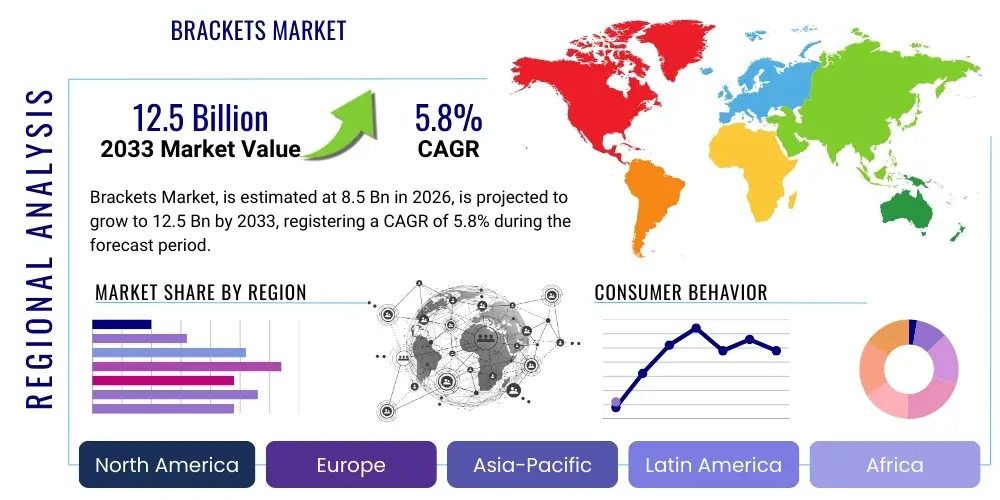

Brackets Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440175 | Date : Jan, 2026 | Pages : 241 | Region : Global | Publisher : MRU

Brackets Market Size

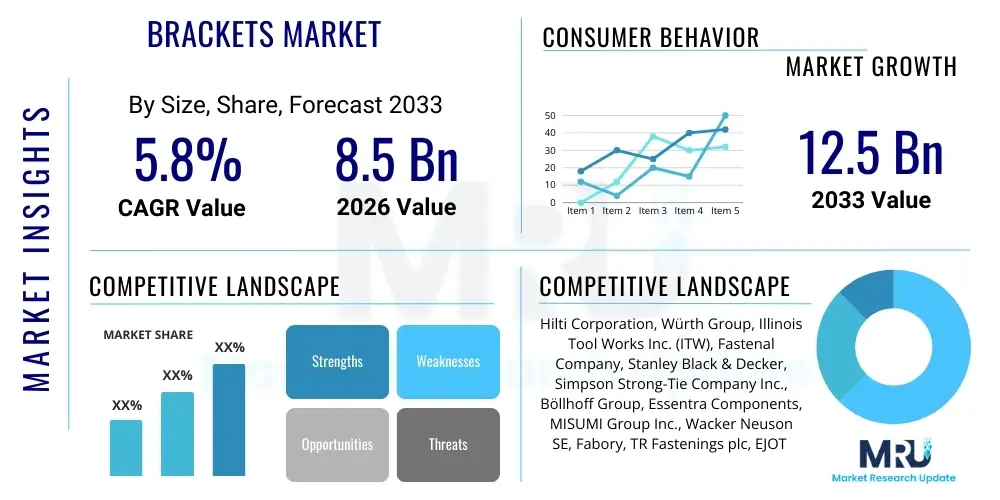

The Brackets Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 8.5 Billion in 2026 and is projected to reach USD 12.5 Billion by the end of the forecast period in 2033. This robust growth is primarily driven by escalating construction activities globally, increasing demand from the automotive and aerospace sectors for lightweight and high-strength fastening solutions, and the continuous expansion of manufacturing industries seeking efficient and reliable structural support components. The market's expansion is further bolstered by advancements in material science and manufacturing technologies, allowing for the production of more durable, customizable, and application-specific brackets that meet evolving industry standards and performance requirements.

Brackets Market introduction

The Brackets Market encompasses a vast array of components designed to provide structural support, attachment, or alignment across diverse industries. These essential elements, often overlooked, play a critical role in the integrity and functionality of countless products and structures, ranging from large-scale infrastructure projects to intricate electronic devices. Brackets are fundamentally mechanical fasteners that connect two or more parts, offering rigidity, load-bearing capabilities, and precise positioning. Their prevalence underscores their indispensable nature in modern engineering and construction, where robust and reliable connections are paramount for safety, performance, and longevity.

Product descriptions for brackets vary widely based on material, design, and intended application. Common materials include various grades of metal (steel, aluminum, brass, titanium), plastics (nylon, PVC, ABS), and advanced composites, each selected for specific strength, weight, corrosion resistance, and cost profiles. Designs range from simple L-shaped, Z-shaped, and corner brackets used for basic structural support to highly specialized mounting brackets for complex machinery, adjustable brackets for flexible installations, and unique orthodontic brackets. Their major applications span across construction (framing, shelving, pipe support), automotive (engine mounts, body panels), aerospace (structural assemblies, interior fittings), electronics (PCB mounts, component securing), furniture (assembly, stability), industrial machinery (component fastening, alignment), and even healthcare (orthodontics, medical equipment).

The benefits derived from using brackets are manifold, including enhanced structural stability, effective load distribution, secure connectivity, increased modularity in design, ease of installation, and long-term durability. These advantages contribute significantly to overall product quality and operational efficiency. Driving factors for market growth include rapid urbanization and infrastructure development, particularly in emerging economies, leading to increased demand in construction. Furthermore, the burgeoning manufacturing sector, continuous innovation in product design requiring tailored fastening solutions, the growing popularity of DIY home improvement projects, and the ongoing technological advancements in material engineering and automated manufacturing processes continue to propel the Brackets Market forward.

Brackets Market Executive Summary

The Brackets Market is currently experiencing dynamic shifts driven by global industrial expansion, technological advancements, and evolving consumer demands. Key business trends include a significant push towards customization and precision engineering, with manufacturers increasingly offering tailored bracket solutions to meet specific industry requirements for lightweight, high-strength, and corrosion-resistant components. There is also a growing emphasis on sustainable manufacturing practices and the use of eco-friendly materials, responding to global environmental regulations and corporate social responsibility initiatives. Furthermore, the adoption of automation and advanced robotics in bracket manufacturing processes is enhancing production efficiency, reducing costs, and improving product consistency, thereby reshaping the competitive landscape and driving innovation in design and material utilization.

Regionally, the Asia Pacific (APAC) market stands out as the fastest-growing segment, propelled by massive infrastructure projects, robust manufacturing sector expansion, and rapid urbanization, especially in countries like China and India. North America and Europe, while mature markets, continue to demonstrate stable demand, driven by innovation in aerospace, automotive, and high-tech electronics sectors, alongside stringent quality and safety standards that necessitate high-performance bracket solutions. Latin America and the Middle East & Africa (MEA) are emerging as significant growth pockets, fueled by investments in construction, energy infrastructure, and industrial development, presenting new opportunities for bracket manufacturers and suppliers.

Segmentation trends indicate a diversified market, with material type, application, and end-use industry being primary differentiators. Metal brackets, particularly steel and aluminum variants, continue to dominate due to their strength and versatility, though plastic and composite brackets are gaining traction in applications where weight reduction and corrosion resistance are critical, such as in aerospace and certain automotive components. The construction and automotive industries remain the largest application segments, experiencing steady demand, while the aerospace and electronics sectors are witnessing accelerated growth due to technological advancements and increasing production volumes. The market is also seeing a rise in specialized brackets for niches like orthodontics and renewable energy installations, indicating a broader diversification of product offerings and revenue streams for market players.

AI Impact Analysis on Brackets Market

The integration of Artificial Intelligence (AI) into the Brackets Market is poised to revolutionize various stages, from initial design and material selection to manufacturing, quality control, and supply chain management. Users are particularly interested in how AI can optimize bracket performance, reduce production costs, and accelerate time-to-market. Key themes emerging from user inquiries include the potential for AI-driven generative design to create novel, optimized bracket geometries that maximize strength-to-weight ratios, alongside AI's capability in predictive maintenance for manufacturing equipment to minimize downtime. Concerns also revolve around the capital investment required for AI implementation and the need for a skilled workforce to leverage these advanced technologies effectively, balancing innovation with practicality and cost-efficiency.

- AI-driven Generative Design: Enables the automated creation of complex, highly optimized bracket geometries that improve structural integrity while minimizing material usage and weight, tailored precisely to performance requirements and load conditions.

- Predictive Maintenance: AI algorithms analyze sensor data from manufacturing machinery to predict potential failures, allowing for proactive maintenance and significantly reducing unexpected downtime and operational costs in bracket production facilities.

- Automated Quality Control: AI-powered vision systems perform rapid and highly accurate inspections of finished brackets, detecting microscopic flaws or deviations from design specifications with greater consistency and speed than human inspectors, ensuring higher product quality.

- Supply Chain Optimization: AI enhances logistics and inventory management by forecasting demand more accurately, optimizing warehousing, and streamlining distribution networks, leading to reduced lead times and improved responsiveness for bracket suppliers.

- Material Selection and Optimization: AI assists in identifying the most suitable materials for specific bracket applications by analyzing vast datasets of material properties, performance under stress, and cost implications, leading to better material utilization and innovation.

- Process Optimization: Machine learning algorithms analyze manufacturing parameters (e.g., cutting speeds, welding temperatures) to identify optimal settings that improve efficiency, reduce waste, and enhance the consistency and quality of bracket production.

- Customization and Personalization: AI facilitates mass customization by quickly adapting designs and manufacturing processes to produce bespoke brackets for individual client needs without significant cost escalation, catering to niche market demands.

DRO & Impact Forces Of Brackets Market

The Brackets Market is influenced by a complex interplay of drivers, restraints, and opportunities, shaping its growth trajectory and competitive landscape. Key drivers include accelerating urbanization and population growth, which fuel massive infrastructure and residential construction projects globally, particularly in developing economies. The robust expansion of the automotive sector, driven by increasing vehicle production and the demand for lightweight yet durable components to enhance fuel efficiency and safety, also significantly boosts market demand. Furthermore, the continuous advancements in manufacturing technologies and material science, leading to the development of high-performance, customized bracket solutions, coupled with the rising global expenditure on industrial machinery and equipment, underpin the market's sustained growth. These factors collectively create a strong foundation for ongoing market expansion, pushing manufacturers to innovate and diversify their product portfolios.

Despite these growth drivers, the market faces several notable restraints. Volatility in raw material prices, particularly for metals like steel, aluminum, and specialized alloys, poses a significant challenge, directly impacting production costs and profit margins for bracket manufacturers. Stringent environmental regulations and trade policies, especially concerning material sourcing and manufacturing emissions, can lead to increased compliance costs and limit operational flexibility. The availability of alternative joining methods, such as welding, adhesives, and advanced composite bonding, presents a competitive threat, as these methods may offer advantages in specific applications or material combinations. Additionally, global economic downturns or geopolitical instabilities can severely disrupt supply chains, reduce industrial output, and diminish overall demand for construction and manufacturing components, thereby restraining market growth.

Opportunities within the Brackets Market are abundant and diverse, offering avenues for significant innovation and expansion. Emerging markets, particularly in Asia Pacific and Latin America, present vast untapped potential due to their ongoing industrialization and infrastructure development. The increasing focus on sustainable construction practices and green building initiatives creates demand for eco-friendly and energy-efficient bracket solutions. Furthermore, the advent of smart brackets, integrated with sensors for real-time monitoring of structural integrity, temperature, or vibration, represents a significant technological opportunity to add value and open new application areas. The adoption of additive manufacturing (3D printing) for complex bracket geometries, offering rapid prototyping and customization, also provides a lucrative avenue for market players to differentiate their offerings and cater to niche, high-value segments. These opportunities encourage strategic investments in R&D and market diversification.

Segmentation Analysis

The Brackets Market is comprehensively segmented to provide a detailed understanding of its diverse components and evolving demand patterns across various industries and applications. This segmentation enables market participants to identify key growth areas, understand competitive dynamics, and tailor their strategies to specific market niches. The market is primarily categorized by material type, which dictates strength, durability, and cost; by bracket type, reflecting structural design and function; by application, showcasing end-use industries; by end-use industry, distinguishing between residential, commercial, and industrial sectors; and by distribution channel, defining how products reach their customers. Each segment plays a crucial role in the overall market landscape, influenced by specific technological advancements, regulatory frameworks, and economic factors.

- By Material

- Metal Brackets

- Steel (Stainless Steel, Carbon Steel, Galvanized Steel)

- Aluminum

- Brass

- Titanium

- Other Alloys

- Plastic Brackets

- Nylon

- PVC (Polyvinyl Chloride)

- ABS (Acrylonitrile Butadiene Styrene)

- Polypropylene (PP)

- Polycarbonate (PC)

- Other Engineered Plastics

- Composite Brackets

- Fiberglass Reinforced Composites

- Carbon Fiber Reinforced Composites

- Other Advanced Composites

- Metal Brackets

- By Type

- L-Brackets

- Z-Brackets

- Corner Brackets

- Shelf Brackets

- Mounting Brackets (e.g., TV mounts, engine mounts)

- Adjustable Brackets

- Gusset Brackets

- Beam Brackets

- Pipe Brackets

- Angle Brackets

- Specialty Brackets (e.g., Orthodontic Brackets, Solar Panel Brackets)

- By Application

- Construction

- Residential Construction

- Commercial Construction

- Industrial Construction

- Infrastructure Development

- Automotive

- Passenger Vehicles

- Commercial Vehicles

- Electric Vehicles

- Aerospace & Defense

- Aircraft Manufacturing

- Spacecraft

- Military Equipment

- Electronics & Electrical

- Consumer Electronics

- Industrial Electronics

- Telecom Equipment

- Furniture & Fixtures

- Industrial Machinery & Equipment

- HVAC (Heating, Ventilation, and Air Conditioning)

- Renewable Energy (Solar Panel Mounting)

- Orthodontics & Medical Devices

- Consumer Goods & DIY

- Construction

- By End-Use Industry

- Residential Sector

- Commercial Sector

- Industrial Sector

- Institutional Sector

- By Distribution Channel

- Online

- E-commerce Platforms

- Manufacturer Websites

- Offline

- Direct Sales

- Distributors & Wholesalers

- Retail Stores (Hardware Stores, Home Improvement Centers)

- Online

Value Chain Analysis For Brackets Market

The value chain for the Brackets Market is a complex network involving multiple stages, from raw material sourcing to final product consumption, each contributing to the creation and delivery of value. The upstream segment of the value chain is dominated by raw material suppliers, including primary producers of metals such as steel, aluminum, brass, and titanium, as well as chemical companies providing polymers for plastic brackets and specialized materials for composites. These suppliers are critical as the quality, cost, and availability of raw materials directly impact the manufacturing process and the final product's attributes. Following raw material procurement, the value chain moves to component manufacturers and specialized material processors who transform raw materials into semi-finished products or specific alloys and compounds ready for bracket fabrication, including processes like smelting, extrusion, and material shaping.

Midstream activities primarily involve bracket manufacturers who engage in various fabrication processes such as stamping, cutting, bending, welding, casting, injection molding, and machining to produce the wide array of bracket types required by the market. These manufacturers invest heavily in advanced machinery, quality control systems, and skilled labor to ensure precision, durability, and adherence to industry standards. Many manufacturers also offer customization services, designing and producing bespoke brackets to meet specific client requirements. Post-manufacturing, brackets undergo various finishing processes, including surface treatments like galvanization, powder coating, painting, and anodizing, which enhance their corrosion resistance, aesthetic appeal, and overall lifespan, adding significant value to the final product.

The downstream segment of the value chain focuses on the distribution and sale of brackets to end-users. Distribution channels are varied, encompassing direct sales to large original equipment manufacturers (OEMs), major construction companies, and industrial clients, allowing for customized orders and direct technical support. Indirect distribution is facilitated through a robust network of wholesalers, distributors, and retailers, including large hardware stores, home improvement centers, and specialized industrial supply outlets, catering to a broader range of customers including contractors, small businesses, and DIY consumers. The proliferation of e-commerce platforms has also emerged as a significant distribution channel, providing global reach and convenience for both manufacturers and buyers. Efficient logistics and supply chain management are paramount in the downstream segment to ensure timely delivery and market responsiveness, contributing significantly to customer satisfaction and market penetration.

Brackets Market Potential Customers

The Brackets Market serves an extraordinarily diverse range of potential customers, spanning virtually every industrial and consumer sector due to the fundamental need for structural support, fastening, and alignment in countless applications. At the forefront are entities within the construction sector, including residential and commercial building contractors, infrastructure development companies, and industrial construction firms, all requiring brackets for framing, shelving, roofing, piping, and various structural connections. Similarly, automotive manufacturers, encompassing both traditional internal combustion engine vehicle producers and the rapidly expanding electric vehicle segment, rely heavily on brackets for engine mounts, chassis components, interior fittings, and panel assemblies, seeking solutions that offer strength, weight reduction, and durability.

Beyond construction and automotive, a significant customer base resides within the aerospace and defense industry, where precision-engineered, lightweight, and high-strength brackets are crucial for aircraft structural assemblies, engine components, and defense equipment, adhering to stringent safety and performance standards. Electronics manufacturers, from consumer electronics giants to industrial equipment producers, also represent a substantial segment, utilizing brackets for PCB mounting, component securing, and housing assemblies. The furniture industry, industrial machinery manufacturers, and companies specializing in HVAC systems, renewable energy installations (e.g., solar panel mounting), and even specialized fields like orthodontics and medical device manufacturing, consistently demand a wide array of customized and standard brackets to ensure product integrity and functionality. Each of these end-user segments requires specific bracket characteristics, driving innovation and specialization within the market.

Furthermore, the Brackets Market extends significantly to the retail sector, catering to a vast population of DIY enthusiasts, professional handymen, and small contractors. Hardware stores, home improvement centers, and online e-commerce platforms serve as critical points of sale for these individual buyers and smaller businesses seeking standard and off-the-shelf bracket solutions for repairs, renovations, and personal projects. The agricultural sector, marine industry, and even artistic and display professionals also constitute niche but important customer segments, utilizing brackets for various equipment, fixtures, and installations. The breadth of applications underscores the universal demand for reliable fastening and support components, making virtually any entity involved in manufacturing, assembly, construction, or maintenance a potential customer for bracket products.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 8.5 Billion |

| Market Forecast in 2033 | USD 12.5 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Hilti Corporation, Würth Group, Illinois Tool Works Inc. (ITW), Fastenal Company, Stanley Black & Decker, Simpson Strong-Tie Company Inc., Böllhoff Group, Essentra Components, MISUMI Group Inc., Wacker Neuson SE, Fabory, TR Fastenings plc, EJOT Holding GmbH & Co. KG, BOSSARD Holding AG, Spirol International Corporation, Penn Engineering, Nord-Lock Group, ARaymond, Anixter International Inc., MacLean-Fogg Company |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Brackets Market Key Technology Landscape

The Brackets Market is continually evolving, driven by significant advancements in manufacturing processes and material science, leading to the development of more efficient, durable, and sophisticated products. One of the most impactful technologies is additive manufacturing, commonly known as 3D printing, which allows for the creation of complex, customized bracket geometries with reduced material waste and shorter lead times. This technology is particularly valuable for producing lightweight, high-performance brackets for aerospace and medical applications, where intricate designs and specific material properties are critical. Furthermore, advanced material composites, such as carbon fiber and fiberglass reinforced polymers, are gaining traction, offering superior strength-to-weight ratios and enhanced corrosion resistance compared to traditional metal brackets, thereby enabling innovations in automotive and aerospace industries for weight reduction and improved fuel efficiency.

Precision manufacturing techniques, including advanced CNC machining, laser cutting, and robotic welding, are fundamental to producing high-quality brackets with tight tolerances and consistent performance. These technologies ensure accurate dimensions, smooth finishes, and robust connections, meeting the stringent quality standards required across various industrial applications. Automated stamping and forming processes, often integrated with sophisticated sensor feedback systems, optimize production efficiency and reduce labor costs, allowing for high-volume manufacturing of standard bracket types. The application of specialized surface treatments, such as galvanization, powder coating, anodizing, and electrophoretic deposition (EPD), significantly enhances the durability, corrosion resistance, and aesthetic appeal of brackets, extending their lifespan and performance in harsh environments.

Emerging technologies also include the integration of "smart" functionalities into brackets, incorporating sensors for real-time monitoring of stress, vibration, temperature, or structural integrity. These smart brackets can provide invaluable data for predictive maintenance in industrial machinery or structural health monitoring in civil infrastructure, paving the way for more intelligent and responsive systems. Digital twin technology is increasingly being used in the design and prototyping phases, allowing manufacturers to simulate bracket performance under various load conditions and environmental stresses before physical production. This reduces design iterations, accelerates product development, and ensures optimal performance. The continuous adoption of these cutting-edge technologies is crucial for manufacturers to remain competitive, innovate product offerings, and address the evolving demands for high-performance, specialized, and cost-effective bracket solutions in a global market.

Regional Highlights

- North America: A mature market characterized by high adoption rates of advanced manufacturing technologies and a strong presence of key industries such as aerospace, automotive, and construction. The region benefits from significant investments in R&D and a focus on high-performance, specialized bracket solutions, driven by stringent regulatory standards and a demand for durable, reliable components.

- Europe: Exhibits steady growth, propelled by a robust automotive sector, extensive industrial base, and significant investments in infrastructure and renewable energy projects. European markets emphasize quality, precision engineering, and increasingly, sustainable manufacturing practices and the use of eco-friendly materials, aligning with regional environmental policies.

- Asia Pacific (APAC): The fastest-growing region in the Brackets Market, fueled by rapid urbanization, massive infrastructure development initiatives, and the booming manufacturing sectors in countries like China, India, and Southeast Asian nations. APAC's growth is also significantly driven by the expansion of electronics production and a growing middle class contributing to increased construction and automotive demand.

- Latin America: An emerging market with significant growth potential, driven by ongoing infrastructure projects, industrial expansion, and an increasing automotive manufacturing presence. Brazil and Mexico are key contributors, with demand for brackets stemming from both domestic projects and export-oriented manufacturing.

- Middle East & Africa (MEA): Shows promising growth, particularly due to large-scale construction projects, diversification efforts away from oil economies, and investments in industrial and energy infrastructure. Countries in the GCC region are leading this growth, with demand for robust and climate-resistant bracket solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Brackets Market.- Hilti Corporation

- Würth Group

- Illinois Tool Works Inc. (ITW)

- Fastenal Company

- Stanley Black & Decker

- Simpson Strong-Tie Company Inc.

- Böllhoff Group

- Essentra Components

- MISUMI Group Inc.

- Wacker Neuson SE

- Fabory

- TR Fastenings plc

- EJOT Holding GmbH & Co. KG

- BOSSARD Holding AG

- Spirol International Corporation

- Penn Engineering

- Nord-Lock Group

- ARaymond

- Anixter International Inc.

- MacLean-Fogg Company

Frequently Asked Questions

What is driving the growth of the Brackets Market?

The Brackets Market is primarily driven by global infrastructure development, rapid urbanization, expansion of the automotive and aerospace industries, increasing demand from the electronics and industrial machinery sectors, and continuous advancements in material science and manufacturing technologies. The rising popularity of DIY projects and the need for specialized fastening solutions across diverse applications also contribute significantly to market expansion.

What are the primary types of brackets available in the market?

The market offers a wide array of bracket types, broadly categorized by their design and function. Common types include L-Brackets, Z-Brackets, Corner Brackets, Shelf Brackets, and various Mounting Brackets used for securing components. Additionally, specialized brackets such as adjustable brackets, gusset brackets, beam brackets, pipe brackets, and even orthodontic brackets cater to specific application requirements across industries.

How is technology impacting the Brackets Market?

Technology is significantly transforming the Brackets Market through advancements like additive manufacturing (3D printing) for complex geometries, advanced material composites for lightweight and strong solutions, and precision manufacturing techniques such as CNC machining and robotic welding. The integration of AI for generative design and predictive maintenance, along with smart brackets featuring sensor technology, is enhancing product performance, efficiency, and real-time monitoring capabilities.

What are the key challenges faced by bracket manufacturers?

Key challenges for bracket manufacturers include the volatility of raw material prices, particularly for metals, which impacts production costs and profitability. Additionally, stringent environmental regulations, intense competition from alternative joining methods, and the need for continuous innovation to meet evolving industry standards and customization demands pose significant hurdles. Economic downturns and supply chain disruptions can also impact market stability and growth.

Which regions offer the most significant growth opportunities for the Brackets Market?

The Asia Pacific (APAC) region stands out as the most promising for growth, driven by extensive infrastructure projects, a booming manufacturing sector, and rapid urbanization in countries like China and India. Emerging markets in Latin America and the Middle East & Africa (MEA) also present substantial opportunities due to their ongoing industrialization and increasing investments in construction and energy infrastructure.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Seismic Brackets Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Ceramic Brackets Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033

- Boat Instrument Brackets Market Statistics 2025 Analysis By Application (Sailboats, Yachts, Others), By Type (Navigation Instrument Brackets, Tablet Computer Brackets, iPad Brackets, Others), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Boat Engine Brackets Market Statistics 2025 Analysis By Application (Monohull, Multihull, Others), By Type (Adjustable, Fixed, Others), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager