Brushless Motorised Chain Hoist Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432141 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Brushless Motorised Chain Hoist Market Size

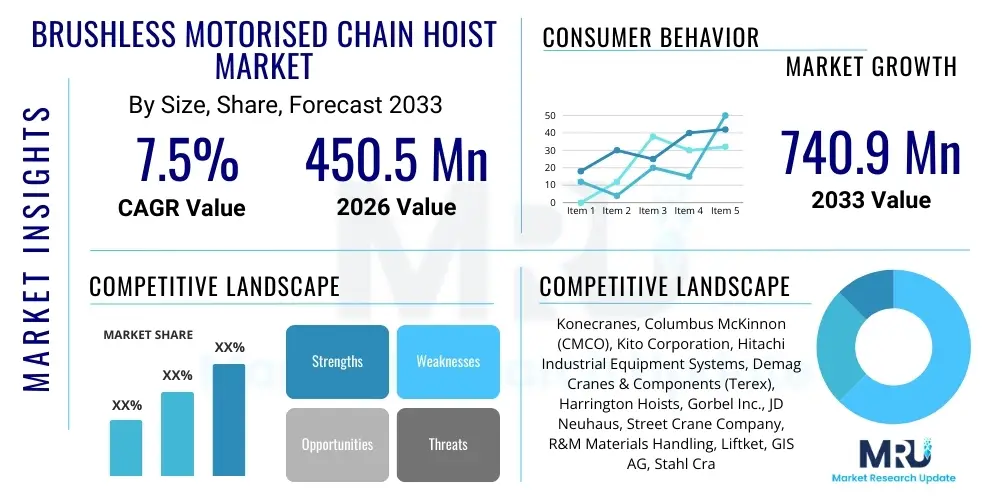

The Brushless Motorised Chain Hoist Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2026 and 2033. The market is estimated at USD 450.5 Million in 2026 and is projected to reach USD 740.9 Million by the end of the forecast period in 2033.

Brushless Motorised Chain Hoist Market introduction

The Brushless Motorised Chain Hoist Market encompasses advanced material handling equipment utilizing highly efficient brushless DC (BLDC) motors for vertical lifting operations. Unlike traditional brushed motors, BLDC technology offers superior torque delivery, reduced maintenance requirements due to the absence of physical brushes, enhanced energy efficiency, and significantly extended operational life. These hoists are integral to modern industrial processes requiring precise, repeatable, and heavy-duty lifting capabilities in environments ranging from general manufacturing floors to highly controlled cleanroom settings. The core product provides a robust, electronically controlled solution for optimizing production flow and ensuring stringent safety standards are met during load manipulation.

Major applications for brushless motorized chain hoists span across critical sectors including automotive assembly lines, heavy machinery manufacturing, complex warehousing and logistics operations, and shipbuilding. The inherent benefits of using brushless technology—such as compact design, lower noise levels, and excellent speed control—make them indispensable for automated production cells and high-cycle applications where downtime is extremely costly. Furthermore, the enhanced reliability and ability to integrate sophisticated electronic controls facilitate seamless adoption within Industry 4.0 frameworks, supporting data logging and predictive maintenance strategies that optimize overall equipment effectiveness (OEE).

The market growth is primarily driven by the global push towards automation and efficiency in manufacturing processes, coupled with stricter industrial safety regulations that favor high-precision lifting gear. Additionally, the rising cost of energy and the corporate emphasis on sustainable operations strongly support the adoption of energy-efficient BLDC-equipped hoists over older, less efficient AC or brushed DC alternatives. The continued expansion of global supply chains and the resulting increase in demand for warehousing capacity and automated storage and retrieval systems (AS/RS) further propel the demand for these sophisticated hoisting solutions across developed and emerging economies alike.

Brushless Motorised Chain Hoist Market Executive Summary

The Brushless Motorised Chain Hoist Market is experiencing substantial expansion, driven by crucial business trends focusing on sustainable manufacturing, operational digitalization, and high precision in material handling. Key business trends include the rapid replacement cycle of older, inefficient hoisting equipment with BLDC models that reduce total cost of ownership (TCO) through minimized maintenance and lower energy consumption. The integration capabilities of these hoists—allowing for seamless communication with programmable logic controllers (PLCs) and manufacturing execution systems (MES)—are accelerating adoption in automated environments. Regional trends indicate robust growth in Asia Pacific, propelled by massive industrial infrastructure development in China and India, while North America and Europe maintain strong positions due to stringent safety standards and the ongoing modernization of existing factory infrastructure. The shift toward electrification across industrial equipment globally serves as a foundational catalyst for market expansion.

Segment trends highlight the dominance of the variable speed control segment, aligning with the industry demand for precise positioning required in tasks such as die changing and engine placement. By capacity, the medium-duty hoists (2 to 5 tons) account for the largest market share, catering primarily to the booming automotive and general manufacturing sectors. However, the heavy-duty segment (above 5 tons) is projected to exhibit the highest CAGR, spurred by large-scale infrastructure projects and investment in specialized industries like aerospace and heavy engineering. The proliferation of IIoT devices is fundamentally transforming the hoist monitoring and control sub-segments, enabling features like remote diagnostics and condition-based monitoring, which significantly enhance operational longevity and reduce unexpected failures.

Overall, the market trajectory is highly positive, reflecting a fundamental technological shift within industrial lifting. Companies are focusing intensely on miniaturization and increasing the power density of brushless motor technology, allowing for more compact and powerful hoist designs. Strategic mergers, acquisitions, and partnerships are shaping the competitive landscape, with established players leveraging their distribution networks to promote advanced BLDC solutions, while niche technology providers focus on specific applications like explosive atmospheres (Ex-rated hoists) or ultra-high precision requirements. This dynamic environment necessitates continuous innovation in motor control algorithms and materials science to maintain a competitive edge and capture market opportunities stemming from global industrial maturation.

AI Impact Analysis on Brushless Motorised Chain Hoist Market

Common user questions regarding AI's influence on the Brushless Motorised Chain Hoist Market primarily revolve around how machine learning can enhance operational efficiency, prevent catastrophic failures, and integrate seamlessly into smart factories. Users frequently ask about the practical implementation of predictive maintenance algorithms, the feasibility of AI-driven anomaly detection in lifting profiles, and the standardization of data collection protocols from embedded sensors. Key concerns include data security, the necessity of specialized personnel to manage AI systems, and the return on investment (ROI) associated with implementing sophisticated machine learning models for equipment monitoring. The consensus expectation is that AI will transform hoists from simple lifting tools into highly intelligent, self-optimizing material handling assets, capable of contributing actively to holistic production system efficiency and safety. The market anticipates a significant shift towards "smart hoists" that autonomously manage load profiles and flag potential failures long before they impact production schedules.

- AI integration enables predictive maintenance by analyzing vibration, current draw, and temperature data from BLDC motors and gearboxes to forecast component failure accurately.

- Machine learning algorithms optimize hoist operational cycles, ensuring energy consumption is minimized based on real-time load and movement patterns.

- AI facilitates sophisticated load balancing and anti-sway features, crucial for precision handling in automated assembly lines, improving overall process repeatability.

- Generative AI models assist in the rapid design and simulation of customized brushless hoist systems tailored for specific, complex industrial environments.

- Intelligent diagnostics allow remote fault detection and root cause analysis, drastically reducing mean time to repair (MTTR) and minimizing human intervention.

- AI-driven safety protocols monitor operator behavior and environmental conditions, autonomously slowing or stopping operations if predefined risk metrics are exceeded.

- Integration with Digital Twins allows factory managers to simulate the impact of hoist usage on overall production throughput and schedule maintenance without affecting uptime.

DRO & Impact Forces Of Brushless Motorised Chain Hoist Market

The Brushless Motorised Chain Hoist Market is fundamentally shaped by several powerful drivers, chief among them being the pervasive demand for high efficiency and reliability in modern manufacturing, directly addressed by BLDC technology. This is further amplified by strict global safety standards requiring precise load control and the minimization of equipment downtime. However, restraints exist, particularly the higher initial capital expenditure compared to conventional hoists, which can slow adoption in price-sensitive emerging markets. Furthermore, the specialized electronic controls required for brushless systems necessitate higher skilled maintenance personnel, posing a challenge in regions with skill gaps. Opportunities are abundant, rooted in the massive global growth of e-commerce logistics (requiring highly automated warehouses), expansion into hazardous and cleanroom applications where brushless motors excel due to reduced particle generation, and the potential for leveraging advanced IIoT integration for holistic asset management. These forces create a dynamic landscape where initial cost barriers are gradually overcome by long-term operational savings and enhanced productivity.

The primary impact forces propelling the market forward are technological advancements in power electronics and motor control systems. Miniaturization of controllers and increasing power density in rare-earth magnets (used in high-performance BLDC motors) enable manufacturers to offer smaller, lighter hoists with greater lifting capacity, fundamentally altering equipment design. Conversely, the restraint imposed by global supply chain volatility, particularly concerning critical electronic components and rare-earth materials, significantly impacts production timelines and cost stability. The opportunity to standardize communication protocols (like OPC UA) for hoist integration into smart factory architectures represents a critical leverage point, ensuring that brushless hoists are not standalone assets but integral, communicative components of a digitalized production ecosystem. Successfully navigating these impact forces—balancing high-tech innovation with supply chain resilience—is paramount for sustained market success.

Segmentation Analysis

The Brushless Motorised Chain Hoist market is comprehensively segmented based on technology type, lifting capacity, operating speed mechanism, and key end-user industry, reflecting the diverse application requirements globally. Technology segmentation differentiates between standard BLDC hoists and specialized variants such as explosion-proof or harsh environment models. The capacity segmentation is crucial, determining the primary target sectors, from light assembly operations requiring low capacity to heavy engineering and infrastructure demanding high-capacity lifting solutions. Operating speed is segmented into fixed speed and the highly critical variable speed control, which is gaining traction due to the demand for superior precision and smooth movement in automated settings. Understanding these segments is vital for manufacturers to tailor their product offerings and marketing strategies effectively to specific industrial needs and regulatory landscapes.

- By Lifting Capacity

- Below 1 Ton

- 1 Ton to 5 Tons (Medium Duty)

- Above 5 Tons (Heavy Duty)

- By Operating Speed

- Fixed Speed Hoists

- Variable Speed Control Hoists (VFD/Inverter Driven)

- By Power Source

- Single Phase (Lower Capacity)

- Three Phase (Industrial Heavy Duty)

- By End-User Industry

- Automotive and Transportation

- Heavy Machinery Manufacturing

- Logistics and Warehousing (e-commerce focus)

- Aerospace and Defense

- General Manufacturing

- Chemical and Petrochemical (Explosion-Proof applications)

- By Sales Channel

- Direct Sales (Major Projects)

- Distributors and Dealers

- Online Channels (Replacement Parts and Small Units)

Value Chain Analysis For Brushless Motorised Chain Hoist Market

The value chain for the Brushless Motorised Chain Hoist Market begins with upstream activities focused on the procurement and manufacturing of highly specialized components, most notably the BLDC motors themselves, high-performance permanent magnets (often rare-earth materials), specialized motor controllers (inverters/VFDs), and robust mechanical components like gears, chains, and hooks. The competitive advantage upstream lies in securing reliable, high-quality, and cost-effective supplies of magnets and semiconductor components necessary for the electronic control systems. Integration of these components occurs during the manufacturing phase, where quality control and assembly precision are critical due to the complex interaction between electronic control and mechanical systems. Manufacturers must invest heavily in automated assembly and testing procedures to ensure the precise operation and safety compliance of the final product.

The downstream activities involve distribution, installation, and comprehensive aftermarket services. Distribution channels are typically a mix of direct sales—preferred for large industrial contracts and custom-engineered systems—and indirect channels relying on certified regional distributors and dealers who offer localized support and maintenance. The efficiency of the distribution network is crucial, as hoists are often large capital equipment purchases requiring significant logistical coordination. Post-sales service, including periodic maintenance, repair, and supplying genuine replacement parts (especially electronic modules and specialized chains), contributes substantially to the overall profitability and customer retention within the market. Direct service contracts are increasingly utilized, often incorporating remote monitoring capabilities leveraging IIoT to ensure proactive maintenance.

The transition from a purely transactional sales model to a service-centric approach is observable in the value chain, where the emphasis shifts towards minimizing equipment downtime through digitalization. Direct engagement with major end-users allows manufacturers to co-develop highly customized solutions, capturing higher margins and securing long-term service agreements. The indirect channel plays a vital role in reaching small and medium enterprises (SMEs) and providing essential regional inventory holding and immediate technical support. Optimization across the entire chain—from magnet sourcing stability upstream to providing fast, competent aftermarket service downstream—is essential for sustained market leadership.

Brushless Motorised Chain Hoist Market Potential Customers

Potential customers for Brushless Motorised Chain Hoists are defined by their operational scale, their requirement for precision lifting, and their dedication to adopting energy-efficient and low-maintenance capital equipment. The primary buyers are large-scale manufacturers in the automotive sector, where hoists are indispensable for managing engine blocks, chassis components, and final assembly tasks, demanding high cycle rates and accurate positioning. Similarly, heavy machinery manufacturers, including those producing construction equipment and agricultural vehicles, are major end-users due to the necessity of lifting massive, awkward components during fabrication. Furthermore, the burgeoning e-commerce and logistics sector, characterized by highly automated mega-warehouses and distribution centers utilizing AS/RS systems, represents a rapidly growing customer base prioritizing speed, reliability, and integration capability of their lifting devices.

A second critical customer segment includes specialized industrial environments such as pharmaceutical manufacturing, semiconductor fabrication (cleanrooms), and facilities handling flammable materials (petrochemicals and chemical processing). In these settings, the non-sparking characteristics, sealed design, and precise electronic control of brushless hoists are mandatory for maintaining sterile conditions or adhering to Ex-rating safety requirements. Infrastructure projects, including shipbuilding, power generation facilities, and large construction sites, also constitute significant buyers of heavy-duty brushless hoists (5+ tons capacity) due to the need for continuous, reliable lifting in harsh outdoor or challenging internal environments. These diverse end-users share a common requirement for high uptime and reduced operating costs, which brushless technology intrinsically provides.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.5 Million |

| Market Forecast in 2033 | USD 740.9 Million |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Konecranes, Columbus McKinnon (CMCO), Kito Corporation, Hitachi Industrial Equipment Systems, Demag Cranes & Components (Terex), Harrington Hoists, Gorbel Inc., JD Neuhaus, Street Crane Company, R&M Materials Handling, Liftket, GIS AG, Stahl CraneSystems, Verlinde, ZPMC. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Brushless Motorised Chain Hoist Market Key Technology Landscape

The technological landscape of the Brushless Motorised Chain Hoist market is dominated by advancements in permanent magnet synchronous motor (PMSM) technology, which represents the highest evolution of BLDC systems for industrial hoisting. These motors offer incredibly high power density and efficiency, enabling smaller, lighter, and yet more powerful hoists than previous generations. Crucially, the deployment of sophisticated vector control (Field-Oriented Control or FOC) algorithms in the variable frequency drives (VFDs) ensures precise torque and speed management across the entire operational range, eliminating jerks and providing ultra-smooth, slow-speed positioning capabilities essential for high-precision assembly tasks. This technological synergy between advanced motor design and smart electronics is the core differentiator for modern brushless hoists, offering superior performance over conventional AC motor counterparts.

Furthermore, the integration of Industrial Internet of Things (IIoT) sensors and communication modules has become a standard feature, fundamentally transforming the hoist from a mechanical tool to a smart asset. Embedded sensors monitor key performance indicators (KPIs) such as motor temperature, vibration levels, and load cycles, transmitting this data via secure wireless protocols (like MQTT) to centralized maintenance systems or cloud platforms. This capability supports real-time remote diagnostics, condition monitoring, and facilitates the shift toward prescriptive maintenance schedules, significantly maximizing equipment lifespan and operational uptime. The reliance on advanced microprocessors and robust power semiconductors (like IGBTs or MOSFETs) within the VFDs ensures reliable operation even under fluctuating electrical loads and harsh industrial environments.

Safety technology is also a major technological focus, incorporating features such as electronic limit switches, advanced brake monitoring systems (often utilizing redundant magnetic braking alongside mechanical brakes), and smart overload protection that communicates load status directly to the control system. The development of robust enclosure ratings (IP65+) is essential for protecting the sophisticated electronics from dust, moisture, and chemicals prevalent in heavy industry. Future technological evolution is centered on refining sensor accuracy, enhancing the resilience of rare-earth magnet performance under high thermal stress, and integrating standardized digital communication interfaces to ensure seamless plug-and-play functionality within diverse smart factory ecosystems.

Regional Highlights

The global market for Brushless Motorised Chain Hoists exhibits varied growth dynamics across key geographical regions, influenced heavily by regional industrial maturity, regulatory frameworks, and investment in automation infrastructure. Asia Pacific (APAC) stands out as the fastest-growing region, driven by explosive growth in manufacturing capacities, particularly in China, South Korea, and India. Large government investments in infrastructure, the establishment of massive logistics hubs to support global trade, and the rapid adoption of automated assembly lines across the automotive and electronics sectors fuel the demand here. Manufacturers are actively localizing production and service networks in APAC to capitalize on the scaling industrialization.

North America and Europe represent mature markets characterized by replacement demand and a strong emphasis on modernization and safety compliance. In these regions, the demand is largely driven by the necessity to upgrade aging lifting equipment to meet stringent safety standards (like CE marking in Europe) and to achieve higher energy efficiency goals, making the energy-saving brushless technology highly attractive. The adoption rates of advanced variable speed hoists and IIoT-enabled features are highest in these regions, reflecting a strong integration into Industry 4.0 paradigms within specialized industries such as aerospace and advanced manufacturing.

Latin America and the Middle East & Africa (MEA) are emerging markets, primarily driven by investments in the mining, oil & gas, and heavy construction sectors. While adoption rates are slower due to price sensitivity, the shift toward standardized, high-reliability equipment is gradually increasing, particularly in economically diversifying nations like Saudi Arabia, UAE, and Brazil. Growth in these regions is expected to accelerate as industrial safety standards tighten and global players increase their direct presence and distribution coverage, emphasizing robust, low-maintenance brushless solutions suitable for challenging climate conditions.

- Asia Pacific (APAC): Highest growth market; driven by massive automotive and electronics manufacturing expansion, logistics modernization, and significant industrial infrastructure investment, especially in China and India.

- North America: Strong demand for high-precision, variable speed hoists; market driven by regulatory compliance, replacement cycles, and sophisticated integration into smart factory environments (Aerospace, Defense, Automotive).

- Europe: Focus on energy efficiency, adherence to strict CE safety directives, and strong uptake in robotics integration; key markets include Germany, France, and Italy, emphasizing premium, high-reliability hoists.

- Middle East & Africa (MEA): Emerging demand fueled by investment in oil & gas, petrochemicals, and large construction projects; preference for durable, weather-resistant hoists capable of handling extreme temperatures.

- Latin America: Gradual adoption spurred by mining and heavy engineering sectors; market characterized by a mix of new installations and strategic upgrades prioritizing robust functionality and ease of local servicing.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Brushless Motorised Chain Hoist Market.- Konecranes

- Columbus McKinnon (CMCO)

- Kito Corporation

- Hitachi Industrial Equipment Systems

- Demag Cranes & Components (Terex)

- Harrington Hoists

- Gorbel Inc.

- JD Neuhaus

- Street Crane Company

- R&M Materials Handling

- Liftket

- GIS AG

- Stahl CraneSystems

- Verlinde

- ZPMC

- Whiting Corporation

- Abus Kransysteme

- Chester Hoist

- Acco Material Handling Solutions

- Electrolift Inc.

Frequently Asked Questions

Analyze common user questions about the Brushless Motorised Chain Hoist market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of a brushless chain hoist over traditional AC hoists?

Brushless Motorised Chain Hoists offer significantly higher energy efficiency, require substantially less maintenance due to the elimination of wearable brushes, provide superior speed and position control via VFDs, and possess a longer operational lifespan, leading to reduced total cost of ownership (TCO).

How does BLDC technology impact the safety features of material handling systems?

BLDC technology, combined with precise electronic controls, drastically improves safety by enabling highly accurate load positioning, better anti-sway control, rapid and controlled braking response, and seamless integration with intelligent overload protection systems, minimizing operational risks.

Which end-user industry is driving the highest growth in the demand for these hoists?

The automotive manufacturing sector and the rapidly expanding logistics and e-commerce warehousing industries are the highest growth drivers, owing to their critical need for high-cycle operations, stringent positioning accuracy, and integration into fully automated production and retrieval systems.

What role does IIoT play in the future development of brushless motorized chain hoists?

IIoT enables hoists to become smart assets by facilitating condition monitoring, real-time remote diagnostics, and predictive maintenance scheduling through integrated sensors and data connectivity, optimizing uptime and drastically improving operational efficiency within Industry 4.0 environments.

Is the initial investment cost for a brushless hoist justified by its long-term performance?

Yes, while brushless hoists have a higher initial capital outlay than conventional models, the investment is justified by the substantial long-term savings derived from reduced energy consumption, minimal maintenance requirements, superior durability, and significant reduction in unplanned operational downtime.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager