop autoclave market also include advancements aimed at improving energy efficiency and environmental sustainability, such as optimized heating elements, advanced insulation techniques, and intelligent water consumption management systems. Furthermore, the incorporation of advanced diagnostics and predictive maintenance capabilities, often supported by integrated sensors and rudimentary AI algorithms, helps in identifying potential issues before they lead to downtime, thereby extending the lifespan of the equipment and reducing maintenance costs. The emphasis is also on ergonomic designs, reduced footprint for space-constrained environments, and lower noise levels, all contributing to a more user-friendly and efficient laboratory or clinical environment. The interplay of these technological advancements ensures that benchtop autoclaves remain at the forefront of sterilization technology, meeting the evolving demands of diverse end-user applications.

Regional Highlights

- North America: This region holds a significant share of the benchtop autoclave market, driven by a highly developed healthcare infrastructure, stringent regulatory frameworks for infection control, high healthcare expenditure, and a robust presence of key market players and research institutions. The United States and Canada are leading contributors, characterized by widespread adoption of advanced sterilization technologies and a consistent demand for replacement units and upgrades.

- Europe: Europe represents another mature market with substantial demand, primarily fueled by strict European Union regulations regarding medical device sterilization (e.g., EN 13060 for small steam sterilizers), increasing geriatric population, and well-established pharmaceutical and biotechnology industries. Countries like Germany, the UK, France, and Italy are key markets, focusing on high-quality, energy-efficient, and compliant sterilization solutions.

- Asia Pacific (APAC): The APAC region is projected to exhibit the highest growth rate during the forecast period. This growth is attributed to rapidly developing healthcare infrastructure, increasing government investments in public health, a growing patient population, rising awareness of infection control, and expanding life science research activities in countries such as China, India, Japan, and South Korea. The region offers significant opportunities for market expansion due to its large untapped market potential.

- Latin America: This region is experiencing steady growth in the benchtop autoclave market, driven by improving healthcare access, increasing healthcare expenditure, and a growing emphasis on modernizing medical and dental facilities. Brazil, Mexico, and Argentina are key countries where demand is gradually rising, supported by government initiatives to enhance public health services and control infectious diseases.

- Middle East and Africa (MEA): The MEA market is an emerging region with growing potential, influenced by increasing investments in healthcare infrastructure, particularly in countries like Saudi Arabia, UAE, and South Africa. The rising awareness of hygiene standards, coupled with international collaborations in healthcare, is contributing to the gradual adoption of advanced sterilization equipment. However, challenges related to economic stability and access to advanced technology in some parts of the region persist.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Benchtop Autoclave Market.- Tuttnauer

- Prestige Medical

- Midmark Corporation

- BMT Medical Technology s.r.o.

- MELAG Medizintechnik

- W&H Dentalwerk International

- Shinva Medical Instrument Co. Ltd.

- Priorclave Ltd

- Astell Scientific

- Getinge AB

- Thermo Fisher Scientific

- Fedegari Autoclavi S.p.A.

- Steris Corporation

- Consolidated Sterilizer Systems

- Sakura Seiki Co., Ltd.

- Belimed AG

- CertoClav GmbH

- Benchmark Scientific

- Scican

- Matachana

Frequently Asked Questions

Analyze common user questions about the Benchtop Autoclave market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary applications of benchtop autoclaves?

Benchtop autoclaves are primarily utilized for sterilizing medical and dental instruments, laboratory equipment such as glassware and media, and decontaminating certain types of biological waste. They are essential in hospitals, dental clinics, research laboratories, pharmaceutical companies, and tattoo studios to ensure the complete eradication of microorganisms and prevent cross-contamination.

How do different classes of benchtop autoclaves (N, S, B) differ?

The classes define their sterilization capabilities: Class N autoclaves are for unwrapped, solid items; Class S autoclaves handle specific wrapped or hollow items as per manufacturer instructions with basic vacuum; Class B autoclaves are the most advanced, using a sophisticated vacuum system for all load types, including porous, wrapped, and complex hollow instruments, meeting the highest international standards.

What are the key factors driving the growth of the benchtop autoclave market?

Market growth is driven by increasing global healthcare expenditure, stringent regulatory mandates for infection control, the rising prevalence of infectious diseases, expansion of dental and life sciences industries, and continuous technological advancements offering more efficient and user-friendly devices. The demand for localized and rapid sterilization solutions also plays a significant role.

What role does artificial intelligence play in modern benchtop autoclaves?

AI is increasingly integrated into modern benchtop autoclaves to enhance operational efficiency, offer predictive maintenance, optimize sterilization cycles based on load, and provide advanced diagnostics. It also enables improved data logging, remote monitoring, and intelligent user interfaces, leading to greater reliability, reduced downtime, and enhanced compliance reporting capabilities.

What considerations are important when selecting a benchtop autoclave for a healthcare facility?

Key considerations include the types of instruments to be sterilized (determining the required autoclave class), desired capacity, cycle speed, available budget, regulatory compliance needs, ease of use, maintenance requirements, and the availability of after-sales service and support. Features like data logging, connectivity, and energy efficiency are also increasingly important for modern facilities.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager