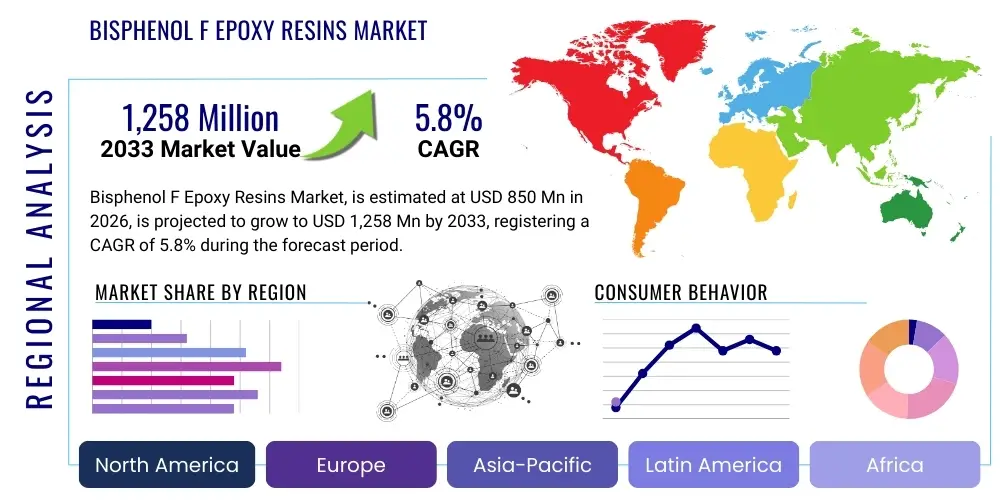

Bisphenol F Epoxy Resins Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438717 | Date : Dec, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Bisphenol F Epoxy Resins Market Size

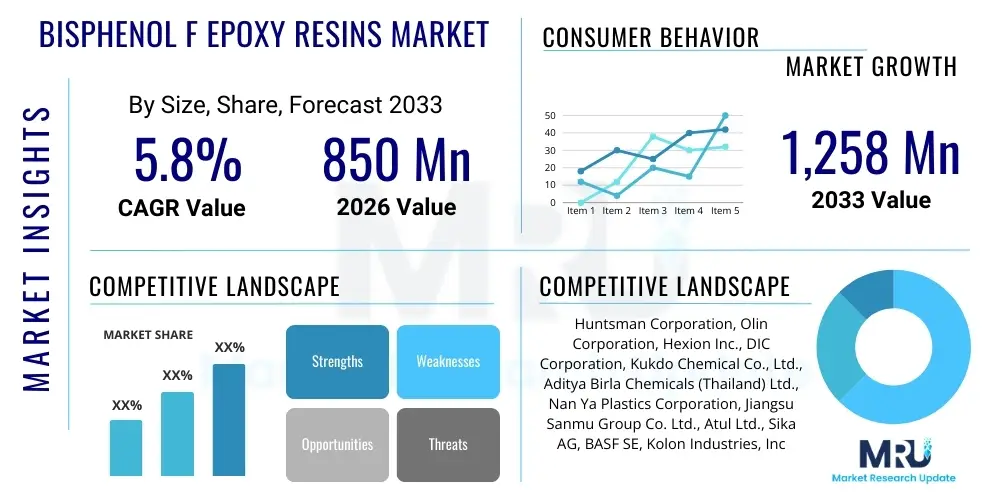

The Bisphenol F Epoxy Resins Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 850 Million in 2026 and is projected to reach USD 1,258 Million by the end of the forecast period in 2033.

Bisphenol F Epoxy Resins Market introduction

The Bisphenol F (BPF) Epoxy Resins Market encompasses highly specialized polyepoxide compounds derived from bisphenol F and epichlorohydrin. Unlike the standard Bisphenol A (BPA) resins, BPF resins possess a lower molecular weight, reduced viscosity, and higher functionality, making them indispensable in formulations requiring superior flow characteristics, solvent reduction, and enhanced chemical resistance. These attributes are critically important in high-performance applications such as protective coatings, especially for marine and industrial structures, civil engineering composites, and advanced electrical laminates. The inherent technical superiority of BPF resins drives their adoption where demanding environmental or operational conditions necessitate robust material performance, positioning them as a premium alternative in the broader epoxy market.

The product is fundamentally utilized across diverse industrial sectors due to its exceptional adhesion properties, thermal stability, and low crystallization tendency. Major applications include high-solids and solvent-free coatings, which are increasingly favored due to stringent volatile organic compound (VOC) regulations worldwide. Furthermore, BPF resins are key components in formulating composite materials for aerospace and automotive industries, where lightweight yet strong materials are required. The key benefits driving market growth include their faster curing cycles, improved resistance to solvents and acids, and the ability to be formulated into low-viscosity systems that facilitate easier handling and processing in manufacturing environments, contributing significantly to reduced production time and energy consumption.

Driving factors for the Bisphenol F Epoxy Resins Market growth primarily include the rapid expansion of infrastructure development and maintenance activities globally, particularly in Asia Pacific, necessitating high-performance anti-corrosion coatings. The increasing demand for safer, environmentally compliant coating systems, such as zero-VOC floor coatings and protective pipe linings, further stimulates BPF consumption. Additionally, the ongoing trend toward miniaturization and enhanced performance in the electronics sector, requiring high-grade encapsulants and laminating materials, solidifies the market's trajectory. However, the market must continuously navigate regulatory pressures concerning all bisphenol derivatives, although BPF is often utilized as a substitution for BPA in specific applications where regulatory advantages are sought.

Bisphenol F Epoxy Resins Market Executive Summary

The Bisphenol F Epoxy Resins Market demonstrates robust growth driven by accelerating demand for solvent-free and high-solids coating solutions across core industrial verticals including marine, oil and gas, and construction. Business trends indicate a strategic shift by major manufacturers toward expanding production capacity in Asia Pacific, particularly China and India, to capitalize on burgeoning infrastructural investments and lower operational costs. Key market players are heavily investing in product innovation focused on bio-based or functionalized BPF derivatives to improve sustainability profiles and meet evolving regulatory mandates, positioning product differentiation as a crucial competitive edge. The emphasis on high-throughput manufacturing processes utilizing BPF’s low viscosity attributes is redefining efficiency standards within the protective coatings value chain, compelling formulators to transition away from traditional, higher-viscosity resins.

Regional trends clearly highlight Asia Pacific as the dominant and fastest-growing region, fueled by massive government spending on infrastructure projects like bridges, pipelines, and renewable energy installations, which require specialized corrosion-resistant linings. North America and Europe, while mature markets, exhibit steady demand primarily due to stringent regulatory environments enforcing the use of VOC-compliant and high-durability coatings for aging infrastructure rehabilitation. European markets, in particular, show higher adoption rates for BPF resins in advanced composites and wind energy components, adhering to high technical specifications for structural integrity and longevity. The dynamic interplay between industrial development in emerging economies and regulatory-driven quality improvements in developed economies defines the regional growth landscape.

Segmentation trends reveal that the Coatings segment maintains the largest market share, driven by the exceptional anti-corrosive and barrier properties BPF resins provide in industrial maintenance and marine environments. The Composites segment, however, is forecast to exhibit the highest CAGR, primarily attributed to increasing consumption in wind turbine blades, high-performance aerospace components, and automotive lightweighting initiatives. Furthermore, demand for liquid BPF resins significantly outweighs solid resins due to their ease of incorporation into solvent-free systems and their inherent suitability for various application methods, including spraying and rolling. Manufacturers are increasingly focusing R&D efforts on tailored BPF resins specific to electrical and electronic encapsulations, catering to the rising complexities of high-density electronic circuits and insulation needs.

AI Impact Analysis on Bisphenol F Epoxy Resins Market

User inquiries regarding the intersection of AI and the Bisphenol F Epoxy Resins market commonly revolve around optimizing formulation complexity, predicting material performance under varied stresses, and enhancing supply chain efficiency. Key concerns include how AI can manage the subtle differences in resin batches, reduce formulation trial-and-error cycles for niche applications (like marine coatings exposed to extreme salinity), and forecast raw material price volatility (epichlorohydrin and bisphenol F). Users expect AI to accelerate the discovery of novel, potentially bio-derived BPF alternatives and to refine manufacturing parameters to achieve ultra-consistent quality required for demanding applications such as semiconductor encapsulation. The synthesized user concern centers on leveraging predictive analytics and machine learning to achieve unparalleled product consistency and cost-efficiency in a market defined by high specification requirements and raw material instability.

- AI-Driven Formulation Optimization: Machine learning algorithms rapidly test millions of potential resin-hardener-additive combinations, significantly reducing R&D time for specific performance criteria (e.g., curing time, chemical resistance).

- Predictive Quality Control (PQC): AI systems monitor production variables (temperature, pressure, mixing speed) in real-time, predicting potential defects or deviation in resin properties before they occur, ensuring batch-to-batch consistency essential for high-spec industrial use.

- Supply Chain and Inventory Management: Predictive analytics forecast demand fluctuations and optimize raw material procurement, mitigating risks associated with feedstock price volatility and logistical disruptions, specifically for key precursors like BPF monomer.

- Simulation of Material Performance: AI models simulate the aging process and performance of BPF coatings and composites under extreme conditions (e.g., UV exposure, thermal cycling, aggressive chemicals), accelerating product qualification without extensive physical testing.

- Accelerated Material Discovery: AI assists in screening potential novel, non-bisphenol-based alternatives or structurally modified BPF derivatives that retain performance characteristics but comply better with evolving sustainability regulations.

DRO & Impact Forces Of Bisphenol F Epoxy Resins Market

The market dynamics of Bisphenol F Epoxy Resins are shaped by a strong combination of demand-side drivers, stringent health-related restraints, and significant opportunities arising from technological shifts and regulatory demands for sustainability. The primary driver is the accelerating global need for high-performance protective coatings, particularly in the oil and gas sector and maritime industry, where BPF resins offer superior corrosion protection and durability compared to standard epoxies. However, the market faces persistent scrutiny due to health and safety concerns surrounding all bisphenol compounds, leading to continuous regulatory pressure and necessitating substantial investment in toxicology research and formulation adjustments to ensure compliance. The overarching impact forces include regulatory intervention and technological advancements which constantly push manufacturers toward cleaner production methods and safer material profiles.

Key restraining factors include the relatively higher cost of BPF monomers compared to the ubiquitous BPA, limiting its adoption in cost-sensitive, low-end applications. Furthermore, the volatility in raw material pricing, particularly for epichlorohydrin, subjects manufacturers to unpredictable fluctuations in operational costs, thereby pressuring profit margins and supply chain stability. Despite these challenges, significant growth opportunities are emerging from the shift toward advanced composites in the automotive and aerospace industries seeking lightweighting solutions, utilizing BPF’s excellent mechanical properties. Additionally, the development of solvent-free and low-VOC compliant systems, enabled by the low viscosity of BPF resins, represents a substantial market opportunity, aligning with global environmental governance trends.

The market’s overall trajectory is defined by the critical need to balance high-performance expectations against environmental stewardship. The increasing regulatory pressure on VOC emissions acts as an indirect driver for BPF resins used in high-solids formulations, transforming a restraint (regulatory scrutiny of bisphenols) into an opportunity (preference for BPF due to low-viscosity VOC compliance). The impact forces of innovation are evident in the continuous efforts to synthesize non-toxic, structurally similar polyepoxides and to integrate them seamlessly into existing application infrastructure. Ultimately, the market growth will be dictated by the industry’s ability to effectively address perceived toxicological risks while maintaining the superior technical performance that BPF is renowned for in critical infrastructure protection.

Segmentation Analysis

The Bisphenol F Epoxy Resins market is systematically segmented based on their physical form, primary application area, and the end-use industry that dictates material specifications. This granular segmentation provides a clear understanding of the diverse consumer needs, ranging from large-scale infrastructure projects requiring bulk liquid resins for corrosion protection to highly specialized electronic manufacturers demanding solid BPF forms for encapsulation and insulation. The segmentation based on form—liquid versus solid—is critical, as liquid BPF dominates due to its ease of handling in high-solids systems, while solid BPF caters to powder coatings and certain electrical applications where low melt viscosity is essential. Application categories, such as coatings, adhesives, and composites, reflect the functional properties of the resin, with coatings being the volume driver due to heavy industrial maintenance demand globally.

End-use segmentation highlights the critical dependency of the BPF market on robust industrial sectors. Marine and construction constitute the largest consumer base, utilizing BPF resins extensively for their superior moisture and saltwater resistance in ship hulls, offshore platforms, and protective concrete coatings. The electronics and electrical sector, though smaller in volume, demands the highest purity and specialized forms of BPF for insulation materials, circuit boards, and casting compounds, often requiring tightly controlled material specifications. Furthermore, the burgeoning wind energy sector, categorized within the Composites end-use, is rapidly expanding its consumption of BPF resins for lightweight, fatigue-resistant blade manufacturing, signaling a crucial area of future growth and technical evolution within the market landscape.

- By Form:

- Liquid Bisphenol F Epoxy Resins

- Solid Bisphenol F Epoxy Resins

- By Application:

- Coatings (Protective, Marine, Automotive, Industrial Maintenance)

- Adhesives

- Composites (Aerospace, Wind Energy, General Composites)

- Electrical and Electronics Encapsulation

- Casting and Tooling

- By End-Use Industry:

- Construction

- Marine

- Automotive

- Oil and Gas

- Electrical and Electronics

- Aerospace

Value Chain Analysis For Bisphenol F Epoxy Resins Market

The value chain for Bisphenol F Epoxy Resins commences with the upstream extraction and synthesis of key petrochemical precursors: Bisphenol F (BPF monomer) and Epichlorohydrin (ECH). This stage is characterized by high capital intensity and dependency on fluctuating crude oil prices, dictating the ultimate cost structure of the final resin. Manufacturers involved in the intermediate processing stage convert these raw materials into functional liquid or solid BPF epoxy resins through controlled polymerization and condensation reactions. The quality and consistency of these input materials directly impact the performance attributes (such as viscosity and epoxy equivalent weight) of the final product, demanding stringent supplier qualification and feedstock management to ensure high-grade resin output suitable for demanding industrial applications like aerospace composites and marine coatings.

The midstream involves the formulation and modification of the base resin by specialist formulators who incorporate hardeners, accelerators, fillers, and performance additives to create specific end-use products, such as high-solids coating kits or advanced composite prepregs. This formulation expertise adds significant value, tailoring the BPF resin system to precise specifications required by diverse industries (e.g., fast cure for adhesives, superior chemical resistance for tank linings). Distribution channels play a critical role in connecting manufacturers and formulators to the downstream end-users. Direct distribution is common for high-volume sales to major industrial consumers (like shipyards or large construction firms), ensuring technical support and tailored logistics. Indirect distribution, leveraging specialized chemical distributors, is essential for reaching smaller formulators and regional end-users, providing inventory management and localized technical service.

Downstream utilization primarily involves professional applicators and component manufacturers in sectors like infrastructure, automotive, and electronics. For instance, contractors apply BPF-based protective coatings to pipelines and bridges, while composite manufacturers integrate BPF resins into matrix materials for structural parts. The performance feedback loop is vital in the downstream stage, as real-world performance data guides upstream product improvements and formulation adjustments. The increasing regulatory emphasis on sustainability also pressures the entire chain, driving demand for BPF produced through greener processes and formulated into low-VOC systems. The efficiency of the entire value chain is optimized through robust supply agreements and deep technical collaboration between resin producers and major formulators.

Bisphenol F Epoxy Resins Market Potential Customers

Potential customers for Bisphenol F Epoxy Resins are highly specialized entities operating in environments requiring materials with exceptional durability, adhesion, and chemical resistance, far surpassing the capabilities of general-purpose resins. These end-users are typically large industrial consumers or specialized manufacturing firms focused on capital goods and critical infrastructure. The primary buyer segments include industrial coating applicators specializing in heavy-duty corrosion protection for marine vessels, offshore oil platforms, chemical storage tanks, and wastewater treatment facilities, where the low water absorption and high barrier properties of BPF resins are mandatory. These buyers often prioritize long-term performance and lifecycle cost reduction over initial material expenditure, positioning BPF as a premium, value-added solution.

A second major category comprises manufacturers in the electrical and electronics sector, particularly those producing high-performance circuit boards, specialized insulation varnishes, and encapsulation compounds for sensitive electronic components, where BPF's low ionic contamination and excellent thermal stability are crucial. These customers seek highly consistent, ultra-pure resins that guarantee reliable electrical performance under continuous operational stresses. Furthermore, the composites industry, including aerospace component suppliers and wind turbine blade manufacturers, represents a rapidly growing customer base. These firms leverage BPF resins for their ability to be processed into high-strength, lightweight composite structures with superior fatigue resistance, supporting demanding applications in structural components where material failure is unacceptable.

In summary, the key buyers are typically organizations with rigorous quality control standards and certifications (e.g., ISO, API, NACE) that require material traceability and proven performance. They include major shipbuilding and repair yards, infrastructure construction companies (bridges, tunnels), automotive parts suppliers focused on electric vehicle components, and large-scale industrial maintenance service providers. Their purchasing decisions are driven by technical specifications, compliance with environmental regulations (specifically VOC reduction), and the proven reliability of the resin system to extend the service life of high-value assets, making BPF an investment rather than a commodity purchase.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 850 Million |

| Market Forecast in 2033 | USD 1,258 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Huntsman Corporation, Olin Corporation, Hexion Inc., DIC Corporation, Kukdo Chemical Co., Ltd., Aditya Birla Chemicals (Thailand) Ltd., Nan Ya Plastics Corporation, Jiangsu Sanmu Group Co. Ltd., Atul Ltd., Sika AG, BASF SE, Kolon Industries, Inc., Chang Chun Group, Sinopec Baling Company, Cardolite Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Bisphenol F Epoxy Resins Market Key Technology Landscape

The technological landscape of the Bisphenol F Epoxy Resins market is characterized by continuous efforts to enhance purity, modify resin structure for targeted performance, and develop safer, more efficient synthesis routes. A primary technological focus is on optimizing the polycondensation reaction between Bisphenol F and Epichlorohydrin to yield resins with ultra-low viscosity and tightly controlled molecular weight distribution, which is essential for achieving high-solids formulations that minimize VOC content. Advanced manufacturing techniques, including continuous processing and sophisticated purification methods (like thin-film evaporation), are being deployed to eliminate impurities and ensure the high batch-to-batch consistency demanded by critical end-use sectors such as electronics and aerospace, where minor variations can lead to structural failure.

Another crucial area of innovation involves the development of specialized grades, such as brominated BPF epoxies for flame retardancy in electrical laminates, and functionalized BPF resins modified with rubber or specialized polyamines to enhance toughness, flexibility, and resistance to thermal shock. Formulators are heavily investing in incorporating reactive diluents and advanced hardener technologies, moving beyond conventional amines to use novel anhydride or mercaptan systems, which enable fast cure rates even at ambient temperatures without compromising the superior mechanical properties intrinsic to BPF structures. This innovation is critical for expanding BPF applicability in field-applied coatings and rapid repair systems, directly challenging the use of solvents.

Furthermore, sustainability is driving technological shifts toward bio-based or alternative feedstocks. While direct bio-BPF synthesis is challenging, research is focused on utilizing renewable resources to synthesize bio-based curing agents and diluents compatible with standard BPF resins, effectively lowering the overall carbon footprint of the formulated product. Process intensification technologies, aimed at reducing energy consumption and waste generation during the manufacturing of BPF and its precursors, are also gaining traction. The integration of advanced computational fluid dynamics (CFD) modeling helps optimize reactor design and process conditions, maximizing yield and purity while minimizing environmental impact, ensuring the technology remains competitive against other resin chemistries.

Regional Highlights

The Asia Pacific (APAC) region stands out as the predominant market for Bisphenol F Epoxy Resins, demonstrating both the largest consumption volume and the highest projected growth rate throughout the forecast period. This dominance is intrinsically linked to the immense scale of ongoing infrastructure development across nations like China, India, and Southeast Asian countries, requiring vast quantities of durable protective coatings for new ports, pipelines, highways, and industrial facilities. The rapidly expanding manufacturing base in these regions, particularly in electronics and automotive production (including electric vehicle components), further necessitates the specialized low-viscosity, high-performance characteristics offered by BPF resins for encapsulation and lightweight composites. While regulatory enforcement regarding VOC limits is increasing, the sheer volume of new construction projects ensures APAC remains the global epicenter of BPF resin demand.

Europe and North America represent mature markets characterized by stable, high-value consumption driven primarily by infrastructure maintenance and stringent environmental regulations. In Europe, the market growth is underpinned by the advanced manufacturing sectors, notably aerospace and the robust wind energy industry, which utilizes BPF resins for highly resilient composite structures. Strict EU directives necessitate the use of low-VOC and solvent-free coating systems, making BPF’s low viscosity an ideal property for compliance in industrial floor coatings and anticorrosive treatments for aging civil assets. North America exhibits strong demand in the oil and gas sector for internal pipe linings and marine coatings, coupled with significant use in the electrical segment due to high quality and safety standards.

Latin America (LATAM) and the Middle East & Africa (MEA) are emerging regions that show promising growth, particularly in specific market niches. MEA’s demand is heavily concentrated in the oil and gas sector, driven by massive investments in new exploration and refining infrastructure requiring premium corrosion protection against harsh desert and marine conditions. LATAM’s growth is more localized, linked to specific large-scale infrastructure and mining projects where robust coating solutions are essential. Consumption in these regions is sensitive to global commodity prices and localized industrial policies, but the specialized nature of BPF resins ensures sustained demand where standard epoxy performance is insufficient, particularly for aggressive chemical resistance requirements.

- Asia Pacific (APAC): Dominant market volume and highest growth CAGR, driven by vast infrastructure development, expanding electronics manufacturing, and significant marine industrial activity. Key countries include China, India, and South Korea.

- Europe: Mature market focused on high-specification applications, leading regulatory compliance in VOC reduction, strong uptake in wind energy composites, and advanced aerospace components. Germany, France, and Italy are major consumers.

- North America: Stable demand fueled by aging infrastructure rehabilitation, substantial use in the protective coatings for the oil and gas industry, and strict quality requirements in electrical and electronic encapsulation.

- Middle East & Africa (MEA): Growth concentrated in high-performance coatings for the petrochemical and maritime industries, driven by large-scale capital projects related to energy export infrastructure.

- Latin America (LATAM): Emerging market potential linked to specific large-scale mining operations and regional infrastructure projects requiring superior corrosion resistance in diverse climatic zones.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Bisphenol F Epoxy Resins Market.- Huntsman Corporation

- Olin Corporation

- Hexion Inc.

- DIC Corporation

- Kukdo Chemical Co., Ltd.

- Aditya Birla Chemicals (Thailand) Ltd.

- Nan Ya Plastics Corporation

- Jiangsu Sanmu Group Co. Ltd.

- Atul Ltd.

- Sika AG

- BASF SE

- Kolon Industries, Inc.

- Chang Chun Group

- Sinopec Baling Company

- Cardolite Corporation

- Momentive Performance Materials Inc.

- Evonik Industries AG

- The Dow Chemical Company

- Allnex Group

- Wuxi Bright Chemical Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Bisphenol F Epoxy Resins market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary performance advantages of Bisphenol F Epoxy Resins over standard Bisphenol A (BPA) resins?

BPF epoxy resins offer significantly lower viscosity, which facilitates the formulation of high-solids and solvent-free coatings (reducing VOCs). They also provide enhanced chemical resistance, superior flexibility, and better performance in low-temperature curing applications, making them ideal for specialized protective coatings and electrical insulation.

Which end-use industry drives the highest demand volume for Bisphenol F Epoxy Resins?

The Coatings segment, particularly industrial maintenance, marine, and protective coatings (for infrastructure and oil/gas pipelines), accounts for the largest demand volume, driven by BPF's exceptional anticorrosive barrier properties against harsh environments.

How does global regulation concerning bisphenols impact the Bisphenol F Epoxy Resins market growth?

While BPF faces regulatory scrutiny similar to other bisphenols, its low-viscosity property enables compliance with stricter environmental regulations (such as VOC limits) in coatings. Increased health concerns around BPA sometimes prompt substitution toward BPF in specific applications, acting as a complex, dual-sided market driver.

Which geographical region is projected to experience the fastest growth rate in the BPF Epoxy Resins market?

Asia Pacific (APAC) is projected to exhibit the fastest growth, primarily due to large-scale government investment in infrastructure (bridges, ports), rapid industrial expansion, and the accelerating development of the regional electronics and automotive manufacturing sectors.

What is the current technological trend concerning the development of BPF epoxy resins?

Current technological trends focus on developing ultra-low viscosity grades for zero-VOC formulations, enhancing the resin purity for electronics applications, and integrating bio-based hardeners and modifiers to improve sustainability and compliance with environmental standards.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Bisphenol F Epoxy Resins Market Size Report By Type (Low Viscosity Bisphenol F Epoxy Resins, Medium Viscosity Bisphenol F Epoxy Resins, High Viscosity Bisphenol F Epoxy Resins), By Application (Coating, Adhesives, Composite Materials, Electrical Insulating Material, Others), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Bisphenol F Epoxy Resins Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Low Viscosity Bisphenol F Epoxy Resins, Medium Viscosity Bisphenol F Epoxy Resins, High Viscosity Bisphenol F Epoxy Resins), By Application (Coatings & Paints, Inks, Adhesives, Ceramics, Textiles, Electric & Electronics, Others), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager