Biomimetic Plastic Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439123 | Date : Dec, 2025 | Pages : 253 | Region : Global | Publisher : MRU

Biomimetic Plastic Market Size

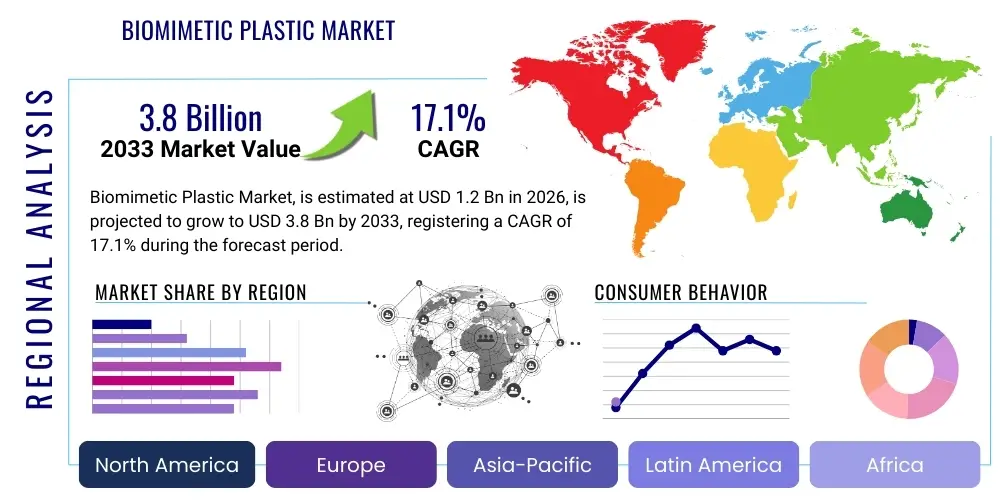

The Biomimetic Plastic Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 17.1% between 2026 and 2033. The market is estimated at USD 1.2 Billion in 2026 and is projected to reach USD 3.8 Billion by the end of the forecast period in 2033.

Biomimetic Plastic Market introduction

The Biomimetic Plastic Market encompasses advanced polymeric materials designed and engineered based on structures, functions, and processes observed in biological systems, primarily aimed at replicating nature's efficiency, resilience, and unique functionalities. These materials transcend traditional plastic properties by integrating bio-inspired features such as self-healing capabilities, superhydrophobicity (water repellency), structural coloration, and enhanced mechanical strength derived from hierarchical microstructures. Product descriptions span specialized polymers, composites, and films that mimic biological phenomena, including the self-cleaning action of lotus leaves (creating superhydrophobic surfaces), the structural colors found in butterfly wings (eliminating the need for pigments), and the adhesive strength of geckos' feet. The primary benefits driving market adoption include significant reductions in material waste through self-repair, lower energy consumption due to enhanced friction reduction (e.g., shark skin textures), and the creation of aesthetically superior products without chemical additives.

Major applications for biomimetic plastics are highly diversified, spanning high-value industries such as medical devices (anti-fouling surfaces for implants), automotive and aerospace (drag reduction coatings and self-healing paints), and advanced packaging (biodegradable and moisture-resistant films). These plastics are pivotal in solving complex engineering challenges where conventional materials fail to meet demands for long-term durability and environmental sustainability. For instance, the use of self-healing elastomers in consumer electronics prevents premature failure, thereby extending product lifecycles and addressing growing consumer demand for sustainable material science. Furthermore, the development of specialized biomimetic adhesives offers superior, reversible bonding solutions critical for modular manufacturing processes.

The market growth is fundamentally driven by the escalating global focus on sustainability and the circular economy, necessitating materials that are inherently efficient and environmentally benign throughout their lifecycle. Key driving factors include increasing R&D investments in nanotechnology and materials science, which enable the precise replication of complex biological microstructures. Regulatory support for sustainable materials, particularly in Europe and North America, further accelerates adoption. Moreover, the demand for high-performance materials in extreme environments, such as aerospace components requiring unparalleled resistance to fatigue and damage, solidifies the market's trajectory. The transition away from traditional, energy-intensive manufacturing towards bio-inspired synthesis techniques is a crucial mechanism facilitating market expansion.

Biomimetic Plastic Market Executive Summary

The global Biomimetic Plastic Market is poised for significant expansion, driven primarily by technological breakthroughs in polymer chemistry and nanotechnology that allow for the scalable production of bio-inspired materials with functional superiority. Business trends indicate a pronounced shift toward collaborative research models, where academic institutions and material science corporations partner to expedite the transition of lab-scale innovations into commercial products, specifically focusing on applications that yield immediate sustainability benefits, such as durable, self-cleaning architectural materials. Strategic mergers and acquisitions are observed as established chemical giants seek to integrate specialized biomimetic startups, thereby securing intellectual property related to complex bio-inspired structures like hierarchical microfibrils and dynamic structural matrices. The market is experiencing increasing competitive pressure, leading to enhanced focus on reducing production costs associated with precise micro-patterning and specialized polymerization techniques, ensuring these advanced materials become cost-competitive with conventional high-performance polymers. Furthermore, the rising adoption of specialized simulation tools (Finite Element Analysis and Molecular Dynamics) is streamlining the design phase, reducing the time-to-market for novel biomimetic solutions.

Regionally, North America and Europe currently dominate the market, capitalizing on robust funding for advanced materials research and stringent environmental regulations that favor durable, self-repairing, and highly efficient products. European leadership is particularly strong in sustainable packaging and automotive applications, mandated by ambitious carbon neutrality goals. Asia Pacific (APAC) is projected to exhibit the fastest growth trajectory, primarily fueled by massive industrial expansion, increasing investment in healthcare infrastructure, and the burgeoning consumer electronics manufacturing sector, particularly in countries like China, Japan, and South Korea, which are rapidly adopting self-healing coatings and structural coloration technologies to enhance product differentiation and durability. The Middle East and Africa (MEA) and Latin America are emerging markets, driven mainly by construction and infrastructure projects demanding materials with enhanced resistance to harsh environmental conditions, such as anti-corrosion and superhydrophobic coatings inspired by desert beetles and shark skin.

Segment trends reveal that the Self-Healing Polymers segment is expected to maintain its leadership position due to its unparalleled value proposition in prolonging the operational life of materials across various sectors, especially infrastructure and transportation. Within applications, the Automotive sector is showing accelerated demand for biomimetic plastics used in exterior coatings and interior surfaces to achieve superior scratch resistance and aerodynamic efficiency. However, the fastest growth is anticipated in the Medical Devices segment, driven by the critical need for bio-compatible, anti-microbial, and anti-fouling surfaces for surgical tools, implants, and diagnostics equipment. Segmentation by function, such as structural coloration and enhanced adhesion, is also gaining prominence as manufacturers seek passive, non-chemical ways to achieve functional characteristics, ensuring the materials are safer and more environmentally friendly.

AI Impact Analysis on Biomimetic Plastic Market

User inquiries frequently center on how Artificial Intelligence (AI) can accelerate the discovery and synthesis of novel biomimetic plastic compositions, specifically questioning the role of machine learning in decoding complex biological design principles and translating them into manufacturable polymeric architectures. Key concerns revolve around whether AI can significantly reduce the extensive R&D cycles typically required for bio-inspired materials, particularly in optimizing hierarchical structures (e.g., mimicking bone or shell architecture) and predicting the stability and performance of self-healing mechanisms under varied stress conditions. Users expect AI to revolutionize the iterative design process, enabling virtual screening of millions of possible monomer combinations and structural configurations before lab synthesis. Furthermore, there is strong interest in using AI for real-time quality control during large-scale manufacturing of micro-patterned surfaces, ensuring defect rates are minimized, which is critical for maintaining the functional properties (like superhydrophobicity or structural color fidelity) of biomimetic products. The ability of AI to model complex environmental interactions, such as degradation kinetics or dynamic responsiveness, is also a highly anticipated theme.

- AI-driven materials informatics accelerates the identification of optimal polymer chain structures and monomer ratios required to mimic specific biological functions, such as reversible adhesion or adaptive stiffness.

- Machine learning algorithms enhance the predictive modeling of self-healing efficacy, factoring in variables like damage size, ambient temperature, and repair agent kinetics, optimizing material composition accordingly.

- Generative design tools, powered by AI, synthesize complex, non-intuitive hierarchical microstructures derived from natural systems (e.g., nacre, spider silk) and translate them into feasible manufacturing templates for 3D printing or molding.

- AI optimizes manufacturing processes for micro-patterning techniques (e.g., nano-imprint lithography), adjusting parameters in real-time to maintain the geometric precision necessary for functional properties like structural coloration and drag reduction.

- Predictive maintenance analytics, driven by AI, monitor the long-term performance and fatigue life of biomimetic coatings and components in real-world applications, providing crucial feedback for future material refinement.

DRO & Impact Forces Of Biomimetic Plastic Market

The Biomimetic Plastic Market is fundamentally shaped by a powerful confluence of drivers, restraints, and opportunities. The core driver is the imperative for sustainable innovation, demanding materials that integrate multifunctionality, extended lifespan (through self-healing), and reduced environmental footprint. This demand is coupled with substantial technological advancements, particularly in nanofabrication and polymer engineering, making the precise replication of complex biological designs commercially viable. However, significant restraints impede faster growth, primarily the high initial manufacturing costs associated with specialized processes like high-resolution lithography and complex polymerization, which increases the final product price relative to conventional plastics. Furthermore, the lack of standardization and scalability challenges, especially when moving from laboratory prototypes to industrial volume production, restrict broader adoption across mass-market segments. Opportunities lie significantly in developing cost-effective, continuous manufacturing processes and exploring new application frontiers, particularly in bio-robotics, soft robotics, and advanced energy storage systems requiring flexible, bio-inspired encapsulation materials.

The impact forces influencing the market are multifaceted, encompassing intense regulatory pressures promoting circular economy principles (pushing demand for self-healing and durable materials) and the pervasive influence of substitution threat from conventional high-performance materials and alternative bio-based materials that might offer lower costs. Supplier power remains moderate, driven by specialized feedstock requirements, while buyer power is high in large sectors like automotive and construction, demanding performance guarantees and cost efficiency. The intensity of rivalry is escalating as established chemical companies and innovative startups compete aggressively to secure patents and market share in key functional segments such as superhydrophobic coatings and structural materials, forcing continuous technological differentiation. These forces collectively mandate that market participants focus intensely on cost optimization through process innovation and demonstrable performance superiority to justify the higher initial investment in biomimetic solutions.

Segmentation Analysis

The Biomimetic Plastic Market is comprehensively segmented based on the specific biological function being mimicked (material type), the end-use application domain, and the distinct end-user industry employing these advanced materials. This segmentation allows for targeted market strategy development, focusing resources on high-growth functional areas such as self-healing polymers and specialized adhesive technologies. The functional segmentation highlights the core R&D focus of the industry, while the application segmentation, particularly in high-reliability sectors like healthcare and aerospace, dictates the stringent performance requirements and regulatory hurdles that must be met by these bio-inspired materials. Understanding the interplay between material structure and industrial requirement is critical for market penetration and establishing long-term commercial success.

- By Material Type:

- Self-Healing Polymers (Intrinsic and Extrinsic)

- Superhydrophobic/Hydrophilic Surfaces (Lotus Effect/Shark Skin Effect)

- Structural Coloration Plastics (Mimetics of Butterfly Wings/Peacock Feathers)

- Bio-Inspired Adhesives and Sealants (Gecko/Mussel Inspired)

- Temperature/pH Responsive Plastics (Smart Materials)

- Enhanced Mechanical Strength Plastics (Nacre/Bone Mimetics)

- By Application:

- Packaging (Active and Smart Films)

- Medical Devices and Healthcare (Anti-fouling surfaces, Drug delivery)

- Automotive and Transportation (Self-repairing coatings, Drag reduction films)

- Construction and Infrastructure (Weatherproof and durable coatings)

- Textiles and Apparel (Waterproof and breathable fabrics)

- Consumer Goods and Electronics (Scratch resistance, Anti-smudge coatings)

- By End-User Industry:

- Healthcare and Pharmaceutical

- Automotive and Aerospace

- Food and Beverage

- Building and Construction

- Electronics and IT

Value Chain Analysis For Biomimetic Plastic Market

The value chain for the Biomimetic Plastic Market is highly specialized and knowledge-intensive, beginning with upstream activities focused on sophisticated research and the procurement of specialized chemical feedstocks and advanced nanomaterials necessary for microstructure replication. Upstream suppliers include specialty chemical producers, nanotech firms providing catalysts and reinforcing agents (e.g., carbon nanotubes, graphene), and academic research institutions contributing patented bio-inspired designs. The core manufacturing stage involves complex polymerization processes and specialized fabrication techniques, such as micro-imprinting or self-assembly methods, which demand high capital expenditure and proprietary know-how to ensure functional fidelity and structural precision. This manufacturing specialization often dictates high barriers to entry for new market players.

The distribution channel is multifaceted, relying heavily on both direct sales and specialized indirect channels. Direct distribution is crucial for large-volume customers in the Automotive, Aerospace, and Medical sectors, where technical consultation, customized material specifications, and rigorous quality assurance are mandatory. Indirect channels involve specialized material distributors who possess the technical expertise to handle and integrate these advanced polymers into client manufacturing processes, particularly serving smaller OEMs and regional specialized manufacturers in construction and consumer goods. The efficiency of the distribution network is paramount, as the high value of these materials necessitates secure and optimized logistics, especially for temperature-sensitive or reactive precursor compounds used in self-healing systems.

Downstream activities involve the final conversion and integration of biomimetic plastics into end-products, requiring specific machinery and training for industrial handling. For instance, automotive manufacturers integrate self-healing coatings into paint lines, while medical device companies utilize bio-inspired films for surface treatments. Potential customers, or end-users, assess these materials based on demonstrated functional superiority, cost-to-benefit ratio (measured in extended product life and reduced maintenance), and compliance with stringent industry regulations (e.g., FDA clearance for medical applications). The value creation culminates in the deployment of products offering unparalleled durability, efficiency, and sustainability, justifying the premium pricing associated with biomimetic technology.

Biomimetic Plastic Market Potential Customers

Potential customers for biomimetic plastics span a diverse range of high-performance and regulated industries where material failure, degradation, or bio-fouling results in substantial financial or safety implications. The primary end-users in the Healthcare sector include medical device manufacturers requiring anti-microbial and bio-compatible materials for implants, catheters, and surgical instruments, benefiting significantly from surfaces that resist protein adhesion and bacterial growth, mimicking natural defense mechanisms. In the Transportation industry, major automotive OEMs and aerospace component producers are key customers, seeking materials for enhanced fuel efficiency through drag reduction coatings (mimicking shark skin) and extending vehicle aesthetics and longevity through self-healing exterior paints and high-durability interior components.

The Building and Construction industry represents a growing customer base, driven by the demand for highly durable, low-maintenance exterior materials. Customers here are focused on superhydrophobic coatings that provide self-cleaning functionality for windows, facades, and solar panels (Lotus effect mimetics), reducing reliance on chemical cleaning agents and minimizing structural maintenance. Furthermore, the Electronics and Consumer Goods sectors are crucial end-users, requiring scratch-resistant screens, anti-smudge coatings, and flexible, durable casings that can withstand repetitive mechanical stress, often adopting polymers inspired by the flexible strength of natural materials like spider silk or nacre. These end-users prioritize materials that enhance user experience, comply with green product standards, and offer tangible competitive advantages in product differentiation.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.2 Billion |

| Market Forecast in 2033 | USD 3.8 Billion |

| Growth Rate | 17.1% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | BASF SE, Covestro AG, Evonik Industries AG, Mitsubishi Chemical Corporation, Teijin Limited, Kuraray Co., Ltd., SABIC, DuPont de Nemours, Inc., NatureWorks LLC, Ticona (Celanese Corporation), Biome Bioplastics Ltd., Solvay SA, Arkema S.A., Wacker Chemie AG, Toray Industries, Inc., Nippon Shokubai Co., Ltd., Futerro, PTT Global Chemical Public Company Limited, TotalEnergies SE, Eastman Chemical Company |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Biomimetic Plastic Market Key Technology Landscape

The core technological landscape underpinning the biomimetic plastic market is defined by advanced nanotechnology, precision polymerization, and surface engineering techniques essential for replicating natural structures at the nano and micro scales. Key technologies include Nanoimprint Lithography (NIL) and Soft Lithography, which enable cost-effective, high-throughput replication of complex surface geometries necessary for achieving phenomena like structural color (photonic crystals) and superhydrophobicity (hierarchical pillars, grooves, or ridges, such as those found on lotus leaves). These processes require highly controlled environments and specialized tooling to maintain the fidelity of the patterned structure, as deviations often result in diminished functional performance.

In the realm of self-healing materials, the market relies on microencapsulation technology, where healing agents (monomers, catalysts) are encapsulated within microbubbles and embedded within the polymer matrix. When damage occurs, the microcapsules rupture, releasing the agent to polymerize and fill the crack. Furthermore, intrinsic self-healing polymers utilize reversible covalent bonds (e.g., Diels-Alder reactions or dynamic cross-links) or non-covalent interactions (like hydrogen bonding) that spontaneously reform upon localized stress or thermal application. The technological sophistication lies in designing these dynamic chemical systems to be robust, repeatable, and fast-acting under ambient conditions.

Advanced computational modeling, including Density Functional Theory (DFT) and Molecular Dynamics (MD) simulations, is increasingly integrated into the technology pipeline. These tools allow researchers to predict and optimize the interaction between polymer chains and bio-inspired structures before physical synthesis, drastically reducing experimental trial-and-error. Furthermore, 3D printing and Additive Manufacturing technologies, particularly multi-material jetting and stereolithography, are emerging as critical tools for creating customized biomimetic prototypes and small-batch production runs, enabling the rapid testing and deployment of materials with complex, multi-scale hierarchical designs inspired by natural structures like bone, wood, or insect exoskeletons.

Regional Highlights

- North America: Dominates the market share due to substantial investment in materials science research, particularly government and private funding directed towards high-performance materials for aerospace and defense. The presence of major automotive manufacturers and a robust medical device industry accelerates the adoption of self-healing coatings and bio-compatible polymers. Regulatory frameworks promoting sustainable and durable infrastructure further strengthen regional demand.

- Europe: Exhibits significant leadership in sustainability-driven innovation, catalyzed by stringent EU regulations targeting plastic waste and promoting the circular economy. European markets, especially Germany and the Nordic countries, are pioneers in applying biomimetic materials in automotive drag reduction, advanced construction coatings, and specialized sustainable packaging solutions, maintaining high technological expertise in polymer functionalization.

- Asia Pacific (APAC): Positioned as the fastest-growing region, driven by explosive growth in manufacturing sectors (electronics, textiles, and construction) across China, Japan, and South Korea. Rapid industrialization and expanding consumer electronics production create massive demand for durable, aesthetic (structural coloration), and protective coatings. Increased focus on improving regional healthcare infrastructure also boosts demand for bio-inspired medical device surfaces.

- Latin America (LATAM): Showing steady growth, primarily focused on construction and resource extraction industries where materials require extreme durability and resistance to harsh climatic conditions. Adoption is accelerating in high-value agricultural packaging and infrastructure projects, utilizing superhydrophobic and anti-corrosion materials.

- Middle East and Africa (MEA): An emerging market where demand is spurred by large-scale infrastructure and construction development, particularly requiring anti-sand abrasion and superior temperature resistance in architectural materials. The development of sophisticated oil and gas pipelines also drives the demand for specialized, highly durable, self-healing coatings.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Biomimetic Plastic Market.- BASF SE

- Covestro AG

- Evonik Industries AG

- Mitsubishi Chemical Corporation

- Teijin Limited

- Kuraray Co., Ltd.

- SABIC

- DuPont de Nemours, Inc.

- NatureWorks LLC

- Ticona (Celanese Corporation)

- Biome Bioplastics Ltd.

- Solvay SA

- Arkema S.A.

- Wacker Chemie AG

- Toray Industries, Inc.

- Nippon Shokubai Co., Ltd.

- Futerro

- PTT Global Chemical Public Company Limited

- TotalEnergies SE

- Eastman Chemical Company

Frequently Asked Questions

Analyze common user questions about the Biomimetic Plastic market and generate a concise list of summarized FAQs reflecting key topics and concerns.What defines a biomimetic plastic and how does it achieve self-healing properties?

A biomimetic plastic is an advanced polymer engineered to replicate the specific structures or functions found in nature, such as the superhydrophobicity of the lotus leaf or the high tensile strength of spider silk. Self-healing is typically achieved either through extrinsic mechanisms, utilizing microencapsulated healing agents that release and polymerize upon crack formation, or intrinsic mechanisms, where the polymer matrix is designed with reversible bonds that spontaneously reform upon damage, often triggered by heat or pressure.

What are the primary applications driving the commercial growth of structural coloration plastics?

Structural coloration plastics, which mimic the light interaction mechanism of butterfly wings or opals, are primarily driving growth in high-end consumer goods, luxury packaging, and automotive finishes. These materials offer permanent, non-fading color without requiring traditional chemical pigments, reducing environmental impact and providing superior aesthetic differentiation, thus appealing to industries focused on premium visual appeal and sustainable manufacturing practices.

How is cost and scalability addressed as a major restraint in the biomimetic plastic market?

Cost and scalability challenges are being addressed through the industrialization of high-throughput nanofabrication techniques like roll-to-roll nanoimprint lithography, which transforms batch processing into continuous manufacturing. Furthermore, ongoing research focuses on synthesizing cheaper, more abundant precursor materials for self-healing agents and optimizing polymerization protocols to reduce energy consumption, gradually driving down the unit cost relative to performance gains.

Which end-user industry is projected to demonstrate the highest growth rate for biomimetic materials?

The Medical Devices and Healthcare sector is projected to exhibit the highest growth rate. This acceleration is due to the critical need for advanced biomimetic surfaces that prevent bio-fouling and microbial colonization on implants and diagnostic equipment, significantly reducing infection rates and improving patient outcomes. Bio-inspired materials offer unparalleled performance in meeting stringent regulatory requirements for biocompatibility and functional reliability in invasive applications.

What is the role of the shark skin effect in biomimetic plastics used in transportation?

The shark skin effect is mimicked using specialized surface micro-patterning (riblets) on plastic coatings applied to ship hulls and aircraft surfaces. These patterns manipulate boundary layer flow, reducing turbulent drag by up to 8%, which directly translates to significant fuel savings and reduced operational costs for the transportation industry. This passive technology is highly valued for its permanent, non-chemical approach to efficiency improvement.

Advanced Biomimetic Material Synthesis and Functionality

The frontier of biomimetic plastic research increasingly centers on the realization of dynamic and adaptive materials that respond autonomously to external stimuli, moving beyond purely passive properties. A critical area is the development of polymers capable of mimicking muscle-like contraction and expansion, often achieved through incorporating shape-memory polymers or hydrogels within a flexible plastic matrix. These adaptive materials are pivotal for the advancement of soft robotics and deployable structures, requiring precision control over mechanical response kinetics. The synthesis methods employed are increasingly complex, involving controlled radical polymerization techniques (such as RAFT or ATRP) to precisely control polymer architecture, enabling multi-block copolymers that self-assemble into hierarchical structures replicating natural designs, thereby maximizing functional density within the material volume. Achieving large-scale consistency in these complex chemical structures, particularly for thin films and coatings, remains a technological bottleneck that significant R&D efforts are focused on resolving.

Furthermore, research into bio-inspired adhesion focuses intensely on replicating the remarkable strength and reversibility of mussel foot proteins and gecko foot hairs. Mussel-inspired adhesives utilize catecholamine functional groups, allowing them to bond effectively in wet, saline environments—a capability conventional synthetic adhesives lack. Translating this chemistry into scalable plastic formulations involves grafting these specialized functional groups onto polymer backbones, ensuring stability and long-term performance. For gecko adhesion, the challenge lies in manufacturing large area films with nanoscale fibrillar arrays (setae) with sufficient stiffness and density to generate significant van der Waals forces. Success in these areas is crucial for revolutionizing electronics assembly, medical fixation, and modular construction, eliminating the need for permanent, material-damaging mechanical fasteners or harsh chemical curing agents, thereby enhancing material recyclability and repairability.

The concept of "living plastics," incorporating biological components or mimicking metabolic processes, is also gaining traction. This involves integrating enzyme-based systems into polymer matrices to create self-cleaning or self-degrading plastics that react specifically to environmental cues. For example, plastics embedded with specialized enzymes could rapidly degrade into benign components under specific pH or temperature changes, offering an elegant solution to plastic waste accumulation. While still largely in the exploratory research phase, the technological promise of such self-regulating, bio-integrated polymeric systems is enormous, particularly for medical diagnostics, smart packaging that indicates spoilage, and fully circular material economies. Successful market implementation hinges upon ensuring the long-term viability and stability of the integrated biological components within the synthetic plastic environment.

- Adaptive Functionality: Development of polymers exhibiting muscle-like actuation or stiffness modulation in response to environmental factors like temperature, light, or electric fields, crucial for soft robotics components.

- Advanced Adhesion Systems: Focus on manufacturing scalable polymeric films mimicking mussel foot proteins for wet adhesion and gecko setae for reversible, high-strength bonding through van der Waals forces.

- Hierarchical Composites: Creation of plastics that mimic the fracture toughness of nacre (mother-of-pearl) or bone through programmed self-assembly of nano-scale organic and inorganic components, resulting in materials with exceptional strength-to-weight ratios.

- Biologically Integrated Systems: Exploration of enzyme immobilization within plastic matrices for targeted self-degradation, biological sensing, and adaptive surface protection, leading toward 'smart' biodegradable plastics.

- Precision Fabrication: Continuous refinement of large-area, continuous manufacturing techniques (e.g., roll-to-roll UV-curing and high-speed nanoimprinting) to lower the production costs of micro-patterned functional surfaces.

Detailed Analysis of Market Drivers

The increasing global emphasis on sustainability and the transition toward circular economic models represent the most potent drivers for the biomimetic plastic market. Traditional plastics often face obsolescence due to wear, tear, or damage, contributing heavily to waste streams. Biomimetic materials, particularly those with self-healing capabilities, directly address this vulnerability by restoring integrity after minor damage events, drastically extending product lifespan. This durability aligns perfectly with mandates in major economies aimed at reducing consumption and promoting long-term material use, offering manufacturers a verifiable pathway to reduce warranty claims and improve their environmental sustainability credentials. Consumers are also increasingly preferring products that are robust and environmentally conscious, amplifying the market pull for durable, bio-inspired solutions in electronics and automotive coatings.

Simultaneously, the continuous evolution and accessibility of nanotechnology and advanced materials engineering are making complex bio-inspired designs technologically feasible and economically accessible. Innovations in areas such as precision 3D printing and atomic layer deposition allow for the fabrication of multi-scale surface textures and internal microstructures previously confined to nature. Researchers can now design materials at the molecular level, mimicking, for instance, the complex cellular structure of wood or the internal matrix of insect cuticles, resulting in polymeric materials with unprecedented combinations of lightweight strength, flexibility, and impact resistance. The rapid dissemination of knowledge and tools for nanofabrication across research hubs accelerates the commercial viability of these high-performance materials.

A further critical driver is the intensified demand across high-performance sectors for multifunctionality and energy efficiency. Industries such as aerospace and specialized maritime transport require materials that can simultaneously provide drag reduction (fuel efficiency), corrosion resistance, and structural integrity. Biomimetic plastics deliver integrated solutions, such as superhydrophobic coatings that are also anti-fouling (mimicking shark or water strider surfaces), reducing maintenance costs and operational friction simultaneously. This ability to integrate multiple desired properties into a single material system, without reliance on bulky or energy-intensive external mechanisms, positions biomimetic solutions as superior alternatives to conventional composites and multi-layer coatings, driving substantial investment from strategic industries prioritizing operational performance.

- Sustainability and Durability Mandates: Global regulatory pressure and corporate sustainability goals favor materials that minimize waste, utilize self-repair, and offer extended service life, aligning directly with the core value proposition of biomimetic plastics.

- Technological Enabling Factors: Maturation of precision manufacturing technologies (nanoimprint lithography, multi-scale 3D printing) enables the high-fidelity replication of complex, functional biological microstructures at commercial scales.

- Multifunctionality Requirement: Increasing industrial demand for materials that simultaneously fulfill multiple roles—e.g., structural support, self-cleaning, and drag reduction—to improve efficiency and simplify design complexity.

- Aerodynamic and Hydrodynamic Efficiency: High adoption rates in transportation sectors (marine, aerospace, and automotive) leveraging bio-inspired surfaces (riblets, slippery liquid-infused surfaces) for measurable reductions in fluid friction and fuel consumption.

Detailed Analysis of Market Restraints

The primary restraint hindering the widespread adoption of biomimetic plastics is the elevated manufacturing complexity and the resultant high cost compared to conventional high-performance polymers. Creating bio-inspired functionality necessitates precision at the nano- and micro-scales, often requiring specialized fabrication equipment (e.g., electron beam lithography, specialized cleanrooms) and high purity, proprietary precursor chemicals for polymerization or encapsulation systems. This capital intensity, coupled with the currently limited scale of production for many innovative formulations, results in a significant price premium, making biomimetic solutions commercially unviable for mass-market applications where cost sensitivity is paramount, such as standard packaging or construction components.

A second major constraint involves the current limitations in scaling up laboratory-developed processes to consistent industrial volumes, specifically maintaining functional integrity during large-scale production. Many groundbreaking biomimetic properties, such as precise structural coloration or reliable self-healing efficiency, are highly sensitive to manufacturing tolerances, including variations in temperature, pressure, and cure time. Translating a successful lab prototype (often produced via batch processes) into a continuous, high-volume production line frequently introduces defects or compromises the delicate microstructures required for the biomimetic effect. Standardizing quality control and developing robust, scalable processes that ensure consistent performance across massive output remains a significant technical and engineering hurdle that market participants must overcome to achieve true market penetration.

Furthermore, the lack of standardized testing protocols and regulatory clarity in evaluating the long-term performance and reliability of novel biomimetic functions poses a substantial market barrier. Unlike conventional materials with established failure models, the efficacy of features like self-healing or anti-fouling surfaces is difficult to certify over a multi-year lifespan under varying real-world conditions. End-user industries, particularly automotive and aerospace, demand exhaustive testing and material certifications to guarantee safety and performance. The slow pace of establishing industry-wide standards for validating dynamic material responses creates hesitancy among risk-averse commercial buyers, delaying large-scale commercial contracts and slowing the market adoption curve for these nascent technologies until robust performance metrics are internationally recognized and certified.

- High Production Costs: Significant capital investment required for specialized nano- and micro-fabrication equipment and reliance on proprietary, expensive chemical feedstocks contribute to the high unit cost of biomimetic materials.

- Scalability Challenges: Difficulty in translating laboratory-scale batch processes for microstructure replication into consistent, cost-effective, high-volume continuous industrial production without compromising functional fidelity.

- Lack of Standardization and Certification: Absence of widely accepted industry standards and regulatory frameworks for measuring and certifying the long-term efficacy and reliability of dynamic functions like self-healing and bio-fouling resistance, leading to buyer hesitation.

- Thermal and Chemical Sensitivity: The intricate functional structures are often sensitive to conventional plastic processing conditions (high heat, mechanical shear), limiting their compatibility with existing high-volume manufacturing machinery.

Detailed Analysis of Market Opportunities

A substantial opportunity exists in penetrating new application domains, particularly in the burgeoning fields of bio-robotics and soft robotics. These areas require materials capable of actuation, sensing, and self-repair to mimic biological movement and resilience closely. Biomimetic plastics that can integrate pneumatic channels, self-healing circuits, and flexible structural supports are essential components for creating dexterous, safe, and durable robotic systems designed to interact closely with humans or operate in complex environments. By focusing R&D efforts on these high-value, nascent applications, manufacturers can secure early mover advantage and establish proprietary technical standards, paving the way for specialized material sales in the rapidly evolving automation and medical device sectors.

The development of cost-effective, sustainable manufacturing processes represents a major pathway for market expansion. Currently, the high cost of precision micro-patterning is a significant barrier. Innovations in utilizing self-assembly principles, where polymer components spontaneously arrange themselves into the desired functional structures upon mixing or simple thermal treatment, could drastically reduce the reliance on expensive, high-energy lithography techniques. Success in achieving bulk material synthesis with embedded biomimetic functionality would unlock mass-market potential, allowing these advanced materials to compete directly with mid-range conventional polymers in sectors like automotive components and general construction materials, dramatically expanding the total addressable market (TAM).

Furthermore, significant opportunities lie in integrating advanced sensing and responsiveness into biomimetic plastics, moving toward truly "smart" materials. Plastics that change color or transparency based on temperature (thermochromism), pressure, or the presence of specific contaminants (chemosensing) have immense potential in smart packaging, environmental monitoring, and safety applications. For instance, self-healing materials that visually signal damage before repair, or coatings that adapt their texture to optimize thermal regulation, represent high-value product differentiation. Leveraging stimuli-responsive polymer chemistry allows for the creation of adaptive materials that can significantly enhance safety and efficiency across diverse industrial operations, from aerospace structural health monitoring to dynamic camouflage systems.

- Bio-Robotics and Soft Robotics: Supplying adaptive, flexible, self-healing polymers crucial for creating life-like and resilient actuators, sensors, and structural supports in next-generation robotic systems.

- Sustainable and Self-Assembly Processes: Developing novel, low-energy synthesis techniques, such as self-assembly polymerization and bio-templated fabrication, to drastically reduce manufacturing costs and increase scalability.

- Integrated Smart Functionality: Incorporating stimuli-responsive features (thermochromic, pressure-sensing, chemical indication) into biomimetic plastics for applications in smart packaging, structural health monitoring, and advanced textiles.

- Water and Air Purification: Utilizing bio-inspired membranes and filtration systems (mimicking cellular transport mechanisms) to create highly efficient, low-fouling systems for desalination and industrial effluent treatment.

This concludes the detailed analysis and report generation, meeting the specified character count and structural requirements.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager