Calcium Phosphate Based Ceramic Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433794 | Date : Dec, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Calcium Phosphate Based Ceramic Market Size

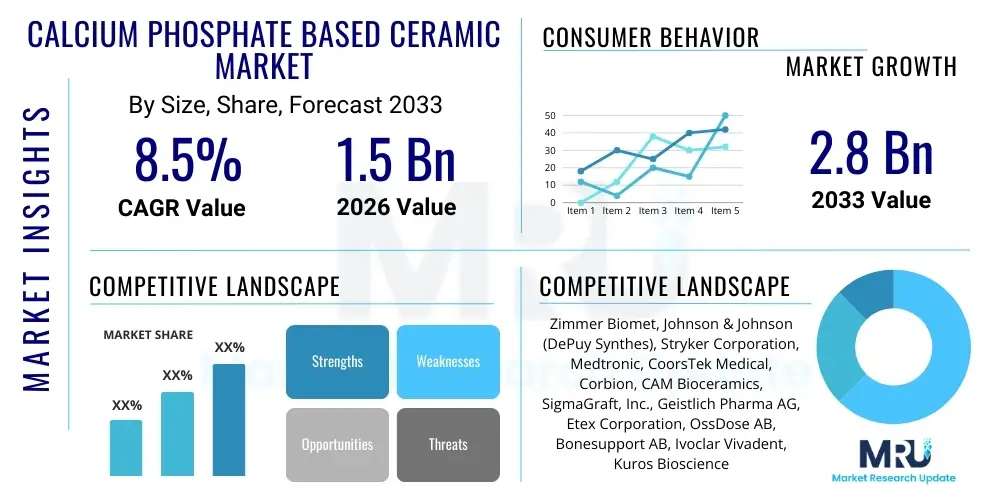

The Calcium Phosphate Based Ceramic Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 1.5 Billion in 2026 and is projected to reach USD 2.8 Billion by the end of the forecast period in 2033.

Calcium Phosphate Based Ceramic Market introduction

The Calcium Phosphate Based Ceramic Market encompasses biomaterials primarily utilized in orthopedic, dental, and tissue engineering applications due to their exceptional biocompatibility and osteoconductivity. These ceramics, which include Hydroxyapatite (HA), Tricalcium Phosphate (TCP), and combinations thereof, closely mimic the mineral composition of natural bone tissue, facilitating osseointegration and promoting new bone growth. The rising prevalence of degenerative bone diseases, coupled with a globally aging population requiring frequent reconstructive procedures, serves as the foundational driver for market expansion.

Calcium phosphate ceramics are highly valued for their ability to be fabricated into various forms, such as coatings, porous scaffolds, bone fillers, and cements, making them indispensable in complex surgical environments. Major applications include bone graft substitutes, joint replacement coatings to enhance fixation, and dental implants. The primary benefit these materials offer is their resorbability and non-toxic degradation profile, meaning they gradually dissolve and are replaced by native bone tissue over time, minimizing long-term foreign body reactions.

The market growth is substantially driven by advancements in material science, particularly the development of nanostructured calcium phosphate ceramics which exhibit superior mechanical properties and enhanced bioactivity. Furthermore, the increasing adoption of minimally invasive surgical techniques, which often rely on advanced synthetic bone substitutes, fuels demand. Regulatory approvals for new composite materials and the sustained research focus on personalized medicine and regenerative therapies further cement the importance of calcium phosphate ceramics in modern medical practice.

Calcium Phosphate Based Ceramic Market Executive Summary

The Calcium Phosphate Based Ceramic Market is characterized by robust growth, primarily propelled by favorable demographic trends, technological innovations in biomaterials, and increasing governmental and private sector investment in healthcare infrastructure globally. Key business trends include strategic mergers and acquisitions among major material suppliers and medical device manufacturers aiming to integrate advanced ceramic production capabilities. Furthermore, there is a strong shift towards the development of biphasic and composite calcium phosphate formulations, combining the benefits of fast resorption (like TCP) with high stability (like HA), optimizing clinical outcomes across diverse surgical needs.

Regionally, North America and Europe maintain dominance due to established healthcare reimbursement policies, high volumes of orthopedic procedures, and intense research and development activities focused on regenerative medicine. However, the Asia Pacific region is poised for the highest growth rate, driven by rapidly expanding healthcare access, growing medical tourism, and increasing awareness regarding advanced synthetic bone substitutes, particularly in densely populated countries like China and India. This regional dynamic suggests a future market landscape where manufacturing and consumption increasingly decentralize toward emerging economies.

Segment-wise, Hydroxyapatite (HA) currently holds the largest market share owing to its excellent stability and widespread use as a coating material for metallic implants. Nonetheless, the Biphasic Calcium Phosphate (BCP) segment is anticipated to witness the fastest growth, favored by surgeons seeking controlled degradation kinetics. Application analysis highlights orthopedics as the critical revenue generator, followed closely by dental applications, fueled by the rising demand for sophisticated dental reconstruction and osseous repair procedures. The underlying trend across all segments emphasizes biocompatibility, mechanical strength, and tailored material porosity for specific tissue engineering requirements.

AI Impact Analysis on Calcium Phosphate Based Ceramic Market

User inquiries regarding AI's impact on the Calcium Phosphate Based Ceramic Market primarily revolve around optimizing material synthesis, predicting long-term in-vivo performance, and streamlining regulatory pathways for new biomaterials. Concerns frequently address how AI models can predict subtle differences in cellular response based on ceramic structure (porosity, grain size, chemistry) and how machine learning algorithms can accelerate the identification of optimal doping elements or composite ratios to enhance osteoinductivity. Users expect AI to reduce the time and cost associated with iterative laboratory testing and clinical trials, ensuring faster translation of advanced ceramic technologies from bench to bedside, thereby accelerating market access and innovation cycles.

AI's role is transformative in three key areas: advanced material informatics, clinical trial optimization, and personalized implant design. Material informatics employs machine learning to correlate synthesis parameters with mechanical and biological properties, allowing researchers to rapidly design novel calcium phosphate formulations with predictable clinical outcomes. In clinical trials, AI can analyze vast patient datasets and imaging results to predict the success rate of a specific ceramic implant in various patient demographics, enhancing the precision of clinical data interpretation and accelerating regulatory submission processes.

Furthermore, the integration of AI with additive manufacturing (3D printing) is crucial. AI algorithms optimize the geometry and porosity of patient-specific ceramic scaffolds based on CT or MRI data, ensuring the fabricated structure perfectly matches the defect site and provides optimal conditions for vascularization and bone regeneration. This level of customization, driven by sophisticated computational analysis, significantly improves surgical efficiency and patient recovery, positioning AI as a vital tool for next-generation biomaterial development and utilization in the orthobiologics sector.

- AI-driven optimization of ceramic synthesis parameters (temperature, pressure, composition) to ensure highly consistent material quality.

- Machine Learning models predicting the long-term degradation rate and osseointegration success of calcium phosphate scaffolds in diverse biological environments.

- Accelerated discovery of novel bioceramic composites and dopants through high-throughput virtual screening enabled by AI.

- Enhanced personalized implant design by utilizing deep learning to create patient-specific porous architectures for 3D printed ceramics.

- Optimization of clinical trial design and patient selection, leveraging AI to analyze complex biological markers and predict therapeutic response to ceramic grafts.

- Automated quality control systems in manufacturing using computer vision and AI for detecting microstructural flaws in finished ceramic products.

DRO & Impact Forces Of Calcium Phosphate Based Ceramic Market

The Calcium Phosphate Based Ceramic Market is primarily driven by the escalating global need for bone graft substitutes stemming from sports injuries, trauma cases, and age-related bone degradation. Significant drivers include the expanding elderly population, which experiences higher rates of orthopedic and dental conditions requiring intervention, and continuous technological progress resulting in bioceramics with superior mechanical characteristics and enhanced bioactivity. These favorable dynamics create strong market momentum, ensuring sustained adoption across reconstructive surgeries.

Restraints, however, pose certain challenges, particularly the high cost associated with manufacturing and subsequent regulatory compliance for advanced synthetic materials. Furthermore, the inherent brittleness of certain ceramic formulations, especially under significant load-bearing conditions, limits their applicability in certain critical orthopedic sites. Competition from established alternative grafting materials, such as autografts and allografts, which are often preferred by surgeons despite their limitations, also moderates the growth rate in specific clinical niches.

Opportunities are predominantly centered on the development of smart, multifunctional ceramics that can deliver therapeutic agents or exhibit antibacterial properties, broadening their utility beyond mere structural support. The convergence of calcium phosphate materials with tissue engineering and regenerative medicine—particularly in developing bio-inks for 3D bioprinting of complex tissues—presents lucrative avenues. Impact forces demonstrate high momentum from market drivers due to the non-negotiable medical need, while regulatory hurdles and material constraints exert a moderate to high counter-force requiring continuous innovation to overcome inherent technical limitations.

Segmentation Analysis

The Calcium Phosphate Based Ceramic Market segmentation provides a granular view of material preferences, product types, and application areas that define market dynamics and investment opportunities. Analysis is typically structured around Type (Hydroxyapatite, Tricalcium Phosphate, Biphasic Calcium Phosphate), Form (Powder, Granules, Cement, Coatings), and Application (Orthopedics, Dental, Cosmetics, and Others). This detailed breakdown allows stakeholders to identify fast-growing niches, such as Biphasic Calcium Phosphate for complex spine fusion surgeries, and emerging applications in areas like maxillofacial reconstruction.

The segmentation by product type is critical as it reflects the technical evolution and acceptance of materials based on specific clinical requirements. Hydroxyapatite (HA) remains the cornerstone due to its proven long-term stability and osteoconductive capabilities, heavily favored for implant coatings. However, the move toward Tricalcium Phosphate (TCP) and Biphasic Calcium Phosphate (BCP) demonstrates a growing surgical preference for materials offering controlled biodegradability and resorption rates, allowing the body to naturally replace the ceramic scaffold with living bone tissue more efficiently. BCP, combining the stability of HA with the resorbability of TCP, is increasingly becoming the preferred synthetic graft option.

Application segmentation reveals the dominance of the orthopedics sector, encompassing trauma fixation, joint reconstruction, and spine fusion procedures, which account for the majority of revenue. The dental segment, however, is expanding rapidly, driven by the increasing number of implant procedures, periodontal defect repair, and ridge augmentation processes where calcium phosphate cements and granules are extensively utilized. Strategic investment focuses heavily on improving product handling characteristics, such as injectability and setting time, especially for ceramic cements used in minimally invasive surgical interventions across these primary application domains.

- By Type:

- Hydroxyapatite (HA)

- Tricalcium Phosphate (TCP)

- Biphasic Calcium Phosphate (BCP)

- Tetracalcium Phosphate (TTCP)

- By Form:

- Powder and Granules

- Cements and Pastes

- Coatings

- Scaffolds and Blocks

- By Application:

- Orthopedics (Spine Fusion, Trauma, Joint Reconstruction)

- Dental (Bone Defect Repair, Ridge Augmentation, Periodontics)

- Drug Delivery Systems

- Tissue Engineering and Regeneration

- By End-User:

- Hospitals

- Ambulatory Surgical Centers (ASCs)

- Specialty Clinics (Orthopedic and Dental)

Value Chain Analysis For Calcium Phosphate Based Ceramic Market

The value chain for the Calcium Phosphate Based Ceramic Market begins with the rigorous upstream process involving the sourcing and purification of high-purity raw materials, primarily calcium carbonate and phosphoric acid, which are critical precursors for synthesis. Upstream activities are dominated by specialized chemical suppliers ensuring material consistency, which directly impacts the biocompatibility and mechanical reliability of the final ceramic product. This is followed by complex synthesis and material processing stages, including precipitation, hydrothermal treatment, and sintering, which determine the crystalline structure, porosity, and phase composition (HA, TCP, or BCP) of the ceramic.

The midstream phase involves manufacturers converting these base powders into commercially viable forms, such as blocks, granules, injectable cements, or specialized coatings applied to metallic implants. This stage is highly capital-intensive, requiring advanced equipment for high-temperature processing and additive manufacturing techniques like 3D printing for customized scaffolds. Quality control and regulatory compliance are paramount here, ensuring the final product meets stringent medical device standards (e.g., FDA, CE mark) regarding sterility, mechanical strength, and dissolution rates before entering the distribution network.

Downstream analysis focuses on the distribution channels, which are typically bifurcated into direct sales teams targeting large hospital groups and indirect channels utilizing third-party medical device distributors and wholesalers. Direct channels are crucial for specialized, high-volume products requiring technical support, while indirect channels provide broad market penetration into smaller surgical centers and specialty clinics. The final customers are surgeons and hospitals in the orthopedics and dental departments, whose purchasing decisions are highly influenced by clinical performance data, perceived product reliability, and pricing structures dictated by complex reimbursement scenarios.

Calcium Phosphate Based Ceramic Market Potential Customers

Potential customers for calcium phosphate based ceramics primarily reside within specialized medical institutions focused on musculoskeletal and dental reconstruction. Hospitals, particularly those with major trauma centers and orthopedic departments, represent the largest segment of end-users. These facilities purchase significant volumes of ceramic bone graft substitutes and HA-coated implants for procedures ranging from complex fracture repair and joint revisions to spinal fusion surgeries. Purchasing decisions in this segment are heavily influenced by clinical efficacy studies, long-term biocompatibility data, and hospital formularies that prioritize cost-effectiveness alongside performance.

Ambulatory Surgical Centers (ASCs) and specialized orthopedic/dental clinics constitute a rapidly growing customer base. ASCs prefer minimally invasive solutions and products that streamline surgical workflow, driving demand for ready-to-use injectable calcium phosphate cements and pre-shaped granules for localized defect filling. Dental clinics and periodontists utilize these materials extensively for socket preservation, periodontal bone regeneration, and augmentation procedures prior to dental implant placement. This segment emphasizes ease of handling, predictable resorption, and fast integration to ensure successful outcomes for elective procedures.

Furthermore, academic and industrial research institutions are significant consumers of specialized, highly controlled calcium phosphate materials. These customers utilize the ceramics for fundamental research in tissue engineering, drug delivery matrix development, and testing novel cell-based therapies. Their purchasing is focused on small-batch, high-purity materials often customized for specific particle size or porosity characteristics. The procurement strategy for this segment prioritizes technical specifications and scientific collaboration potential over sheer volume, driving demand for specialized material suppliers rather than large finished product manufacturers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.5 Billion |

| Market Forecast in 2033 | USD 2.8 Billion |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Zimmer Biomet, Johnson & Johnson (DePuy Synthes), Stryker Corporation, Medtronic, CoorsTek Medical, Corbion, CAM Bioceramics, SigmaGraft, Inc., Geistlich Pharma AG, Etex Corporation, OssDose AB, Bonesupport AB, Ivoclar Vivadent, Kuros Biosciences, Curasan AG, Trelleborg AB, Ceraver, Promimic AB, Novabone Products, Inc., Cellon S.A. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Calcium Phosphate Based Ceramic Market Key Technology Landscape

The technological landscape of the Calcium Phosphate Based Ceramic Market is characterized by a strong focus on enhancing material performance through controlled synthesis and advanced fabrication methods. A core technological trend involves the precise control of phase purity and stoichiometry during the manufacturing process, such as wet chemical precipitation and high-temperature sintering, to ensure predictable degradation and biological response. Innovations in nanostructured materials, where particle size is reduced to the nanoscale, significantly increase the surface area and dissolution rate, thereby enhancing cellular adhesion and speeding up the osteoconductive process crucial for effective bone regeneration.

Additive manufacturing, specifically 3D printing (including robocasting and selective laser sintering), represents a paradigm shift in ceramic fabrication. This technology allows for the creation of intricate, patient-specific porous scaffolds with interconnected pore networks designed to mimic the natural cancellous bone structure, optimizing nutrient flow and cell infiltration. Furthermore, the development of injectable, self-setting calcium phosphate cements (CPCs) is a significant technology, enabling minimally invasive repair of bone defects. These CPCs are designed to be mechanically stable post-setting while remaining fully resorbable, mitigating the need for secondary surgeries often required with temporary fixation devices.

Another crucial technological direction is the functionalization of calcium phosphate surfaces. This involves coating the ceramics with biological molecules, such as growth factors (e.g., BMPs) or peptides, or incorporating antibacterial agents (like silver nanoparticles) to create multifunctional biomaterials. These functionalized ceramics not only provide structural support but also actively participate in the healing process by accelerating bone formation or preventing post-operative infection, thus significantly improving clinical outcomes and widening the therapeutic window for these advanced bone substitutes.

Regional Highlights

The global Calcium Phosphate Based Ceramic Market exhibits distinct regional dynamics driven by varying levels of healthcare expenditure, surgical volumes, regulatory environments, and research capabilities across geographies. North America, encompassing the United States and Canada, currently holds the largest market share. This dominance is attributed to high patient awareness, advanced healthcare infrastructure, substantial investment in orthopedic research, and favorable reimbursement policies that support the usage of premium synthetic bone graft substitutes. The region leads in adopting cutting-edge technologies, particularly in specialized areas like spinal fusion and complex joint reconstruction, ensuring continuous high demand for both HA coatings and BCP scaffolds.

Europe represents the second-largest market, characterized by stringent regulatory oversight via the European Medicines Agency (EMA) and strong academic research collaboration focusing on advanced biomaterials. Countries such as Germany, the UK, and France are major consumers, supported by universal healthcare systems and a high incidence of age-related orthopedic conditions. The European market shows a pronounced trend towards bio-absorbable and injectable ceramic products, driven by the push for less invasive surgical techniques and optimized patient recovery pathways.

The Asia Pacific (APAC) region is projected to register the highest Compound Annual Growth Rate (CAGR) over the forecast period. This rapid expansion is fueled by improving economic conditions, massive population size, increasing accessibility to modern surgical treatments, and the burgeoning medical device manufacturing sector, particularly in China, Japan, and South Korea. While the cost sensitivity remains a factor, the increasing prevalence of road accidents and the rising demand for sophisticated dental implants are rapidly transforming APAC from a materials supplier to a major consumer market for finished calcium phosphate ceramic products.

Latin America and the Middle East & Africa (MEA) currently hold smaller market shares but offer significant long-term growth potential. In Latin America, improving healthcare access and infrastructure development in key economies like Brazil and Mexico are driving increased utilization of synthetic bone substitutes, particularly in private healthcare settings. The MEA region’s growth is anchored by investments in modernizing healthcare facilities, particularly in the Gulf Cooperation Council (GCC) countries, focusing on specialized orthopedic care and trauma management. However, market adoption in these regions is often constrained by fragmented reimbursement structures and dependence on imported advanced ceramic products.

- North America: Dominant market share due to high surgical procedure volume, robust R&D, advanced medical technology adoption, and strong regulatory support for novel biomaterials.

- Europe: Second-largest market, characterized by a high preference for injectable cements and bio-resorbable materials, supported by established public healthcare systems and focused academic research.

- Asia Pacific (APAC): Fastest-growing region, driven by expanding healthcare infrastructure, rising incidence of trauma, high demand for dental implants, and increasing disposable income in countries like China and India.

- Latin America (LATAM): Emerging market showing steady growth, primarily in urban centers and private hospitals, focusing on improving surgical outcomes in trauma and elective orthopedic procedures.

- Middle East and Africa (MEA): Growth driven by medical tourism investments in the GCC countries and increasing awareness of advanced bone replacement options in specialized clinics.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Calcium Phosphate Based Ceramic Market.- Zimmer Biomet

- Johnson & Johnson (DePuy Synthes)

- Stryker Corporation

- Medtronic

- CoorsTek Medical

- Corbion

- CAM Bioceramics

- SigmaGraft, Inc.

- Geistlich Pharma AG

- Etex Corporation

- OssDose AB

- Bonesupport AB

- Ivoclar Vivadent

- Kuros Biosciences

- Curasan AG

- Trelleborg AB

- Ceraver

- Promimic AB

- Novabone Products, Inc.

- Cellon S.A.

Frequently Asked Questions

Analyze common user questions about the Calcium Phosphate Based Ceramic market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function of calcium phosphate ceramics in orthopedics?

The primary function is to serve as synthetic bone graft substitutes, providing a scaffold (osteoconduction) that guides and supports the regeneration of new, viable bone tissue, particularly in non-load-bearing or low-load-bearing applications.

What are the key differences between Hydroxyapatite (HA) and Tricalcium Phosphate (TCP)?

HA is highly stable and slowly resorbed, offering long-term structural integrity, often used for coatings. TCP is more rapidly biodegradable and completely resorbed by the body, favored when faster material replacement by natural bone is desired.

How does 3D printing technology impact the manufacturing of calcium phosphate ceramics?

3D printing allows for the precise fabrication of highly porous, patient-specific scaffolds with complex, interconnected geometries, optimizing the material structure for enhanced biological performance and bone ingrowth compared to conventional solid blocks.

Which application segment holds the largest market share for these ceramics?

The Orthopedics application segment, encompassing trauma repair, spinal fusion, and joint revision surgeries, currently holds the largest market share due to the high volume and complexity of bone reconstruction procedures worldwide.

Are calcium phosphate ceramics used in drug delivery systems?

Yes, due to their porosity and biocompatibility, these ceramics are increasingly utilized as localized drug delivery carriers to release antibiotics, growth factors, or pain medications directly at the surgical site, improving therapeutic effectiveness and reducing systemic side effects.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager