Bungee Shock Cord Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 434930 | Date : Dec, 2025 | Pages : 258 | Region : Global | Publisher : MRU

Bungee Shock Cord Market Size

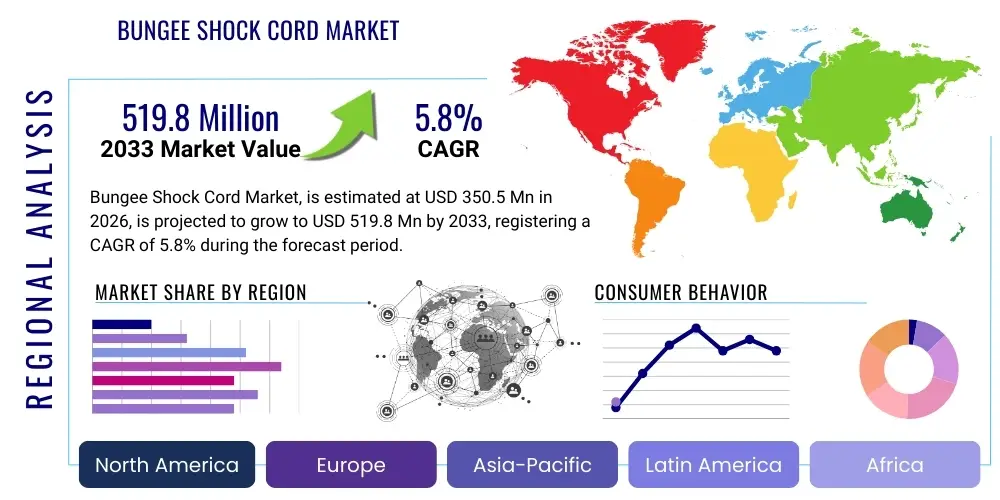

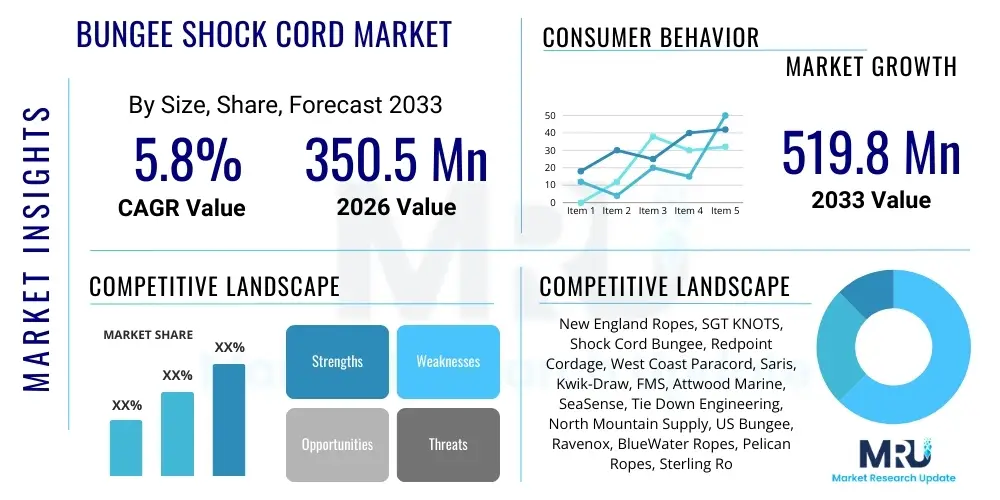

The Bungee Shock Cord Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 350.5 Million in 2026 and is projected to reach USD 519.8 Million by the end of the forecast period in 2033.

Bungee Shock Cord Market introduction

The Bungee Shock Cord Market encompasses the production, distribution, and utilization of highly elastic cords, typically featuring a core of natural or synthetic rubber strands surrounded by a woven sheath of materials such as nylon, polyester, or polypropylene. This construction allows the cord to absorb substantial kinetic energy, providing essential shock absorption, elasticity, and securing capabilities across diverse industrial and consumer applications. The primary function of the shock cord is to stretch and quickly return to its original length, making it invaluable where resilience and dynamic tension management are required, such as in securing tarpaulins, equipment bundling, and automotive tie-downs. The market is characterized by a high degree of material specificity, where cord diameter and jacket material dictate the cord's load capacity, abrasion resistance, and intended environment of use (e.g., UV-resistant jackets for marine applications).

Major applications of Bungee Shock Cords span critical sectors including marine and maritime operations, where their resistance to saltwater and UV degradation is paramount for docking and securing covers; the automotive industry for cargo nets and internal restraints; and the robust growth sector of outdoor recreation and sporting goods, utilizing cords for camping gear, tent poles, and luggage security. The flexibility and ease of use of these cords, coupled with their ability to perform repeatedly under high strain, establish them as a preferred fastening and tensioning solution over traditional rigid ropes or inelastic straps. Furthermore, the defense and military sectors rely on high-specification shock cords for securing sensitive equipment during transport and for specialized tactical gear.

The market growth is fundamentally driven by the global expansion of recreational activities, including camping, boating, and adventure sports, which necessitate lightweight and reliable securing mechanisms. Technological advancements focused on improving cord longevity, specifically through enhanced rubber formulations that offer better cold flexibility and resistance to petroleum products, are also significant market drivers. Additionally, increased construction activity globally demands high-quality tie-downs and restraints, further bolstering industrial application demand. The core benefits, including superior elongation properties (often 100% to 150% stretch), durability, and cost-effectiveness relative to complex mechanical tensioning systems, solidify the Bungee Shock Cord's position as an indispensable component in various end-user markets.

Bungee Shock Cord Market Executive Summary

The Bungee Shock Cord Market is poised for steady expansion through the forecast period, driven primarily by robust demand from the outdoor recreation and marine sectors, which continue to prioritize high-performance, weather-resistant securing solutions. Key business trends indicate a shift towards advanced synthetic materials, such as specialized EPDM and high-grade nylon jackets, enhancing product lifecycle and utility in harsh environments. Manufacturers are increasingly focusing on customization, offering specialty cords with unique diameters, colors, and end-fittings (hooks, clips) to cater to specific industrial and OEM requirements, thus commanding higher profit margins compared to generic retail products. Consolidation among core material suppliers and increased automation in the braiding and assembly processes are optimizing operational efficiencies across the value chain, addressing concerns related to labor costs and material input volatility.

Regionally, North America maintains market dominance due to high levels of consumer spending on recreational vehicles (RVs), boating, and camping equipment, supported by an established culture of DIY and outdoor activities. Europe follows closely, characterized by a strong marine industry and stringent quality standards for industrial equipment, pushing demand for premium, certified shock cords. Asia Pacific (APAC) is projected to exhibit the fastest growth rate, fueled by expanding manufacturing hubs, rapid urbanization leading to increased construction and infrastructure projects, and rising disposable incomes boosting participation in leisure activities. Investment in localized production facilities within APAC is a strategic trend allowing global players to mitigate logistical costs and better serve regional OEMs.

Segment trends highlight the 1/4 inch and 3/8 inch diameter segments as major revenue contributors, representing the optimal balance of strength and flexibility required for most general utility and medium-duty industrial applications. In terms of material, the synthetic rubber/EPDM core segment is experiencing accelerated growth, largely due to its superior resistance to extreme temperatures, ozone, and UV radiation compared to traditional natural latex. The distribution landscape is evolving, with online retail and direct-to-consumer channels witnessing rapid adoption, providing specialty manufacturers direct access to end-users and allowing for more targeted marketing of customized cord solutions, thereby challenging traditional brick-and-mortar hardware store distribution models.

AI Impact Analysis on Bungee Shock Cord Market

Users frequently inquire about how AI can optimize the typically manual and material-intensive process of shock cord manufacturing, particularly regarding raw material sourcing, quality control, and predictive maintenance. Common concerns center on whether AI can effectively manage the inherent variability in natural rubber elasticity and synthetic polymer consistency, and how it might influence product traceability and supply chain resilience. Expectations are high that AI-driven analytics will revolutionize demand forecasting for seasonal recreational markets and industrial inventory management. The central theme emerging from these queries is the desire to leverage AI for achieving greater precision in tension specifications and automating the detection of material flaws, thereby reducing waste and ensuring product reliability under operational stress.

AI's influence is transforming several facets of the Bungee Shock Cord market, starting with predictive modeling for raw material procurement. Machine learning algorithms analyze global commodity prices, geopolitical stability, and weather patterns that affect natural rubber yields, providing manufacturers with optimal timing and pricing strategies for inventory acquisition. Furthermore, in the manufacturing phase, AI-powered computer vision systems are deployed to inspect the uniformity of the cord's woven jacket and the integrity of the elastic core in real-time. These systems can detect subtle defects—such as uneven braiding, core migration, or slight variances in diameter—that are imperceptible to the human eye, ensuring only high-specification products proceed to final assembly. This proactive quality assurance dramatically reduces recall risk and enhances overall brand reputation for durability.

Beyond quality control, AI is instrumental in streamlining logistics and optimizing the complex global supply chain. AI-driven routing and warehouse management systems minimize shipping delays and costs, crucial for manufacturers dealing with bulk materials and varied finished product sizes. For the retail segment, predictive analytics utilize historical sales data, social media trends related to outdoor activities, and weather forecasts to accurately predict regional and seasonal demand for specific cord diameters and colors. This allows retailers and distributors to maintain optimal inventory levels, minimizing stockouts during peak seasons (e.g., summer boating months) and reducing obsolescence, thereby enhancing profitability across the entire distribution network.

- AI-powered predictive maintenance minimizes downtime for braiding and extrusion machinery, maximizing output efficiency.

- Computer vision systems automate defect detection in weaving and core alignment, ensuring adherence to stringent load and elongation specifications.

- Machine learning optimizes inventory management and supply chain logistics based on granular regional demand forecasting for recreational markets.

- Data analytics facilitate the design phase by simulating material performance under various stress conditions, accelerating R&D for new polymer blends.

- AI enhances traceability by tracking batches of core rubber and jacket materials from source to final product, crucial for industrial and military certifications.

DRO & Impact Forces Of Bungee Shock Cord Market

The Bungee Shock Cord Market is primarily driven by the burgeoning popularity of outdoor recreational activities globally, coupled with ongoing technological advancements that improve cord durability and performance, especially in high-stress environments like marine and industrial logistics. However, the market faces significant restraints, chiefly concerning the volatile cost of raw materials, particularly natural latex and petrochemical-derived synthetic polymers (e.g., polyester, polypropylene). Opportunities are abundant in the development of specialized, eco-friendly cord formulations and integrating smart technologies for enhanced monitoring in industrial applications. These factors combine to create a dynamic market environment where material innovation and supply chain resilience determine competitive success, impacting pricing structures and product lifecycle expectations.

Drivers for market expansion include the sustained growth in marine vessel ownership and the increasing complexity of cargo securing regulations, which mandate reliable tensioning devices. The military and defense sectors represent a stable, high-value segment, requiring customized, highly durable, and flame-retardant shock cords for specialized equipment and parachute systems. Furthermore, consumer demand for aesthetically pleasing and high-visibility cords for personal use (e.g., securing bike racks, bundling household items) continues to push innovation in jacket colors and patterns. The primary challenge, or restraint, remains the reliance on global commodity markets for raw rubber, making manufacturers susceptible to sudden price shocks and supply disruptions. Additionally, the proliferation of low-quality, inexpensive cords from uncertified sources poses a competitive restraint to premium manufacturers, often misleading consumers on critical metrics like UV resistance and elongation tolerance.

Significant opportunities lie in the development and scaling of bio-based and recycled polymer alternatives for the cord jacket and core, aligning with global sustainability mandates and attracting environmentally conscious consumer segments. The market impact forces include the increasing regulatory scrutiny on product safety and performance, especially in the EU and North America, which pushes smaller players out and favors established manufacturers capable of high-level quality certification. Porter's Five Forces analysis highlights the high bargaining power of large distributors who control access to consumer markets, while the threat of substitution remains moderate, primarily from ratchet straps or specialized netting systems, though the shock cord's unique elasticity provides a distinct functional advantage that is difficult to fully replicate, particularly for shock mitigation.

Segmentation Analysis

The Bungee Shock Cord market segmentation provides a comprehensive view of the product landscape based on crucial operational characteristics such as diameter, material composition, and application sector. Analyzing these segments is vital for manufacturers to tailor production capabilities and for marketers to target specific end-user needs, whether they are seeking high-tensile cords for securing heavy loads in industrial logistics or lightweight, UV-resistant cords for securing marine bimini tops. The distinct requirements across segments—ranging from extreme weather resistance in military applications to high aesthetics in retail consumer products—drive differentiated pricing strategies and innovation efforts across the value chain. This granular breakdown allows for accurate market sizing and forecasting based on macro-economic shifts within specific industry verticals.

Segmentation by diameter is critical as it directly correlates with tensile strength and maximum working load, which are key determinants for user purchasing decisions. Smaller diameters (1/8 inch to 1/4 inch) dominate the consumer and light recreation markets, offering flexibility and low profile. Conversely, larger diameters (3/8 inch and above) are reserved for heavy-duty industrial, military, and specific marine rigging applications where robust strength and durability are non-negotiable, often commanding a significant price premium due to the higher material input required. The material segmentation (Natural Rubber vs. Synthetic Rubber/EPDM) highlights the industry's shift towards synthetic options due to their superior chemical and ozone resistance, despite the higher initial cost compared to natural latex.

Application segmentation reveals the core consumption patterns, with Recreation/Outdoor and Marine segments serving as the primary revenue generators, characterized by high-volume seasonal demand. The Automotive and Industrial segments, while potentially lower volume, require cords meeting stringent performance standards and longevity requirements, driving demand for specialized, high-grade materials. Understanding the interplay between these segmentation variables allows stakeholders to forecast market saturation points and identify untapped niches, such as custom-engineered cords for specialized industrial automation tasks or modular building construction.

- By Diameter:

- 1/8 inch (3.175 mm)

- 3/16 inch (4.76 mm)

- 1/4 inch (6.35 mm)

- 5/16 inch (7.94 mm)

- 3/8 inch (9.525 mm)

- 1/2 inch (12.7 mm)

- Others (e.g., specialty large industrial diameters)

- By Material Core:

- Natural Rubber/Latex

- Synthetic Rubber (e.g., EPDM, Polyisoprene)

- Polypropylene/Latex Blends

- By Jacket Material:

- Nylon

- Polyester

- Polypropylene

- High-Density Polyethylene (HDPE)

- By Application:

- Automotive (Cargo Nets, Tie Downs)

- Marine (Dock Lines, Boat Covers, Rigging)

- Industrial (Tarpaulin Securing, Equipment Bundling, Scaffolding)

- Recreation/Outdoor (Camping, Hiking, Sporting Goods)

- Military/Defense

- Aerospace

- By Distribution Channel:

- Online Retail

- Hardware Stores/DIY Centers

- Specialty Stores (Marine/Outdoor Equipment)

- Direct Sales (OEM and Industrial Supply)

Value Chain Analysis For Bungee Shock Cord Market

The value chain for the Bungee Shock Cord market begins with the upstream sourcing of raw materials, primarily natural latex or synthetic rubbers for the core, and various polymers like nylon, polyester, and polypropylene for the protective sheath. This upstream segment is characterized by significant price volatility and reliance on global commodity markets, necessitating strong procurement strategies to maintain cost competitiveness. Manufacturing involves specialized processes, including rubber extrusion (for forming the core strands) and sophisticated textile braiding or weaving (for the jacket). Quality control during this stage is paramount, focusing on elasticity consistency, UV resistance integration into the jacket, and the overall longevity of the composite structure. Manufacturers often invest heavily in highly automated braiding machinery to ensure consistent diameter and tension.

The midstream phase focuses on assembly, cutting, and fitting the shock cord with various end components, such as hooks, clips, and specialized terminals made of plastic or metal. This stage often involves high levels of customization based on specific industrial client or retail packaging needs. Downstream distribution is multifaceted. Direct distribution channels are prevalent for large industrial Original Equipment Manufacturers (OEMs), military contracts, and specialized marine outfitters, requiring bulk quantities and specific certifications. These direct sales often involve long-term contracts and stringent specification adherence, resulting in high-value, stable revenue streams for manufacturers.

The indirect distribution channel caters primarily to the consumer and small business markets, relying on robust partnerships with hardware store chains, major online retailers (e.g., Amazon, specialty marine websites), and outdoor equipment specialty stores. The efficiency of the indirect channel is heavily dependent on effective logistics management and competitive pricing to capture the high-volume, lower-margin retail sales. Successful market penetration hinges on manufacturers balancing the need for high customization for industrial clients with the economies of scale required for consumer-grade product lines, ensuring that packaging and point-of-sale materials effectively communicate the cord's load rating and application suitability.

Bungee Shock Cord Market Potential Customers

Potential customers for Bungee Shock Cords are highly diversified, spanning multiple industries where securing, shock absorption, and tensioning are fundamental requirements. The largest segment of end-users comprises outdoor enthusiasts, recreational boaters, and campers who utilize the cords for everyday tasks such as securing luggage, tying down equipment, or setting up tents. These consumers prioritize ease of use, durability against basic weather elements, and moderate tensile strength, typically favoring retail-packaged cords of smaller to medium diameters.

A high-value segment includes industrial and commercial entities, such as logistics companies, construction firms, and trucking operators. These buyers use large, heavy-duty cords for securing cargo loads on flatbed trailers, bundling pipes, and securing large industrial tarps and scaffolding materials. Their purchasing criteria are dominated by high working load limits, resistance to abrasion, oils, and chemicals, and compliance with transportation safety regulations. This segment typically purchases in bulk directly from manufacturers or specialized industrial suppliers, demanding rigorous quality assurance documentation.

Specialized customers include the marine industry, ranging from commercial shipping to recreational yachting, where shock cords must possess exceptional UV stability, saltwater corrosion resistance, and specific elongation properties for docking and fender lines. Additionally, government and military agencies are crucial customers, demanding highly customized, robust cords meeting specific military standards (Mil-Spec), often requiring specialized flame-retardant or non-conductive jacket materials for critical applications in defense logistics and aviation, representing a premium market segment focused exclusively on performance and reliability.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 350.5 Million |

| Market Forecast in 2033 | USD 519.8 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | New England Ropes, SGT KNOTS, Shock Cord Bungee, Redpoint Cordage, West Coast Paracord, Saris, Kwik-Draw, FMS, Attwood Marine, SeaSense, Tie Down Engineering, North Mountain Supply, US Bungee, Ravenox, BlueWater Ropes, Pelican Ropes, Sterling Rope, MGS Supply, Samson Rope Technologies, Custom Cordage. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Bungee Shock Cord Market Key Technology Landscape

The manufacturing of Bungee Shock Cord relies on a convergence of advanced material science and textile engineering, focused primarily on maximizing elasticity retention, tensile strength, and environmental resilience. A cornerstone technology is the multi-strand rubber extrusion process, which ensures the core's elastic elements are uniformly thick and chemically treated (vulcanized) to achieve optimal elasticity and minimize degradation over time. Recent technological advancements include the use of thermoset elastomers like EPDM (Ethylene Propylene Diene Monomer) instead of traditional natural latex for the core, providing significantly enhanced resistance to ozone, UV radiation, and extreme temperatures, making the resulting cords suitable for rugged, long-term outdoor and marine deployment.

The jacket production technology utilizes high-speed, precision braiding and weaving machinery. Modern braiding machines employ computerized controls to maintain a consistent braid density and tension throughout the length of the cord. This precision prevents "core migration" or "telescoping," where the elastic core slides out of the jacket under heavy load—a common failure point in lower-quality cords. Furthermore, functional coatings applied to the jacket material represent a significant technological trend. These coatings incorporate UV inhibitors, water repellents, or flame retardants directly into the polyester or nylon fiber structure during the weaving process, dramatically extending the operational lifespan and safety profile of the finished product, crucial for highly regulated sectors like automotive and defense.

Automation technology is increasingly vital in the final assembly stage, particularly for high-volume retail products. Automated cutting, tipping (heat sealing the ends), and attachment of end-fittings (hooks, toggles) have replaced laborious manual processes. Robotic systems are employed to ensure consistent end-fitting crimping force, guaranteeing that the terminal connections can withstand the maximum rated load of the cord without failing. The integration of IoT sensors in high-end industrial cords, while nascent, presents an emerging technological landscape, allowing for real-time monitoring of tension and stress fatigue in critical infrastructure or logistics applications, moving the product from a passive fastener to an active, monitored component.

Regional Highlights

Regional dynamics play a crucial role in shaping the demand, product specifications, and competitive strategies within the Bungee Shock Cord Market, driven by variances in industrial activity, climate, and recreational culture. North America, encompassing the US and Canada, currently holds the largest market share. This dominance is attributable to high consumer spending on recreational activities, including extensive RV ownership, boating, and camping, which fuels persistent demand for high-quality, readily available consumer cords. Furthermore, a robust freight and logistics industry, reliant on large diameter industrial tie-downs, solidifies the region's market position. The presence of major outdoor equipment manufacturers and a strong DIY culture further ensures consistent high-volume demand.

Europe represents the second-largest market, characterized by stringent quality and safety regulations, particularly those originating from the European Union (EU), which mandate high durability and traceability for industrial and commercial marine applications. Key contributors are Germany, with its large automotive and industrial manufacturing base requiring specialized cords for securing components and internal vehicle restraints, and maritime nations like the UK, France, and Scandinavia, which drive demand for marine-grade, salt and UV-resistant cords. European manufacturers often focus on premium, higher-priced cords distinguished by environmental certifications and long warranty periods, catering to a sophisticated consumer base that prioritizes product longevity over cost.

Asia Pacific (APAC) is projected to be the fastest-growing region, driven by massive investments in infrastructure development, rapid industrialization, and the consequential growth of logistics and construction sectors, particularly in China and India. The rapid expansion of local manufacturing for consumer goods, sporting equipment, and military supplies also fuels local demand for bungee cord components. While price sensitivity remains higher in this region, there is a clear upward trend in demand for mid-range and high-quality synthetic cords, replacing basic materials, as local industries seek improved performance and export capabilities that align with international standards. Latin America and the Middle East & Africa (MEA) are emerging markets, with demand primarily tied to oil and gas operations, basic construction, and localized outdoor recreation, showing potential for future growth as economic diversification progresses.

- North America: Market leader, driven by high consumer adoption in marine and outdoor recreation; emphasis on retail availability and strong logistics sector demand for heavy-duty cords.

- Europe: Strong second position, characterized by demanding industrial specifications (Automotive, Logistics) and a large, quality-focused marine sector; high preference for certified, premium synthetic cords.

- Asia Pacific (APAC): Fastest growth trajectory, fueled by expanding manufacturing hubs, massive construction and infrastructure projects, and increasing local recreational spending, shifting focus from basic to performance-grade cords.

- Latin America (LATAM): Growth tied to resource extraction (mining, energy) and basic industrial needs; demand concentrated in utility and general-purpose cords.

- Middle East & Africa (MEA): Emerging market, with demand driven by defense spending, maritime activities, and rapid urbanization demanding specialized industrial securing solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Bungee Shock Cord Market.- New England Ropes (Teufelberger Group)

- SGT KNOTS

- Shock Cord Bungee

- Redpoint Cordage

- West Coast Paracord

- Saris Cycling Group

- Kwik-Draw Products

- FMS (Fasteners & More Supply)

- Attwood Marine

- SeaSense

- Tie Down Engineering

- North Mountain Supply

- US Bungee

- Ravenox

- BlueWater Ropes

- Pelican Ropes

- Sterling Rope Co.

- MGS Supply

- Samson Rope Technologies

- Custom Cordage

Frequently Asked Questions

Analyze common user questions about the Bungee Shock Cord market and generate a concise list of summarized FAQs reflecting key topics and concerns.What factors determine the lifespan and durability of a Bungee Shock Cord?

Durability is primarily determined by the material composition, specifically the elastic core (Synthetic EPDM offers longer life than Natural Latex) and the jacket material (Polyester and Nylon provide better UV and abrasion resistance than Polypropylene). Proper storage away from continuous UV exposure and harsh chemicals significantly extends the cord's operational lifespan.

How does core material (Natural Latex vs. Synthetic Rubber) impact Bungee Shock Cord performance?

Natural Latex provides superior initial elasticity and stretch (high elongation) but degrades rapidly when exposed to sunlight, ozone, and petroleum products. Synthetic Rubbers, particularly EPDM, offer lower elongation but demonstrate vastly superior resistance to weathering, UV radiation, and high temperatures, making them the preferred choice for industrial and marine applications demanding longevity.

Which application segment holds the highest growth potential in the Bungee Shock Cord Market?

The Recreation/Outdoor and Marine segments are expected to show robust and sustained growth, driven by increasing global participation in leisure activities and rising marine vessel ownership. The fastest regional growth, however, is projected in the Industrial and Construction segments within the Asia Pacific region due to rapid infrastructure development.

What is the typical working load limit (WLL) difference between different bungee cord diameters?

Working load limits increase substantially with diameter. For instance, a common 1/4 inch (6mm) bungee cord might have a WLL suitable for light securing (e.g., 50-70 lbs break strength), while heavy-duty 1/2 inch (12.7mm) industrial cords can handle significantly higher dynamic loads, often exceeding 200 lbs, making diameter the critical specification for heavy-duty tasks.

Are there environmentally friendly or sustainable options emerging in the shock cord market?

Yes, manufacturers are actively developing sustainable solutions, primarily focusing on using recycled polymers (like recycled PET) for the cord jacket and exploring bio-based elastomers for the core. While these options are currently premium-priced, they are gaining traction, especially in European and North American consumer markets driven by increasing regulatory focus on sustainable product materials.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager