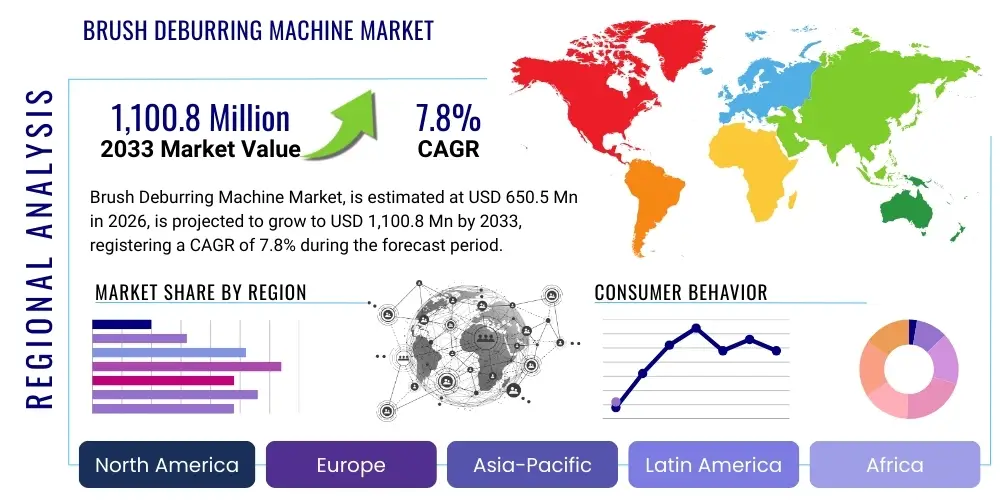

Brush Deburring Machine Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436067 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Brush Deburring Machine Market Size

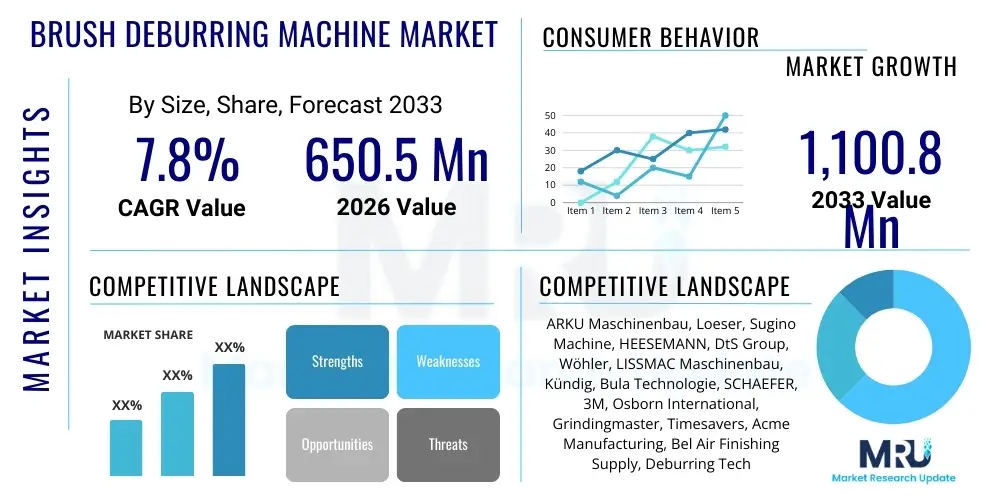

The Brush Deburring Machine Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 650.5 Million in 2026 and is projected to reach USD 1,100.8 Million by the end of the forecast period in 2033.

Brush Deburring Machine Market introduction

The Brush Deburring Machine Market encompasses specialized industrial equipment designed to remove burrs, sharp edges, and surface imperfections generated during manufacturing processes such as cutting, punching, milling, and grinding. These machines utilize various types of abrasive brushes—including wire, nylon abrasive, and composite materials—to achieve high-quality surface finishes necessary for component functionality and aesthetic appeal. The primary function is to enhance the precision and safety of parts used across demanding industries, ensuring components meet strict regulatory standards for critical applications like aerospace turbine blades, automotive engine parts, and medical implants.

The product portfolio within this market ranges from compact, manual bench-top units suitable for low-volume production to large, fully automated, CNC-controlled systems integrated into high-throughput production lines. Major applications span the metal fabrication, automotive, aerospace, and electronics sectors, where consistent edge quality and surface integrity are paramount. The benefits derived from utilizing these advanced deburring solutions include significant reduction in labor costs, improved part uniformity, minimized risk of fatigue failure due to stress concentration points (burrs), and enhanced operational efficiency. Furthermore, modern brush deburring technology often incorporates wet processing or dust collection systems to maintain a cleaner working environment and comply with occupational health and safety regulations.

Driving factors propelling market expansion include the global increase in precision manufacturing requirements, particularly in emerging economies undergoing rapid industrialization. The shift towards light-weighting materials, such as specialized aluminum alloys and composites in automotive and aerospace industries, necessitates more controlled and gentle finishing processes that brush deburring machines provide effectively. Additionally, the ongoing adoption of Industry 4.0 principles, favoring automation and connectivity, drives demand for high-end, intelligent deburring systems that can adjust parameters dynamically based on part specifications and feedback from integrated quality control sensors, thereby optimizing throughput and minimizing waste.

Brush Deburring Machine Market Executive Summary

The Brush Deburring Machine Market is experiencing robust expansion driven by the confluence of increasing automation across manufacturing sectors and the relentless pursuit of zero-defect quality standards globally. Key business trends indicate a strong move towards multi-functional machines that can perform deburring, edge rounding, and surface finishing simultaneously, reducing cycle times and capital investment requirements for end-users. Strategic alliances and mergers between brush manufacturers and machine builders are becoming common, aimed at developing optimized abrasive media and machine synergy. Furthermore, sustainability is emerging as a critical trend, pushing manufacturers toward energy-efficient models and closed-loop systems that minimize coolant and abrasive consumption.

Regional trends reveal Asia Pacific (APAC) as the dominant and fastest-growing market segment, primarily fueled by the burgeoning automotive manufacturing base in China, India, and Southeast Asia, coupled with substantial government investments in domestic defense and aerospace capabilities. North America and Europe, characterized by highly mature manufacturing ecosystems, exhibit strong demand for sophisticated, high-precision automated systems, driven by high labor costs and stringent quality regulations, particularly in the medical device and specialty tooling sectors. The Middle East and Africa (MEA) are showing promising growth, particularly in infrastructure and energy-related manufacturing, increasing the need for industrial finishing equipment.

Segment trends underscore the dominance of automatic brush deburring machines due to their scalability and ability to handle large volumes with superior consistency compared to manual or semi-automatic alternatives. By application, the Automotive segment remains the largest consumer, necessitated by the complexity and volume of components (e.g., transmission parts, brake systems). However, the Aerospace and Medical Devices segments are exhibiting the highest growth rates, reflecting their critical demand for ultra-precise edge quality and surface preparation, often requiring specialized planetary or wet deburring technologies. The increasing sophistication of CNC integration and robotic handling systems defines the trajectory of technology segmentation moving forward.

AI Impact Analysis on Brush Deburring Machine Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Brush Deburring Machine Market center predominantly on themes of process optimization, predictive maintenance, and quality control automation. Common questions address how AI can analyze complex part geometries to determine optimal brushing parameters, whether machine learning algorithms can predict brush wear life accurately to minimize downtime, and how AI-driven vision systems can replace human inspection for surface finish verification. The overarching concern is how AI integration can transition deburring from a traditionally empirical, trial-and-error process into a fully data-driven, adaptive manufacturing step, thereby eliminating manual adjustments and ensuring consistent quality across diverse material batches and complex component designs. Users anticipate AI will drive significant cost savings through reduced material waste and improved uptime, fundamentally altering the skill sets required to operate and maintain these high-precision systems.

- AI-driven parameter optimization: Algorithms analyze component CAD models, material hardness, and initial burr size to autonomously set ideal brush speed, pressure, and oscillation patterns.

- Predictive Maintenance (PdM): Machine learning models process vibration, temperature, and current consumption data to forecast potential mechanical failures or imminent brush replacement needs, maximizing machine uptime.

- Automated Quality Control: Integrated AI-powered vision systems (e.g., machine learning-enhanced cameras) inspect finished parts in real-time, instantly identifying defects or inconsistent surface roughness without human intervention.

- Adaptive Process Control: AI systems enable dynamic adjustments during the deburring cycle to compensate for inconsistencies in raw material or tool wear, ensuring consistent output quality regardless of external variables.

- Enhanced Energy Efficiency: AI optimizes machine operation cycles and power consumption based on real-time workload, contributing to lower operational costs and better environmental compliance.

- Improved Human-Machine Interaction: AI facilitates easier programming and troubleshooting via natural language interfaces and augmented reality tools, simplifying operations for technical staff.

DRO & Impact Forces Of Brush Deburring Machine Market

The Brush Deburring Machine Market is significantly influenced by powerful dynamics stemming from industrial modernization, materials science advancements, and global supply chain pressures. Drivers include the stringent quality standards mandated by industries like aerospace (e.g., Nadcap requirements) and medical devices (e.g., ISO 13485 compliance), which necessitate precise edge finishing to prevent catastrophic failures in critical components. The continuous evolution towards complex geometries produced by additive manufacturing (3D printing) and high-speed CNC machining generates complex burr characteristics that only advanced brush deburring systems can effectively manage. Furthermore, increasing automation across global manufacturing lines pushes facilities to replace laborious, inconsistent manual deburring with robust, repeatable machine processes to sustain competitive advantage.

Restraints primarily revolve around the high initial capital investment required for automated, multi-axis brush deburring systems, which can be prohibitive for small and medium-sized enterprises (SMEs). The operational complexity of these advanced machines necessitates highly skilled technicians for programming, maintenance, and process optimization, leading to a recognized skill gap in certain geographical regions. Additionally, the challenge of developing universal abrasive media capable of handling the increasing variety of hard, abrasive, and heat-sensitive materials (such as high-nickel alloys and ceramics) without compromising material integrity or brush life remains a continuous technical constraint that limits wider adoption in some niche areas.

Opportunities for growth are abundant, particularly in integrating robotics and advanced sensors (such as 3D scanners) to achieve fully autonomous deburring cells capable of 'lights-out' manufacturing. The burgeoning electric vehicle (EV) sector, which requires specialized deburring for intricate battery cooling plates and motor components, presents a high-growth application segment. Moreover, the expanding focus on edge rounding for functional purposes (e.g., improving coating adhesion, stress relief) rather than just burr removal opens new pathways for specialized machine development. Impact forces, driven by geopolitical instability affecting supply chains and fluctuating commodity prices (especially for steel and specialized abrasives), require manufacturers to adopt more resilient, localized manufacturing strategies and seek versatile, material-agnostic deburring solutions.

- Drivers: Increased demand for precision components; rising adoption of automation and robotics; stringent quality standards in aerospace and medical sectors; proliferation of advanced manufacturing techniques (e.g., additive manufacturing).

- Restraints: High capital expenditure for fully automated systems; technical challenges in deburring complex or hardened materials; shortage of highly specialized machine operators and programmers.

- Opportunities: Expansion into the Electric Vehicle (EV) component manufacturing; development of hybrid deburring systems (combining brushing with other technologies like vibratory finishing); growth in localized, customized small-batch production.

- Impact Forces: Rapid technological obsolescence driven by Industry 4.0; volatile raw material costs impacting machine and consumable pricing; environmental regulations promoting dry or minimal-lubrication processing methods.

Segmentation Analysis

The Brush Deburring Machine Market is segmented based on the operational mechanism, the degree of automation, the component size handling capabilities, and the end-use industry. This segmentation provides a granular view of market dynamics, revealing varying growth rates and technological preferences across different industrial applications. The most critical differentiation lies in the level of automation, separating manual, cost-effective solutions used in job shops from highly sophisticated, robotic, or CNC-integrated systems favored by Tier 1 automotive suppliers and aerospace manufacturers who require verifiable, repeatable processes for safety-critical parts. Understanding these segments is vital for manufacturers to tailor machine design, abrasive media, and service offerings to meet specific client production volumes and quality requirements.

- By Type:

- Rotary Deburring Machines

- Planetary Deburring Machines (for sheet metal and complex edges)

- Linear/Belt Deburring Machines (mainly for flat surfaces)

- CNC-Integrated Deburring Modules

- By Operation:

- Manual/Semi-Automatic

- Fully Automatic/Robotic Cells

- By End-Use Industry:

- Automotive & Transportation

- Aerospace & Defense

- Medical Devices & Instruments

- General Metal Fabrication

- Electronics & Electrical Components

- Tooling & Machinery

- By Abrasive Media:

- Wire Brushes (Steel, Brass)

- Abrasive Nylon Brushes (Silicon Carbide, Ceramic)

- Composite Brushes

Value Chain Analysis For Brush Deburring Machine Market

The value chain for the Brush Deburring Machine Market begins with the upstream suppliers responsible for providing raw materials and core technology components. This includes specialized metals for machine fabrication (steel, aluminum), high-precision electrical components (motors, sensors, PLCs), and critical consumable inputs such as high-grade abrasive filament materials (nylon, ceramics, specialized wires). Innovation upstream is focused on developing smarter sensors for adaptive control and designing more durable, self-sharpening abrasive brushes that minimize operational pauses for changeovers. The competitive landscape upstream is driven by cost efficiency and the ability to meet stringent quality specifications required for high-speed machining environments.

Midstream, the machine manufacturers and integrators assemble these components into specialized deburring systems. This stage involves significant Research and Development (R&D) investment focused on advanced kinematics (e.g., multi-axis movement), thermal stability, and software integration (CNC programming, robotic interfaces). Distribution channels play a critical role, involving direct sales teams for complex, customized, high-value robotic cells, and indirect distribution through industrial equipment distributors and regional resellers for standard, off-the-shelf units. Effective distribution relies heavily on technical support infrastructure, offering installation, training, and ongoing maintenance services, crucial for complex industrial machinery.

The downstream segment involves the end-users—the manufacturers who integrate these machines into their production lines. Key downstream activities include process engineering, operator training, and continuous monitoring of machine performance and surface quality output. Feedback from end-users regarding burr types, material sensitivities, and cycle time requirements drives future innovation back up the chain. For specialized machines targeting regulated industries (like aerospace), adherence to vendor qualification processes and providing comprehensive service agreements are essential components of value delivery, ensuring operational compliance and maximum uptime.

Brush Deburring Machine Market Potential Customers

Potential customers for Brush Deburring Machines are predominantly enterprises engaged in high-volume or high-precision metal and material processing where surface quality is a functional requirement. The primary buyers include Tier 1 and Tier 2 suppliers in the automotive industry, particularly those manufacturing engine blocks, transmissions, brake components, and chassis parts, where component reliability is directly linked to passenger safety and regulatory compliance. The shift towards EV manufacturing further targets producers of intricate aluminum heat exchangers and motor laminations, requiring minimal residual magnetism and extreme surface cleanliness.

Another major customer segment is the aerospace and defense sector, comprising OEMs and maintenance, repair, and overhaul (MRO) facilities that handle mission-critical components such as turbine blades, structural airframe parts, and specialized engine components. In this sector, burr removal must be precise, often requiring specific edge rounding radii to mitigate stress risers and prevent metal fatigue failure. Medical device manufacturers, specializing in surgical instruments, implants (e.g., knee joints, spinal plates), and minimally invasive tools, constitute a rapidly growing customer base, driven by the absolute necessity of flawless surface finish for biocompatibility and ease of sterilization, favoring automated, repeatable, and validated deburring processes.

Furthermore, general fabrication shops, mold and die makers, and electronics manufacturers procuring stamped parts or printed circuit board components also represent substantial demand. For these customers, the adoption of brush deburring machines is often driven by the need to scale production volumes while maintaining a consistent quality standard superior to manual finishing techniques. The trend towards integrating these machines into existing production cells via robot loading systems appeals strongly to large manufacturing facilities focused on maximizing throughput and minimizing human error.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 650.5 Million |

| Market Forecast in 2033 | USD 1,100.8 Million |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ARKU Maschinenbau, Loeser, Sugino Machine, HEESEMANN, DtS Group, Wöhler, LISSMAC Maschinenbau, Kündig, Bula Technologie, SCHAEFER, 3M, Osborn International, Grindingmaster, Timesavers, Acme Manufacturing, Bel Air Finishing Supply, Deburring Technologies, PFERD, Tyrolit, Boschert, Apex Machine Group, Weber-Steinmüller. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Brush Deburring Machine Market Key Technology Landscape

The key technology landscape in the Brush Deburring Machine Market is rapidly evolving, moving away from simple mechanical operations towards sophisticated, integrated solutions that offer enhanced precision and adaptability. Central to this evolution is the integration of high-speed Computer Numerical Control (CNC) technology, allowing for precise control over brush speed, feed rate, and angular alignment relative to complex part contours. This level of control is essential for deburring intricate components manufactured via high-precision milling or laser cutting, ensuring consistent edge rounding and surface finish without damaging thin or delicate features. Furthermore, the development of specialized kinematic structures, particularly in planetary head designs, allows brushes to sweep across all edges of a component simultaneously, significantly reducing processing time and improving efficiency for sheet metal applications.

The materials science surrounding the abrasive media itself constitutes a major technological focus. Manufacturers are continually developing new abrasive filament materials, such as ceramic-embedded nylon and specialized diamond-impregnated brushes, designed to maximize lifespan, maintain cutting efficiency on hard exotic alloys (e.g., titanium, Inconel), and minimize heat generation during the process. Wet deburring systems, which utilize coolant circulation, are becoming standard for handling materials prone to thermal deformation or requiring ultra-clean surfaces, driven by environmental controls and demands for finer finishes. The technological shift is fundamentally supported by advanced software for simulation and offline programming, enabling engineers to model the deburring process virtually before committing to expensive physical setup and testing, thereby reducing integration time.

The most significant technological advancement lies in the adoption of closed-loop feedback systems and machine vision. Modern brush deburring machines are increasingly equipped with high-resolution cameras and 3D laser scanners that assess the presence and size of burrs before and after processing. This data is fed back into the machine's control system, often managed by AI algorithms, allowing for dynamic adjustment of processing parameters in real-time. This level of autonomy ensures that every component is processed to the exact specification, eliminating over-processing or under-processing, which is critical for maximizing brush life and maintaining tight tolerance standards. These technologies facilitate the seamless integration of deburring operations into fully automated, robotic production lines, enhancing operational efficiency and data traceability in compliance with Industry 4.0 mandates.

Regional Highlights

Regional dynamics play a crucial role in shaping the Brush Deburring Machine Market, reflecting varying levels of industrial maturity, regulatory environments, and capital investment capacities across different geographies. Asia Pacific (APAC) currently dominates the market in terms of volume and is projected to exhibit the highest Compound Annual Growth Rate (CAGR) throughout the forecast period. This rapid growth is attributable to massive government-supported initiatives in key manufacturing nations, particularly China and India, focusing on expanding domestic automotive production, fostering electronics manufacturing (e.g., smartphone components, micro-electromechanical systems), and building robust defense manufacturing bases. The competitive landscape in APAC favors cost-effective, high-throughput automatic machines capable of handling large production runs, although demand for high-end European and American precision machinery is rising rapidly as quality standards elevate.

North America and Europe represent mature markets characterized by stringent quality assurance protocols, high labor costs, and a strong preference for highly automated, precision-oriented deburring solutions. In North America, the market growth is heavily concentrated within the aerospace, medical device, and specialized tooling sectors, driving demand for multi-axis CNC systems capable of complex contour deburring and validated process documentation. European markets, particularly Germany and Switzerland, remain global technology leaders, focusing on sustainability, energy efficiency, and the development of intelligent, self-optimizing deburring cells integrated within smart factory environments (Industry 4.0). The high cost of labor in these regions makes the investment in automation overwhelmingly economically favorable, ensuring continued demand for top-tier systems.

Latin America and the Middle East & Africa (MEA) are emerging regions for this market. Latin America, spurred by renewed foreign direct investment in automotive assembly and mining equipment fabrication in countries like Mexico and Brazil, is slowly transitioning from manual to semi-automatic deburring solutions. The MEA region, particularly the Gulf Cooperation Council (GCC) states, is investing heavily in diversification away from oil and gas, focusing on developing domestic defense capabilities, infrastructure, and general fabrication industries. This creates opportunities for basic to mid-range automatic deburring machines. Growth in these regions is often influenced by global economic stability and commodity prices, which dictate the pace of industrial capital expenditure. Technology adoption tends to focus initially on proven, robust, and easy-to-maintain machinery due to limited access to highly specialized technical support infrastructure compared to industrialized nations.

- North America: Focus on aerospace, medical implants, and high-precision components; high demand for automation and validated processes.

- Europe: Technological innovation hub; emphasis on Industry 4.0 integration, energy efficiency, and high-end planetary deburring systems for complex sheet metal.

- Asia Pacific (APAC): Largest market volume and fastest growth rate; driven by automotive, electronics, and mass metal fabrication, particularly in China and India.

- Latin America: Moderate growth fueled by automotive and capital equipment manufacturing; gradual shift from manual processes to semi-automatic systems.

- Middle East and Africa (MEA): Emerging market potential linked to infrastructure projects and defense industry localization; steady demand for foundational industrial machinery.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Brush Deburring Machine Market.- ARKU Maschinenbau

- Loeser

- Sugino Machine

- HEESEMANN

- DtS Group

- Wöhler

- LISSMAC Maschinenbau

- Kündig

- Bula Technologie

- SCHAEFER

- 3M (Abrasive Products Division)

- Osborn International

- Grindingmaster

- Timesavers

- Acme Manufacturing

- Bel Air Finishing Supply

- Deburring Technologies

- PFERD

- Tyrolit

- Boschert

- Apex Machine Group

- Weber-Steinmüller

Frequently Asked Questions

Analyze common user questions about the Brush Deburring Machine market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the demand for fully automatic brush deburring machines?

The primary driver is the necessity for repeatable, high-quality finishing of safety-critical components, especially in aerospace and automotive industries, coupled with the rising cost and scarcity of skilled manual labor globally, necessitating high-throughput automation.

How do brush deburring machines handle complex material types like titanium and nickel alloys?

Advanced brush deburring machines utilize specialized abrasive media, such as ceramic or diamond-embedded nylon brushes, combined with precision CNC controls and wet processing systems to effectively remove tough burrs while mitigating excessive heat generation and material smearing.

Which geographical region exhibits the fastest growth potential in the deburring machine market?

Asia Pacific (APAC), particularly China and India, demonstrates the fastest growth potential, driven by vast expansion in domestic manufacturing capacity across automotive, electronics, and general metal fabrication sectors, demanding high-volume processing equipment.

What role does Industry 4.0 play in the evolution of brush deburring technology?

Industry 4.0 enables the integration of sensors, AI, and cloud connectivity into deburring machines, allowing for real-time monitoring, predictive maintenance, automated quality control via vision systems, and seamless integration into fully autonomous smart factory workflows.

What is the key difference between rotary and planetary brush deburring systems?

Rotary systems typically use fixed brushes for stationary parts or simple movements, while planetary systems involve brushes rotating around a central point, often simultaneously oscillating, making them ideal for achieving uniform edge rounding on complex geometries and perforated sheet metal parts.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager