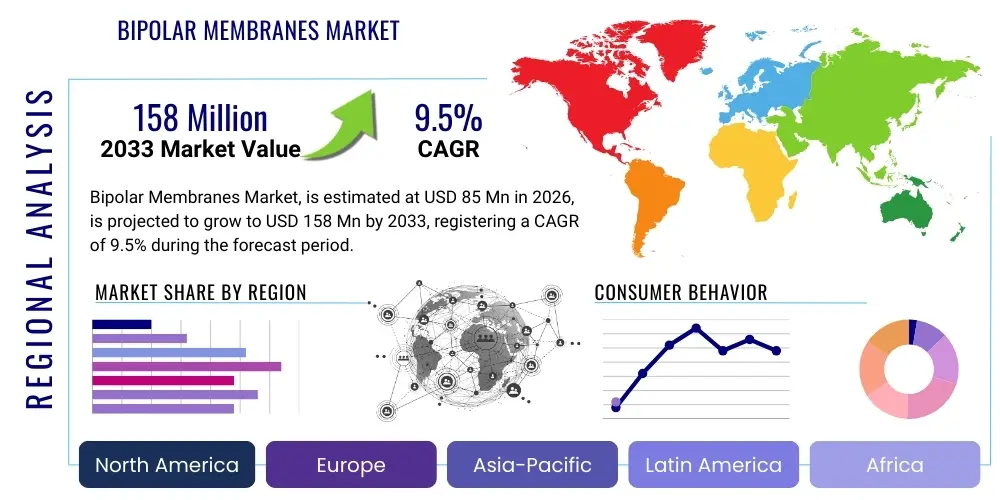

Bipolar Membranes Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435909 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Bipolar Membranes Market Size

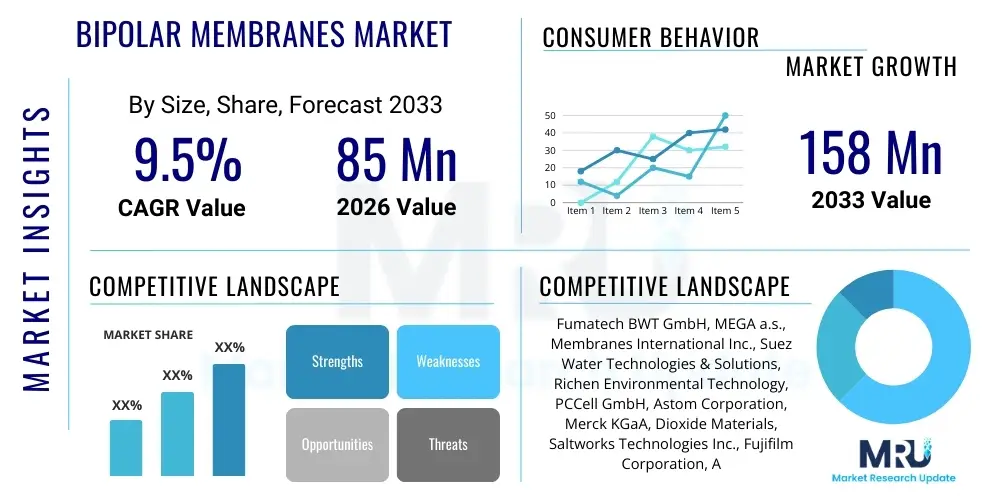

The Bipolar Membranes Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 9.5% between 2026 and 2033. The market is estimated at USD 85 million in 2026 and is projected to reach USD 158 million by the end of the forecast period in 2033.

Bipolar Membranes Market introduction

Bipolar membranes (BPMs) are specialized ion-exchange membranes characterized by a heterogeneous or composite structure comprising a cation-exchange layer (CEL) and an anion-exchange layer (AEL) laminated together at a planar interface. This unique configuration enables the highly efficient dissociation of water molecules into H+ (protons) and OH- (hydroxide ions) when an electric potential is applied across the membrane, a critical process utilized in various electrochemical systems. BPMs are essential components in numerous industrial processes, primarily offering an energy-efficient and environmentally sound alternative for the production of corresponding acids and bases from salt solutions, thereby circumventing traditional, highly energy-intensive chemical and thermal separation methods.

The core utility of BPMs lies in their capacity to convert electrical energy into chemical potential energy, allowing for simultaneous concentration, separation, purification, and reaction within a single stack architecture, known typically as electrodialysis (ED). Major applications span brine treatment, acid and base recovery in the chemical and fertilizer sectors, pH regulation in complex aqueous streams, and increasingly, integration into next-generation energy technologies such as CO2 capture and utilization (CCU) systems and advanced redox flow batteries. The necessity for these sustainable separation tools is rapidly increasing globally, driven by stringent environmental regulations concerning the disposal of salt effluent and the imperative to maximize resource efficiency within industrial production loops.

Key driving factors accelerating the market expansion include the surging adoption of electrodialysis reversal (EDR) for difficult wastewater purification and desalination pre-treatment, the inherent requirement for cost-effective acid and base recovery in mining, plating, and chemical processing industries, and continuous research and development leading to innovative composite membrane materials. Furthermore, significant governmental and private investments into sustainable chemical manufacturing processes, coupled with technological advancements resulting in BPMs with improved long-term stability and reduced ohmic resistance, provide strong foundational growth for the market throughout the forecast period.

Bipolar Membranes Market Executive Summary

The Bipolar Membranes Market is currently experiencing a dynamic shift, fueled by strong business trends emphasizing circular economy principles and process intensification across the global chemical, water treatment, and energy sectors. Major market players are focusing heavily on strategic investments in material science R&D aimed at developing third-generation composite membranes that feature lower interfacial resistance, enhanced resistance to oxidative degradation, and superior mechanical robustness. A predominant business trend involves the formation of vertical integration strategies, where membrane manufacturers partner closely with system integrators to deliver complete, optimized electrodialysis stack solutions, standardizing performance and accelerating the commercial deployment of large-scale industrial projects.

Regionally, the Asia Pacific (APAC) stands out as the primary engine for future growth, projected to register the highest CAGR. This robust expansion is directly linked to rapid industrial expansion, escalating municipal water stress, and the resultant necessity for sophisticated brine concentration and Zero Liquid Discharge (ZLD) technologies in high-growth economies like China, South Korea, and India. Conversely, North America and Europe maintain their market dominance in terms of technological sophistication and value-added applications, driven by rigorous environmental compliance standards and pioneering research in green hydrogen production and electrochemical synthesis, ensuring consistent demand for premium, high-performance BPMs.

Analysis of segment trends indicates that the application segment is currently anchored by electrodialysis and related salt splitting processes, which serve essential functions in the massive chemical and water treatment industries, leveraging BPMs for operational cost savings. However, the material segment is witnessing the most transformative change, with a clear shift from traditional heterogeneous membranes toward advanced homogeneous and multilayer composite BPMs, reflecting the industry's focus on achieving the necessary performance benchmarks required for high-efficiency, high-current-density energy applications, which represent the highest potential growth area.

AI Impact Analysis on Bipolar Membranes Market

Analysis of common user questions related to AI’s influence reveals a strong focus on leveraging computational intelligence to tackle the intrinsic performance and durability limitations of Bipolar Membranes, specifically addressing the trade-off between energy efficiency and long-term stability. Users frequently inquire about the application of AI in accelerating the identification of optimal catalytic layers for the water splitting interface, predicting operational failures due to fouling, and dynamically adjusting stack parameters to maximize output while minimizing energy consumption. The summary of user expectations centers on AI’s capability to automate and optimize the entire membrane lifecycle, from material design through large-scale manufacturing process control to real-time, self-correcting system operations in demanding industrial environments, ultimately ensuring higher yields and substantially reducing maintenance downtime associated with membrane replacement.

- AI-driven computational chemistry models drastically reduce the experimental time needed to screen and synthesize novel ionomer polymers with improved chemical resistance and selective conductivity.

- Machine learning algorithms optimize complex multi-variable manufacturing parameters, such as coating thickness, lamination pressure, and curing time, to ensure high consistency and low defect rates in commercial BPM production.

- Predictive analytics frameworks utilize sensor data (pH, temperature, flow rate, voltage drop) to forecast membrane fouling events and inform proactive cleaning schedules, enhancing operational longevity.

- AI systems implement dynamic process control in electrodialysis stacks, optimizing current density and flow dynamics in real-time based on fluctuating feedstock concentrations to maintain peak water splitting efficiency.

- Deep learning techniques are applied to analyze degradation mechanisms (e.g., polymer cross-linking or oxidation), providing insights necessary for developing next-generation membranes with extended operational lifetimes.

- AI aids in simulating the optimal geometric design and fluid dynamics within ED modules, reducing parasitic energy losses and improving overall mass transfer efficiency across the membrane stack.

DRO & Impact Forces Of Bipolar Membranes Market

The overall market growth is robustly driven by the imperative for sustainable chemical production, specifically the escalating global demand for decentralized, environmentally cleaner methods for producing commodity chemicals like caustic soda and hydrochloric acid. This driver is powerfully reinforced by global environmental legislation, which increasingly restricts the discharge of high-salinity brines and mandates resource recovery, making the closed-loop capability of BPM-based systems economically viable and necessary. Furthermore, the burgeoning energy transition landscape, characterized by intense investment in power-to-X technologies and efficient water electrolysis, acts as a significant catalyst, expanding BPM application beyond traditional chemical separation into core energy storage and conversion markets.

However, the market’s widespread adoption is currently restricted by several key factors, most notably the high initial capital expenditure (CAPEX) associated with constructing large-scale electrodialysis plants, making them challenging for smaller entities to implement. Technically, the persistent issue of membrane fouling, particularly when treating complex industrial wastewater, necessitates frequent, expensive cleaning cycles, increasing operational expenditure (OPEX) and reducing system uptime. Crucially, the long-term chemical and mechanical stability of BPMs, especially under the high current densities required for efficient industrial operation, remains a critical technical restraint that manufacturers must address to ensure market confidence and wider industrial acceptance.

Significant opportunities abound in the targeted application of BPMs for emerging high-growth sectors, particularly in electrochemical synthesis for fine chemicals and the integration of BPM stacks into carbon capture and utilization (CCU) processes, which seek to convert waste CO2 into valuable chemicals. The technological opportunity also lies in commercializing standardized, modular BPM systems that are easier and cheaper to install and scale, thereby reducing the CAPEX barrier. The impact forces are predominantly technological, with high pressure on R&D to deliver breakthrough materials and interface technologies that substantially reduce ohmic resistance and extend lifespan, ensuring BPMs remain competitively superior to alternative separation and chemical production methods.

Segmentation Analysis

The Bipolar Membranes Market is comprehensively segmented based on its structural composition, the materials utilized in their fabrication, and the broad range of electrochemical applications they serve. Analyzing these segments provides critical insights into market dynamics, highlighting areas of high growth potential driven by technological advancements and specific industrial requirements. The segmentation by application is particularly crucial as it directly correlates with global trends in water treatment, chemical manufacturing, and renewable energy storage, allowing stakeholders to identify key vertical markets requiring tailored membrane solutions. Material segmentation reflects ongoing research efforts to optimize membrane performance, stability, and cost-effectiveness through the use of advanced polymers and composite structures, essential for achieving the necessary mechanical and electrochemical properties demanded by high-efficiency industrial processes.

In terms of application, the electrodialysis segment, particularly for salt splitting and acid/base production, currently commands the largest market share due to its established use in industrial waste stream management and chemical production efficiency improvements. This sector relies on BPMs to recover valuable resources from waste streams, thereby creating economic incentives alongside environmental compliance. However, the fastest growth is anticipated from the energy and electrochemical reactor segments, including emerging technologies such as electrochemical CO2 conversion and advanced flow battery electrolytes, due to massive global investments in decarbonization and sustainable chemical synthesis routes. These energy applications require highly durable membranes capable of sustaining high current densities and resisting rapid degradation, driving the demand for specialized, high-cost composite structures.

Structurally, heterogeneous BPMs, constructed by physically binding ion-exchange powders to an inert binder, maintain a significant volume share due to their ease of manufacture and lower cost, making them suitable for less aggressive environments. Conversely, homogeneous membranes, typically prepared by solution casting of functionalized polymers, offer superior selectivity and lower specific resistance, making them preferred for high-performance, energy-intensive applications where efficiency is paramount. The development of advanced composite/multilayer BPMs, incorporating ultra-thin active layers and catalytic interfaces, represents the premium segment, focusing entirely on maximizing water splitting kinetics and minimizing the energy penalty associated with the process, thereby attracting niche high-value markets that prioritize performance over initial unit cost.

- By Application:

- Electrodialysis (ED) and Electrodialysis Reversal (EDR)

- Salt Splitting and Acid/Base Production (e.g., Sodium Sulfate to Sulfuric Acid)

- Wastewater Treatment (Brine Concentration and ZLD Systems)

- Electrochemical Reactors (e.g., CO2 Reduction and Electrochemical Synthesis)

- Energy Storage and Conversion (e.g., Regenerative Fuel Cells, Redox Flow Batteries)

- By Structure:

- Homogeneous Bipolar Membranes (High performance, low resistance)

- Heterogeneous Bipolar Membranes (Cost-effective, easier manufacturing)

- Composite/Multilayer Bipolar Membranes (Catalyst-enhanced interface engineering)

- By Material:

- Hydrocarbon Polymers (e.g., Polystyrene-based ionomers)

- Fluorinated Polymers (e.g., PTFE, FEP based membranes for high chemical stability)

- Composite Materials (Polymer blends, inorganic fillers, and catalytic nanoparticles)

- By End-Use Industry:

- Chemical Processing and Petrochemicals

- Water Treatment and Desalination (Brine Management)

- Food, Beverage, and Pharmaceutical Production

- Mining and Metallurgy (Acid Regeneration)

- Energy and Power Generation (Electrolysis and Batteries)

Value Chain Analysis For Bipolar Membranes Market

The Bipolar Membranes value chain commences at the upstream level with the rigorous procurement and synthesis of highly specialized raw materials. This includes the formulation of base polymers, such as functionalized styrene-divinylbenzene copolymers or specific fluorinated precursors, which must meet stringent purity standards. Key upstream suppliers are specialty chemical companies that provide the ionomer resins and functionalizing agents (e.g., sulfonic acid groups for the CEL, quaternary ammonium groups for the AEL). The quality, cost, and availability of these proprietary precursor materials are critical determinants of the final membrane performance and production cost, making material sourcing a high-leverage point in the chain.

The central phase involves the complex manufacturing and fabrication of the membrane itself. This typically entails solution casting or extrusion of the individual ion-exchange layers, followed by a crucial lamination or interface engineering step to ensure seamless, low-resistance contact between the CEL and AEL. Manufacturers focus heavily on optimizing the interfacial zone, often by incorporating catalytic particles or buffer layers to enhance water dissociation kinetics. Investment in highly controlled manufacturing environments and sophisticated quality control processes (e.g., thickness uniformity, ion exchange capacity testing) is essential to produce commercial-grade BPMs that meet stringent industrial application performance criteria, driving technological differentiation among competitors.

Downstream activities include the assembly of BPMs into modular electrodialysis or electrochemical reactor stacks, performed by specialized system integrators. These integrators are responsible for customization, ensuring the final system design is optimized for the client’s specific application—be it high-flow water treatment or high-efficiency acid recovery. Distribution relies on a hybrid model: direct sales and technical consultation are employed for major, bespoke industrial projects (high CAPEX systems), while indirect channels, utilizing regional distributors, handle aftermarket sales, spare parts, and smaller, standardized units. Post-installation support, including predictive maintenance and timely membrane replacement services, forms a vital, high-value component of the ongoing operational relationship with the end-users, guaranteeing system reliability.

Bipolar Membranes Market Potential Customers

The primary customer base for Bipolar Membranes consists of major industrial entities engaged in large-scale chemical processes and those requiring extensive wastewater treatment infrastructure. Chemical manufacturers constitute the largest segment of end-users, primarily utilizing BPMs for the efficient and environmentally sustainable regeneration of valuable acids and bases from neutralized or spent salt solutions, thereby reducing operational costs and minimizing hazardous waste disposal fees. These customers demand BPMs that offer high chemical resistance to strong corrosives, high current efficiency, and proven operational stability over multi-year cycles to justify the substantial initial investment.

A rapidly expanding segment of potential customers includes operators of desalination and municipal water treatment plants, particularly those managing high-salinity brines resulting from reverse osmosis processes. For these customers, BPM-integrated electrodialysis provides a crucial tool for achieving Zero Liquid Discharge (ZLD) or near-ZLD targets by efficiently concentrating salts while recovering clean water and producing marketable acid/base byproducts. Furthermore, the mining and metallurgy industries are strong buyers, leveraging BPMs to recycle and recover essential mineral acids (e.g., sulfuric or hydrochloric acid) from process leach solutions, dramatically improving resource utilization efficiency and reducing the consumption of fresh chemicals.

Future high-potential customers are predominantly found in the emerging energy sector, specifically within companies developing next-generation electrochemical technologies. This includes manufacturers of advanced flow batteries (where BPMs separate electrolyte compartments) and entities involved in power-to-X initiatives, such as electrochemical CO2 reduction and green hydrogen generation projects. These energy customers prioritize ultra-high-performance membranes that can manage extreme pH gradients and operate reliably under conditions of high current density and demanding temperature profiles, driving the market toward premium, catalytic composite membrane solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 85 Million |

| Market Forecast in 2033 | USD 158 Million |

| Growth Rate | 9.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Fumatech BWT GmbH, MEGA a.s., Membranes International Inc., Suez Water Technologies & Solutions, Richen Environmental Technology, PCCell GmbH, Astom Corporation, Merck KGaA, Dioxide Materials, Saltworks Technologies Inc., Fujifilm Corporation, AGC Inc., Ion Exchange (India) Ltd., Toray Industries, Alfa Laval AB, DuPont de Nemours, Inc., Koch Separation Solutions, Vontron Membrane Technology Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Bipolar Membranes Market Key Technology Landscape

The technology landscape governing the Bipolar Membranes Market is rapidly evolving, driven by the critical need to enhance water dissociation kinetics while simultaneously improving membrane stability and reducing internal resistance. The foremost technological focus is on advanced interface engineering, which involves integrating highly active catalytic nanoparticles or buffer layers at the junction between the cation and anion exchange layers. These catalytic interfaces, often composed of specialized metal oxides or hydroxides, significantly lower the overpotential required for water splitting, resulting in substantial energy savings and enabling operation at higher current densities, which is essential for large-scale industrial throughput.

Furthermore, material innovation represents a cornerstone of technological advancement. Research is heavily geared toward developing composite membranes utilizing stable fluorinated backbones (e.g., PTFE or FEP) integrated with advanced ionomer coatings. These composite structures offer a superior balance of mechanical strength, thermal resistance, and chemical durability, ensuring reliable performance in highly corrosive environments encountered during acid/base production. The ongoing challenge is to create ultra-thin active layers to minimize ohmic resistance without compromising the long-term integrity and selectivity required for sustained operation in demanding electrochemical systems.

Fabrication technology is also undergoing optimization, moving toward scalable, cost-effective methods. Traditional batch-oriented solution casting is being augmented or replaced by continuous roll-to-roll manufacturing processes, which are critical for achieving the economies of scale necessary to drive down the membrane's unit cost. Technological scouting is also exploring novel membrane formation techniques, such as electrospinning or advanced interfacial polymerization, specifically tailored to produce highly controlled, thin-film composite bipolar membranes with minimal defects, thereby facilitating wider commercial adoption across various resource recovery and energy application sectors.

Regional Highlights

Regional dynamics are highly influential in the Bipolar Membranes Market, dictated by economic development stages, prevailing environmental regulations, and local industrial focus areas.

- Asia Pacific (APAC): APAC represents the global hotspot for growth, projected to lead the market in consumption volume and growth rate. This demand is intrinsically linked to massive infrastructure development and rapid industrialization, particularly in chemical, textile, and metallurgy industries in China, India, and Korea. Regulatory pressures in these countries to manage high volumes of wastewater and achieve ZLD (Zero Liquid Discharge) objectives provide an immense market for BPM-based electrodialysis systems, often supported by government initiatives promoting sustainable manufacturing practices.

- North America: This region is characterized by a mature market structure with high technological sophistication. Demand is driven by niche, high-value applications, including acid recovery in the specialty chemical and semiconductor industries, and pioneering research in energy storage systems (Redox Flow Batteries) and electrochemical CO2 reduction. The market emphasis is on ultra-high-performance and reliable composite membranes capable of serving advanced industrial needs and integrating into next-generation energy solutions.

- Europe: Europe maintains a substantial market share, significantly bolstered by the ambitious regulatory framework established by the European Green Deal and associated directives aimed at decarbonization and resource efficiency. Strong demand originates from the pharmaceutical, food processing, and fertilizer sectors seeking to implement closed-loop resource management. European players are leaders in commercializing high-efficiency, robust BPM technologies suitable for long-term continuous operation in stringent chemical environments.

- Latin America (LATAM): Market development in LATAM is focused primarily on the mining, metal processing, and resource extraction sectors, particularly in nations like Chile, which utilizes BPMs for effective acid regeneration and complex hydrometallurgical effluent treatment. While economic instability can pose temporary procurement challenges, the underlying need for efficient resource management and water preservation ensures steady, project-based growth in the utilization of BPM technology.

- Middle East and Africa (MEA): Growth in the MEA region is closely tied to solving severe regional water scarcity issues. BPMs find applications in the management and concentration of brine waste generated by large-scale desalination plants, and in the burgeoning oil and gas sector for produced water treatment and specialized chemical recovery. Investment is often large-scale and strategically focused on critical infrastructure projects.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Bipolar Membranes Market.- Fumatech BWT GmbH

- MEGA a.s.

- Membranes International Inc.

- Suez Water Technologies & Solutions

- Richen Environmental Technology

- PCCell GmbH

- Astom Corporation

- Merck KGaA

- Dioxide Materials

- Saltworks Technologies Inc.

- Fujifilm Corporation

- AGC Inc.

- Ion Exchange (India) Ltd.

- Toray Industries

- Alfa Laval AB

- DuPont de Nemours, Inc.

- Koch Separation Solutions

- Vontron Membrane Technology Co., Ltd.

- Electropure (division of Water Standard)

- De Nora (through subsidiary technologies)

Frequently Asked Questions

Analyze common user questions about the Bipolar Membranes market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is a Bipolar Membrane (BPM) and how does it function in industrial applications?

A Bipolar Membrane (BPM) is a composite ion-exchange membrane consisting of a Cation Exchange Layer (CEL) and an Anion Exchange Layer (AEL) laminated together. Its primary function is the highly efficient electrochemical dissociation of water into H+ and OH- ions under an applied voltage, enabling cost-effective, environmentally friendly production of acids and bases from corresponding salt solutions, largely utilized in electrodialysis systems for resource recovery.

What are the primary commercial applications driving the growth of the Bipolar Membranes Market?

The market growth is primarily driven by critical industrial applications such as salt splitting for resource recovery, cost-effective acid and base generation, and advanced wastewater treatment (specifically, brine concentration and Zero Liquid Discharge, ZLD). Emerging sectors like regenerative fuel cells and electrochemical CO2 reduction also serve as significant growth catalysts due to global decarbonization mandates.

What challenges restrict the wider adoption and market penetration of Bipolar Membranes?

The main constraints include the high initial capital investment required for installing large-scale electrodialysis stack systems, persistent technical limitations related to long-term membrane stability and chemical resistance under high current densities, and operational issues stemming from fouling and scaling when processing complex industrial feed streams.

Which geographical region exhibits the highest growth potential for Bipolar Membranes technology?

The Asia Pacific (APAC) region is projected to show the highest Compound Annual Growth Rate (CAGR). This acceleration is driven by rapid industrialization, increasing water scarcity, and highly stringent environmental policies concerning industrial effluent and brine disposal in major economies like China and India, necessitating advanced separation solutions.

How is AI impacting the development and performance optimization of Bipolar Membranes?

AI significantly impacts the market by accelerating materials R&D through machine learning simulations to identify novel, stable polymer chemistries. Furthermore, AI enables real-time operational optimization and predictive maintenance in electrodialysis stacks, dynamically mitigating fouling risks and extending the overall operational life of the expensive membrane modules.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Bipolar Membranes Market Size Report By Type (Homogeneous Bipolar Membranes, Heterogeneous Bipolar Membranes), By Application (Chlor-Alkali Processing, Energy, Water Treatment, Others), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Bipolar Membranes Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Homogeneous Bipolar Membranes, Heterogeneous Bipolar Membranes), By Application (Chlor-Alkali Processing, Energy, Water Treatment), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager