Brazed Aluminum Heat Exchangers Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432356 | Date : Dec, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Brazed Aluminum Heat Exchangers Market Size

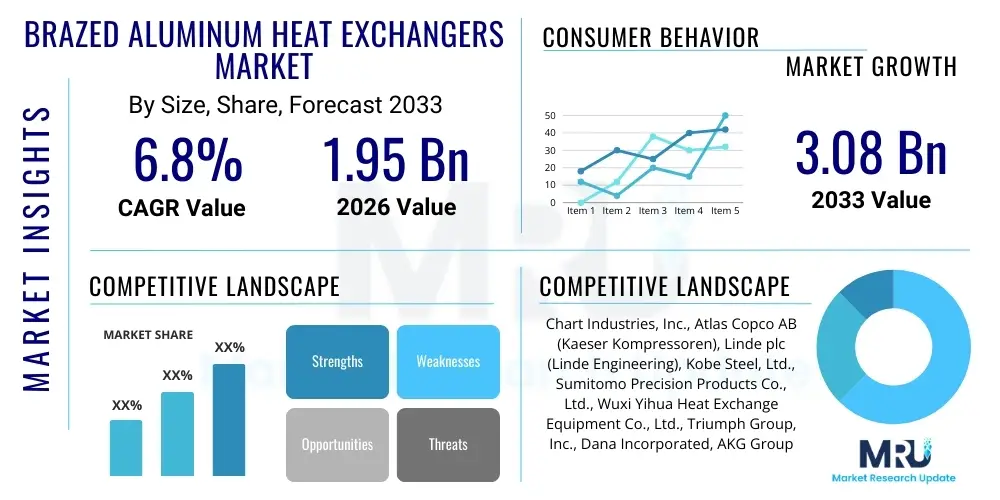

The Brazed Aluminum Heat Exchangers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.95 Billion in 2026 and is projected to reach USD 3.08 Billion by the end of the forecast period in 2033.

Brazed Aluminum Heat Exchangers Market introduction

Brazed Aluminum Heat Exchangers (BAHEs), commonly known as Plate Fin Heat Exchangers, represent critical technology essential for high-efficiency heat transfer across various industrial sectors. These devices are characterized by their compact size, lightweight construction, and robust thermal performance, achieved through the vacuum brazing of corrugated fins, separator plates, bars, and headers made primarily of aluminum alloys. Their superior thermal efficiency compared to traditional shell and tube exchangers makes them indispensable, particularly in applications requiring high heat flux density and minimal footprint, which is a common requirement in energy-intensive processes like cryogenic air separation and petrochemical refining.

The core application of BAHE technology lies in handling multiple fluid streams simultaneously, often under high-pressure conditions and extreme temperature differences. Major sectors driving demand include air separation units (ASUs) for oxygen and nitrogen production, natural gas liquefaction (LNG), power generation utilizing recuperators and intercoolers, and sophisticated cooling systems within aerospace and defense. The inherent benefits of aluminum, such as corrosion resistance and low density, coupled with the strong metallurgical bond formed during the brazing process, ensures long operational lifespans and reduced maintenance requirements, thereby cementing their position as the preferred heat transfer solution in demanding environments.

Brazed Aluminum Heat Exchangers Market Executive Summary

The Brazed Aluminum Heat Exchangers market is experiencing robust growth driven primarily by escalating demand for cleaner energy solutions and the expansion of the cryogenic industry, particularly LNG and industrial gas production. Key business trends indicate significant investment in manufacturing automation and advanced vacuum brazing techniques to enhance product quality and handle larger, more complex units required by megaprojects. Furthermore, there is a clear trend toward customized designs and modular solutions, allowing BAHE manufacturers to penetrate niche markets such as specialized semiconductor cooling and high-performance vehicle thermal management systems.

Regionally, Asia Pacific maintains dominance, fueled by massive infrastructure projects, burgeoning petrochemical industries, and aggressive expansion in cryogenic manufacturing in countries like China and India. North America and Europe demonstrate mature market characteristics, focusing primarily on technological upgrades, energy efficiency mandates, and increasing adoption in high-specification sectors like aerospace and green hydrogen production. Segment trends highlight that the plate-fin BAHE configuration continues to lead the market due to its versatility, while the cryogenic application segment remains the largest revenue generator, although the automotive segment, focusing on specialized engine cooling and battery thermal management, is poised for the highest CAGR driven by electric vehicle proliferation.

AI Impact Analysis on Brazed Aluminum Heat Exchangers Market

User inquiries regarding the integration of Artificial Intelligence (AI) in the Brazed Aluminum Heat Exchangers market predominantly revolve around optimizing manufacturing processes, predictive maintenance scheduling, and enhancing thermodynamic design efficiency. Users are keenly interested in how machine learning algorithms can rapidly analyze complex operating parameters to predict potential failures (such as fouling or thermal stress accumulation) before they manifest, thereby minimizing costly downtime. Furthermore, common questions address the role of generative design AI in rapidly prototyping optimized fin geometries and flow paths that surpass conventionally engineered designs, leading to superior heat transfer coefficients and reduced material usage in line with sustainability goals. The collective expectation is that AI will transform BAHE production from a bespoke, experience-based process into a data-driven, highly optimized manufacturing ecosystem, lowering defect rates and expediting time-to-market for complex, custom units.

- AI optimizes BAHE manufacturing schedules and resource allocation, improving throughput.

- Machine learning enhances Predictive Maintenance (PdM) programs, forecasting corrosion or fouling based on operational data.

- Generative design AI accelerates the development of novel fin geometries for improved thermal performance and pressure drop characteristics.

- Deep learning algorithms refine non-destructive testing (NDT) interpretation during quality control checks, detecting micro-defects in brazing seams.

- AI-driven simulation tools reduce physical prototyping costs and shorten the design cycle for highly customized applications (e.g., aerospace intercoolers).

DRO & Impact Forces Of Brazed Aluminum Heat Exchangers Market

The Brazed Aluminum Heat Exchangers market trajectory is powerfully shaped by the global shift towards high-efficiency energy systems and the robust expansion of industrial gas and LNG infrastructure. Drivers include stringent governmental regulations promoting energy conservation and the unique capability of BAHEs to function effectively in cryogenic environments, essential for natural gas processing and air separation. Restraints center primarily around the intensive capital investment required for specialized vacuum brazing furnaces and the inherent susceptibility of aluminum alloys to specific corrosive media, necessitating careful material selection and maintenance protocols. Opportunities arise from the rapidly expanding green hydrogen economy, where BAHEs are crucial in electrolysis cooling and subsequent compression/storage stages, coupled with the increasing integration of BAHEs into advanced thermal management systems for electric vehicles and data centers.

The impact forces within the market are predominantly driven by technological sophistication and supply chain resilience. High barriers to entry, stemming from the need for precise manufacturing tolerances and proprietary brazing techniques, solidify the position of established players. The forward integration of digitalization tools, including IoT sensors for real-time monitoring and AI for design optimization, acts as a pivotal impact force accelerating innovation. Conversely, fluctuations in aluminum prices and geopolitical instability affecting energy megaprojects represent external forces that can moderate market growth, underscoring the necessity for diversified sourcing and strong risk management strategies across the value chain. Ultimately, the market is pushed by the unwavering global demand for lightweight, compact, and highly efficient heat transfer solutions.

Segmentation Analysis

The Brazed Aluminum Heat Exchangers market is broadly segmented based on configuration, application, and end-use industry, providing a granular view of demand dynamics across key vertical markets. Configuration analysis reveals that the Plate-Fin architecture dominates due to its high surface area-to-volume ratio and capability to handle multi-stream operations, crucial for cryogenic processes. Meanwhile, customized segments, such as micro-channel heat exchangers, are gaining traction, especially in sensitive electronics and compact automotive environments where space constraint is paramount. Analyzing these segments helps stakeholders understand where specific technological expertise and investment are most critical for future growth.

Application-based segmentation highlights Cryogenic Separation (including Air Separation Units and LNG production) as the primary revenue stream, demonstrating the irreplaceable role of BAHEs in maintaining extremely low temperatures efficiently. However, the diversification of end-use industries, particularly the petrochemical and power generation sectors requiring high-pressure gas-to-gas heat recovery systems, is driving consistent demand. The market’s segmentation reflects a balance between established, high-volume industrial applications and emerging, high-growth niche areas requiring precision-engineered solutions, ensuring long-term market stability and diversified investment potential for manufacturers.

- By Configuration:

- Plate-Fin Heat Exchangers (PFHE)

- Printed Circuit Heat Exchangers (PCHE)

- Micro-Channel Heat Exchangers

- Standard (Block Type)

- By Application:

- Cryogenic Separation

- Natural Gas Liquefaction (LNG)

- Petrochemical Refining

- Power Generation (Recuperators/Intercoolers)

- Automotive Cooling Systems (Charge Air Coolers, Battery Thermal Management)

- Air Compression/Drying

- Aerospace & Defense

- By End-Use Industry:

- Oil & Gas and Petrochemicals

- Air Separation and Industrial Gases

- Power Generation

- Automotive & Transportation

- Aerospace

- Marine

Value Chain Analysis For Brazed Aluminum Heat Exchangers Market

The value chain for the Brazed Aluminum Heat Exchangers market commences with the upstream supply of specialized aluminum alloys, particularly those tailored for vacuum brazing processes, requiring stringent quality control to ensure metallurgical integrity. Key upstream activities involve the sourcing and preparation of materials, including the precision manufacturing of fins, plates, and bars. Midstream activities, which represent the core competency of BAHE manufacturers, center on complex design engineering, precise assembly, and the critical vacuum brazing process itself, which demands specialized, high-capital equipment and proprietary technical expertise to achieve the necessary strength and leak tightness.

Downstream activities involve post-brazing treatment, rigorous quality assurance (including pressure and leak testing), packaging, and distribution. The distribution channel structure often utilizes both direct sales for large, complex, custom-engineered projects (such as major LNG plants or defense contracts) and indirect distribution through specialized engineering procurement and construction (EPC) firms or regional distributors for standardized units or aftermarket service components. Direct sales ensure deep technical engagement between the manufacturer and the end-user, crucial for high-specification projects, while indirect channels provide market breadth and localized service support.

Brazed Aluminum Heat Exchangers Market Potential Customers

Potential customers for Brazed Aluminum Heat Exchangers are predominantly large-scale industrial operators and governmental entities engaged in energy production, processing, and high-specification manufacturing. The primary buyers are companies specializing in Air Separation Units (ASUs) who rely on BAHEs for the liquefaction of air components (oxygen, nitrogen, argon) necessary for industrial gas supply. Secondly, global energy majors and independent power producers focusing on Natural Gas Liquefaction (LNG) facilities are significant customers, as BAHEs are integral to the main cryogenic heat exchange process.

In addition to energy and gas producers, the market caters extensively to Engineering, Procurement, and Construction (EPC) companies that manage megaprojects in the oil & gas and petrochemical sectors, often integrating BAHEs into complex refinery processes. Furthermore, high-performance end-users like aerospace manufacturers (requiring lightweight intercoolers for aircraft engines), specialized automotive companies (developing battery thermal management systems for high-range EVs), and large-scale data center operators seeking compact, high-density cooling solutions represent rapidly growing customer segments, emphasizing the versatility and technical appeal of brazed aluminum technology.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.95 Billion |

| Market Forecast in 2033 | USD 3.08 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Chart Industries, Inc., Atlas Copco AB (Kaeser Kompressoren), Linde plc (Linde Engineering), Kobe Steel, Ltd., Sumitomo Precision Products Co., Ltd., Wuxi Yihua Heat Exchange Equipment Co., Ltd., Triumph Group, Inc., Dana Incorporated, AKG Group, Visteon Corporation, Calsonic Kansei Corporation (Marelli), Shanghai SENIU Chemical Equipment Co., Ltd., Air Products and Chemicals, Inc., Heatric (A Dover Company), IHI Corporation, Alfa Laval AB, Modine Manufacturing Company, MAHLE GmbH, SPX FLOW, Inc., Hangyang Group. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Brazed Aluminum Heat Exchangers Market Key Technology Landscape

The technological landscape of the Brazed Aluminum Heat Exchangers market is dominated by advancements in vacuum brazing techniques and sophisticated heat transfer surface design. Vacuum brazing remains the core technology, ensuring a clean, high-integrity metallurgical bond between components without the need for flux, which is crucial for achieving high thermal efficiency and resisting corrosion in demanding applications. Recent technological efforts focus on developing larger vacuum furnaces capable of processing massive BAHE cores required for modern LNG megaprojects, alongside perfecting the process control systems to minimize thermal distortion and maximize yield rates for complex multi-stream units.

Beyond manufacturing methods, significant innovation is concentrated on fin geometry and flow path optimization. Micro-fin and offset-strip fin designs are continually being refined to maximize the surface area-to-volume ratio while mitigating pressure drop, a critical trade-off in fluid dynamics. Furthermore, the integration of advanced computational fluid dynamics (CFD) and thermal simulation software is paramount, allowing engineers to rapidly prototype and test designs virtually for specific operational envelopes, particularly in high-pressure gas recuperation and compact aerospace heat sinks. The convergence of precise manufacturing, advanced material science (aluminum alloys optimized for cryogenic performance), and digitalization defines the leading edge of BAHE technology.

Regional Highlights

The global market for Brazed Aluminum Heat Exchangers exhibits pronounced regional disparities in terms of growth rate, application focus, and technological maturity, largely mirroring global industrial and energy investment patterns. Asia Pacific (APAC) stands out as the engine of market expansion, primarily due to relentless industrialization, massive investments in new LNG export facilities (particularly in Australia and Southeast Asia), and the rapid scaling of domestic air separation capabilities in China and India. The APAC region benefits from large-scale government-backed infrastructure development and a growing demand for cost-efficient, high-capacity heat transfer solutions, making it the highest revenue generating region.

North America and Europe, while growing at a comparatively slower pace, represent highly mature and technologically demanding markets. Growth in these regions is driven by replacement cycles, modernization of existing industrial infrastructure, and a strong focus on high-value applications such as aerospace, defense, and the emerging green hydrogen value chain. European manufacturers, in particular, lead in applying BAHE technology to highly regulated environments, adhering to stringent environmental standards and precision engineering requirements. Meanwhile, the Middle East and Africa (MEA) and Latin America are poised for accelerated growth, contingent upon the successful completion of planned oil and gas processing projects and new petrochemical complex constructions, which require significant BAHE investments.

- Asia Pacific (APAC): Dominates the market due to robust demand from LNG, Air Separation Units (ASUs), and rapid expansion of the petrochemical sector, notably in China and India. Focus on large-scale industrial units and infrastructure.

- North America: Driven by technological innovation in aerospace intercoolers, defense applications, and the modernization of natural gas processing plants; high uptake in specialized electric vehicle thermal management.

- Europe: Characterized by stringent energy efficiency regulations, leading to demand for high-performance recuperators and exchangers in chemical processing and power generation; a key adopter of BAHE technology in Green Hydrogen infrastructure.

- Middle East & Africa (MEA): Growth tied directly to massive investments in new oil & gas upstream and downstream capacity, including large refinery expansion and dedicated LNG export terminals.

- Latin America: Market expansion driven by modernization of existing petrochemical complexes, particularly in Brazil and Mexico, alongside growing requirements for air separation units in mining and industrial manufacturing.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Brazed Aluminum Heat Exchangers Market, characterized by their proprietary vacuum brazing expertise, global operational footprints, and focus on high-specification applications.- Chart Industries, Inc.

- Atlas Copco AB (Kaeser Kompressoren)

- Linde plc (Linde Engineering)

- Kobe Steel, Ltd.

- Sumitomo Precision Products Co., Ltd.

- Wuxi Yihua Heat Exchange Equipment Co., Ltd.

- Triumph Group, Inc.

- Dana Incorporated

- AKG Group

- Visteon Corporation

- Calsonic Kansei Corporation (Marelli)

- Shanghai SENIU Chemical Equipment Co., Ltd.

- Air Products and Chemicals, Inc.

- Heatric (A Dover Company)

- IHI Corporation

- Alfa Laval AB

- Modine Manufacturing Company

- MAHLE GmbH

- SPX FLOW, Inc.

- Hangyang Group

Frequently Asked Questions

Analyze common user questions about the Brazed Aluminum Heat Exchangers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary applications driving the demand for Brazed Aluminum Heat Exchangers?

The primary applications driving demand are cryogenic processes, specifically Air Separation Units (ASUs) for producing industrial gases (O2, N2) and Natural Gas Liquefaction (LNG), where their high efficiency and ability to handle multi-stream fluid flows at extremely low temperatures are essential for commercial operation.

How does the Plate-Fin configuration contribute to market dominance in BAHE technology?

The Plate-Fin configuration dominates because it offers a significantly high heat transfer surface area per unit volume, resulting in a compact and lightweight design. This is crucial for large-scale industrial installations like LNG plants and is superior in efficiency compared to traditional shell and tube exchangers.

What are the major challenges restraining the growth of the Brazed Aluminum Heat Exchangers market?

Key restraints include the extremely high capital expenditure required for setting up specialized vacuum brazing facilities and the technical expertise necessary to achieve the precise manufacturing tolerances. Additionally, aluminum’s vulnerability to specific corrosive environments limits its use in certain high-temperature, aggressive chemical processes.

Which regional market is exhibiting the fastest growth in the BAHE sector and why?

The Asia Pacific (APAC) region is projected to exhibit the fastest growth, primarily fueled by extensive investment in new petrochemical facilities, expansion of industrial gas production capacity, and large-scale infrastructure projects across key economies like China, India, and Southeast Asia.

How is the Green Hydrogen economy influencing the future of Brazed Aluminum Heat Exchangers?

The Green Hydrogen economy presents a significant opportunity. BAHEs are vital for efficient thermal management in electrolysis cooling, hydrogen compression systems, and subsequent storage/transport liquefaction processes, positioning them as critical components in the transition to sustainable energy infrastructure.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager