Beveling Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434291 | Date : Dec, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Beveling Machine Market Size

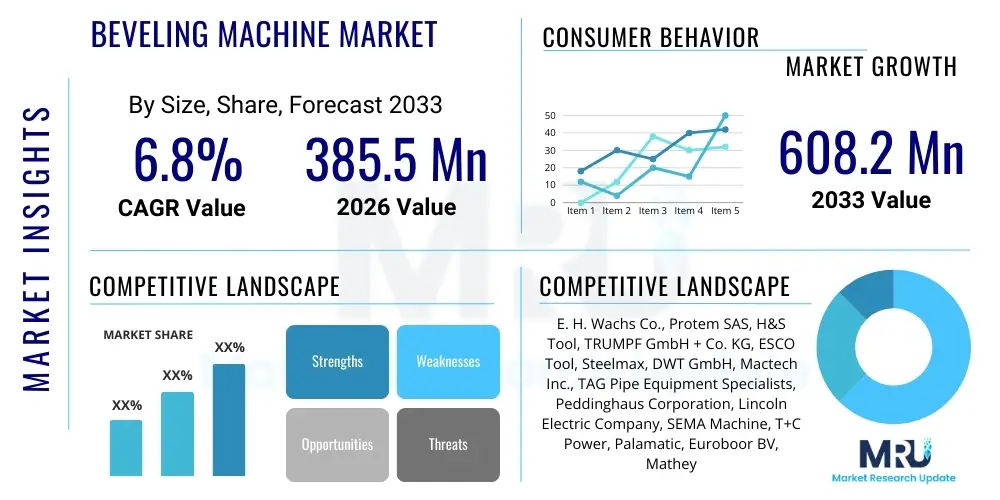

The Beveling Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at $385.5 million in 2026 and is projected to reach $608.2 million by the end of the forecast period in 2033.

Beveling Machine Market introduction

The Beveling Machine Market encompasses specialized industrial equipment designed to cut angled edges, or bevels, on workpieces, primarily pipes, plates, and tubes. This essential process prepares materials for welding, improves edge finish, or removes sharp burrs for safety and aesthetic purposes. Beveling machines utilize various technologies, including milling, plasma, oxy-fuel, and mechanical cutting, to achieve precise angular specifications required across heavy industries. The product range is diverse, spanning from portable handheld tools used in field operations to large, automated stationary systems integrated into production lines. Key operational parameters include bevel angle accuracy, material compatibility (metals, alloys, plastics), and processing speed.

Major applications of beveling machines are concentrated within sectors requiring high-integrity welds, notably oil and gas pipeline construction, shipbuilding, structural steel fabrication, pressure vessel manufacturing, and aerospace maintenance. The precise edge preparation facilitated by these machines ensures robust, defect-free welds crucial for maintaining structural integrity and operational safety in high-stress environments. Benefits derived from utilizing high-quality beveling equipment include enhanced weld quality, significant reduction in manual labor and rework, improved production efficiency, and adherence to stringent international safety and quality standards (e.g., ASME, API). The sophistication of modern machinery often allows for complex profiles, such as J-bevels or compound bevels, previously challenging to achieve manually.

The market growth is fundamentally driven by the resurgence in global infrastructure projects, particularly in developing economies, necessitating extensive steel and pipe fabrication. Furthermore, the mandatory requirements for high-precision bevels in critical applications, such as nuclear power infrastructure and high-pressure fluid transport, consistently push demand for advanced, automated beveling solutions. Technological advancements, including the incorporation of CNC controls and automated feeding systems, minimize human error and maximize throughput, serving as strong driving factors for market expansion. Increased focus on worker safety and ergonomic design in industrial settings also favors the adoption of mechanized beveling equipment over hazardous manual processes.

Beveling Machine Market Executive Summary

The global Beveling Machine Market is experiencing robust expansion, primarily fueled by massive investments in the energy and construction sectors, particularly in the Asia Pacific region. Business trends indicate a noticeable shift toward highly automated and portable CNC-enabled machines, reflecting the industry's need for higher precision, faster operational speeds, and adaptability in varied work environments, from centralized fabrication shops to remote field sites. Manufacturers are concentrating on developing multi-functional machines capable of processing diverse materials and generating complex bevel profiles (e.g., compound, J-prep) in a single pass, enhancing overall cost-efficiency and minimizing setup time. Furthermore, stringent regulatory mandates regarding weld quality in infrastructure projects necessitate the continuous upgrading of existing equipment fleets.

Regional trends reveal Asia Pacific as the dominant and fastest-growing market, primarily due to large-scale infrastructure development in China and India, coupled with significant growth in shipbuilding activities in South Korea and Japan. North America and Europe maintain a strong position characterized by the high adoption rate of sophisticated, high-end automated systems, driven by high labor costs and the imperative for industrial decarbonization requiring new energy infrastructure (e.g., hydrogen pipelines). The Middle East remains a critical demand center, heavily reliant on beveling equipment for its extensive oil and gas exploration, production, and pipeline maintenance activities. The competitive landscape globally is moderately consolidated, with major players focusing on strategic mergers, geographical expansion, and intense research and development to introduce proprietary cutting technologies.

Segmentation trends highlight that plate beveling machines, crucial for structural fabrication and shipbuilding, account for a substantial market share. However, the pipe beveling segment is poised for rapid growth, driven by extensive pipeline projects globally. Mechanized and automated equipment segments are consistently outperforming manual and semi-automatic types, particularly in terms of revenue generation, reflecting the industrial priority of precision and throughput. Based on operational technology, milling bevelers are gaining prominence due to their capability to handle hard materials and deliver superior surface finishes, although plasma and oxy-fuel technologies remain cost-effective choices for high-volume, less stringent applications. End-user demand is heavily concentrated in the Oil & Gas and Heavy Fabrication sectors, which demand rugged, reliable, and high-capacity machinery.

AI Impact Analysis on Beveling Machine Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Beveling Machine Market center primarily on themes of predictive maintenance, process optimization, and automation integration. Users frequently question how AI algorithms can enhance the precision of bevel angles, reduce material wastage during cutting, and predict machine component failures before they occur. There is strong interest in the feasibility of AI-driven systems adjusting cutting parameters in real-time based on material inconsistencies or wear characteristics of the cutting tool. Concerns often revolve around the cost of implementing such sophisticated software and the requirement for specialized operational expertise. Overall, the expectation is that AI will transform beveling from a standardized machining task into a highly adaptive, self-optimizing process, significantly boosting productivity and minimizing downtime, especially in high-volume, critical fabrication environments.

- AI enhances predictive maintenance schedules by analyzing vibration, temperature, and current draw data, minimizing unplanned downtime.

- Real-time process optimization through machine learning algorithms adjusts feed rates and spindle speeds based on material composition and tool wear, ensuring consistent bevel quality.

- Improved quality control via computer vision and deep learning models automatically detects and flags defects in the prepared bevel surface, ensuring adherence to welding standards.

- Optimization of material nesting and cutting paths using AI reduces material waste, particularly relevant in plate beveling operations.

- Autonomous operation capabilities allow machines to learn and adapt to changing input conditions, reducing the need for constant human supervision and increasing operational safety.

DRO & Impact Forces Of Beveling Machine Market

The market dynamics of the Beveling Machine sector are shaped by a complex interplay of growth drivers, structural restraints, emerging opportunities, and competitive impact forces. The dominant driver remains the continuous global investment in crucial infrastructure, including energy pipelines, bridges, high-rise construction, and maritime vessels, which invariably requires extensive preparation of steel plates and pipes for robust welding. Furthermore, the accelerating trend toward automation in manufacturing floors, driven by rising labor costs and the necessity for higher quality standards, pushes end-users toward sophisticated CNC and robotic beveling systems. The increasing complexity of modern engineering projects demands specialized bevel profiles (e.g., compound, variable-depth), which only advanced mechanized equipment can reliably deliver, amplifying market demand.

However, the market faces significant restraints, notably the high initial capital expenditure associated with purchasing advanced, fully automated beveling machines, which can deter Small and Medium Enterprises (SMEs) from adoption. Furthermore, the operational challenges related to the need for highly skilled technicians to program, maintain, and troubleshoot complex CNC bevelers represent a supply-side constraint. Economic volatility, particularly affecting key end-user sectors like oil and gas, can lead to deferred capital spending on machinery, impacting sales cycles. Environmental regulations concerning metal dust and waste disposal also impose operational compliance burdens on machine operators and manufacturers alike.

Opportunities for growth are abundant, particularly in the development of lightweight, highly portable beveling solutions suitable for maintenance, repair, and overhaul (MRO) activities in remote locations, which is a rapidly expanding segment. The transition to advanced materials, such as titanium and specialized alloys in aerospace and defense, creates demand for bevelers utilizing specialized cutting tools and high-precision controls. Moreover, the integration of Industry 4.0 technologies—IoT, cloud connectivity, and advanced diagnostics—presents a pathway for manufacturers to offer enhanced service contracts and data-driven optimization solutions. Impact forces primarily stem from intense price competition among global manufacturers, coupled with the influence of raw material costs (steel, specialized components) on final product pricing and market accessibility. The necessity for manufacturers to continually innovate and protect intellectual property related to unique cutting geometries also exerts significant competitive pressure.

Segmentation Analysis

The Beveling Machine Market is extensively segmented based on criteria such as the type of material processed (pipe or plate), operational mode (manual, semi-automatic, automatic/CNC), and the underlying cutting technology employed. This segmentation is crucial for understanding specific industrial needs, as different applications require distinct machine characteristics—for instance, high throughput plate beveling for shipyards versus precise, portable pipe beveling for field pipeline repairs. The ongoing trend is toward consolidation in the automatic segment, reflecting the industrial pursuit of precision and efficiency.

- By Product Type:

- Pipe Beveling Machine

- Plate Beveling Machine

- Portable Beveling Machine (often used for on-site/MRO)

- By Automation Level:

- Manual

- Semi-Automatic

- Automatic and CNC

- By Technology:

- Milling (Mechanical)

- Plasma Beveling

- Oxy-Fuel Beveling

- Grinding

- By End-User Industry:

- Oil and Gas

- Shipbuilding and Marine

- Heavy Fabrication (Structural Steel, Boiler)

- Aerospace and Defense

- Automotive

- Power Generation (Conventional and Nuclear)

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East & Africa (MEA)

Value Chain Analysis For Beveling Machine Market

The value chain for the Beveling Machine Market begins with the upstream suppliers responsible for raw materials and essential components. This includes providers of high-grade steel and specialized alloys for machine frames, precision electronic components (sensors, CNC controllers, motors), and specialized tooling (milling inserts, cutting blades). The quality and availability of these components directly influence the final performance, durability, and cost of the beveling machine. Strong relationships with reliable component suppliers are critical for maintaining competitive pricing and ensuring the incorporation of the latest automation technologies, such as advanced servo drives and proprietary control software. Effective upstream management focuses heavily on supply chain resilience and component standardization.

The midstream stage involves the design, manufacturing, assembly, and quality assurance processes carried out by the original equipment manufacturers (OEMs). Manufacturing involves complex machining operations, integrating mechanical assemblies with sophisticated electrical and software systems. OEMs invest heavily in research and development to improve cutting efficiency, reduce footprint, and enhance user interfaces. Distribution channels form the critical link to the end-users. Direct sales teams are often utilized for large, high-value, custom-engineered systems, allowing for direct customer consultation and tailored solutions. Conversely, indirect channels, involving regional distributors, value-added resellers (VARs), and dedicated agents, handle standardized or portable equipment, offering localized inventory, technical support, and after-sales service. The selection of the distribution channel is highly dependent on the target market's size and geographic spread.

The downstream segment encompasses the installation, training, maintenance, and service provided to end-users across various industries like oil & gas and shipbuilding. After-sales support, including spare parts availability and technical consultation, is a key competitive differentiator, particularly for complex CNC machines where downtime is costly. Potential customers evaluate suppliers not just on the initial machine cost but significantly on the total cost of ownership (TCO) and the longevity of support offered. The value chain concludes with the ultimate application of the prepared material in high-integrity structures, where the precision delivered by the beveling machine directly impacts the project's success and safety compliance.

Beveling Machine Market Potential Customers

Potential customers for beveling machines are diverse, spanning multiple heavy industrial sectors that rely on welded metal structures. The primary buyers are large fabrication shops specializing in heavy steel structures, pressure vessel manufacturers, and enterprises involved in large infrastructure projects. These end-users demand high-capacity, stationary plate bevelers and large pipe beveling systems capable of handling thick materials and high throughput rates consistently. Purchasing decisions are typically driven by factors such as required dimensional accuracy, compliance with international welding codes (e.g., AWS, DNV), and the machine’s reliability in continuous operation.

A significant segment of buyers comprises companies within the energy sector, specifically pipeline construction and oil and gas field services. These entities often procure highly portable, robust, and often hydraulically or pneumatically driven beveling machines for on-site preparation of pipes during installation, repair, and maintenance activities (MRO). Their requirements emphasize ease of transportation, quick setup time, and ability to operate reliably in harsh environmental conditions. The increasing shift towards cleaner energy infrastructure, such as hydrogen pipelines and offshore wind farm foundations, is creating a new category of specialized buyer demanding bespoke solutions tailored for novel material requirements and complex joint designs.

Furthermore, smaller fabrication shops and metalworking contractors constitute a stable customer base, predominantly opting for manual or semi-automatic bench-top machines for lower volume, general-purpose beveling tasks. Educational institutions and vocational training centers also represent a smaller but stable segment, purchasing simpler models for training purposes. The procurement process across all these buyer groups is characterized by rigorous technical evaluation, long sales cycles, and a focus on long-term supplier relationships that can guarantee parts and technical evolution for the expected lifespan of the capital equipment.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $385.5 Million |

| Market Forecast in 2033 | $608.2 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | E. H. Wachs Co., Protem SAS, H&S Tool, TRUMPF GmbH + Co. KG, ESCO Tool, Steelmax, DWT GmbH, Mactech Inc., TAG Pipe Equipment Specialists, Peddinghaus Corporation, Lincoln Electric Company, SEMA Machine, T+C Power, Palamatic, Euroboor BV, Mathey Dearman, KERN GmbH, GBC Industrial Tools S.p.A., Foster Industrial, KOIKE ARONSON, INC. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Beveling Machine Market Key Technology Landscape

The technology landscape within the Beveling Machine Market is continuously evolving, moving toward greater automation, precision, and multi-functionality. Current established technologies include mechanical milling bevelers, which offer superior surface finish and precision critical for high-specification welds; thermal cutting processes like plasma and oxy-fuel, which provide high cutting speed for thick plates, albeit with lower edge quality requiring secondary finishing; and abrasive technologies like grinding for localized or minor adjustments. The industry standard is shifting towards CNC (Computer Numerical Control) integration across all platforms, ensuring repeatability and allowing operators to program complex geometries, such as J-bevels or variable-angle preparations, with minimal setup time and maximum accuracy. This focus on digital control is foundational for integrating into smart factory environments.

Emerging technologies focus heavily on optimizing efficiency and material handling. Robotic beveling cells are becoming more prevalent in large fabrication environments, leveraging computer vision and real-time path correction to automatically track material edges and compensate for dimensional variations, significantly reducing human intervention and error. Furthermore, manufacturers are exploring advanced material science in cutting tool development, utilizing specialized coatings and ceramics to increase tool life and maintain sharpness when processing exotic materials like high-strength low-alloy steels (HSLA) and nickel alloys used in aerospace and high-pressure applications. This enhances the machine's ability to handle harder, lighter, and more specialized metals increasingly favored in modern construction.

A key area of technological advancement is focused on portable machine design, incorporating ergonomic factors and battery-operated solutions to enhance operational flexibility in field environments. Furthermore, data connectivity (IoT integration) is a rapidly growing trend, allowing machines to transmit performance data, diagnostics, and utilization metrics to central monitoring systems. This integration supports predictive maintenance protocols and facilitates remote diagnostics, which significantly enhances asset utilization rates. The next generation of beveling technology is expected to feature integrated metrology and adaptive controls, where sensors measure the bevel geometry immediately after cutting and automatically adjust parameters to ensure the final product adheres perfectly to the required specifications without manual intervention.

Regional Highlights

The global distribution of the Beveling Machine Market demand is heterogeneous, reflecting varied levels of industrial maturity, infrastructure spending, and regional emphasis on specific sectors like oil and gas versus renewable energy.

- Asia Pacific (APAC): APAC dominates the global market both in terms of consumption volume and growth rate. This is primarily attributed to unprecedented infrastructural expansion in China, India, and Southeast Asia, coupled with robust activities in shipbuilding (South Korea, Japan, China) and steel manufacturing. The region is characterized by high demand for both volume-based thermal beveling and precision milling machines to support massive manufacturing and construction bases. Increased capital investment in domestic manufacturing capabilities further solidifies APAC's leading position.

- North America: North America represents a mature market with a high adoption rate of automated and high-precision CNC beveling solutions. Demand is driven by strict regulatory standards for pipeline integrity, substantial investment in energy infrastructure (oil, gas, and renewable transmission lines), and a push toward integrating Industry 4.0 principles in fabrication shops. The focus here is on reducing labor dependency and achieving superior quality finishes, favoring high-end equipment like robotic and integrated milling systems.

- Europe: The European market is characterized by stringent quality requirements and a strong emphasis on environmental sustainability and worker safety. Key drivers include renewable energy projects (offshore wind structures, hydrogen pipelines), automotive manufacturing, and defense sector expenditures. Western European nations, particularly Germany and Italy, are leaders in manufacturing high-quality mechanical and portable beveling machines, sustaining domestic demand and providing sophisticated exports globally.

- Middle East & Africa (MEA): MEA is a critical market, heavily influenced by large-scale oil and gas exploration, expansion, and maintenance activities. Demand for heavy-duty pipe beveling machines and field service equipment is consistently high due to extensive pipeline networks and refinery construction. While facing geopolitical stability challenges, strategic infrastructure investments continue to drive predictable machinery demand, often preferring durable, robust equipment capable of handling harsh desert conditions.

- Latin America (LATAM): LATAM’s market growth is moderate but promising, primarily tied to fluctuating commodity prices affecting the regional oil, gas, and mining sectors. Brazil and Mexico are key markets, showing potential for increased adoption of modern beveling technology as they upgrade aging infrastructure and enhance domestic fabrication capabilities to become more competitive globally. Localized manufacturing hubs are slowly increasing their demand for advanced automated systems.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Beveling Machine Market.- E. H. Wachs Co.

- Protem SAS

- H&S Tool

- TRUMPF GmbH + Co. KG

- ESCO Tool

- Steelmax

- DWT GmbH

- Mactech Inc.

- TAG Pipe Equipment Specialists

- Peddinghaus Corporation

- Lincoln Electric Company

- SEMA Machine

- T+C Power

- Palamatic

- Euroboor BV

- Mathey Dearman

- KERN GmbH

- GBC Industrial Tools S.p.A.

- Foster Industrial

- KOIKE ARONSON, INC.

Frequently Asked Questions

Analyze common user questions about the Beveling Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of using a milling beveling machine over plasma or oxy-fuel methods?

Milling beveling machines offer superior precision, excellent surface finish, and minimal heat-affected zones (HAZ), crucial for preparing high-quality welds, particularly on specialized alloys. While slower than thermal cutting, they achieve higher accuracy and repeatability necessary for critical applications like nuclear components or high-pressure vessels.

How does the integration of CNC technology benefit the efficiency of beveling operations?

CNC integration allows for precise, automated control over cutting parameters, enabling operators to program complex and variable bevel profiles (such as J-bevels or compound angles) with high repeatability. This significantly reduces setup time, minimizes material waste due to human error, and ensures consistent quality across large production batches, directly boosting operational throughput.

Which end-user segment drives the highest demand for portable beveling machines globally?

The Oil and Gas sector, particularly activities related to pipeline maintenance, repair, and overhaul (MRO), drives the highest demand for portable beveling machines. These machines are essential for efficiently and accurately preparing pipe ends on-site, often in remote or confined spaces where stationary equipment is impractical or impossible to use.

What major restraints impede the widespread adoption of highly automated beveling machines by smaller enterprises?

The primary restraint is the significant capital expenditure required for acquiring highly automated CNC or robotic beveling systems. Additionally, the necessity for specialized technical expertise for programming, operation, and maintenance of these complex machines poses a barrier for Small and Medium Enterprises (SMEs) with limited technical staffing resources.

What is the Compound Annual Growth Rate (CAGR) projected for the Beveling Machine Market during the forecast period?

The Beveling Machine Market is projected to exhibit a steady Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. This growth is underpinned by persistent global infrastructure spending and the ongoing industrial shift toward higher precision and automation standards in metal fabrication.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Portable Beveling Machine Market Statistics 2025 Analysis By Application (Profiles, Plates, Pipes), By Type (Pneumatic, Electric, Other), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Stationary Beveling Machine Market Statistics 2025 Analysis By Application (Profiles, Plates, Pipes), By Type (Pneumatic, Electric, Other), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Electric Beveling Machine Market Statistics 2025 Analysis By Application (Profiles, Plates, Pipes), By Type (Stationary, Portable), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Pneumatic Beveling Machine Market Statistics 2025 Analysis By Application (Profiles, Plates, Pipes), By Type (Stationary, Portable), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Portable Type Beveling Machine Market Statistics 2025 Analysis By Application (Profiles, Plates, Pipes), By Type (Pneumatic, Electric, Other), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager