Calcium Cyanamide Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 432486 | Date : Dec, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Calcium Cyanamide Market Size

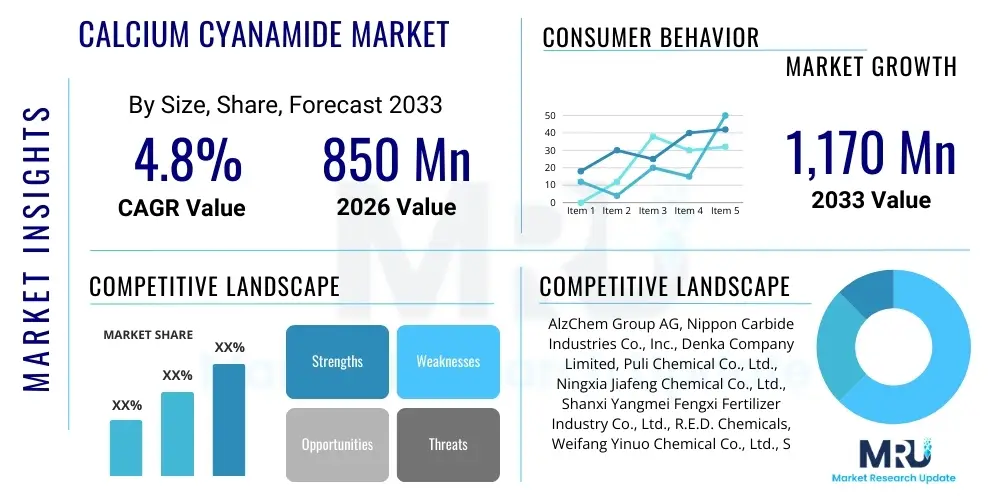

The Calcium Cyanamide Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 4.8% between 2026 and 2033. The market is estimated at USD 850 Million in 2026 and is projected to reach USD 1,170 Million by the end of the forecast period in 2033.

Calcium Cyanamide Market introduction

The Calcium Cyanamide (CaCN2) market, historically recognized under the trade name Nitrolime, encompasses the global activities of synthesizing, marketing, and applying this critical nitrogen-containing chemical compound. CaCN2 is manufactured primarily via the high-temperature Frank-Caro process, which involves heating calcium carbide with nitrogen gas. This process is highly energy-intensive, making the cost of electricity and raw materials like coke and limestone pivotal determinants of market profitability and geographical distribution of production facilities. Calcium Cyanamide is distinguished from conventional nitrogen fertilizers by its unique ability to break down slowly in the soil, releasing nitrogen gradually while simultaneously exhibiting significant biocidal and herbicidal properties. This dual functionality is the core value proposition driving its continued adoption in specialized agriculture and horticulture across various climatic zones.

The chemical’s applications are broadly categorized into agricultural and industrial sectors. In agriculture, CaCN2 is indispensable for several purposes: as a slow-release nitrogen fertilizer that prevents rapid leaching and volatilization; as a soil conditioner and sanitizer effective against nematodes, fungi, and specific soilborne pests; and as a contact herbicide targeting germinating weeds without damaging established crops when applied correctly. The agricultural market segment benefits from global efforts to enhance crop quality and yield in intensive farming systems, particularly where soil health remediation is required. Demand is further influenced by the growing acceptance of specialized, multi-functional agricultural inputs that align with principles of sustainable soil management and precision nutrient delivery, mitigating the environmental externalities associated with rapid-release nitrogen compounds.

On the industrial front, Calcium Cyanamide serves as a foundational precursor chemical. Its conversion into Dicyandiamide (DCD) represents a major industrial pathway. DCD is critical in the production of fire retardants, epoxy resins, and as an intermediary in pharmaceutical synthesis. Furthermore, CaCN2 is the primary source for producing Melamine, a high-volume chemical used in the manufacturing of robust thermosetting plastics, durable laminates for furniture and construction, and specialized coatings. The continuous robust expansion of construction, automotive manufacturing, and consumer durable goods industries, particularly within developing economies, guarantees a stable and escalating long-term demand for industrial-grade Calcium Cyanamide, making this segment a key focus for future investment and capacity expansion among market leaders.

Calcium Cyanamide Market Executive Summary

The global Calcium Cyanamide market demonstrates resilient growth, projected to achieve a CAGR of 4.8% through 2033, fundamentally driven by expanding industrial applications and the necessity for specialized, high-efficacy agricultural inputs. Strategic business trends highlight a concentration of production in the Asia Pacific region, primarily capitalizing on cost efficiencies related to raw material proximity and energy supply. Key market players are increasingly adopting vertical integration strategies, particularly securing the supply of calcium carbide, to stabilize cost structures and mitigate the impact of volatile energy markets. Product innovation focuses heavily on developing controlled-release and high-purity grades to meet stringent regulatory requirements in developed markets and enhance performance in downstream chemical synthesis, showcasing a clear trend towards value-added product offerings.

Regionally, the market presents a dichotomy: Asia Pacific leads consumption due to rapid industrialization (DCD/Melamine use) and intensive agriculture, while North America and Europe focus on premium, environmentally compliant formulations. The regulatory landscape in Europe, characterized by stricter limits on agrochemical usage and nitrogen emissions, necessitates technological differentiation and localized production strategies centered on safety and efficacy. Conversely, emerging markets in Latin America and MEA are characterized by increasing import reliance coupled with rapidly modernizing agricultural practices, providing lucrative, high-volume opportunities for established international suppliers capable of managing complex logistics and market entry barriers.

Segmentation analysis reveals that while the Agricultural sector maintains volume dominance, the Industrial Application segment is set for accelerated value growth. Within the industrial sector, the demand for high-purity Calcium Cyanamide used in specialized chemical processes, particularly those yielding pharmaceutical-grade DCD or advanced polymer precursors, shows the most promising trajectory. Investment is flowing into enhancing the purity of technical grades and streamlining the conversion process to DCD, reflecting a shift in market emphasis toward high-value, non-commodity chemical utilization. The sustained health of the construction and automotive sectors acts as a reliable foundation for industrial segment expansion, safeguarding the long-term viability of CaCN2 as a fundamental building block chemical.

AI Impact Analysis on Calcium Cyanamide Market

User queries regarding the integration of Artificial Intelligence (AI) and Machine Learning (ML) in the Calcium Cyanamide sector concentrate on four strategic areas: optimizing the complex, energy-intensive manufacturing process; implementing predictive maintenance regimes for specialized equipment; refining agricultural application precision; and forecasting commodity price volatility. Manufacturers seek AI solutions to model the non-linear kinetics of the Frank-Caro reaction, aiming to identify optimal furnace operating parameters that reduce electricity consumption—a substantial cost component—without compromising product quality or production yield. The potential for AI to integrate real-time sensor data from reactors to autonomously adjust inputs and temperature profiles is seen as the next frontier for operational excellence, crucial for maintaining competitiveness against low-cost producers.

In the agricultural domain, AI is transforming Calcium Cyanamide from a conventional bulk chemical into a component of smart farming systems. ML algorithms process extensive datasets—including drone imagery, hyper-spectral soil analysis, localized weather forecasts, and historical crop performance—to generate highly specific variable rate application maps. These maps dictate the precise location, timing, and quantity of CaCN2 required, ensuring targeted soil sanitation and nutrient delivery. This precision minimizes fertilizer waste, reduces environmental impact (such as nitrate leaching into groundwater), and maximizes the return on investment for the farmer. Such AI-driven deployment significantly enhances the perception of CaCN2 as an environmentally responsible, high-performance agricultural input, helping overcome past regulatory hurdles associated with blanket application methods.

Furthermore, AI plays a vital role in enhancing supply chain resilience and strategic decision-making. Predictive analytics are being employed to forecast the highly volatile pricing of calcium carbide, natural gas, and electricity, allowing producers to implement proactive procurement strategies and hedge against cost fluctuations. For distributors, AI-powered demand forecasting optimizes inventory levels and logistics planning for seasonal agricultural demand and continuous industrial requirements, minimizing storage costs and ensuring timely supply. The application of AI in metallurgical and quality control steps also increases, with automated vision systems and machine learning models ensuring that the refined CaCN2 grade consistently meets the exacting standards required for downstream specialized chemical synthesis, thereby reducing waste and reprocessing costs significantly.

- AI-driven Precision Agriculture: Optimizing CaCNamide dosage and placement using geospatial data, leading to up to 20% reduction in unnecessary application volumes.

- Predictive Maintenance (Pdm): Implementation of ML models to analyze vibration and thermal data from electric arc furnaces and nitrogen kilns, preventing catastrophic failures and securing continuous operation.

- Energy Consumption Optimization: Utilizing neural networks to model and minimize the electrical energy required for the Frank-Caro process, addressing the key cost driver for manufacturing.

- Commodity Price Forecasting: Leveraging AI to anticipate volatility in raw material and utility costs (coke, calcium carbide, electricity), enabling proactive purchasing and risk mitigation strategies.

- Automated Quality Control: Deployment of computer vision and spectroscopic analysis linked to AI to ensure instantaneous monitoring and adjustment of purity levels for refined CaCNamide grades.

DRO & Impact Forces Of Calcium Cyanamide Market

The fundamental growth drivers in the Calcium Cyanamide market are anchored by the dual necessities of global food security and expanding industrial manufacturing. The demand for enhanced agricultural productivity in densely populated regions, coupled with the unique soil conditioning benefits offered by CaCN2 (e.g., pH balancing and pathogen suppression), ensures persistent demand from the agricultural sector. Industrially, the relentless expansion of sectors reliant on melamine and dicyandiamide—specifically construction (laminates, resins) and advanced materials (fire retardants, specialized coatings)—acts as a powerful, non-cyclical driver, providing stability to the market even during agricultural downturns. The continuous requirement for nitrogen inputs in the world's most critical agricultural hubs underpins the market's long-term volumetric stability.

Conversely, significant restraints hinder more rapid market expansion. The high capital expenditure and extreme energy requirements associated with establishing and operating the Frank-Caro process represent a major barrier to entry and a persistent strain on operating margins, especially for non-integrated producers. More critically, stringent environmental legislation in developed economies targeting the regulation of nitrogen-based compounds and general agrochemical residues poses a constraint. The regulatory classification of CaCN2 requires specialized handling, application equipment, and safety measures, which adds complexity and cost for end-users. Furthermore, the reliance on calcium carbide, whose production is dependent on the volatile price of coal and electricity, introduces significant supply chain risk that manufacturers must actively manage through forward contracting and hedging strategies.

Opportunities for market evolution are concentrated in specialized product development and market penetration strategies. The creation of micro-encapsulated, controlled-release Calcium Cyanamide formulations presents a crucial opportunity to align product performance with environmental sustainability goals, thereby accessing premium markets in Europe and North America and mitigating regulatory pressure. Furthermore, the increasing use of high-purity Dicyandiamide in niche, high-value sectors such as pharmaceutical synthesis and advanced electronics—where specifications for purity are extremely high—opens avenues for higher profitability margins through technological refinement and specialized production lines. The continuous need for specialized soil treatments in organic and conventional high-yield agriculture, particularly in addressing specific pathogens, reinforces the unique market positioning of CaCN2 against generic nitrogen sources.

Segmentation Analysis

Market segmentation for Calcium Cyanamide is crucial for directing strategic resources, distinguishing between high-volume, cost-sensitive markets (agriculture) and high-value, specification-driven markets (industrial). The segmentation by Application clearly isolates the demand drivers: the agricultural segment relies heavily on price sensitivity and volume sales, driven by seasonal farming cycles and commodity crop pricing, whereas the industrial segment is influenced by global manufacturing output and demand for downstream specialized chemicals. The growth projections for these segments differ significantly, necessitating distinct operational models and R&D pipelines for manufacturers serving both sectors.

Segmentation by Grade differentiates between Technical Grade and Refined Grade Calcium Cyanamide. Technical Grade, characterized by higher impurity levels, is generally sufficient for bulk agricultural applications and certain metallurgical processes. In contrast, Refined Grade, often produced through advanced purification and crystallization methods, is essential for industrial synthesis, particularly for DCD used in high-purity applications like pharmaceuticals and specialty coatings, where trace contaminants can compromise product performance. The Refined Grade segment typically commands significantly higher prices and is subject to stricter quality assurance protocols, making it a key area for technological competitive advantage.

- By Application:

- Agriculture (Fertilizers): Bulk volume use providing foundational nitrogen input for major crops.

- Agriculture (Herbicides & Biocides/Soil Sanitizer): Specialized, targeted application for weed control and pathogen elimination (e.g., fungal diseases, nematodes).

- Industrial (Dicyandiamide (DCD) Production): High-growth segment fueling specialty chemical industries (epoxy, flame retardants).

- Industrial (Melamine Production): Volume-driven industrial segment supporting construction and plastics manufacturing.

- Industrial (Steel/Metallurgy): Niche use in nitriding processes for surface hardening.

- By Grade:

- Technical Grade: Standard purity levels suitable for bulk fertilizer and general industrial uses.

- Refined Grade (High Purity): Required for sophisticated downstream chemical synthesis, demanding rigorous contaminant control.

- By Form:

- Powder: Highly reactive form, suitable for specialized industrial mixing and direct soil application.

- Granular: Predominant form for agricultural use, offering improved handling, reduced dust, and slow-release characteristics.

- Liquid Suspension: Emerging form for precise application in advanced irrigation systems or foliar feeding trials.

Value Chain Analysis For Calcium Cyanamide Market

The Calcium Cyanamide value chain is characterized by high integration requirements starting with the upstream supply of energy and raw materials. The chain originates with limestone quarrying, coke procurement, and nitrogen separation from air. These raw inputs are processed into Calcium Carbide (CaC2) in high-temperature electric arc furnaces. Since the carbide production stage consumes immense amounts of electricity, producers often locate facilities near abundant, low-cost power sources, or integrate vertically with captive power generation, offering a significant competitive edge. Upstream efficiency and cost control, particularly over energy usage, are paramount determinants of final CaCN2 pricing and global market positioning.

The manufacturing core involves the controlled conversion of CaC2 to CaCN2 via the Frank-Caro process, followed by purification and formulation into powder or granular grades. The midstream operations are capital-intensive, requiring specialized, high-heat equipment resistant to corrosive chemical environments. Distribution is highly segmented: large volumes of Technical Grade CaCN2 are shipped via rail or specialized containers to fertilizer blenders and major industrial consumers, often through direct supply agreements to minimize handling risks. For agricultural end-users, an extensive network of regional chemical distributors and specialized agricultural cooperatives manage localized inventory and technical support, providing crucial last-mile service and regulatory adherence advice to farmers.

Downstream value creation is maximized in the industrial segment. Manufacturers convert CaCN2 into Dicyandiamide through aqueous dissolution and recrystallization, which in turn feeds into the production of high-margin materials like guar gum alternatives, epoxy hardeners, and sophisticated textile auxiliaries. Similarly, the conversion to Melamine creates substantial value added, supplying the robust global market for high-pressure laminates and kitchenware. The agricultural downstream stage involves soil incorporation and monitoring the resultant positive effects on crop health and yield. The final profitability of the CaCN2 market is heavily reliant on the consistent, high-specification performance of the chemical in these downstream conversion processes, driving ongoing investment in midstream quality control and process refinement.

Calcium Cyanamide Market Potential Customers

The diverse utility of Calcium Cyanamide translates into a broad spectrum of potential customer groups, each with distinct purchasing criteria and volume requirements. Agricultural buyers constitute the largest volume segment, including major fertilizer blending companies, large corporate farming operations focused on high-yield cereal or specialty crops (e.g., potatoes, tobacco), and governmental agricultural bureaus implementing soil remediation programs. These customers demand cost-effective bulk material, reliable logistics, and increasingly, specialized formulations that minimize environmental impact while maximizing efficacy against specific soil pathogens common in monoculture farming systems. Their procurement cycle is highly seasonal, aligning with planting and soil preparation windows.

Industrial customers are generally less price-sensitive than agricultural buyers but require significantly higher technical purity and consistency. This segment includes world-leading chemical manufacturers specializing in thermosetting resins, adhesives, and coatings (Melamine segment), and companies focused on advanced chemical intermediates, including those producing pharmaceuticals, fire retardants, and carbon fiber precursors from Dicyandiamide. Key purchasing factors for industrial clients include long-term contract stability, stringent compliance with quality specifications (e.g., ISO, REACH standards), and technical support regarding conversion efficiency. Metallurgical users, a niche but stable market, include foundries and steel producers utilizing CaCN2 for specialized case-hardening treatments to improve metal durability.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 850 Million |

| Market Forecast in 2033 | USD 1,170 Million |

| Growth Rate | 4.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | AlzChem Group AG, Nippon Carbide Industries Co., Inc., Denka Company Limited, Puli Chemical Co., Ltd., Ningxia Jiafeng Chemical Co., Ltd., Shanxi Yangmei Fengxi Fertilizer Industry Co., Ltd., R.E.D. Chemicals, Weifang Yinuo Chemical Co., Ltd., Sichuan Guangyuan Chemical, Ningxia Coal Industry Co., Ltd., OCI Company Ltd., EuroChem Group AG, Hubei Kingland Chemical Co., Ltd., Qingdao Qingmei Chemical Co., Ltd., Chongqing Hongbo Chemical Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Calcium Cyanamide Market Key Technology Landscape

The core technological foundation of the Calcium Cyanamide market rests upon improvements to the century-old Frank-Caro synthesis method. Current technological priorities are heavily skewed towards enhancing energy efficiency. Manufacturers are implementing advanced insulation materials, optimizing kiln rotation speeds, and employing sophisticated process control software to maintain precise temperature gradients during the nitrogen fixation stage, aiming to substantially reduce the huge electrical power consumption associated with the calcium carbide precursor production. Novel reactor designs, utilizing advanced metallurgy and computational fluid dynamics (CFD) modeling, are being explored to increase throughput capacity per unit of energy input, thereby lowering the cost base and improving the sustainability profile of CaCN2 production globally, a necessity given rising global energy prices.

A critical area of technological innovation is in product formulation, specifically addressing the safety and environmental concerns associated with traditional powdered CaCN2. This involves the development of proprietary granulation processes that yield dust-free, high-density granules, which are safer to handle and apply. Furthermore, the most advanced technology involves micro-encapsulation, where CaCN2 particles are coated with specialized biodegradable polymers. This coating controls the rate at which the chemical decomposes and releases nitrogen into the soil, significantly reducing the immediate toxic burden on soil microbiology and minimizing undesirable nitrogen leaching, making these formulations highly attractive for precision agriculture in sensitive watersheds.

In the industrial purification segment, technology focuses on continuous crystallization and filtration techniques designed to yield ultra-high-purity Refined Grade Calcium Cyanamide. This high purity is essential for manufacturers of specialized Dicyandiamide derivatives used in electronics, high-performance composites, and pharmaceutical synthesis, where even trace metallic contaminants are detrimental. Techniques such as membrane filtration, ion exchange, and multi-stage evaporation are being integrated to achieve purity levels exceeding 99.5%. The deployment of automated spectroscopic analysis (e.g., atomic absorption and mass spectrometry) for real-time quality assurance is paramount, ensuring that the specialized product output adheres rigorously to the demanding specifications of the high-value downstream chemical industry, thus maximizing the market premium achieved by leading producers.

Regional Highlights

- Asia Pacific (APAC): APAC is the dominant force in the Calcium Cyanamide market, accounting for the largest share of global production capacity and consumption. This dominance is intrinsically linked to the immense manufacturing base of China, which benefits from localized and relatively inexpensive access to coal and electricity for calcium carbide production, fostering substantial output volumes. The demand is further fueled by high fertilizer consumption rates across India and Southeast Asia to support large, staple crop agriculture. APAC consumption is also driven by its role as the global hub for melamine and DCD derivative manufacturing, which is integral to the region's rapidly growing construction and automotive sectors. Strategic investment in the region focuses on scaling up production and enhancing supply chain efficiency to meet both domestic and export requirements.

- Europe: The European market for Calcium Cyanamide is highly mature, characterized by stringent regulatory oversight, particularly related to the EU’s Nitrates Directive and strict agrochemical usage standards. Consequently, the market orientation shifts toward specialized, high-performance, controlled-release CaCN2 formulations that minimize environmental risk and maximize efficacy in targeted applications. Although bulk production capacity has been rationalized due to elevated operating costs, particularly energy prices, Europe remains a crucial market for technological innovation and high-value industrial applications, serving sectors demanding premium DCD-derived materials for coatings and advanced composites. Focus is placed on minimizing the carbon footprint throughout the value chain.

- North America: North America presents a stable demand profile, relying heavily on imports for bulk CaCN2, though maintaining some localized specialty production. The agricultural use is concentrated in niche, high-value sectors such as turf management, orchards, and specific row crops where its soil sanitation and unique nutritional benefits are valued. The industrial segment provides consistent demand for high-grade CaCN2 derivatives, supporting the domestic production of flame retardants, construction adhesives, and specialty resins used in advanced manufacturing. Market growth here is primarily dictated by the health of the downstream construction and automotive sectors, with an increasing emphasis on sustainable sourcing and product traceability.

- Latin America (LATAM): LATAM is characterized by rapidly expanding agricultural frontiers and increasing intensification of existing farmlands, particularly in Brazil and Argentina. This drives a significant and growing demand for fertilizer inputs, including CaCN2 for specialized soil health maintenance. The market is primarily import-driven, making it sensitive to global commodity prices and logistics costs. Opportunities exist for international producers who can provide robust supply chain stability and technical support tailored to the unique soil conditions and pest challenges faced across the diverse climatic zones of the continent.

- Middle East and Africa (MEA): The MEA region exhibits emerging demand, fueled by governmental initiatives aimed at improving food security through modernizing agriculture and significant investment in regional infrastructure and petrochemical industries. The region possesses the potential for local production, leveraging low natural gas costs for energy-intensive processes. However, current market penetration is moderate, with consumption concentrated in large agricultural projects and industrial ventures requiring Melamine-based materials. The market faces challenges related to infrastructure development and navigating diverse regulatory and political landscapes.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Calcium Cyanamide Market.- AlzChem Group AG

- Nippon Carbide Industries Co., Inc.

- Denka Company Limited

- Puli Chemical Co., Ltd.

- Ningxia Jiafeng Chemical Co., Ltd.

- Shanxi Yangmei Fengxi Fertilizer Industry Co., Ltd.

- R.E.D. Chemicals

- Weifang Yinuo Chemical Co., Ltd.

- Sichuan Guangyuan Chemical

- Ningxia Coal Industry Co., Ltd.

- OCI Company Ltd.

- EuroChem Group AG

- Hubei Kingland Chemical Co., Ltd.

- Qingdao Qingmei Chemical Co., Ltd.

- Chongqing Hongbo Chemical Co., Ltd.

- Inner Mongolia Wulanchabu Junzheng Chemical Industry Co., Ltd.

- Jiangsu Sopo Chemical Co., Ltd.

- Dalian Ruiguang Chemical Co., Ltd.

- Kaili Chemical Group Co., Ltd.

- Jining Shengli Chemical Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Calcium Cyanamide market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary industrial applications driving Calcium Cyanamide demand?

The primary industrial drivers are the foundational synthesis of Dicyandiamide (DCD), essential for specialty resins, fire retardants, and pharmaceutical intermediaries, and the high-volume production of Melamine, used extensively in durable laminates and thermosetting plastics across the construction and automotive sectors.

How do environmental regulations impact the growth of the Calcium Cyanamide agricultural segment?

Stringent environmental regulations, particularly in Europe, necessitate substantial R&D investment into advanced, polymer-coated, controlled-release CaCN2 formulations. While this increases manufacturing costs, it validates CaCN2 as a precision input that minimizes environmental nitrogen contamination risks, securing its long-term market access.

Which geographical region dominates the global production of Calcium Cyanamide and why?

The Asia Pacific region, specifically mainland China, dominates both production and consumption. This is primarily due to the integrated availability of raw materials (coke/limestone) and access to competitively priced electricity, which is critical for the energy-intensive calcium carbide and CaCN2 manufacturing processes.

What is the key technological focus area for Calcium Cyanamide manufacturers?

The central technological focus is on optimizing energy efficiency within the Frank-Caro process and developing advanced product formulations, specifically highly granular, dust-free forms and micro-encapsulated coatings, to enhance application safety and deliver predictable, slow-release functionality in agriculture.

Is Calcium Cyanamide being substituted by alternatives in fertilizer markets?

While traditional fertilizers like urea compete on pure nitrogen content, CaCN2 maintains a unique market position due to its inherent biocidal and soil conditioning properties. It serves as a specialized, multi-functional input that is often complementary to, rather than replaceable by, standard nitrogen sources.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager