Cable Intermediate Joint Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440135 | Date : Jan, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Cable Intermediate Joint Market Size

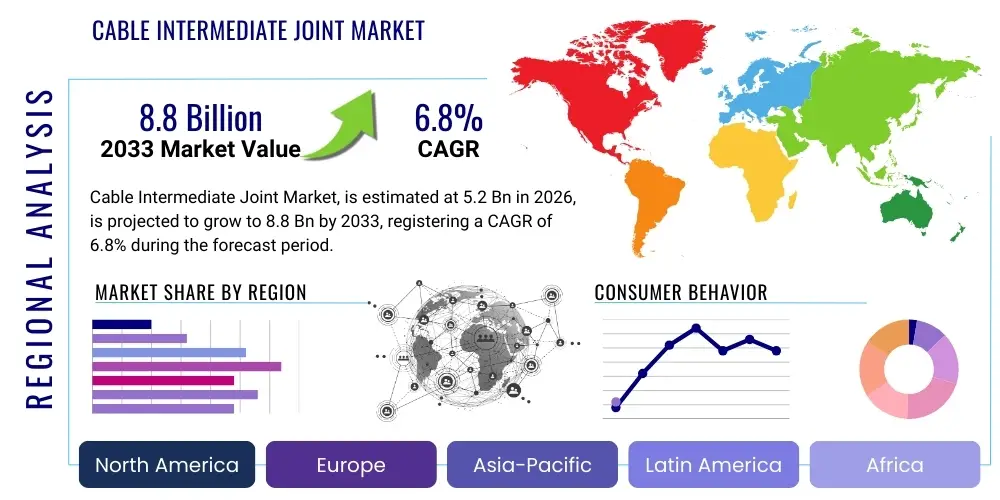

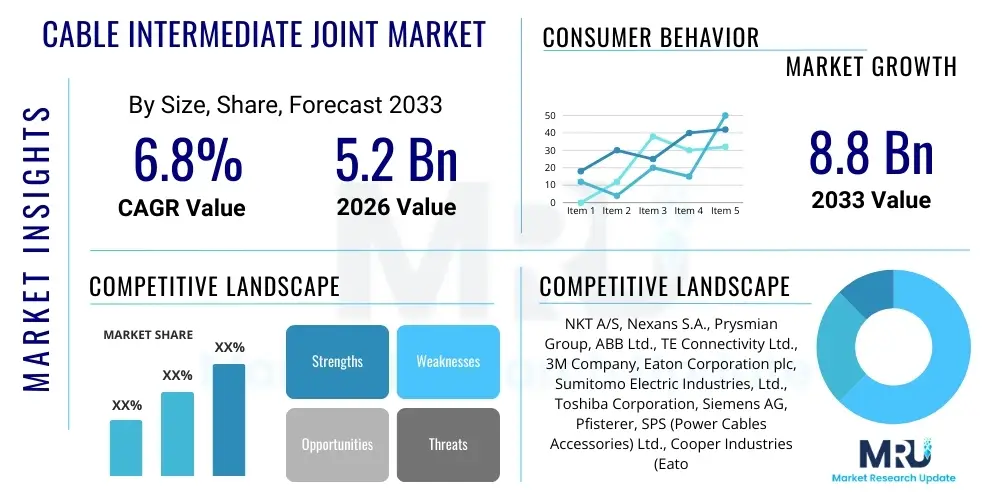

The Cable Intermediate Joint Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 5.2 Billion in 2026 and is projected to reach USD 8.8 Billion by the end of the forecast period in 2033.

Cable Intermediate Joint Market introduction

The Cable Intermediate Joint Market encompasses the global industry involved in the manufacturing, distribution, and installation of specialized electrical accessories designed to connect two lengths of power cables, ensuring continuous electrical conductivity and mechanical integrity. These joints are critical components in electricity transmission and distribution networks, facilitating the extension, repair, or rerouting of underground and overhead cable systems. They are engineered to withstand environmental stresses, maintain insulation properties, and prevent electrical breakdowns, thereby ensuring the reliability and safety of power infrastructure across various applications. The market is characterized by a strong emphasis on material science, insulation technology, and robust mechanical design, continually evolving to meet higher voltage demands and diverse environmental conditions.

Major applications for cable intermediate joints span a broad spectrum of industries and infrastructure projects. In the utilities sector, they are indispensable for power transmission and distribution networks, connecting segments of high-voltage transmission lines, medium-voltage distribution feeders, and low-voltage service cables. Their use extends to large industrial complexes such as manufacturing plants, oil and gas facilities, and mining operations, where robust and reliable power connections are paramount for continuous operations. Furthermore, the burgeoning renewable energy sector, including solar farms and wind power installations, heavily relies on these joints for integrating power into the grid. Beyond industrial and utility uses, they are crucial for urban development projects, tunnel wiring, railway electrification, and marine applications, highlighting their versatility and fundamental role in modern electrical infrastructure globally.

The benefits derived from advanced cable intermediate joints are significant, primarily centered on enhancing system reliability, operational safety, and overall network efficiency. These joints provide hermetic sealing against moisture and contaminants, excellent insulation to prevent short circuits, and robust mechanical strength to withstand external forces, thereby minimizing downtime and maintenance costs. The market is fundamentally driven by several key factors, including the accelerating pace of global urbanization and industrialization, which necessitates continuous expansion and upgrading of electrical grids. Additionally, the increasing focus on renewable energy integration and the modernization of aging infrastructure across developed nations contribute substantially to market growth. Furthermore, governmental initiatives promoting smart grid development and reliable power supply, coupled with a rising demand for electricity in developing economies, are pivotal in shaping the positive trajectory of the Cable Intermediate Joint Market.

Cable Intermediate Joint Market Executive Summary

The Cable Intermediate Joint Market is experiencing dynamic shifts propelled by a confluence of evolving business trends, significant regional developments, and distinct segment-specific demands. Technologically, there is an observable pivot towards more advanced materials and installation methodologies, such as cold shrink and pre-molded technologies, offering enhanced reliability, faster installation times, and reduced labor costs compared to traditional heat shrink methods. Strategic mergers, acquisitions, and partnerships among key players are also common, aimed at consolidating market share, expanding product portfolios, and leveraging synergistic capabilities in research and development. Furthermore, sustainability considerations are increasingly influencing product design, with manufacturers focusing on recyclable materials and energy-efficient production processes. The digitalization of power grids and the push for predictive maintenance solutions are also shaping the demand landscape, fostering innovation in smart joint monitoring systems.

Geographically, the Asia Pacific region continues to dominate the market, primarily driven by rapid industrialization, extensive infrastructure development projects, and burgeoning electricity demand, particularly in countries like China, India, and Southeast Asian nations. Europe is witnessing steady growth, largely fueled by initiatives to modernize aging grid infrastructure, expand renewable energy capacities, and enhance cross-border interconnectivity. North America's market expansion is underpinned by significant investments in smart grid technologies, substation upgrades, and the integration of distributed energy resources, along with substantial government spending on infrastructure renewal. Latin America and the Middle East & Africa regions are also demonstrating considerable potential, driven by urbanization, electrification projects, and increasing foreign direct investment in power sector development. These regional dynamics highlight a globally distributed but regionally nuanced demand for cable intermediate joints, influenced by local economic conditions, regulatory environments, and specific infrastructure priorities.

Segmentation analysis reveals distinct trends across different product types, voltage levels, and end-user applications. The cold shrink technology segment is gaining significant traction due to its ease of installation, safety benefits (no need for heat guns), and superior performance in diverse environmental conditions, gradually outpacing traditional heat shrink solutions in certain applications. In terms of voltage, the medium and high-voltage joint segments are experiencing robust growth, driven by the expansion of large-scale power transmission networks and utility-scale renewable energy projects. Low-voltage joints, while a mature segment, continue to see consistent demand from residential, commercial, and small-scale industrial applications. From an end-user perspective, utility companies remain the largest consumers, with increasing investments in grid modernization and expansion. However, the industrial sector, particularly heavy manufacturing and process industries, along with the rapidly growing renewable energy sector, are emerging as significant drivers, demanding specialized and robust joint solutions tailored to their specific operational requirements and environmental challenges.

AI Impact Analysis on Cable Intermediate Joint Market

Users frequently inquire about how artificial intelligence (AI) can revolutionize the Cable Intermediate Joint Market, focusing on its potential to enhance reliability, optimize maintenance cycles, improve design efficiency, and streamline manufacturing processes. Common questions revolve around AI’s role in predictive analytics for joint failure, automating quality control, optimizing material selection for extreme conditions, and enabling smarter grid integration through real-time monitoring of joint performance. Concerns often include the cost of AI implementation, data security for sensitive infrastructure, and the need for specialized skills to manage AI-driven systems. Expectations largely center on AI significantly reducing operational expenditures, extending asset lifespans, and preventing costly outages, ultimately leading to a more resilient and efficient electrical infrastructure.

- AI-driven predictive maintenance systems can monitor the real-time health of cable intermediate joints by analyzing sensor data (temperature, partial discharge, current load), identifying anomalies, and forecasting potential failures before they occur, thus enabling proactive intervention and reducing unplanned outages.

- AI algorithms can optimize the design and material composition of intermediate joints by simulating various stress conditions, thermal profiles, and environmental factors, leading to more robust, efficient, and cost-effective product development.

- Automated visual inspection systems powered by AI can significantly enhance quality control during the manufacturing process, detecting even minute defects in joint components with higher accuracy and speed than manual inspection, ensuring consistent product quality and reliability.

- AI can improve supply chain logistics and inventory management for cable joint components by predicting demand fluctuations, optimizing stock levels, and streamlining distribution networks, thereby reducing lead times and operational costs.

- Integration of AI with smart grid platforms allows for real-time monitoring and control of power flow through cable joints, enabling dynamic load balancing, fault location, and faster restoration services in the event of grid disturbances, enhancing overall grid resilience and operational efficiency.

- The use of machine learning can help in analyzing large datasets of field performance and failure modes, providing valuable insights for continuous product improvement and informing better installation practices to minimize human error.

DRO & Impact Forces Of Cable Intermediate Joint Market

The Cable Intermediate Joint Market is shaped by a complex interplay of Drivers, Restraints, and Opportunities, which collectively constitute the impact forces influencing its trajectory. Key drivers include the relentless pace of global infrastructure development, particularly in emerging economies where new power transmission and distribution networks are being established and expanded to meet growing energy demands. The worldwide shift towards renewable energy sources such as solar and wind power, which necessitate extensive cabling and jointing solutions for grid integration, also acts as a powerful catalyst. Moreover, the urgent need for modernization and upgrading of aging electrical infrastructure in developed nations to enhance reliability and efficiency further bolsters market demand. Urbanization and industrialization trends globally continuously fuel the need for robust and dependable power connections, creating a persistent demand for high-quality cable intermediate joints.

Despite these strong drivers, the market faces several significant restraints. The high initial installation costs associated with specialized cable joints, particularly for high-voltage applications, can be a barrier for some projects, especially in cost-sensitive markets. Furthermore, the complexity of regulatory frameworks and stringent safety standards, while necessary, can sometimes lead to prolonged project timelines and increased compliance costs for manufacturers and installers. A notable challenge is the persistent shortage of skilled labor required for the precise and safe installation of these critical components, which can impact project execution and quality. The market's susceptibility to economic downturns and fluctuations in raw material prices (e.g., copper, aluminum, polymers) can also lead to project delays or increased operational costs, thereby hindering market growth.

Opportunities within the market are abundant and promising. The increasing adoption of smart grid technologies presents a significant avenue for growth, as intelligent cable joints equipped with monitoring capabilities can contribute to enhanced grid management and predictive maintenance. Continuous technological advancements in material science, leading to the development of more durable, efficient, and environmentally friendly insulation and sealing materials, create new product development prospects. Expansion into emerging economies, where electrification rates are rising and infrastructure development is a national priority, offers lucrative market penetration opportunities. Additionally, the growing focus on retrofitting and refurbishing existing aging infrastructure to extend its lifespan and improve performance provides a substantial market for advanced joint solutions. These opportunities, when strategically capitalized upon, have the potential to significantly mitigate the impact of existing restraints and propel sustained market expansion.

Segmentation Analysis

The Cable Intermediate Joint Market is meticulously segmented across various parameters, including product type, voltage level, and end-user application, providing a granular understanding of market dynamics and catering to diverse operational requirements. This comprehensive segmentation allows market participants to identify specific niches, tailor product offerings, and develop targeted strategies. The market's complexity and the critical role these joints play in power infrastructure necessitate a detailed breakdown to address the unique challenges and demands of different segments, from low-voltage connections in residential buildings to ultra-high-voltage transmission lines spanning vast distances. Understanding these segments is crucial for accurate market sizing, forecasting, and strategic planning for manufacturers, distributors, and utility providers alike.

- By Type:

- Heat Shrink Joints: Traditional technology utilizing heat to shrink tubes for sealing and insulation.

- Cold Shrink Joints: Non-heated application, relying on pre-stretched sleeves that contract upon removal of a core.

- Push-On Joints: Pre-fabricated, easy-to-install joints for specific cable types.

- Pre-molded Joints: Factory-tested, ready-to-use joints that are pushed or bolted onto cable ends.

- By Voltage:

- Low Voltage (up to 1 kV): Primarily used in residential, commercial, and light industrial applications.

- Medium Voltage (1 kV to 36 kV): Essential for distribution networks, industrial power, and renewable energy collection systems.

- High Voltage (above 36 kV): Critical for long-distance power transmission and large-scale power generation integration.

- By End-User:

- Utilities (Power Transmission & Distribution): The largest segment, including national grids, regional power distributors, and private utility companies.

- Industrial (Oil & Gas, Mining, Manufacturing): Demands robust solutions for harsh environments and heavy-duty applications.

- Commercial & Infrastructure (Buildings, Railways, Data Centers): Requires reliable connections for urban development and critical services.

- Renewable Energy (Solar, Wind Farms): Growing segment driven by expansion of renewable energy generation and grid integration projects.

Value Chain Analysis For Cable Intermediate Joint Market

The value chain for the Cable Intermediate Joint Market begins with extensive upstream activities, primarily involving the procurement and processing of critical raw materials. This includes suppliers of high-quality polymers such as EPDM, silicone, and cross-linked polyethylene (XLPE), which form the core insulation and sealing components of the joints. Metal suppliers providing copper and aluminum for conductors, along with manufacturers of specialized adhesives, fillers, and protective coatings, also play a crucial role. The quality and consistency of these raw materials directly impact the performance, durability, and safety of the final cable intermediate joint. Strong relationships with reliable and certified raw material suppliers are paramount for manufacturers to ensure cost-effectiveness, quality control, and compliance with industry standards, forming the foundational stage of product development and production.

Following the manufacturing phase, which involves precision engineering, molding, and assembly, the value chain extends to downstream activities focused on distribution, installation, and post-sales support. Distribution channels are diverse, ranging from direct sales models where manufacturers engage directly with large utility companies or major industrial clients, to indirect channels involving a network of specialized distributors, wholesalers, and electrical contractors. These intermediaries play a vital role in reaching a broader customer base, particularly for smaller projects and regional markets, offering local inventory, technical support, and logistical advantages. The installation phase often involves highly skilled technicians and specialized contractors who ensure proper integration of the joints into the electrical infrastructure, adhering to stringent safety protocols and technical specifications, thereby guaranteeing the long-term reliability of the connections.

The dynamics of direct versus indirect distribution channels significantly influence market reach and customer relationships. Direct sales enable manufacturers to build strong, long-term relationships with key customers, offering tailored solutions, direct technical support, and a deeper understanding of specific project requirements. This approach is particularly common for high-value, complex, or customized high-voltage joint projects. Conversely, indirect channels leverage the extensive networks and local expertise of distributors to penetrate diverse geographical markets and serve a wider array of smaller and medium-sized clients. These distributors often maintain inventories, provide quick delivery, and offer immediate technical assistance, making them invaluable for routine purchases and regional project rollouts. The efficiency and reliability of both upstream supply and downstream distribution channels are critical for market competitiveness, ensuring that high-quality cable intermediate joints are readily available and expertly installed where and when they are needed most.

Cable Intermediate Joint Market Potential Customers

The Cable Intermediate Joint Market caters to a diverse spectrum of potential customers, all of whom share a fundamental need for reliable, efficient, and safe electrical connections within their respective infrastructures. The primary end-users are invariably entities involved in the generation, transmission, and distribution of electricity. This includes large-scale national and regional utility companies responsible for maintaining extensive power grids, which encompass everything from ultra-high-voltage transmission lines spanning continents to low-voltage distribution networks supplying urban and rural areas. These utility providers are constantly investing in grid expansion, modernization, and repair, making them perpetual and substantial buyers of various types of intermediate joints to ensure uninterrupted power supply and system resilience.

Beyond the traditional utilities, a significant customer segment comprises industrial enterprises with substantial power requirements and complex internal electrical networks. This category includes heavy industries such as oil and gas refineries, mining operations, manufacturing plants (e.g., automotive, chemical, steel), and processing facilities. In these environments, the operational continuity and safety of their electrical systems are paramount, often operating under challenging conditions, demanding highly robust and durable cable joint solutions. Any failure in their electrical infrastructure can lead to significant production losses, safety hazards, and substantial financial repercussions, making them discerning buyers prioritizing product quality, reliability, and long-term performance.

Furthermore, the rapid global expansion of renewable energy projects has created a burgeoning customer base, including solar farm developers, wind farm operators, and offshore wind power developers. These projects require extensive cabling systems to collect generated power and integrate it into the main grid, necessitating specialized intermediate joints capable of withstanding environmental stresses specific to renewable energy sites, such as extreme temperatures, moisture, and vibrations. Additionally, the infrastructure and commercial sectors represent growing segments, encompassing railway electrification projects, urban development (e.g., underground subway systems, large commercial buildings, data centers), and maritime applications. These customers seek joints that offer not only high performance but also ease of installation and compliance with specific project standards and certifications, further diversifying the market's demand profile and driving innovation across various product categories.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 5.2 Billion |

| Market Forecast in 2033 | USD 8.8 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | NKT A/S, Nexans S.A., Prysmian Group, ABB Ltd., TE Connectivity Ltd., 3M Company, Eaton Corporation plc, Sumitomo Electric Industries, Ltd., Toshiba Corporation, Siemens AG, Pfisterer, SPS (Power Cables Accessories) Ltd., Cooper Industries (Eaton), Emtelle, Taihan Electric Wire Co., Ltd., ZTT (Zhongtian Technology), Elsewedy Electric, Leoni AG, Encore Wire Corporation, Qingdao Hanhe Cable Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Cable Intermediate Joint Market Key Technology Landscape

The Cable Intermediate Joint Market is continuously evolving, driven by advancements in material science, engineering design, and installation methodologies aimed at enhancing reliability, durability, and ease of use. A primary technological focus is on insulation materials, with a significant shift towards advanced polymers such as EPDM (Ethylene Propylene Diene Monomer) rubber and silicone-based materials. These materials offer superior dielectric strength, weather resistance, UV stability, and flexibility compared to older technologies, ensuring optimal performance in diverse and often harsh environmental conditions. Innovations in material formulations are also leading to fire-resistant and halogen-free options, addressing growing safety and environmental concerns in specific applications, particularly in urban infrastructure and sensitive industrial settings where fire safety is paramount.

Another pivotal area of technological development lies in the design and application methods of the joints themselves. Cold shrink technology has emerged as a preferred solution, gaining traction over traditional heat shrink methods due to its inherent safety (no open flames or heat guns required), quicker installation times, and reduced reliance on skilled labor for complex heating procedures. Cold shrink joints utilize pre-stretched rubber sleeves that contract tightly around the cable when a removable core is pulled, providing a consistent, void-free seal. Pre-molded and push-on technologies also represent significant advancements, offering factory-tested, ready-to-use solutions that reduce on-site assembly errors and installation time, particularly beneficial for medium and high-voltage applications where precision is critical. These technologies contribute to a significant reduction in project execution timelines and enhance overall system reliability by minimizing human error during installation.

Furthermore, the integration of smart technologies is beginning to revolutionize the market, moving beyond passive connection solutions to active monitoring devices. This includes the development of cable joints embedded with sensors capable of real-time monitoring of critical parameters such as temperature, partial discharge activity, and current leakage. These smart joints can transmit data wirelessly to a central control system, enabling predictive maintenance strategies, early fault detection, and enhanced grid management. Such technological capabilities allow utility companies and industrial operators to anticipate potential failures, schedule proactive maintenance, and prevent costly outages, thereby extending the lifespan of assets and improving the overall efficiency and resilience of the electrical network. The trend towards modular designs also facilitates easier installation, repair, and replacement, further enhancing the operational flexibility and maintenance efficiency of cable intermediate joint systems.

Regional Highlights

- Asia Pacific (APAC): Dominates the market due to extensive infrastructure development, rapid urbanization, and increasing industrialization, particularly in China, India, and Southeast Asian countries. Massive investments in power generation, transmission, and distribution networks, coupled with the expansion of renewable energy projects, drive robust demand.

- Europe: Characterized by significant investments in grid modernization, replacement of aging infrastructure, and a strong emphasis on integrating renewable energy sources. Countries like Germany, the UK, France, and Italy are key markets, driven by stringent regulatory standards and commitments to carbon neutrality.

- North America: Experiencing steady growth fueled by substantial government and private sector investments in upgrading electricity grids, integrating smart grid technologies, and enhancing the resilience of power infrastructure against extreme weather events. The United States and Canada are leading this regional expansion.

- Latin America: Demonstrates considerable potential with increasing electrification rates, economic development, and foreign direct investment in energy and infrastructure projects. Countries such as Brazil, Mexico, and Argentina are emerging as important markets for cable intermediate joints as their power grids expand and modernize.

- Middle East & Africa (MEA): Emerging as a growth hub due to rapid urbanization, industrial diversification initiatives, and large-scale infrastructure projects, especially in the GCC countries and parts of North and South Africa. Investments in oil & gas, renewable energy, and public utilities are key drivers.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Cable Intermediate Joint Market.- NKT A/S

- Nexans S.A.

- Prysmian Group

- ABB Ltd.

- TE Connectivity Ltd.

- 3M Company

- Eaton Corporation plc

- Sumitomo Electric Industries, Ltd.

- Toshiba Corporation

- Siemens AG

- Pfisterer

- SPS (Power Cables Accessories) Ltd.

- Cooper Industries (Eaton)

- Emtelle

- Taihan Electric Wire Co., Ltd.

- ZTT (Zhongtian Technology)

- Elsewedy Electric

- Leoni AG

- Encore Wire Corporation

- Qingdao Hanhe Cable Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Cable Intermediate Joint market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary types of cable intermediate joints and their main applications?

The primary types include Heat Shrink, Cold Shrink, Push-On, and Pre-molded joints. Heat shrink uses heat to seal, while cold shrink uses a pre-stretched sleeve that contracts. Push-on and pre-molded are factory-prepared for easy installation. Their main applications range from connecting low-voltage cables in residential and commercial buildings to high-voltage transmission lines in utilities, industrial facilities, and renewable energy projects.

What factors are driving the growth of the Cable Intermediate Joint Market globally?

Key growth drivers include rapid global infrastructure development, particularly in developing economies, the increasing integration of renewable energy sources into national grids, the widespread need for modernization and upgrades of aging electrical infrastructure in developed regions, and the continuous expansion driven by urbanization and industrialization, all of which demand reliable power connections.

How do cable intermediate joints contribute to grid reliability and safety?

Cable intermediate joints are engineered to provide robust insulation, hermetic sealing against moisture and contaminants, and strong mechanical protection, which are crucial for preventing electrical breakdowns, short circuits, and environmental damage. By ensuring a continuous and secure electrical path, they minimize power outages, enhance system stability, and safeguard personnel and equipment, thereby significantly improving overall grid reliability and operational safety.

What role does technology play in the evolution of cable intermediate joints?

Technology plays a critical role through advancements in material science (e.g., EPDM, silicone for better insulation), innovative application methods like cold shrink and pre-molded joints that offer easier and safer installation, and the integration of smart monitoring capabilities (sensors for temperature, partial discharge) that enable predictive maintenance and enhance grid management, leading to more durable and intelligent power connections.

Which geographical regions are expected to exhibit the most significant growth in this market?

The Asia Pacific region is anticipated to show the most significant growth due to extensive infrastructure projects, rapid urbanization, and industrial expansion in countries like China and India. Europe and North America will also experience steady growth driven by grid modernization, renewable energy integration, and infrastructure upgrades. Emerging economies in Latin America and MEA are also poised for substantial growth due to electrification and industrialization initiatives.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager