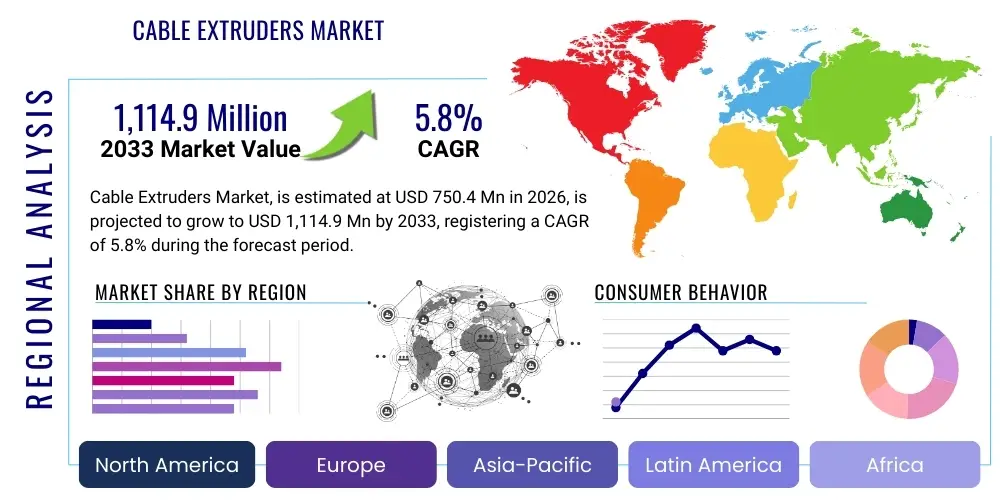

Cable Extruders Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436467 | Date : Dec, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Cable Extruders Market Size

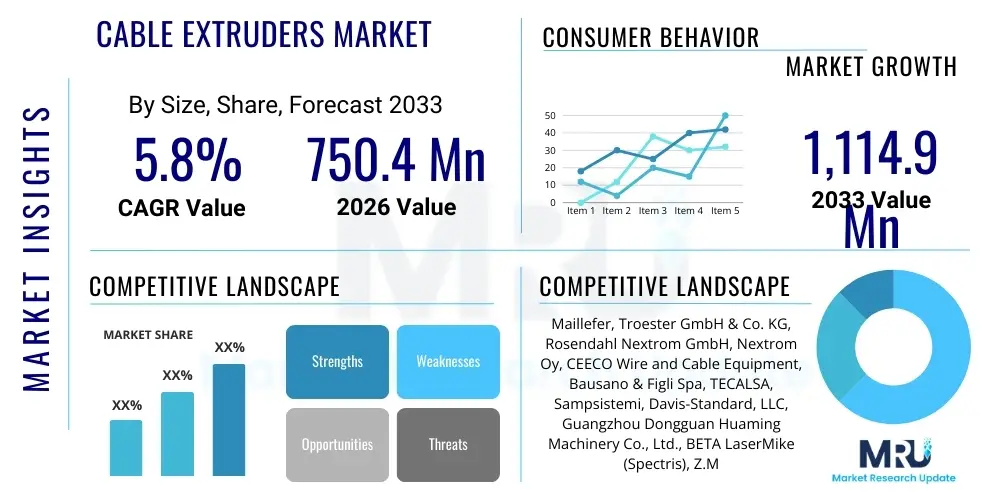

The Cable Extruders Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 750.4 Million in 2026 and is projected to reach USD 1,114.9 Million by the end of the forecast period in 2033.

Cable Extruders Market introduction

The Cable Extruders Market encompasses specialized machinery utilized in the manufacturing process of insulating and jacketing electrical and optical cables. These systems are crucial for ensuring the integrity, durability, and performance characteristics of power transmission lines, communication infrastructure, and specialized wiring systems. The extrusion process involves melting polymer resins and forcing them through a die onto a conductor, achieving precise dimensional control and material uniformity essential for high-quality cable production. Modern cable extruders are designed for high throughput, minimal material waste, and the ability to handle complex materials like cross-linked polyethylene (XLPE) and fluorine polymers, catering to stringent industrial standards.

Major applications for cable extruders span critical infrastructure sectors, including high-voltage power transmission (HV and EHV cables), telecommunications (fiber optic cable sheathing and insulation), and construction (building wires and fire-resistant cables). The foundational benefits derived from advanced extrusion technology include enhanced insulation thickness consistency, improved dielectric strength, and superior resistance to environmental stressors such as moisture, heat, and chemicals. These improvements directly contribute to extended cable service life and reduced operational failures, making modern extrusion equipment indispensable for reliable global connectivity and energy distribution networks.

Market growth is significantly driven by massive global investments in renewable energy integration and smart grid initiatives, which necessitate specialized medium and high-voltage cables. Furthermore, the relentless expansion of 5G networks and data center infrastructure fuels demand for high-performance communication cables requiring precise, defect-free insulation layers. Technological advancements in extruder design, such as tandem extrusion lines and improved cooling systems, are enabling higher line speeds and better quality control, positioning the market favorably for sustained expansion throughout the forecast period, particularly in rapidly urbanizing regions of Asia Pacific.

Cable Extruders Market Executive Summary

The global Cable Extruders Market is characterized by a strategic shift toward highly automated and integrated extrusion lines capable of delivering superior product quality at elevated speeds. Key business trends include the consolidation of specialized machinery manufacturers and an increased focus on developing energy-efficient equipment that meets evolving sustainability mandates. The market is witnessing robust growth in the demand for single-screw extruders tailored for high-volume, standard wire insulation, while twin-screw configurations are gaining traction for handling complex, specialized polymer compounds required for high-performance cables, such as those used in electric vehicle charging infrastructure.

Regional trends highlight the Asia Pacific (APAC) region as the dominant and fastest-growing market, primarily fueled by extensive government-led investments in power transmission infrastructure (Ultra High Voltage lines in China and India) and rapid urbanization driving immense construction and telecommunication demand. Europe and North America, while mature, are focusing heavily on upgrading aging infrastructure and adopting advanced solutions like continuous vulcanization (CCV) lines for XLPE insulation required for submarine and underground power cables. These advanced markets prioritize precision engineering, integration with Industry 4.0 standards, and superior quality control systems integrated into the extrusion process.

Segmentation trends indicate strong growth in the medium to high-voltage cable segment, driven by the global transition away from fossil fuels and the associated necessity for long-distance power transfer from renewable generation sources. In terms of technology, high-speed extruders designed for thin-wall insulation in the automotive sector are experiencing substantial uptake due to the electrification of vehicles. Manufacturers are strategically emphasizing modular design to allow for easier integration of specialized components, such as sophisticated melt pumps and filtering systems, catering to niche market requirements for ultra-clean materials.

AI Impact Analysis on Cable Extruders Market

User queries regarding the intersection of Artificial Intelligence (AI) and the Cable Extruders Market frequently center on process optimization, predictive failure analysis, and enhancing real-time quality assurance capabilities. Users seek confirmation on whether AI-driven systems can effectively reduce material waste, predict equipment downtime before critical failure, and automate complex adjustments traditionally handled by highly skilled operators. The core expectation is that AI integration will transform extrusion lines from sequential processes into adaptive, self-optimizing manufacturing environments, significantly boosting operational efficiency and consistency, particularly for highly regulated cable types where insulation flaws are unacceptable.

AI is beginning to revolutionize the cable extrusion process by applying machine learning algorithms to vast datasets collected from sensors on temperature, pressure, torque, and line speed. This data synthesis enables highly accurate prediction models that optimize material throughput and melt quality, resulting in superior dimensional tolerance and material homogeneity in the finished cable. Furthermore, AI-powered vision systems are being deployed downstream to perform 100% in-line quality checks, identifying minute defects like voids, contamination, or concentricity errors instantly, a capability far exceeding the speed and consistency of traditional manual inspection or basic sensor checks.

The adoption of AI-driven control loops allows extruders to dynamically adjust process parameters—such as screw speed, heating zones, and cooling rates—in response to slight variations in raw material quality or environmental conditions, thereby minimizing scrap rates and maximizing production yield. This level of adaptive control not only saves significant operating costs but also addresses the scarcity of expert extrusion technicians by automating complex decision-making processes. The long-term impact of AI is expected to accelerate the development of 'lights-out' manufacturing facilities for standard cable production, while highly specialized production benefits from unprecedented precision and material traceability.

- Enhanced Predictive Maintenance: AI analyzes vibration and temperature data to schedule maintenance, minimizing unplanned downtime.

- Real-Time Quality Control: Machine vision and learning algorithms detect micro-defects and dimensional inconsistencies instantly during extrusion.

- Process Parameter Optimization: Dynamic adjustment of heat, pressure, and speed based on raw material variability, improving yield and reducing scrap.

- Material Consumption Forecasting: Accurate modeling of required polymers and additives, optimizing inventory management.

- Energy Efficiency Management: AI systems fine-tune extruder motor load and heating elements to reduce overall energy consumption per meter of cable.

DRO & Impact Forces Of Cable Extruders Market

The Cable Extruders Market is principally driven by exponential growth in global power and data infrastructure development, coupled with technological mandates requiring higher quality and performance standards for all types of cables. A major restraint facing manufacturers is the substantial capital expenditure necessary for acquiring and maintaining sophisticated, large-scale extrusion lines, alongside the volatility in raw material polymer prices, which impacts manufacturing profitability. Significant opportunities exist in the development of specialized extrusion technologies for emerging sectors, such as high-temperature superconducting cables, subsea data transmission, and highly customized wires for robotics and aerospace applications. The cumulative impact forces indicate a market characterized by high buyer power due to high capital investment and moderate supplier power influenced by specialized material requirements, moderated by technological differentiation acting as a significant barrier to new market entrants.

Drivers: Global infrastructure modernization initiatives, particularly the replacement of aging power grids in developed economies, act as a primary driver. The massive build-out of renewable energy projects (wind and solar farms) necessitates extensive networks of specialized medium and high-voltage cables for grid connection, directly boosting demand for high-capacity CCV extrusion lines. Furthermore, the widespread deployment of 5G and subsequent 6G telecommunications infrastructure globally requires continuous investment in fiber optic and data cable production, often demanding tandem extrusion systems capable of multiple layered insulation with exceptional precision.

Restraints: The high initial investment cost associated with purchasing state-of-the-art extrusion equipment, particularly continuous vulcanization lines for XLPE cables, presents a significant barrier, especially for smaller market participants. Additionally, the operational complexity of these advanced machines necessitates highly skilled labor for operation and maintenance, contributing to elevated labor costs. Economic downturns or geopolitical instability can dramatically slow infrastructure spending, impacting order volumes for extrusion machinery manufacturers. Regulatory challenges surrounding the disposal and recycling of complex cable materials also present a growing constraint for manufacturers and end-users alike.

Opportunities: Emerging applications in electric vehicle battery wiring (requiring flexible, heat-resistant insulation), aerospace wiring (demanding lightweight, fire-retardant materials), and medical device cables offer high-margin opportunities for specialized extruder suppliers. The shift towards circular economy models creates opportunities for manufacturers to develop machinery optimized for processing recycled or bio-based polymers, appealing to environmentally conscious end-users. Developing integrated Industry 4.0 solutions, including digital twins and remote diagnostics capabilities, presents a competitive advantage by offering improved uptime and operational efficiency to cable manufacturers.

Segmentation Analysis

The Cable Extruders Market is comprehensively segmented based on the type of machinery utilized, the operational capability of the line, and the specific application sector the resulting cable serves. Segmentation by type primarily differentiates between single-screw and twin-screw extruders, reflecting the complexity of the polymer processing required. Single-screw extruders dominate standard insulation applications due to their simplicity and reliability, whereas twin-screw systems are essential for compounds requiring intensive mixing or venting, such as flame-retardant or foamed insulation materials. Operational segmentation focuses on high-speed lines designed for mass-market building wire versus specialized, slower lines necessary for ultra-high voltage (UHV) cable production requiring meticulously controlled cooling and vulcanization processes.

Application segmentation provides critical insight into demand dynamics, with the Power Cable segment historically holding the largest market share due to long-cycle infrastructure projects and grid upgrades. However, the Communication Cable segment, driven by rapid global expansion of data networks and the shift to Fiber-to-the-Home (FTTH) architectures, is projected to exhibit the highest CAGR. The automotive sector, particularly the rapid transition to Electric Vehicles (EVs), is creating substantial demand for thin-wall, high-performance wire and cable insulation, further diversifying the application landscape and necessitating continuous innovation in precise material handling and cooling technologies within the extrusion line.

- By Type:

- Single Screw Extruders

- Twin Screw Extruders

- Planetary Extruders

- By Operation:

- High-Speed Extrusion Lines (for building wire and small diameter cables)

- Standard Extrusion Lines

- Continuous Vulcanization (CCV) Lines (for MV/HV/EHV cables)

- By Application:

- Power Cables (Low, Medium, High Voltage)

- Communication Cables (Data Cables, Fiber Optics Sheathing)

- Automotive Cables (EV and standard wiring harnesses)

- Building & Construction Wires

- Specialty Cables (Aerospace, Medical, Industrial Robotics)

- By End-User:

- Wire and Cable Manufacturers

- OEMs (Original Equipment Manufacturers)

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America (LATAM)

- Middle East & Africa (MEA)

Value Chain Analysis For Cable Extruders Market

The value chain for the Cable Extruders Market begins with the upstream suppliers providing essential components, including high-precision machining services for screws and barrels, specialized heating and cooling units, and complex control system electronics and automation software. The quality and reliability of these upstream inputs directly influence the performance and lifespan of the final extrusion equipment. Extruder manufacturers then design, assemble, and rigorously test the final machinery, often customizing lines based on client specifications regarding line speed, cable diameter range, and required polymer compounds (e.g., PVC, PE, XLPE, FEP). Successful manufacturers integrate robust R&D capabilities to continuously enhance efficiency and incorporate emerging technologies like digital monitoring and process automation.

Downstream analysis focuses on the primary buyers: large-scale global wire and cable manufacturers (such as Prysmian Group, Nexans, and Sumitomo Electric) and smaller, regional specialized cable producers. The distribution channel is predominantly direct, especially for high-value CCV lines and specialized tandem systems, allowing for customized installation, training, and ongoing technical support, which are critical elements of the purchase contract. Indirect distribution may be used for standard peripheral equipment or lower-cost spare parts, often facilitated through established industrial equipment agents or regional distributors who provide local sales and servicing presence. The strong reliance on direct sales ensures that manufacturers maintain tight control over the complex installation and commissioning processes.

The effectiveness of the value chain is increasingly reliant on minimizing lead times and ensuring supply chain resilience for high-cost, specialized materials like nickel alloys used in bimetallic barrels and high-precision gearbox components. The trend toward modular design allows extruder manufacturers to quickly integrate new technologies and accommodate evolving polymer requirements, benefiting the end-users by enabling faster equipment upgrades and reduced obsolescence. Transparency and collaboration between the machinery manufacturer and the cable producer are vital, as the extruder's performance directly dictates the cable's compliance with strict industry standards (e.g., IEC, UL), affecting the end product's market acceptance.

Cable Extruders Market Potential Customers

The primary end-users and buyers of cable extruders are global and regional manufacturers specializing in electrical wires and cables, spanning power transmission, telecommunications, and specialized industrial applications. These customers, ranging from multinational conglomerates with extensive production facilities to focused boutique firms serving niche markets, require reliable, high-precision extrusion equipment to maintain product quality and meet demanding output quotas. Significant investment cycles in the cable manufacturing sector are intrinsically linked to macro-economic infrastructure planning, governmental energy policies, and rapid technological transitions such as the widespread adoption of fiber optics and electric vehicle infrastructure.

Within the power segment, utilities and major EPC (Engineering, Procurement, and Construction) firms indirectly influence demand by setting specifications for high-voltage and extra-high-voltage cables, thereby requiring cable manufacturers to invest in state-of-the-art CCV extrusion lines capable of handling complex insulation structures like triple extrusion of semi-conductive screens and XLPE insulation. In the communication sector, telecommunications providers and data center operators drive demand for machinery capable of producing high-density, low-loss data cables and highly precise fiber optic jacketing, ensuring minimal signal degradation over long distances.

A rapidly expanding customer base resides in the burgeoning automotive and aerospace industries. Automotive cable manufacturers require extruders optimized for thin-wall insulation using specialized, heat-resistant polymers to reduce vehicle weight and improve safety, crucial for the EV revolution. Aerospace and defense contractors also represent high-value potential customers, necessitating highly customized, certified extrusion equipment for producing radiation-hardened and extreme-temperature tolerant wiring, where performance reliability is paramount and dimensional control must be maintained to sub-micron levels. The decision to purchase is heavily influenced by equipment reliability, total cost of ownership (TCO), and the ability of the machinery to switch efficiently between different polymer types.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 750.4 Million |

| Market Forecast in 2033 | USD 1,114.9 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Maillefer, Troester GmbH & Co. KG, Rosendahl Nextrom GmbH, Nextrom Oy, CEECO Wire and Cable Equipment, Bausano & Figli Spa, TECALSA, Sampsistemi, Davis-Standard, LLC, Guangzhou Dongguan Huaming Machinery Co., Ltd., BETA LaserMike (Spectris), Z.M.C. Srl, Sikora AG, Hangzhou EPG Machinery Co., Ltd., Queins Machines GmbH, Dalian Konform Technical Co., Ltd., SIKORA AG, Microdia, Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Cable Extruders Market Key Technology Landscape

The technological landscape of the Cable Extruders Market is defined by relentless innovation aimed at increasing output speed, enhancing material precision, and improving energy efficiency. A pivotal technology is Continuous Vulcanization (CV), specifically Catenary Continuous Vulcanization (CCV) and Vertical Continuous Vulcanization (VCV), which are mandatory for producing medium, high, and extra-high voltage cables insulated with cross-linked polyethylene (XLPE). CCV and VCV lines manage the critical curing process under high pressure and temperature, ensuring the insulation material is perfectly cross-linked, which is vital for the cable's long-term electrical reliability. Modern systems incorporate sophisticated triple extrusion cross-heads to concurrently apply semi-conductive screen layers and the insulation layer, minimizing interfaces and eliminating defects that could lead to electrical treeing failure.

Further technological advancements center around optimizing the melt process and dimensional control. High-performance twin-screw extruders are increasingly used for compounding specialized materials, such as halogen-free, flame-retardant (HFFR) compounds, which require intensive mixing before delivery to the final cross-head. Automated gauging and control systems, often supplied by specialists like BETA LaserMike or SIKORA, utilize non-contact measurement techniques (such as laser or ultrasonic technology) to monitor insulation diameter and concentricity in real-time. This precision feedback loop is crucial for maintaining tight manufacturing tolerances, reducing material consumption, and ensuring product conformity across high-speed lines.

The integration of Industry 4.0 paradigms, including advanced sensor technology, IoT connectivity, and cloud-based data analytics, represents the newest technological frontier. This integration allows for comprehensive monitoring of every critical parameter, facilitating condition monitoring and predictive maintenance. Advanced cooling technologies, such as improved water-trough designs and specialized gas cooling for specific polymer types, also contribute significantly to the high-speed production capability and dimensional stability of extruded cables. These integrated technologies reduce waste, maximize throughput, and ensure the production of complex, multi-layered cables suitable for the demands of smart grids and next-generation communication networks.

Regional Highlights

Regional dynamics within the Cable Extruders Market are heavily segmented by the maturity of electrical infrastructure, the pace of urbanization, and prevailing government investment strategies in digital and energy connectivity.

- Asia Pacific (APAC): APAC remains the primary growth engine, commanding the largest market share due to unprecedented infrastructure expansion across China, India, and Southeast Asian nations. This demand is driven by rapid urbanization, massive investment in UHV (Ultra High Voltage) power transmission grids to connect distant generation sites, and accelerated 5G network rollouts, necessitating substantial purchases of both high-speed wire lines and advanced CCV systems.

- Europe: Europe represents a mature but highly advanced market characterized by stringent quality regulations and a strong focus on renewable energy integration (offshore wind, solar farms). Demand here centers on high-specification, specialized extruders for submarine cables, HVDC (High Voltage Direct Current) lines, and machinery optimized for sustainable, halogen-free, and recyclable polymer compounds. Upgrading aging distribution networks also fuels continuous replacement demand.

- North America: The market in North America is driven by modernization of the aging utility infrastructure, significant public and private investment in fiber optic deployment (driven by the Bipartisan Infrastructure Law in the US), and robust growth in the automotive sector due to EV manufacturing. Manufacturers prioritize automation, data integration (Industry 4.0), and reliability to manage high operating costs.

- Latin America (LATAM): This region is characterized by moderate growth, primarily stemming from sporadic infrastructure projects, electrification expansion in developing areas, and increasing demand for standard building wire. Market demand is often sensitive to economic stability and capital availability, favoring cost-effective and versatile extrusion solutions.

- Middle East & Africa (MEA): Growth in MEA is highly localized, driven by large-scale oil and gas projects requiring specialized instrumentation and control cables, alongside significant government investment in smart city projects (like Saudi Arabia’s NEOM) and regional power grid interconnections. Demand is concentrated in highly specified, high-reliability machinery for crucial national projects.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Cable Extruders Market.- Maillefer

- Troester GmbH & Co. KG

- Rosendahl Nextrom GmbH

- Nextrom Oy

- CEECO Wire and Cable Equipment

- Bausano & Figli Spa

- TECALSA

- Sampsistemi

- Davis-Standard, LLC

- Guangzhou Dongguan Huaming Machinery Co., Ltd.

- BETA LaserMike (Spectris)

- Z.M.C. Srl

- Sikora AG

- Hangzhou EPG Machinery Co., Ltd.

- Queins Machines GmbH

- Dalian Konform Technical Co., Ltd.

- Microdia, Inc.

- Hangzhou Zhongdian Equipment Co., Ltd.

- WTM S.r.l.

- Shanghai Tianfeng Plastic Machinery Co., Ltd.

Frequently Asked Questions

What is the projected CAGR for the Cable Extruders Market?

The Cable Extruders Market is projected to exhibit a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033, driven by global infrastructure modernization and 5G deployment.

Which application segment drives the highest demand for advanced extrusion equipment?

The Power Cables segment, particularly medium and high-voltage applications requiring complex XLPE insulation, drives the highest demand for advanced and high-precision Continuous Vulcanization (CCV) extrusion lines.

How is AI impacting the operational efficiency of cable extruders?

AI integration enhances operational efficiency through predictive maintenance, real-time defect detection via machine vision, and dynamic optimization of process parameters, leading to reduced material waste and improved product consistency.

Which region currently dominates the global market for cable extruders?

The Asia Pacific (APAC) region currently dominates the global market share, primarily due to large-scale government investments in UHV power grids and rapid urbanization across China and India.

What are the primary types of cable extruders used in the market?

The primary types are Single Screw Extruders (used for standard insulation and sheathing) and Twin Screw Extruders (used for specialized compounding and intensive material mixing), along with high-end Continuous Vulcanization (CV) lines.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager