Biodegradable Paper and Plastics Packaging Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434453 | Date : Dec, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Biodegradable Paper and Plastics Packaging Market Size

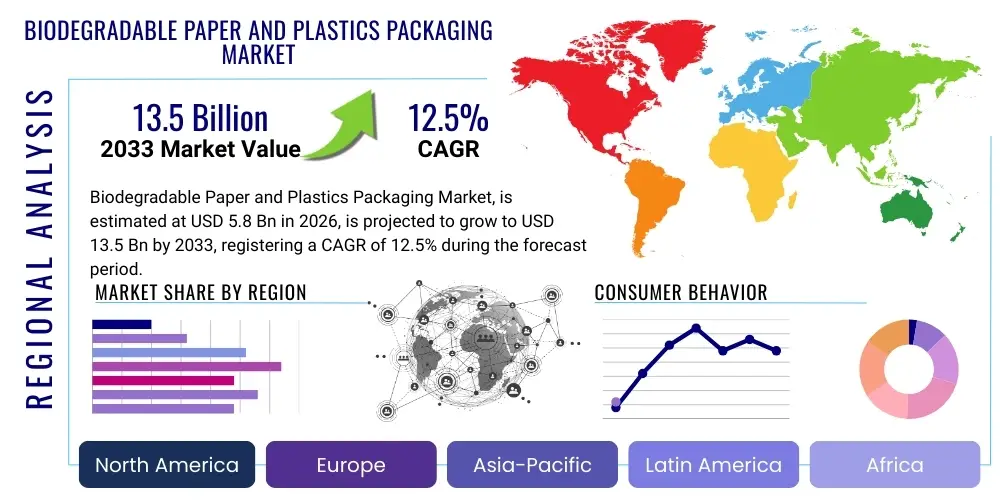

The Biodegradable Paper and Plastics Packaging Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 12.5% between 2026 and 2033. The market is estimated at USD 45.2 Billion in 2026 and is projected to reach USD 103.8 Billion by the end of the forecast period in 2033.

Biodegradable Paper and Plastics Packaging Market introduction

The Biodegradable Paper and Plastics Packaging Market encompasses materials designed to decompose naturally in the environment, minimizing ecological footprints compared to conventional non-biodegradable alternatives. This market is driven by increasing global environmental awareness, stringent government regulations concerning single-use plastics, and rising consumer demand for sustainable packaging solutions across various industries. Key product segments include packaging derived from polylactic acid (PLA), polyhydroxyalkanoates (PHA), starch-based polymers, and recycled paper and cellulose structures, all engineered to break down through microbial action into natural elements like water, carbon dioxide, and biomass within a reasonable timeframe, often under composting conditions.

Major applications of biodegradable packaging span the food and beverage sector—specifically for fresh produce, ready-to-eat meals, and dairy products—along with consumer goods, pharmaceuticals, and cosmetics. The primary benefit of adopting these materials is the reduction of plastic waste accumulation in landfills and oceans, contributing significantly to circular economy initiatives. Furthermore, advancements in barrier properties and shelf-life extension capabilities are making biodegradable plastics a viable substitute for traditional polyethylene (PE) and polypropylene (PP) in complex packaging applications. The integration of high-performance bioplastics with recycled and virgin fiber resources is defining the next generation of sustainable container and film solutions.

Driving factors include global legislative mandates such as the European Union’s Single-Use Plastics Directive and similar policies implemented across North America and Asia Pacific. Additionally, large multinational corporations are setting ambitious sustainability targets, committing to utilize 100% reusable, recyclable, or compostable packaging, which necessitates a rapid transition to biodegradable alternatives. This corporate momentum, coupled with technological innovation lowering production costs and improving material performance, ensures sustained growth for the biodegradable packaging industry over the forecast period.

Biodegradable Paper and Plastics Packaging Market Executive Summary

The Biodegradable Paper and Plastics Packaging Market is characterized by robust growth, propelled by the urgent global mandate for reduced plastic pollution and corporate sustainability commitments. Business trends indicate significant investment in manufacturing capacity expansion, particularly for PHA and PLA production, alongside enhanced research and development focused on creating bio-based barrier layers that meet complex food preservation requirements. Strategic partnerships between chemical companies, material suppliers, and consumer packaged goods (CPG) companies are accelerating the commercialization of novel biodegradable materials, streamlining the supply chain from bio-resource sourcing to final product deployment. Mergers and acquisitions are common as established players seek to acquire specialized technology and secure market share in high-growth segments like flexible biodegradable films and molded pulp packaging.

Regionally, Europe maintains its leadership position due to highly proactive environmental regulations and advanced composting infrastructure, creating a strong pull market for certified biodegradable products. Asia Pacific, however, is projected to exhibit the fastest growth, driven by massive population density, escalating disposable incomes, and increasing awareness in major economies like China and India, where governments are beginning to implement sweeping bans on non-compostable plastics. North America presents a mature but evolving market, focusing heavily on improving recycling rates for fiber-based products and expanding industrial composting capabilities to accommodate bioplastics effectively. The regulatory landscape remains a primary differentiator in regional market dynamics, directly influencing adoption rates and material preference.

Segment trends reveal that the Paper & Paperboard segment, encompassing molded pulp and specialty paper packaging, retains the largest market share due to its established infrastructure, wide acceptance, and superior recyclability. However, the Biodegradable Plastics segment, particularly PLA and PHA, is forecasted to register the highest CAGR, primarily driven by their utility in flexible packaging, films, and transparent food containers—applications traditionally dominated by petroleum-based plastics. The Food & Beverage application sector remains the dominant end-user, accounting for over 60% of the market value, emphasizing the critical role biodegradable solutions play in modern supply chain sustainability. Innovation within barrier coatings and active packaging elements is crucial for segment differentiation and market penetration.

AI Impact Analysis on Biodegradable Paper and Plastics Packaging Market

User inquiries regarding AI in the Biodegradable Paper and Plastics Packaging Market frequently center on how machine learning can optimize material formulation, improve predictive modeling for biodegradation rates, and enhance supply chain efficiency for bio-based feedstock. Users are keen to understand if AI can accelerate the R&D cycle for next-generation biopolymers, specifically targeting improvements in mechanical strength and thermal stability while minimizing production costs. There is a notable concern about the sustainability of the supply chain, leading to questions about AI’s role in optimizing bio-resource cultivation, ensuring traceability, and matching material properties precisely to specific application requirements (e.g., predicting the optimal PLA-PHA blend for a high-moisture product). The central themes revolve around optimization, cost reduction, and accelerating material innovation to meet escalating commercial demand and performance specifications.

Artificial Intelligence applications are significantly influencing the efficiency and sustainability metrics across the lifecycle of biodegradable packaging. In the upstream supply chain, predictive analytics powered by AI optimize the cultivation and harvesting schedules for biomass feedstocks, such as corn starch or sugarcane, ensuring consistent quality and yield for bioplastic production. This minimizes raw material volatility, a historical constraint on biopolymer scalability. Furthermore, AI algorithms are being used in advanced material science simulations to predict the performance characteristics—such as oxygen transmission rate and tensile strength—of new biodegradable formulations, drastically reducing the time and cost associated with physical prototyping and testing.

Downstream, AI-driven sorting technologies are crucial for improving the efficacy of waste management and composting infrastructure. Machine vision systems utilize deep learning to accurately identify and separate certified biodegradable plastics from conventional plastics in waste streams, a necessary step for preventing contamination in both recycling and composting processes. This technological adoption directly addresses one of the market's primary challenges: end-of-life confusion. Moreover, CPG companies employ AI to optimize packaging designs for minimum material usage, maximum protection, and efficient shipping logistics, applying generative design techniques to create lightweight yet robust biodegradable structures.

- AI optimizes biomass feedstock cultivation and supply chain traceability, reducing material costs.

- Machine learning accelerates R&D by simulating biopolymer performance characteristics (mechanical strength, barrier properties).

- Deep learning-based sorting technologies enhance the accurate identification and separation of biodegradable packaging in waste streams.

- Predictive maintenance schedules for production machinery ensure continuous, high-volume manufacturing of bioplastics.

- Generative design AI creates structurally optimized, lightweight biodegradable packaging formats, improving sustainability metrics.

DRO & Impact Forces Of Biodegradable Paper and Plastics Packaging Market

The Biodegradable Paper and Plastics Packaging Market is fundamentally shaped by a confluence of legislative pressure, consumer preference shifts, technological maturity, and infrastructural limitations. Drivers (D) are dominated by global legislative crackdowns on single-use plastics and ambitious corporate zero-waste initiatives. The palpable desire among consumers, especially younger generations, for environmentally benign products forces brands to adopt sustainable packaging quickly. Restraints (R) primarily include the higher relative cost of production for bioplastics compared to traditional polymers, limitations in barrier performance for certain complex applications (e.g., carbonated beverages), and significant public confusion regarding disposal methods, often resulting in contamination of recycling streams. The lack of standardized, widespread industrial composting infrastructure also restricts the viability of many biodegradable solutions.

Opportunities (O) are abundant, centered around emerging high-performance materials like PHA and specialized cellulose films that offer superior mechanical properties and customizable degradation profiles. The pharmaceutical and e-commerce sectors represent high-growth potential end-users requiring innovative protective biodegradable solutions. Furthermore, investment in large-scale domestic production facilities across key regions (e.g., North America and APAC) offers an opportunity to reduce logistics costs and dependence on imported raw materials. Developing clear, globally standardized labeling and certification protocols also presents a significant opportunity to educate consumers and reduce disposal confusion, thereby increasing end-of-life efficiency.

The Impact Forces emphasize how these dynamics interact. Legislative drivers and consumer demand act as powerful external forces accelerating market growth, creating a "pull" effect. Conversely, the high cost and infrastructural constraints act as internal friction, tempering the pace of widespread adoption. Technological advancements serve as the mitigating force, actively working to overcome the restraints by developing cost-effective, high-performance materials. The overall impact force trajectory is strongly positive, indicating that the drivers and opportunities are currently outweighing the restraints, positioning the market for sustained, aggressive expansion.

Segmentation Analysis

The Biodegradable Paper and Plastics Packaging Market is intricately segmented across material type, application, and end-user industry, reflecting the diverse needs and performance requirements across the value chain. Material segmentation is critical, dividing the market into fiber-based solutions, which benefit from established recycling infrastructure, and various biopolymers, which offer performance characteristics closer to conventional plastics. Performance differences, cost structures, and end-of-life options dictate the suitability of specific materials for diverse applications, ranging from protective wraps to high-barrier liquid containers. The maturity of paper packaging contrasts sharply with the rapid innovation cycle seen in bioplastics like PHA, leading to distinct competitive landscapes within these segments.

Application segmentation highlights where biodegradable materials provide the most immediate commercial and environmental impact. Flexible packaging, including films, pouches, and wraps, represents a high-growth area as it directly substitutes highly polluting petroleum-based films prevalent in the food industry. Rigid packaging, such as bottles, trays, and molded pulp containers, relies heavily on material engineering to ensure structural integrity and stackability. End-user analysis reveals that the Food & Beverage industry, driven by short product life cycles and high volumes, dominates consumption. However, the rapidly expanding e-commerce sector is increasingly adopting biodegradable protective mailers and infill materials to align with modern sustainability expectations.

Geographical segmentation underscores regulatory influence and infrastructural readiness. Market segmentation allows stakeholders to target investment effectively, focusing on regions with supportive legislation or applications where performance requirements can be readily met by current biodegradable material capabilities. Understanding these segments is vital for predicting future material preference shifts, particularly as technological improvements address existing performance gaps in moisture and oxygen barrier properties for bioplastics.

- By Material Type:

- Biodegradable Paper & Paperboard (Molded Pulp, Paper Bags, Folding Cartons)

- Biodegradable Plastics (PLA - Polylactic Acid, PHA - Polyhydroxyalkanoates, Starch Blends, Cellulose Films, PBS - Polybutylene Succinate, PBAT - Polybutylene Adipate Terephthalate)

- By Application:

- Rigid Packaging (Bottles, Trays, Clamshells, Containers)

- Flexible Packaging (Films, Bags, Wraps, Pouches)

- By End-User Industry:

- Food & Beverage (Dairy, Fresh Produce, Ready Meals, Confectionery)

- Healthcare & Pharmaceutical

- Cosmetics & Personal Care

- Consumer Goods

- E-commerce & Logistics

Value Chain Analysis For Biodegradable Paper and Plastics Packaging Market

The value chain for biodegradable packaging begins significantly upstream with the sourcing of sustainable raw materials, involving both the cultivation and processing of biomass (e.g., corn, sugarcane, wood pulp) for bioplastics and the responsible harvesting and processing of fiber for paper and paperboard. Upstream analysis focuses on securing consistent, high-quality feedstock, which is highly dependent on agricultural yields and efficient biorefining processes. Key stakeholders at this stage include agricultural commodity providers, biorefinery operators, and specialized chemical companies that synthesize the base biodegradable polymers (e.g., PLA pellets or cellulose fibers). Efficiency and sustainable sourcing certifications (like FSC or equivalent bio-based standards) are crucial upstream factors influencing the final product cost and environmental claims.

The midstream stage involves the conversion of raw materials into finished packaging formats, encompassing material compounding, film extrusion, injection molding, and printing. Packaging converters utilize machinery tailored to handle the often different processing characteristics of bioplastics and recycled fibers compared to traditional materials. This stage requires significant technological expertise to maintain structural integrity, barrier properties, and aesthetic appeal. Innovation in coating and lamination technologies is vital here, often involving direct or indirect distribution channels where specialized packaging manufacturers supply either directly to large CPG companies or through regional distributors catering to small and medium enterprises (SMEs).

Downstream analysis focuses on the distribution, end-use, and crucial end-of-life management. Direct distribution is common for high-volume, bespoke packaging requirements in sectors like food manufacturing, ensuring just-in-time delivery and quality control. Indirect channels involve wholesalers and retailers who serve as the final touchpoint for the consumer. The circular aspect of the value chain closes downstream with waste management operators, industrial composting facilities, and municipal recycling centers, whose operational readiness determines the practical sustainability of the packaging. Effective communication and clear labeling are essential for consumer participation in the correct disposal of these environmentally sensitive materials.

Biodegradable Paper and Plastics Packaging Market Potential Customers

Potential customers for biodegradable paper and plastics packaging are diverse but heavily concentrated in industries that face intense public scrutiny regarding waste generation and require high-volume, disposable solutions. The primary end-users are major global and regional Food & Beverage manufacturers, particularly those focusing on ready-to-eat products, fresh produce, and single-serving packaging where reducing fossil fuel plastic use provides a significant brand image advantage. These customers prioritize materials that offer regulatory compliance in target markets, ensuring their products meet compostability standards in Europe or robust recyclability requirements in North America.

Beyond the dominant food sector, the e-commerce and retail industries represent a rapidly expanding customer base. With the massive increase in online shopping, logistical packaging—including mailer bags, protective films, and void fillers—must align with customer expectations for sustainability. These customers seek lightweight, robust biodegradable solutions that minimize shipping costs while offering verifiable end-of-life credentials. Furthermore, global pharmaceutical and personal care companies are increasingly adopting biodegradable packaging for secondary and tertiary packaging, driven by corporate social responsibility goals and a desire to differentiate their environmentally conscious product lines.

Small and medium-sized enterprises (SMEs), especially within the organic food and artisan consumer product space, are also vital potential customers. Although their volume requirements are smaller, they often lead the adoption curve for new, high-cost biodegradable materials, leveraging sustainable packaging as a core marketing tool. These buyers look for certified compostable or recyclable options suitable for local waste infrastructure, often preferring paper-based or specialized bioplastics like PHA due to their strong environmental profiles.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 45.2 Billion |

| Market Forecast in 2033 | USD 103.8 Billion |

| Growth Rate | 12.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | PTT Global Chemical, Mondi, BASF SE, Amcor PLC, Biopac India Corporation Ltd., International Paper, Smurfit Kappa Group, NatureWorks LLC, Novamont S.p.A., Tetra Pak, WestRock Company, Huhtamaki Oyj, Sealed Air Corporation, TotalEnergies SE, Mitsubishi Chemical Corporation, BillerudKorsnäs AB, Arkema, TIPA Corp, Green-Stack Technologies, Futamura Chemical Co. Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Biodegradable Paper and Plastics Packaging Market Key Technology Landscape

The technological landscape of the biodegradable packaging market is defined by continuous innovation focused on enhancing material performance, reducing processing costs, and improving end-of-life functionality. Key advancements include the refinement of polymerization techniques for bioplastics such as Polylactic Acid (PLA), enabling higher heat resistance and better mechanical properties suitable for hot-fill applications and durable containers. Crucially, the scaling up of Polyhydroxyalkanoates (PHA) production through optimized bacterial fermentation processes represents a significant technological leap, as PHA offers superior biodegradability in diverse environments, including marine settings, addressing a key environmental challenge posed by existing bioplastics.

In the paper and paperboard sector, barrier technology is the central area of innovation. Traditional fossil-fuel-based coatings (like PE) are being replaced by bio-based and biodegradable barrier coatings derived from natural polymers, waxes, and specialized nanocellulose. These coatings improve moisture and grease resistance, allowing paper packaging to enter markets previously restricted to plastic, such as liquid containers and frozen food wraps. Furthermore, advancements in molding and forming technologies, particularly for high-precision molded pulp, are enabling the creation of complex, structural packaging inserts that are fully compostable and offer excellent protective cushioning for electronics and fragile goods.

A critical technological thrust involves optimizing the blend and compounding of various biopolymers to create customized material grades that precisely meet specific functional needs—a technique known as bio-blending. For instance, blending PLA with PBAT or other flexible biopolymers enhances its flexibility and toughness, making it viable for high-stretch films. Simultaneously, advanced analytical and characterization techniques, often utilizing AI, are employed to rapidly assess and certify the compostability and environmental fate of these novel materials under different climactic conditions, ensuring regulatory compliance and consumer confidence in the "biodegradable" claim.

Regional Highlights

- Europe: Europe holds a dominant market share in biodegradable packaging, largely driven by the stringent regulatory framework, notably the EU’s Single-Use Plastics Directive, which mandates reduction targets and bans for many conventional plastic items. The region benefits from a highly developed waste management infrastructure, including widespread industrial composting facilities, which supports the viability and consumer acceptance of compostable plastics like PLA and starch blends. The focus here is on circular economy principles, with strong corporate commitments from major retailers and food service providers to transition to certified biodegradable or highly recyclable paper-based solutions. Innovation is high, particularly in Germany, the UK, and the Benelux countries, focusing on high-barrier food packaging and sustainable fiber sourcing.

- North America: North America, led by the United States and Canada, represents a high-potential market characterized by robust consumer awareness but somewhat fragmented infrastructure. While fiber-based packaging (paper and paperboard) is widely accepted and benefits from strong recycling systems, the adoption of bioplastics is often concentrated in metropolitan areas with accessible composting programs. State-level and municipal regulations, rather than federal mandates, drive much of the biodegradable plastics adoption. Significant investment is being made in the US to scale up domestic production of key biopolymers, such as NatureWorks’ expansion of PLA capacity, aiming to reduce dependence on Asian imports and stabilize material costs for domestic converters.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, fueled by rapid urbanization, massive population growth, and evolving regulatory environments in populous nations like China, India, and Japan. While the region is currently a major producer and exporter of biodegradable plastics, domestic consumption is soaring due to growing middle-class demand for packaged goods and intensifying government action to curb pollution. Countries like India and South Korea have implemented comprehensive plastic bans and promoted incentives for biodegradable alternatives. The market here is characterized by high demand for flexible packaging films and molded fiber solutions for the massive e-commerce and food delivery sectors. Securing sustainable and sufficient feedstock supply remains a key focus.

- Latin America (LATAM): The LATAM region presents a nascent but promising market, primarily driven by tourism-dependent economies (e.g., Caribbean nations and Costa Rica) and large national markets like Brazil and Mexico, which are beginning to implement bans on single-use items. Growth is highly sensitive to economic stability and the establishment of local production capacity. The market relies heavily on imported raw materials, making material cost a significant constraint. However, the high environmental sensitivity of coastal regions provides a strong moral and economic imperative for adopting fully compostable packaging solutions.

- Middle East and Africa (MEA): The MEA market is highly varied. The Middle East, particularly the GCC countries, shows growing interest in biodegradable solutions due to large-scale investment in infrastructure and diversification away from oil economies, coupled with significant sustainability targets for major international events. Africa's market remains largely undeveloped in bioplastics, though there is substantial demand for paper-based packaging. Challenges include limited local manufacturing capabilities and the need for significant investment in waste management infrastructure to support the practical adoption of compostable materials. Regulatory initiatives in South Africa and parts of North Africa are beginning to drive small-scale adoption.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Biodegradable Paper and Plastics Packaging Market.- PTT Global Chemical

- Mondi

- BASF SE

- Amcor PLC

- Biopac India Corporation Ltd.

- International Paper

- Smurfit Kappa Group

- NatureWorks LLC

- Novamont S.p.A.

- Tetra Pak

- WestRock Company

- Huhtamaki Oyj

- Sealed Air Corporation

- TotalEnergies SE

- Mitsubishi Chemical Corporation

- BillerudKorsnäs AB

- Arkema

- TIPA Corp

- Green-Stack Technologies

- Futamura Chemical Co. Ltd.

Frequently Asked Questions

Analyze common user questions about the Biodegradable Paper and Plastics Packaging market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between biodegradable and compostable packaging?

Biodegradable packaging means the material will break down naturally over time, but the specific duration and required environmental conditions are often undefined. Compostable packaging is a subset of biodegradable materials guaranteed to break down completely into non-toxic components (water, CO2, biomass) within a specific timeframe (usually 90–180 days) under controlled, industrial composting conditions, making it the preferred standard for food packaging.

Which biodegradable plastic material is currently leading the market growth?

Polylactic Acid (PLA) currently dominates the market volume among biodegradable plastics due to its cost-effectiveness, versatility, and established production infrastructure. However, Polyhydroxyalkanoates (PHA) are forecasted to exhibit the highest growth rate due to their superior biodegradability in natural environments, including soil and marine settings, making them attractive for high-value applications.

How do stringent government regulations impact the market adoption rates?

Strict regulatory mandates, such as national bans on single-use plastics and Extended Producer Responsibility (EPR) schemes, significantly accelerate the market adoption rate by forcing corporations to transition away from conventional packaging. These regulations stabilize demand and incentivize investment in local biodegradable material production and corresponding composting infrastructure.

What are the main performance constraints facing biodegradable packaging today?

The primary constraints include the difficulty in achieving necessary moisture and oxygen barrier properties comparable to high-performance conventional plastics (like PET or aluminum foil), which is essential for extending the shelf life of sensitive products. Additionally, the relatively higher cost of biodegradable polymers compared to fossil-fuel-based plastics remains a market challenge.

Which region offers the most significant growth opportunity for biodegradable packaging manufacturers?

The Asia Pacific (APAC) region offers the most significant growth opportunity, driven by massive domestic consumption, rapid urbanization, and escalating government investments in sustainable waste management systems across key economies such as China, India, and Southeast Asia, creating a vast and rapidly expanding demand base.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager