Calcium Chloride Desiccant Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432901 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Calcium Chloride Desiccant Market Size

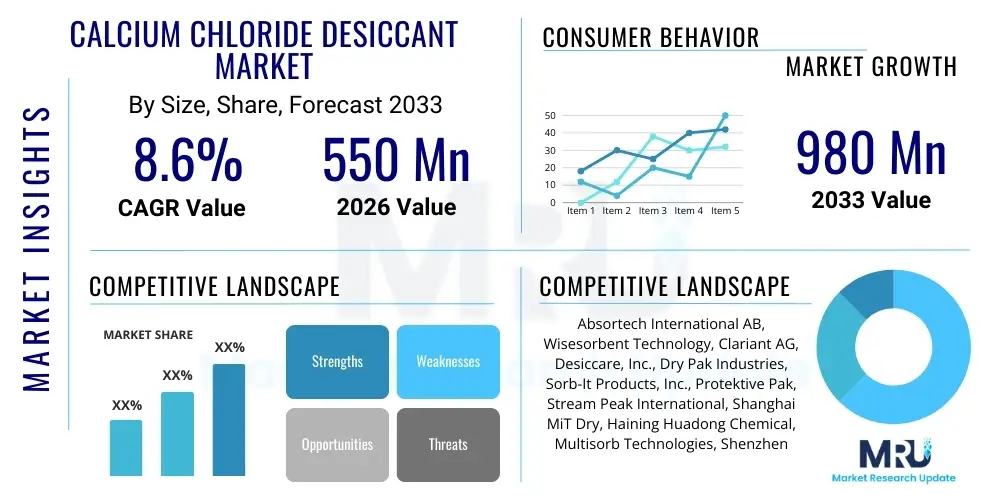

The Calcium Chloride Desiccant Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.6% between 2026 and 2033. The market is estimated at $550 Million USD in 2026 and is projected to reach $980 Million USD by the end of the forecast period in 2033.

Calcium Chloride Desiccant Market introduction

The Calcium Chloride Desiccant Market encompasses specialized products designed for highly effective moisture absorption and humidity control in various industrial and commercial environments. Calcium chloride (CaCl2) is highly hygroscopic, meaning it attracts and holds water molecules from the surrounding atmosphere, making it an excellent desiccant. These products are formulated into various forms, including flakes, granules, and rigid blocks, often packaged in breathable materials to manage humidity levels within enclosed spaces like shipping containers, product packaging, and storage facilities. The primary function is to prevent moisture damage, which manifests as corrosion, mold growth, mildew, warping, and degradation of sensitive materials, thereby ensuring product integrity and extending shelf life.

Major applications of calcium chloride desiccants span across critical sectors such as logistics and shipping, where they are indispensable as container desiccants to combat "container rain" – condensation that occurs due to temperature fluctuations during long-haul transport. Furthermore, they are extensively utilized in the packaging of electronics, preventing humidity-induced short circuits and corrosion of metallic components. The pharmaceutical industry relies on these desiccants to maintain the stability and efficacy of moisture-sensitive drugs, while the food and beverage industry uses them to preserve the freshness and texture of edible goods, preventing spoilage and maintaining quality standards required by international trade.

Key benefits driving market adoption include the superior moisture absorption capacity of CaCl2 compared to alternatives like silica gel or clay, particularly at higher relative humidity levels. This high efficiency translates into cost-effective protection for high-value goods. Additionally, the increasing complexity of global supply chains and the rising volume of international trade, especially across diverse climatic zones, necessitate reliable moisture mitigation solutions. Strict quality control regulations and the growing consumer demand for pristine product condition upon delivery further solidify the essential role of calcium chloride desiccants in modern logistics and manufacturing processes.

Calcium Chloride Desiccant Market Executive Summary

The Calcium Chloride Desiccant Market is characterized by robust growth, driven primarily by the globalization of trade, necessitating secure and humidity-controlled transit solutions, especially within the container shipping sector. Business trends indicate a strong focus on developing eco-friendly desiccant systems, utilizing biodegradable packaging materials, and engineering formulations that offer sustained absorption performance over extended durations. Furthermore, manufacturers are increasingly integrating smart monitoring technologies, such as humidity indicators and IoT-enabled sensors, into desiccant packaging to provide real-time data on environmental conditions during transit, enhancing supply chain visibility and risk mitigation strategies for high-value shipments.

Regional trends highlight the Asia Pacific (APAC) region as the dominant market in terms of production capacity and consumption, fueled by booming manufacturing output in countries like China, India, and Southeast Asia, coupled with their role as major global export hubs for electronics, textiles, and consumer goods. North America and Europe represent mature markets with high demand for premium, high-absorption desiccants, primarily driven by stringent pharmaceutical packaging standards and complex cold chain logistics. Segment trends show significant momentum in the logistics and shipping segment, particularly for container desiccant applications, which require large volumes of high-efficacy CaCl2 products to protect bulk goods from moisture damage over multi-week voyages.

The market structure suggests a competitive landscape where key players are focusing on vertical integration to secure raw material supply (calcium chloride brine extraction or synthesis) and continuous product innovation to improve absorption kinetics and ease of use. Opportunities lie in penetrating emerging markets in Latin America and the Middle East, which are expanding their industrial bases and adopting more sophisticated packaging standards. Restraints, however, include concerns regarding the corrosive nature of discarded calcium chloride solutions, necessitating responsible disposal and the need for non-leaking packaging designs to prevent contact with products.

AI Impact Analysis on Calcium Chloride Desiccant Market

User inquiries regarding AI's influence on the Calcium Chloride Desiccant Market primarily revolve around predictive moisture management, optimization of desiccant quantity, and enhancing supply chain resilience against climate variability. Key concerns center on how AI can integrate with existing logistics infrastructure to move beyond static desiccant deployment toward dynamic, condition-based humidity control. Users anticipate that AI models, utilizing historical shipment data, real-time sensor inputs (temperature, humidity, location), and weather forecasts, can accurately determine the exact type, quantity, and placement of desiccants required for a specific route and cargo type, leading to significant material efficiency and cost savings.

The core expectation is that AI will transform the desiccant market from a reactive supply industry into a proactive, data-driven service sector. AI algorithms can identify high-risk routes prone to severe temperature drops or high humidity spikes (e.g., crossing the equator or transitioning seasons) and automatically flag the need for enhanced moisture protection, optimizing inventory management for desiccant suppliers based on anticipated logistics patterns. This integration facilitates preventative measures, ensuring optimal environmental conditions are maintained throughout the supply chain, minimizing product damage claims, and improving overall operational efficiency for end-users, particularly in high-stakes sectors like pharmaceuticals and specialized electronics manufacturing.

Moreover, AI can play a crucial role in manufacturing optimization. Predictive maintenance models can be applied to desiccant production lines to ensure consistent quality and absorption capacity, minimizing batch variations. Furthermore, machine learning techniques are beginning to analyze the performance feedback of different desiccant formulations under varying real-world conditions, providing R&D teams with actionable insights to accelerate the development of next-generation, super-absorbent calcium chloride products. This shift ensures the desiccant supply is perfectly matched to the dynamic moisture mitigation needs of global trade.

- AI-powered predictive modeling for determining optimal desiccant dosage based on route, climate, and transit time.

- Integration of machine learning algorithms with IoT sensors for real-time humidity monitoring and automated risk alerts during shipping.

- Optimization of desiccant inventory and logistics planning based on global trade flow predictions and seasonal weather patterns.

- Enhanced quality control in manufacturing through AI analysis of production parameters ensuring consistent absorption efficiency.

- Development of smart packaging systems that use AI feedback loops to guide desiccant replacement or adjustment decisions.

DRO & Impact Forces Of Calcium Chloride Desiccant Market

The market is fundamentally driven by the escalating requirements for product preservation in international trade, where goods must traverse extreme temperature and humidity gradients. The high absorption capability of calcium chloride, particularly its efficiency in maintaining low relative humidity levels over long periods, serves as a major driver, making it the preferred choice for container shipping. However, the market faces restraints related to environmental concerns associated with the disposal of spent desiccants, especially the liquid brine byproduct, which can be corrosive and impact soil salinity if not managed properly. Opportunities emerge from the continuous expansion of cold chain logistics and specialized manufacturing (e.g., high-performance batteries, specialized chemicals), demanding precise moisture control, creating niche applications for customized desiccant solutions. The combined influence of these factors dictates market trajectory and innovation cycles.

Impact forces are centered around supply chain resilience and regulatory pressures. The increasing globalization means that disruptions in maritime shipping or fluctuations in raw material costs (calcium chloride production) have immediate effects on desiccant manufacturing and pricing. Furthermore, regulatory bodies in major consumer markets are placing stricter requirements on packaging materials concerning safety, leakage prevention, and environmental footprint, compelling desiccant producers to invest heavily in non-woven, highly durable, and environmentally inert packaging systems. The competitive pressure from alternative desiccants, though currently less efficient for high-humidity applications, necessitates constant R&D investment to maintain calcium chloride's performance superiority.

A significant opportunity is the development of circular economy models for desiccants, exploring methods for regenerating or safely neutralizing the spent calcium chloride brine. Furthermore, the adoption of specialized high-purity calcium chloride desiccants is expanding rapidly in pharmaceutical and medical device packaging, sectors where product integrity is paramount and non-negotiable. The overall impact forces suggest a market moving towards greater technological sophistication, prioritizing material safety, absorption efficiency, and ecological sustainability to meet complex global demand.

Segmentation Analysis

The Calcium Chloride Desiccant Market is comprehensively segmented based on product type, form, application, and geography, reflecting the diverse needs of end-user industries. Analyzing these segments provides strategic insights into market hotspots and technological adoption patterns. The segmentation by application, particularly the split between bulk logistics (container desiccants) and specialized packaging (pharmaceuticals, electronics), reveals distinct requirements regarding absorption rate, capacity, and packaging design. While logistics demand high-volume, cost-effective solutions, pharmaceutical and electronics sectors prioritize premium, high-purity, and leak-proof designs to protect highly sensitive and regulated materials.

Segmentation by form highlights the flexibility of calcium chloride products, ranging from powder and granules, suitable for mixing or insertion into small sachets, to large flakes or rigid blocks, ideal for heavy-duty container applications. The market trend indicates a growing preference for advanced composite desiccants that often combine CaCl2 with binding agents to improve physical stability and control the absorption kinetics, thereby reducing the risk of leakage and managing the heat generated during the absorption process. This product evolution ensures broader applicability across varied climate conditions and shipment durations.

The primary revenue generator remains the container desiccant segment due to the sheer volume of global goods transported by sea. However, the fastest growth is anticipated in specialized segments like high-value electronics and food packaging, driven by increasing disposable income, rising quality expectations, and the subsequent need for sophisticated moisture protection in fast-moving consumer goods (FMCG). Geographic segmentation confirms APAC’s lead, supported by robust export infrastructure and manufacturing hubs, while North America leads in demand for pharmaceutical-grade desiccants.

- By Product Type:

- High Purity Grade

- Industrial Grade

- By Form:

- Flakes

- Granules

- Powder

- Rigid Blocks/Tablets

- Liquid (Used in some industrial drying applications, though less common for packaging)

- By Application:

- Logistics & Shipping (Container Desiccants)

- Food & Beverages

- Pharmaceuticals & Healthcare

- Electronics & Electricals

- Chemicals & Petrochemicals

- Industrial Machinery & Equipment

- Textiles & Leather Goods

- By Region:

- North America

- Europe

- Asia Pacific (APAC)

- Latin America

- Middle East & Africa (MEA)

Value Chain Analysis For Calcium Chloride Desiccant Market

The value chain for the Calcium Chloride Desiccant Market initiates with the upstream analysis, involving the extraction and purification of the primary raw material, calcium chloride. This raw material is typically sourced either through brine extraction (from natural salt lakes or underground deposits) or as a byproduct of the Solvay process (soda ash manufacturing). The efficiency and cost of raw material acquisition significantly impact the final product cost. Manufacturers engaged in desiccant production require specialized processing capabilities to purify the CaCl2 to the required industrial or pharmaceutical grade, followed by granulation or flaking, and formulation with binding agents to enhance stability and absorption kinetics. Securing reliable, cost-effective, and high-quality raw material supplies is a core strategic advantage in the upstream segment, often leading to vertical integration by major players.

The midstream segment involves the core manufacturing process: converting the processed calcium chloride into consumer-ready desiccant products, which includes packaging the desiccant material into specialized, breathable pouches, bags, or boxes. The design and quality of the packaging material (often non-woven fabrics like Tyvek or specialized composites) are critical as they must allow moisture ingress while preventing any leakage of the absorbed brine solution. Packaging technology, focusing on anti-leak measures and physical durability, is a major differentiator in this stage. Distribution channels then link manufacturers to end-users, encompassing both direct sales for large industrial clients (e.g., major shipping lines or bulk exporters) and indirect distribution through specialized logistics providers, chemical distributors, and packaging material suppliers.

Downstream analysis focuses on the end-users—primarily logistics companies, pharmaceutical manufacturers, electronics exporters, and food processors—who integrate desiccants into their packaging protocols. The selection of a desiccant is highly application-specific, depending on humidity levels, transit duration, cargo value, and regulatory compliance. Direct channels are utilized when customers require customized desiccant formulations or large-scale procurement, ensuring technical support and consistent supply. Indirect channels cater to smaller businesses or general logistics needs, providing readily available standard desiccant products. Customer satisfaction relies heavily on the desiccant's performance in preventing damage and the manufacturer's ability to provide clear usage instructions and safety guidelines regarding disposal.

Calcium Chloride Desiccant Market Potential Customers

The end-user base for calcium chloride desiccants is highly diversified yet unified by the universal need for proactive moisture damage prevention in sensitive cargo and stored products. The largest volume consumers are logistics and shipping companies, including global freight forwarders and Non-Vessel Operating Common Carriers (NVOCCs), which purchase container desiccants in massive quantities to protect cargo during intercontinental maritime transit. These entities require desiccants that can withstand long durations at sea and significant temperature variations without compromising integrity or leaking the absorbed moisture.

High-value industrial sectors constitute another critical customer group. This includes multinational corporations specializing in semiconductor manufacturing and electronics assembly, where even minimal moisture can cause catastrophic failure in components. Similarly, pharmaceutical manufacturers are major buyers of high-purity calcium chloride desiccants for primary and secondary packaging to maintain drug stability, efficacy, and compliance with Good Manufacturing Practice (GMP) regulations. Food and beverage exporters, particularly those dealing with dried foods, coffee beans, cocoa, and grains, rely on these desiccants to prevent mold, pest infestation, and spoilage, preserving quality and market value across long supply chains.

The potential customer landscape also extends to specialized manufacturing niches such as manufacturers of precision machinery, automotive parts (especially those requiring corrosion protection), and military equipment that needs long-term preservation in storage. These buyers prioritize custom solutions, technical specification matching, and guaranteed long-term effectiveness. The expansion of e-commerce and direct-to-consumer fulfillment further broadens the customer base, requiring smaller, more user-friendly desiccant packets for individual parcel protection.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $550 Million USD |

| Market Forecast in 2033 | $980 Million USD |

| Growth Rate | 8.6% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Absortech International AB, Wisesorbent Technology, Clariant AG, Desiccare, Inc., Dry Pak Industries, Sorb-It Products, Inc., Protektive Pak, Stream Peak International, Shanghai MiT Dry, Haining Huadong Chemical, Multisorb Technologies, Shenzhen Chunwang Environmental Protection Material, Hengda Chemical, TROPACK PACKMITTEL GMBH, MCJ Supply Chain Management, Unit-Pack Company, Inc., Qingdao Best Desiccant, Container Dri II. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Calcium Chloride Desiccant Market Key Technology Landscape

The technological landscape of the Calcium Chloride Desiccant Market is characterized less by fundamental chemical innovation (as CaCl2 properties are well-established) and more by advancements in formulation, packaging engineering, and smart integration. A crucial development involves the engineering of composite desiccants. These composites often involve blending high-purity calcium chloride with starch, clay, or proprietary gelling agents. This blending serves two primary purposes: firstly, to solidify the hygroscopic material, transforming the absorbed moisture into a gel or solid mass, thereby eliminating the risk of liquid leakage (a significant safety and corrosion concern). Secondly, composite formulations can optimize the absorption rate, ensuring rapid moisture uptake without overwhelming the packaging integrity.

Packaging technology is arguably the most dynamic area of innovation. Modern desiccants utilize highly advanced, non-woven polymer fabrics and Tyvek material, which are robust, tear-resistant, and possess highly controlled permeability. The technological focus here is on creating "one-way" breathable membranes that maximize water vapor transmission rate (WVTR) while ensuring the internal brine solution remains contained, even under mechanical stress or significant absorption capacity utilization. The incorporation of integrated indicator strips, which visually change color when the desiccant has reached its saturation limit, provides a low-cost, immediate assessment tool for supply chain personnel.

Furthermore, digital integration represents a significant technological leap. The market is witnessing the integration of desiccants into IoT-enabled packaging solutions. Miniature, disposable humidity and temperature data loggers are being embedded within or adjacent to desiccant bags, allowing continuous monitoring of the microclimate inside shipping containers. This data is transmitted via cloud platforms, enabling predictive analytics (often AI-driven, as previously discussed) and providing end-to-end visibility. This technology shift moves the desiccant from a simple passive chemical protection method to an active component of a connected supply chain monitoring system, driving efficiency and accountability.

Regional Highlights

- Asia Pacific (APAC): APAC is the engine of global demand and production, driven by massive manufacturing and export industries, especially in electronics, textiles, and bulk commodities (e.g., agricultural products from Southeast Asia). Countries like China, India, and Vietnam are major consumers of container desiccants due to high export volumes. The regional market benefits from the presence of large, low-cost manufacturers, though there is an increasing shift towards high-quality, non-leaking products to meet Western import standards.

- North America: This region is characterized by high demand for specialized, high-purity desiccants, particularly in the pharmaceutical, advanced electronics, and aerospace sectors. The market growth here is stable and focused on high-margin products where failure prevention is paramount. Strict FDA regulations dictate the use of certified, non-toxic, and highly reliable desiccant solutions for medical packaging, driving innovation in leak-proof designs and materials.

- Europe: Similar to North America, the European market prioritizes quality, sustainability, and adherence to complex environmental regulations (e.g., REACH compliance). Significant demand comes from the automotive industry (protecting parts from corrosion during storage), high-end machinery manufacturing, and complex pharmaceutical logistics. There is a notable trend towards adopting eco-friendly packaging materials for desiccants across the European Union.

- Latin America: This region represents a rapidly developing market, fueled by increasing exports of agricultural products (fruits, coffee, meats) and manufactured goods. The long transit routes necessary for exporting to North America and Europe necessitate effective moisture control, creating strong, emerging demand for container desiccants. Market growth is closely tied to infrastructure development and trade agreements.

- Middle East & Africa (MEA): Market growth in MEA is driven by large-scale infrastructural projects, increasing imports of heavy machinery and electronics, and the expansion of the local pharmaceutical sector, particularly in the Gulf Cooperation Council (GCC) countries. The extreme climatic conditions (high temperature and high humidity) in many coastal MEA areas create mandatory requirements for high-performance desiccants to prevent damage during storage and distribution.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Calcium Chloride Desiccant Market.- Absortech International AB

- Wisesorbent Technology

- Clariant AG

- Desiccare, Inc.

- Dry Pak Industries

- Sorb-It Products, Inc.

- Protektive Pak

- Stream Peak International

- Shanghai MiT Dry

- Haining Huadong Chemical

- Multisorb Technologies

- Shenzhen Chunwang Environmental Protection Material

- Hengda Chemical

- TROPACK PACKMITTEL GMBH

- MCJ Supply Chain Management

- Unit-Pack Company, Inc.

- Qingdao Best Desiccant

- Container Dri II (A product line under a larger chemical entity)

- Oxy-Dry (Focusing on packaging solutions)

- Chunwang Industrial

Frequently Asked Questions

Analyze common user questions about the Calcium Chloride Desiccant market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary advantage of calcium chloride desiccants over alternatives like silica gel?

Calcium chloride desiccants offer significantly higher moisture absorption capacity, particularly in environments with high relative humidity (above 80%) and elevated temperatures. This superior performance makes them ideal for maritime container shipping and long-duration storage in tropical or humid climates, where silica gel efficiency drops off substantially.

What is container rain and how do calcium chloride desiccants mitigate it?

Container rain refers to condensation that forms when moist air inside a shipping container cools rapidly (often at night or due to temperature changes across climatic zones), leading to water droplets forming on the ceiling and falling onto the cargo. Calcium chloride desiccants effectively absorb this moisture vapor from the air, maintaining a low dew point and preventing condensation formation, thereby protecting goods from water damage and mold.

Are calcium chloride desiccants safe for use with food and pharmaceutical products?

Yes, when packaged in leak-proof, high-purity, and FDA-compliant materials, calcium chloride desiccants are safe for protecting food and pharmaceutical products. The key is ensuring the desiccant itself is of a high-purity grade and the packaging prevents any direct contact or leakage of the absorbed moisture/brine solution onto the sensitive products. Manufacturers must adhere strictly to international packaging and safety standards.

How are environmental concerns regarding the disposal of spent calcium chloride desiccants being addressed?

To address environmental concerns, manufacturers are increasingly focusing on non-leaking composite formulations that gel the absorbed moisture, making disposal safer. Furthermore, industry efforts are directed toward using biodegradable packaging materials and establishing standardized, safe disposal or neutralization processes for the spent, corrosive calcium chloride brine in compliance with local waste management regulations.

What are the typical forms of calcium chloride desiccants used in logistics applications?

The most common forms used in logistics are large rigid blocks, sheets, or elongated bags containing calcium chloride flakes or granules, designed to be hung inside shipping containers. These large-format desiccants maximize contact surface area for absorption and are engineered for high capacity, often absorbing several liters of water over a transit period to protect bulk cargo.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager