Blanket Aerogel Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440677 | Date : Jan, 2026 | Pages : 245 | Region : Global | Publisher : MRU

Blanket Aerogel Market Size

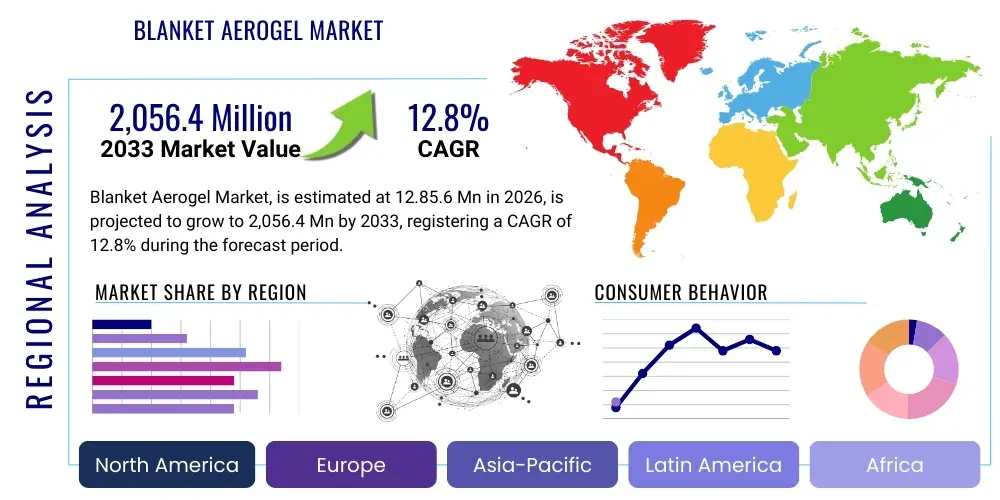

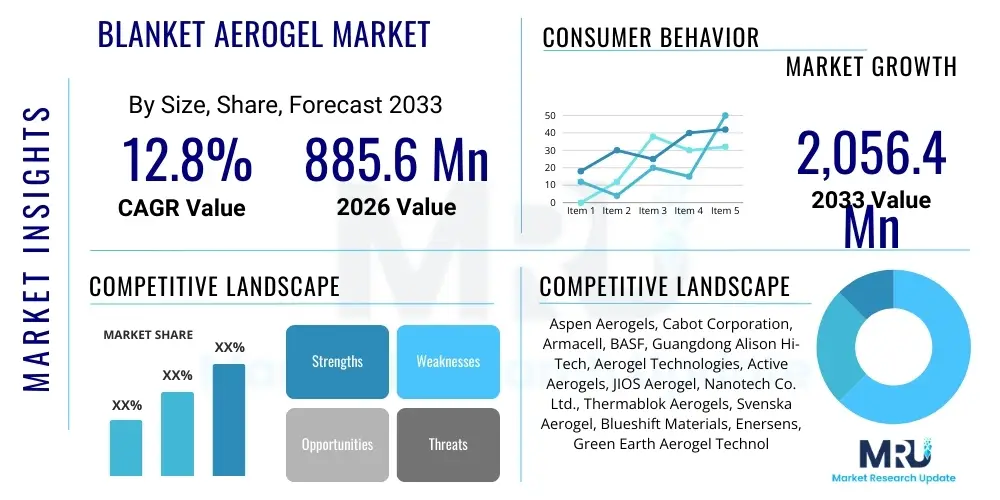

The Blanket Aerogel Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 12.8% between 2026 and 2033. The market is estimated at USD 885.6 million in 2026 and is projected to reach USD 2,056.4 million by the end of the forecast period in 2033.

Blanket Aerogel Market introduction

The Blanket Aerogel Market encompasses high-performance thermal insulation materials characterized by their flexible, thin, and lightweight structure, derived from aerogel technology. These blankets are renowned for possessing the lowest thermal conductivity of any known solid, making them exceptionally efficient insulators. Primarily composed of silica aerogel, these materials are processed into flexible forms suitable for various applications where space is at a premium and superior thermal management is critical. The intrinsic properties of aerogels, such as high porosity, low density, and hydrophobic nature, are preserved in blanket form, offering significant advantages over conventional insulation solutions.

Major applications for blanket aerogels span a diverse range of industries, including oil and gas, building and construction, industrial insulation, aerospace, automotive, and cryogenics. In the oil and gas sector, they are crucial for insulating pipelines and equipment to prevent heat loss or gain, maintain fluid temperatures, and ensure operational efficiency in extreme environments. Within building and construction, blanket aerogels are employed for enhancing thermal performance in walls, roofs, and floors, particularly in retrofit projects or high-performance green buildings where thin insulation layers are desired. For industrial applications, they insulate furnaces, steam pipes, and various process equipment, leading to substantial energy savings and improved safety.

The benefits of blanket aerogels are multifaceted, including superior thermal performance, enabling thinner insulation profiles compared to traditional materials, which saves valuable space and reduces structural load. They offer excellent fire resistance, acoustic insulation properties, and are hydrophobic, resisting moisture absorption. Their durability and long lifespan contribute to lower maintenance costs over time. The market is driven by an escalating global demand for energy efficiency across all sectors, stringent environmental regulations promoting sustainable building practices, and the continuous expansion of industrial infrastructure worldwide. Furthermore, technological advancements leading to cost reductions and enhanced performance characteristics are continually broadening their applicability and market penetration.

Blanket Aerogel Market Executive Summary

The Blanket Aerogel Market is experiencing robust growth, propelled by a confluence of global business trends emphasizing energy efficiency, sustainability, and high-performance material solutions. Industries are increasingly seeking advanced insulation materials to comply with stringent environmental regulations and reduce operational costs associated with energy consumption. This has led to a significant uptick in the adoption of blanket aerogels, particularly in sectors such as oil and gas, where maintaining temperature stability in extreme conditions is paramount, and in construction, where superior thermal envelopes are critical for green building initiatives. The market is also benefiting from continuous innovation in manufacturing processes, which are gradually improving scalability and reducing production costs, thereby making aerogel blankets more competitive against traditional insulation options. Furthermore, the rising investment in industrial infrastructure development and urban expansion, particularly in emerging economies, is creating substantial demand for advanced insulation solutions.

From a regional perspective, Asia Pacific (APAC) is emerging as a dominant force in the Blanket Aerogel Market, driven by rapid industrialization, burgeoning construction activities, and increasing energy demands in countries like China and India. The region's expanding manufacturing base and growing investment in oil and gas exploration and production contribute significantly to market expansion. North America and Europe, while more mature markets, continue to exhibit steady growth, primarily due to rigorous energy efficiency standards, extensive renovation and retrofit projects for aging infrastructure, and a strong focus on sustainable building practices. These regions are also hubs for advanced material research and development, fostering innovation in aerogel technology and applications. Latin America and the Middle East & Africa (MEA) are showing promising growth potential, fueled by ongoing infrastructure development projects, investments in petrochemical and industrial facilities, and a nascent but growing awareness of advanced insulation benefits.

In terms of segmentation, silica-based blanket aerogels currently hold the largest market share due to their proven performance, widespread availability of raw materials, and relatively established manufacturing processes. However, research and development into polymer and carbon aerogels are opening new avenues for specialized applications requiring different mechanical or electrical properties. Application-wise, the oil and gas segment remains a significant consumer, driven by extensive pipeline networks and processing facilities requiring high-performance insulation. The building and construction sector is also witnessing substantial growth, as aerogel blankets offer compelling advantages for enhancing building energy performance without compromising space. Emerging applications in automotive (especially electric vehicles for battery thermal management) and aerospace are poised for rapid expansion, indicating a diversification of demand and new opportunities for market players.

AI Impact Analysis on Blanket Aerogel Market

User inquiries concerning the impact of AI on the Blanket Aerogel Market primarily center on its potential to revolutionize various stages of the product lifecycle, from material discovery and manufacturing to application and market analysis. Users are keenly interested in how AI can accelerate the development of novel aerogel compositions with enhanced properties, streamline complex production processes to reduce costs and improve efficiency, ensure stringent quality control, and optimize supply chains. There's significant curiosity about AI's role in predictive maintenance for manufacturing equipment, its capacity for real-time defect detection in blanket production, and its ability to forecast market trends and demand fluctuations accurately. Underlying these questions is an expectation that AI will drive down the typically high costs associated with aerogel production, broaden its applicability by enabling tailored solutions, and ultimately make blanket aerogels a more widespread and competitive insulation material, addressing concerns about scalability and affordability.

- AI-driven material discovery and design for novel aerogel compositions with improved thermal, mechanical, and hydrophobic properties, accelerating R&D cycles and leading to the creation of more specialized and efficient blanket aerogel products.

- Optimization of manufacturing processes, including sol-gel synthesis and supercritical drying, through AI-powered algorithms to enhance yield, reduce energy consumption, minimize waste, and improve overall production efficiency, directly impacting cost-effectiveness.

- Enhanced quality control and defect detection during blanket aerogel production using computer vision and machine learning techniques, ensuring product consistency and performance standards are met while reducing manual inspection efforts.

- Predictive maintenance for aerogel manufacturing equipment, leveraging AI to analyze sensor data and anticipate potential failures, thereby minimizing downtime, extending equipment lifespan, and ensuring continuous production flow.

- AI-enabled market analysis and demand forecasting, providing deeper insights into industry trends, customer needs, and competitive landscapes, allowing manufacturers to make more informed strategic decisions regarding production volumes, pricing, and product development.

- Supply chain optimization and logistics management through AI, improving raw material sourcing, inventory management, and distribution networks, leading to reduced lead times and operational costs for blanket aerogel manufacturers and suppliers.

- Development of smart insulation systems integrating aerogel blankets with AI-enabled sensors for real-time monitoring of thermal performance, enabling dynamic adjustments to building energy management systems and optimizing energy consumption in smart infrastructure.

DRO & Impact Forces Of Blanket Aerogel Market

The Blanket Aerogel Market is significantly influenced by a dynamic interplay of drivers, restraints, opportunities, and various impact forces that shape its growth trajectory and competitive landscape. Key drivers include the escalating global demand for energy-efficient materials across diverse industries, particularly driven by stringent environmental regulations and rising energy costs, which compel businesses and consumers to adopt superior insulation solutions. The inherent advantages of blanket aerogels, such as ultra-low thermal conductivity, lightweight nature, and hydrophobic properties, position them as an ideal choice over traditional insulation methods, especially in space-constrained or high-performance applications. Furthermore, the rapid expansion of industrial infrastructure, alongside significant investments in building and construction, particularly in emerging economies, creates a fertile ground for the increased adoption of these advanced materials. Regulatory mandates promoting sustainable construction and energy conservation acts further bolster demand for high-performance insulation solutions like blanket aerogels.

However, the market also faces considerable restraints, primarily the high initial cost of blanket aerogels compared to conventional insulation materials. This elevated cost, often attributed to complex and energy-intensive manufacturing processes, can deter widespread adoption, especially in cost-sensitive markets or for projects with limited budgets. Another significant restraint is the relatively limited awareness and understanding of aerogel technology among end-users and decision-makers in certain regions or industries, leading to slower market penetration. The intricate and proprietary manufacturing processes involved, which often require specialized equipment and expertise, can also pose barriers to entry for new players, limiting competition and potentially hindering rapid price reductions. Competition from established and cheaper insulation alternatives, though less effective, continues to present a challenge, requiring continuous demonstration of aerogel's superior long-term value proposition.

Despite these challenges, numerous opportunities are emerging that are poised to accelerate market growth. Ongoing research and development efforts are focused on innovating cost-effective and scalable production technologies, such as ambient pressure drying, which could significantly lower manufacturing costs and expand market accessibility. The exploration of new application areas, including thermal management in electric vehicle batteries, cryogenics for liquefied natural gas (LNG) transport and storage, and specialized aerospace components, presents substantial growth avenues. The increasing focus on green building initiatives and energy retrofits in developed economies offers a robust platform for blanket aerogel adoption, given their superior insulation capabilities and contribution to reduced carbon footprints. Furthermore, the development of hybrid aerogel materials and composites that combine the benefits of aerogels with other materials can create new products with enhanced properties and broader applicability, catering to previously untapped market segments. Strategic collaborations between manufacturers, research institutions, and end-users are also instrumental in fostering innovation and market acceptance.

Impact forces such as technological advancements, global economic conditions, raw material availability and pricing volatility, and the evolving regulatory landscape exert considerable influence on the blanket aerogel market. Breakthroughs in aerogel synthesis and processing technologies, including advancements in precursor materials and drying techniques, directly impact product performance and cost-effectiveness. Economic stability and growth influence investment in infrastructure and industrial projects, which are major demand drivers for insulation materials. The supply chain for key raw materials like silica precursors and solvents can be subject to price fluctuations and availability issues, affecting production costs. Lastly, changes in environmental regulations, building codes, and energy efficiency mandates globally can either stimulate or constrain market growth, making the regulatory environment a critical external force shaping the market's trajectory.

Segmentation Analysis

The Blanket Aerogel Market is strategically segmented to provide a granular understanding of its diverse components and dynamics, facilitating targeted market strategies and product development. These segmentations typically revolve around the type of material used in the aerogel composition, and the specific application industries where these advanced insulation blankets are deployed. Each segment offers distinct growth opportunities and faces unique challenges, reflecting varied technological requirements, cost sensitivities, and performance criteria across different end-use sectors. Analyzing these segments helps stakeholders identify key demand drivers, assess competitive landscapes, and forecast future trends, providing a comprehensive view of the market's structure and potential for expansion. The underlying factors influencing each segment, such as material innovation, regulatory frameworks, and specific industrial needs, are critical for understanding the market's overall trajectory and identifying areas for strategic investment.

- By Material:

- Silica Aerogel: Dominant segment due to established production, excellent thermal properties, and widespread application.

- Polymer Aerogel: Emerging segment offering enhanced flexibility, mechanical strength, and potential for tunable properties.

- Carbon Aerogel: Niche segment known for electrical conductivity and high surface area, used in specialized applications.

- Other Aerogels: Includes metal oxide, sulfide, and hybrid aerogels, under development for specific high-performance needs.

- By Application:

- Oil & Gas: Insulation for pipelines, storage tanks, and process equipment in upstream, midstream, and downstream operations.

- Building & Construction: Thermal envelopes for residential, commercial, and industrial buildings; retrofitting older structures.

- Industrial: High-temperature insulation for furnaces, boilers, steam pipes, and process vessels in various manufacturing sectors.

- Aerospace & Defense: Insulation for aircraft, spacecraft, and military equipment requiring lightweight and high-performance solutions.

- Automotive: Thermal management for electric vehicle batteries, exhaust systems, and cabin insulation.

- Cryogenics: Insulation for cryogenic storage tanks, pipelines, and equipment handling liquefied gases at extremely low temperatures.

- Others: Includes applications in apparel, electronics, healthcare, and marine.

Value Chain Analysis For Blanket Aerogel Market

The value chain for the Blanket Aerogel Market is a complex ecosystem beginning with the sourcing of raw materials and extending through manufacturing, distribution, and final application. The upstream segment involves the procurement of key raw materials, predominantly silica precursors (such as alkoxysilanes like tetraethyl orthosilicate - TEOS or tetramethyl orthosilicate - TMOS) and various solvents (e.g., ethanol, methanol, acetone). These suppliers play a critical role, as the purity, cost, and availability of these chemical components directly impact the quality and manufacturing cost of aerogel blankets. Research and development activities, often conducted by specialized chemical companies or academic institutions, also form an integral part of the upstream segment, focusing on novel precursor synthesis, process optimization, and the creation of new aerogel formulations with enhanced properties or reduced costs. Efficient sourcing and strong supplier relationships are crucial for maintaining a competitive edge in this initial stage, particularly given the specialized nature of some precursor materials.

The midstream segment is dominated by aerogel manufacturers who specialize in the intricate processes of aerogel synthesis and blanket formation. This involves the sol-gel process, where precursors are hydrolyzed and condensed to form a gel, followed by critical drying steps, such as supercritical drying (using CO2) or ambient pressure drying. These drying techniques are highly specialized and energy-intensive, making them a significant determinant of the final product cost and performance. After drying, the aerogel material is typically processed into flexible blankets, often by integrating it with fibrous reinforcement materials (e.g., fiberglass, polyester) to provide mechanical strength and maintain its form. Key activities at this stage include process engineering, quality control, and product innovation, aimed at improving scalability, reducing production costs, and tailoring blanket properties to specific application requirements. Manufacturers may also engage in customization, offering different thicknesses, densities, and facings for their aerogel blanket products.

The downstream segment encompasses the distribution, sales, and end-use application of blanket aerogels. Distribution channels are varied, involving direct sales to large industrial clients (e.g., major oil and gas companies, large construction firms) for significant projects, and indirect sales through a network of specialized distributors and insulation contractors for smaller-scale projects or broader market reach. These distributors often provide value-added services such as cutting, fabrication, and technical support. The final stage involves the application of blanket aerogels by end-users in sectors like oil and gas, building and construction, industrial, aerospace, and automotive. Effective marketing, technical support, and post-sales services are crucial in the downstream segment to educate potential customers about the benefits and proper installation of aerogel blankets, particularly given their premium positioning. Optimizing the entire value chain for efficiency, cost-effectiveness, and responsiveness to market needs is vital for sustained growth in the Blanket Aerogel Market.

Blanket Aerogel Market Potential Customers

Potential customers for Blanket Aerogel Market span a wide array of industries, each seeking advanced thermal management solutions to meet specific operational and regulatory requirements. The primary end-users are enterprises and organizations operating in sectors where energy efficiency, space optimization, and extreme temperature resilience are paramount. In the oil and gas industry, customers include exploration and production companies, pipeline operators, and refinery owners who require high-performance insulation for pipelines, storage tanks, and various processing equipment to prevent heat loss, maintain process temperatures, and ensure worker safety. These customers often face challenging environmental conditions and strict safety standards, making the superior thermal performance and durability of aerogel blankets highly valuable for their infrastructure projects, both onshore and offshore, including LNG facilities and chemical plants.

Another significant customer base resides within the building and construction sector, encompassing commercial and residential developers, architects, general contractors, and building owners. These clients are increasingly seeking innovative insulation materials to achieve higher energy ratings for new constructions, comply with stringent green building certifications, and undertake energy-efficient retrofits of existing structures. Blanket aerogels appeal to this segment due to their thin profile, which allows for maximizing usable space, and their exceptional insulation properties, which reduce heating and cooling costs while enhancing occupant comfort. The material's fire resistance and moisture repellency further add to its attractiveness for long-term building performance. Additionally, within the industrial manufacturing sector, potential customers include power generation plants, chemical processing facilities, metallurgical plants, and other heavy industries that require insulation for high-temperature equipment, boilers, furnaces, and steam piping to improve operational efficiency, reduce energy waste, and ensure process stability.

Beyond these major segments, the aerospace and defense industries represent a crucial niche for blanket aerogels, with customers including aircraft manufacturers, spacecraft developers, and defense contractors. They utilize aerogel blankets for lightweight thermal insulation in aircraft cabins, satellite components, and missile systems, where minimizing weight and maximizing thermal protection are critical design parameters. The automotive sector, particularly manufacturers of electric vehicles (EVs), is an emerging but rapidly growing customer segment, using aerogel blankets for battery thermal management to optimize performance, extend range, and enhance safety by preventing thermal runaway. Furthermore, companies involved in cryogenic applications, such as the production, storage, and transport of liquefied gases like LNG, nitrogen, and oxygen, are key customers who rely on aerogel blankets for their unparalleled insulation capabilities at extremely low temperatures, ensuring minimal boil-off and safe handling of these volatile substances. The expanding range of specialized applications highlights the growing diversity of potential buyers across various high-value industries.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 885.6 Million |

| Market Forecast in 2033 | USD 2,056.4 Million |

| Growth Rate | 12.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Aspen Aerogels, Cabot Corporation, Armacell, BASF, Guangdong Alison Hi-Tech, Aerogel Technologies, Active Aerogels, JIOS Aerogel, Nanotech Co. Ltd., Thermablok Aerogels, Svenska Aerogel, Blueshift Materials, Enersens, Green Earth Aerogel Technologies, Nanjing Techair, Insulating Materials, A.S.P. Sealing Solutions, Denka Company Limited, Morgan Advanced Materials, Nano High-Tech |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Blanket Aerogel Market Key Technology Landscape

The Blanket Aerogel Market is characterized by a sophisticated technological landscape that underpins the production of these high-performance materials, with continuous innovation driving advancements in efficiency, scalability, and cost reduction. At the core of aerogel manufacturing is the sol-gel process, a chemical method where liquid precursors (typically alkoxysilanes for silica aerogels) are mixed to form a colloidal suspension (sol), which then undergoes gelation to form a wet gel network. The precise control over the sol-gel chemistry, including pH, temperature, and precursor concentration, is critical for dictating the final porosity, surface area, and mechanical properties of the aerogel. Recent technological focus in this area involves developing new, more environmentally friendly precursors and optimizing reaction kinetics to improve gel formation and reduce processing times, thereby enhancing overall production throughput and reducing material waste.

Following the sol-gel process, the most crucial and technologically intensive step is the drying of the wet gel to remove the pore liquid without collapsing the fragile nanostructure. Supercritical drying (SCD), traditionally using supercritical carbon dioxide, is the most established and effective method, enabling the production of aerogels with extremely low densities and high porosities. However, SCD is a batch process that requires high pressure and specialized equipment, contributing significantly to manufacturing costs and scalability challenges. Consequently, substantial research and development are concentrated on alternative drying techniques, such as ambient pressure drying (APD), which utilizes surface modification to prevent capillary collapse during solvent evaporation. While APD can offer a more cost-effective and scalable solution, achieving comparable performance to SCD-produced aerogels remains a key technological challenge that is continually being addressed through material science innovations and process engineering refinements.

Beyond the core synthesis and drying, the formation of aerogel blankets involves several other key technologies. This includes the integration of aerogel granules or powders with various fibrous reinforcement materials, such as fiberglass or polyester felts, to provide mechanical integrity and flexibility, transforming the brittle aerogel into a durable blanket form. Advanced binding and encapsulation techniques are also crucial to prevent dusting, enhance handling, and tailor the external properties of the blankets for specific applications, such as adding water-repellent or fire-retardant coatings. Roll-to-roll manufacturing processes are being developed and refined to enable continuous, high-volume production of aerogel blankets, moving away from batch-oriented methods and further driving down unit costs. Furthermore, ongoing research into hybrid aerogel materials, which combine aerogels with other functional components, and the use of nanotechnology to engineer specific properties, are expanding the functional capabilities and application range of blanket aerogels, marking a dynamic and innovative technological landscape.

Regional Highlights

- North America: This region represents a mature yet robust market for blanket aerogels, driven by stringent energy efficiency regulations, significant investments in oil and gas infrastructure, and a strong focus on sustainable building practices. The demand from industrial insulation, particularly in petrochemical and manufacturing facilities, remains high. Additionally, the growing aerospace and defense sectors, alongside increasing adoption in electric vehicle thermal management, contribute substantially to market growth. Extensive retrofit projects for commercial and residential buildings to improve energy performance also present a consistent demand for high-performance insulation solutions like aerogel blankets.

- Europe: Europe is a leading market, characterized by some of the most rigorous energy performance standards and environmental directives globally, particularly within the European Union. This regulatory environment strongly promotes the adoption of advanced insulation materials for both new constructions and extensive building renovation programs. Countries like Germany, the UK, and France are significant consumers, driven by industrial applications, a push for nearly zero-energy buildings (NZEB), and a strong commitment to reducing carbon emissions. Innovation in aerogel technology and applications, often supported by public and private funding for sustainable materials research, further strengthens the regional market.

- Asia Pacific (APAC): The APAC region stands as the fastest-growing market for blanket aerogels, fueled by rapid industrialization, massive infrastructure development, and booming construction activities, especially in China, India, and Southeast Asian countries. The escalating energy demand across the region, coupled with a growing awareness of energy conservation, is driving the adoption of high-performance insulation in both new industrial projects and commercial buildings. The expansion of the oil and gas sector, particularly LNG facilities and pipeline networks, as well as the rapidly growing automotive (EV) manufacturing base, further propels the demand for aerogel blankets in this dynamic region.

- Latin America: This region is an emerging market for blanket aerogels, with significant potential driven by investments in oil and gas exploration and production, particularly in Brazil, Mexico, and Argentina. The development of new industrial infrastructure and a gradual increase in awareness regarding energy efficiency in the construction sector are also contributing to market expansion. While currently smaller, the increasing focus on sustainable development and improving energy performance in industrial and commercial applications suggests a steady growth trajectory in the coming years.

- Middle East and Africa (MEA): The MEA region presents substantial growth opportunities, primarily due to vast investments in oil and gas projects, petrochemical industries, and large-scale infrastructure development initiatives. Countries like Saudi Arabia, UAE, and Qatar are key players, with continuous expansion in industrial facilities, power generation plants, and commercial complexes requiring advanced thermal insulation solutions to operate efficiently in challenging climatic conditions. A growing emphasis on diversifying economies and adopting sustainable building practices further supports the increasing demand for high-performance materials like blanket aerogels.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Blanket Aerogel Market.- Aspen Aerogels

- Cabot Corporation

- Armacell

- BASF

- Guangdong Alison Hi-Tech Co., Ltd.

- Aerogel Technologies, LLC

- Active Aerogels (Portugal)

- JIOS Aerogel (South Korea)

- Nanotech Co. Ltd. (China)

- Thermablok Aerogels Ltd. (UK)

- Svenska Aerogel AB (Sweden)

- Blueshift Materials Inc.

- Enersens (France)

- Green Earth Aerogel Technologies (GET)

- Nanjing Techair Aerogel Co., Ltd.

- Insulating Materials (IMI)

- A.S.P. Sealing Solutions GmbH

- Denka Company Limited

- Morgan Advanced Materials

- Nano High-Tech Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Blanket Aerogel market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are blanket aerogels and their primary uses?

Blanket aerogels are flexible, lightweight insulation materials derived from aerogel, known for their exceptionally low thermal conductivity. They are primarily used in industries such as oil and gas (pipelines, equipment), building and construction (walls, roofs), industrial insulation (furnaces, pipes), aerospace (aircraft, spacecraft), and automotive (EV battery thermal management) for high-performance thermal management.

What are the main advantages of using blanket aerogels over traditional insulation?

Key advantages include superior thermal performance, allowing for thinner insulation profiles, saving space and weight. They also offer excellent fire resistance, hydrophobicity, acoustic insulation, and durability, providing long-term energy savings and reduced maintenance compared to conventional materials like fiberglass or mineral wool.

What factors are driving the growth of the blanket aerogel market?

Market growth is primarily driven by increasing global demand for energy-efficient solutions, stringent environmental regulations pushing for sustainable building and industrial practices, the expansion of industrial infrastructure, and rising energy costs that incentivize superior insulation. Technological advancements aimed at reducing production costs and enhancing performance also contribute significantly.

What are the major challenges faced by the blanket aerogel market?

The primary challenges include the high initial cost of blanket aerogels compared to traditional insulation, stemming from complex manufacturing processes. Additionally, limited awareness among potential end-users and competition from established, lower-cost insulation alternatives pose significant hurdles to broader market adoption.

How is innovation impacting the future of blanket aerogel technology?

Innovation is crucial, focusing on developing more cost-effective and scalable production methods like ambient pressure drying, alongside exploring new precursor materials. Research into hybrid aerogel composites and specialized applications in areas like electric vehicles and cryogenics is expanding the market, making aerogel blankets more versatile and accessible for future high-performance demands.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager