Can Seamers Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439803 | Date : Jan, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Can Seamers Market Size

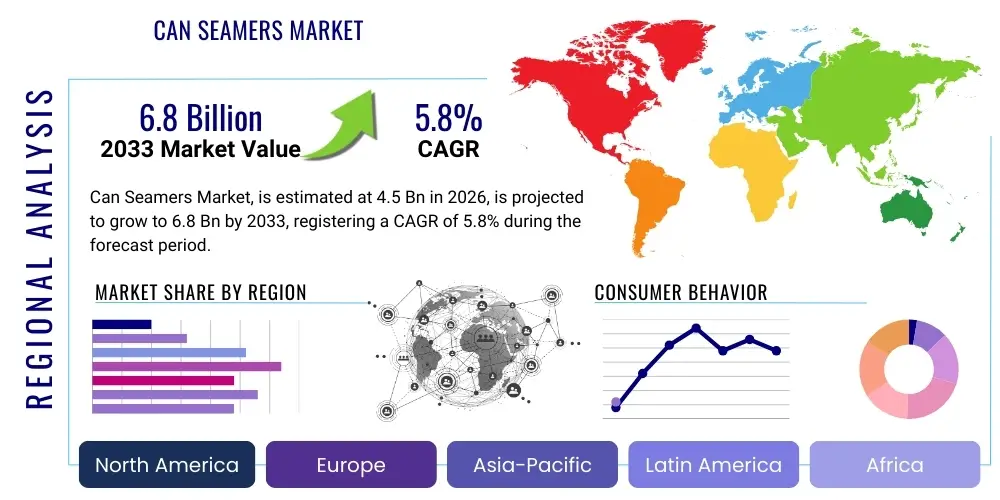

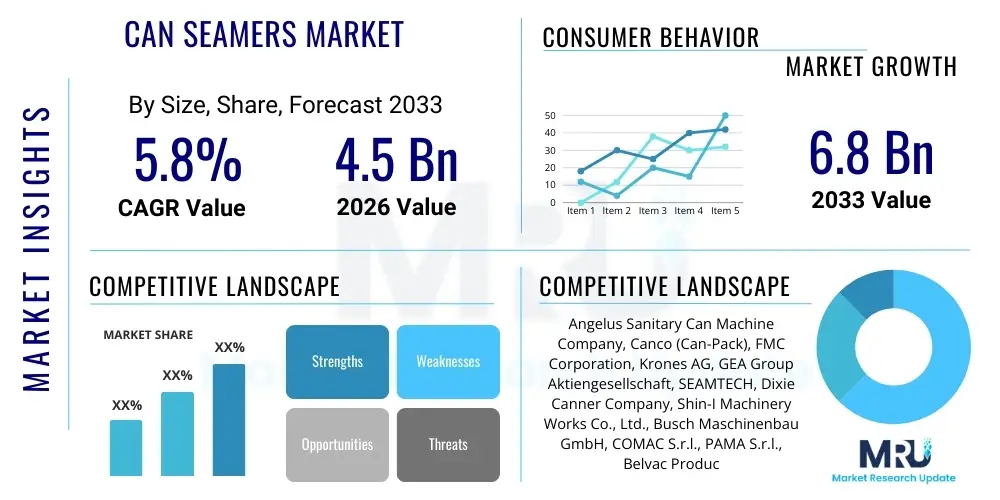

The Can Seamers Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $4.5 Billion in 2026 and is projected to reach $6.8 Billion by the end of the forecast period in 2033.

Can Seamers Market introduction

Can seamers are precision machinery integral to the packaging industry, designed to hermetically seal lids onto cans, thereby ensuring product integrity, extended shelf-life, and protection against external contaminants. These machines execute a complex double seaming process, which involves interlocking the can body flange and the lid curl to create an airtight seal, a critical step for preserving food, beverages, and other sensitive products. Their robust construction and sophisticated mechanisms allow for high-speed operation and consistent quality, meeting the rigorous demands of modern manufacturing lines.

The primary applications of can seamers span across a multitude of sectors, predominantly the food and beverage industry, where they are indispensable for packaging items ranging from canned fruits, vegetables, and meats to carbonated drinks, juices, and pet food. Beyond consumables, can seamers also find significant utility in pharmaceutical packaging for sterile medical supplies and in the chemical industry for sealing containers of paints, aerosols, and other industrial substances. The versatility of these machines to handle various can sizes, materials, and product types underscores their foundational role in global supply chains.

The key benefits derived from employing advanced can seamers include superior product preservation, reduced spoilage, and enhanced food safety, which are paramount for consumer health and brand reputation. Driving factors for market growth include the escalating global demand for convenience food and beverages, the increasing adoption of automated packaging solutions to boost production efficiency and lower labor costs, and ongoing technological advancements in sealing precision and speed. Furthermore, the rising focus on sustainable packaging materials and processes, coupled with stringent regulatory standards for product safety and quality, continues to fuel innovation and expansion within the can seamers market, as manufacturers seek more efficient, reliable, and environmentally friendly sealing solutions.

Can Seamers Market Executive Summary

The Can Seamers Market is experiencing dynamic growth driven by evolving global consumption patterns and an increased emphasis on automated, efficient, and safe packaging solutions across diverse industries. Key business trends point towards a growing demand for high-speed, fully automatic can seaming machines capable of integrating seamlessly into Industry 4.0 environments, featuring advanced sensors, predictive maintenance capabilities, and real-time data analytics. Manufacturers are increasingly investing in sophisticated equipment that offers greater flexibility in handling various can sizes and materials, alongside improved energy efficiency and reduced operational footprints. The competitive landscape is characterized by innovation in sealing technology, aimed at enhancing seal integrity and minimizing product waste, reflecting a broader industry shift towards operational excellence and sustainability.

Regional trends indicate robust expansion in emerging economies, particularly across the Asia Pacific, Latin America, and Middle East & Africa regions, propelled by rapid urbanization, rising disposable incomes, and the expansion of domestic food and beverage manufacturing capabilities. These regions are witnessing significant infrastructure development in the packaging sector, fostering a fertile ground for the adoption of new can seaming technologies. Conversely, mature markets in North America and Europe are focusing on upgrading existing machinery with advanced automation, optimizing production lines for greater sustainability, and adapting to stricter regulatory frameworks regarding packaging materials and processes. The drive for localization of production and reduction of supply chain vulnerabilities also plays a crucial role in shaping regional investment patterns.

Segment trends within the can seamers market highlight the continued dominance of the food and beverage industry as the primary end-user, with particularly strong demand stemming from the soft drinks, beer, and prepared foods segments. There is a discernible shift towards automatic can seamers due to their capacity for high-volume production and consistent quality, pushing semi-automatic and manual options to niche or smaller-scale operations. Furthermore, the market is observing increased innovation in handling aluminum and steel cans, reflecting material preferences driven by recycling initiatives and consumer choice. This comprehensive market evolution, characterized by technological advancement, strategic regional expansion, and segment-specific growth, underscores a robust outlook for the can seamers industry, poised for sustained expansion through the forecast period.

AI Impact Analysis on Can Seamers Market

User questions regarding the impact of Artificial Intelligence (AI) on the Can Seamers Market frequently revolve around how AI can enhance operational efficiency, ensure product quality, and contribute to predictive maintenance. Common concerns include the complexity of integrating AI systems into existing machinery, the initial investment costs, and the need for skilled personnel to manage and interpret AI-driven data. Users are keen to understand how AI can reduce downtime, optimize seaming parameters in real-time, and detect defects with greater precision than traditional methods. Expectations are high for AI to revolutionize machine uptime, minimize waste, and improve overall production line performance through intelligent automation and adaptive control systems.

The integration of AI in can seamer technology is set to transform the industry by enabling unprecedented levels of precision, autonomy, and efficiency. AI-powered vision systems can meticulously inspect every can seam for imperfections at high speeds, far surpassing human capabilities and reducing the incidence of faulty products reaching the market. This not only enhances product safety and quality assurance but also significantly minimizes material waste and associated reprocessing costs. Furthermore, AI algorithms can analyze vast datasets from seaming operations, identifying subtle patterns and correlations that are invisible to conventional monitoring systems, leading to more informed decision-making and operational adjustments.

Beyond quality control, AI’s profound impact extends to predictive maintenance, a critical area for continuous production environments. By learning from machine sensor data, AI models can anticipate potential equipment failures before they occur, scheduling maintenance proactively and thereby drastically reducing unexpected downtime and costly emergency repairs. This shift from reactive to predictive maintenance optimizes maintenance schedules, extends the lifespan of machinery, and ensures maximum operational throughput. The continuous optimization of seaming parameters, adaptive control over varying can specifications, and the potential for fully autonomous seaming lines represent the future promise of AI in this vital sector, addressing key user demands for reliability and cost-effectiveness.

- AI-driven vision systems enable real-time, high-speed defect detection for can seams, significantly improving quality control and reducing product recalls. These systems can identify minute imperfections invisible to the human eye, ensuring superior seal integrity and consumer safety.

- Predictive maintenance powered by machine learning algorithms analyzes operational data to forecast equipment failures, allowing for proactive maintenance scheduling, minimizing unscheduled downtime, and extending machine lifespan. This optimizes operational efficiency and reduces repair costs.

- Optimized seaming parameters through AI ensure consistent seal quality across various can types and materials by dynamically adjusting machine settings based on real-time feedback and learned patterns. This leads to reduced waste and improved resource utilization.

- Enhanced operational efficiency is achieved by AI-driven automation that manages throughput, energy consumption, and raw material usage, leading to a more streamlined and cost-effective production process. AI can orchestrate multiple seaming units for maximum output.

- Supply chain optimization benefits from AI by providing insights into production capacities, demand fluctuations, and material requirements, helping manufacturers adapt quickly to market changes and maintain optimal inventory levels for can seamer components and supplies.

- AI facilitates adaptive learning for can seamer machines, enabling them to automatically adjust to new can designs, lid specifications, or material variations with minimal human intervention, accelerating product changeovers and increasing manufacturing flexibility.

- Improved data analytics and reporting are made possible through AI, transforming raw operational data into actionable insights for continuous process improvement, helping manufacturers identify bottlenecks and areas for efficiency gains in their seaming operations.

- Robotic integration with AI allows for more precise and versatile handling of cans before and after the seaming process, reducing manual labor, improving safety, and enabling complex sorting or packaging tasks to be performed with high accuracy and speed.

DRO & Impact Forces Of Can Seamers Market

The Can Seamers Market is influenced by a complex interplay of drivers, restraints, opportunities, and inherent impact forces that collectively shape its growth trajectory and competitive landscape. A primary driver is the pervasive and growing global demand for packaged food and beverages, fueled by urbanization, evolving consumer lifestyles, and an increasing preference for convenience products with extended shelf-life. This consistent demand necessitates high-speed, reliable, and efficient can seaming solutions to meet production quotas. Coupled with this, the relentless pursuit of automation and efficiency within the packaging industry, driven by rising labor costs and the need for consistent quality, propels investments in advanced automatic can seamers that can integrate into smart factory ecosystems.

However, the market also faces significant restraints. The substantial initial capital investment required for high-precision can seaming machinery can be a barrier for new entrants and smaller enterprises, limiting market accessibility and adoption. Furthermore, the ongoing maintenance and operational costs, including specialized parts and skilled labor for servicing, add to the total cost of ownership. The market also contends with intense competition from alternative packaging solutions such as flexible pouches, cartons, and plastic containers, which continuously innovate to offer competitive advantages in terms of cost, weight, and perceived sustainability. Regulatory complexities concerning food safety, material compliance, and environmental standards also pose challenges, requiring manufacturers to continuously adapt their processes and equipment.

Opportunities for growth are abundant, particularly in emerging markets where rapid economic development and increasing disposable incomes are catalyzing the expansion of domestic food and beverage production. These regions present untapped potential for new installations and technology upgrades. The advent of smart factories and Industry 4.0 paradigms offers a significant opportunity for integrating can seamers with IoT sensors, AI-driven analytics, and robotic systems, leading to enhanced predictive maintenance, real-time quality control, and optimized production flows. Moreover, the increasing global focus on sustainable packaging materials and processes, including lightweighting and improved recyclability of cans, creates avenues for innovation in seamer technology that supports these environmental objectives. Customization and flexibility in production lines, catering to diverse product ranges and shorter runs, further present opportunities for specialized machinery development.

Impact forces on the market are profound and multi-faceted. Technological innovation remains a critical force, continuously pushing the boundaries of seaming speed, precision, and machine intelligence, which directly influences efficiency and product quality. Evolving consumer preferences, particularly a growing demand for convenience, health-conscious options, and sustainably packaged goods, directly impacts the types of cans used and, consequently, the design and capabilities of can seamers. Stringent global food safety and quality regulations compel manufacturers to adopt highly reliable and auditable seaming processes, driving the demand for advanced inspection and quality assurance features. Lastly, global economic shifts, including trade policies, raw material price fluctuations, and geopolitical events, can influence investment decisions, supply chain stability, and overall market dynamics, necessitating adaptive strategies from market participants.

Segmentation Analysis

The Can Seamers Market is comprehensively segmented to provide a granular understanding of its diverse landscape, reflecting variations in machine capabilities, application areas, and end-user requirements. This segmentation allows for targeted market analysis, identifying specific growth drivers and challenges within each category. The primary segmentation criteria typically include the type of seaming machine, its application across different industries, the end-user scale of operation, and the material of the cans being sealed. This multi-dimensional approach highlights the specialized needs of various market participants and the technological advancements tailored to meet these unique demands, ranging from high-speed automated lines for large manufacturers to versatile semi-automatic units for specialized or smaller-batch production.

- Type:

- Automatic Can Seamers: These machines are designed for high-volume production lines, offering superior speed, precision, and integration capabilities with minimal human intervention. They are equipped with advanced control systems and are critical for large-scale food, beverage, and industrial packaging operations where efficiency and consistency are paramount.

- Semi-Automatic Can Seamers: Providing a balance between automation and manual operation, these machines are suitable for medium-volume production, specialized products, or start-up businesses. They offer flexibility in handling various can sizes and types with moderate investment and operational complexity.

- Manual Can Seamers: Typically used for very low-volume production, artisanal products, research and development, or small-scale experimental runs. These machines require significant manual input but are cost-effective for niche applications where speed is not the primary concern.

- Application:

- Food & Beverage: The largest segment, encompassing a vast array of products such as carbonated soft drinks, beer, fruit juices, dairy products, preserved fruits and vegetables, meat, seafood, and pet food. This segment drives the bulk of demand due to global consumption patterns and shelf-life requirements.

- Pharmaceuticals: Used for sealing sterile containers for medical products, ensuring tamper-proof packaging and product integrity crucial for health and safety standards. This application requires highly precise and hygienic seaming solutions.

- Chemicals: Involves the packaging of paints, aerosols, industrial solvents, and other chemical compounds. Seamers for this application often need to withstand corrosive substances and provide robust, leak-proof seals for safety and compliance.

- Others: Includes packaging for industrial goods, cosmetics, and various specialized products where hermetic sealing is essential for protection, preservation, or preventing leakage during storage and transportation.

- End-Use:

- Large-Scale Manufacturing Units: Big corporations and multinational companies with extensive production lines and high output requirements. They primarily invest in fully automatic, high-speed can seamers with advanced integration capabilities.

- Small & Medium-Sized Enterprises (SMEs): Businesses with moderate production volumes, often focusing on niche products, local markets, or specialized packaging. They typically utilize semi-automatic or versatile automatic can seamers that offer flexibility and cost-efficiency.

- Material:

- Aluminum Cans: Widely used for beverages (soft drinks, beer) due to their lightweight, recyclability, and aesthetic appeal. Seamers for aluminum cans are designed for high speed and precise handling of thinner gauge materials.

- Steel Cans: Predominantly used for food preservation (fruits, vegetables, meats) and some industrial applications. Steel cans offer strength and durability, requiring robust seaming mechanisms.

- Tin Cans: A traditional material, often used interchangeably with steel cans (tin-plated steel). Seamers handle these materials with established techniques focused on strong, reliable seals.

- Composite Cans: Increasingly used for powdered products, snacks, and specialty items, these cans combine layers of different materials (e.g., paperboard, foil, plastic). Seaming technology for composite cans addresses the unique challenges of sealing dissimilar materials.

Value Chain Analysis For Can Seamers Market

The value chain for the Can Seamers Market is a sophisticated network encompassing several crucial stages, starting from the sourcing of raw materials and extending through manufacturing, distribution, and ultimately to the end-user. This intricate chain highlights the interdependence of various stakeholders and the sequential processes that add value at each step. Understanding this value chain is essential for identifying areas of efficiency, potential bottlenecks, and opportunities for strategic collaboration, from the initial design and engineering of seaming machinery to its operational deployment and after-sales support in diverse packaging environments.

Upstream analysis in the can seamers market focuses on the suppliers of essential components and raw materials that form the backbone of these complex machines. This includes manufacturers of high-grade steel and aluminum for machine frames and precision parts, specialized electronics and control system providers (PLCs, HMIs, sensors), motor and drive manufacturers (servo motors, gearboxes), and precision engineering firms for tooling, dies, and seaming rolls. The quality and reliability of these upstream inputs directly impact the performance, longevity, and accuracy of the final can seaming equipment. Strong relationships with reliable component suppliers are crucial for maintaining manufacturing quality, managing costs, and ensuring timely production of can seamer units.

Downstream analysis primarily concerns the end-users and the subsequent steps where the can seamers are integrated into broader packaging lines. The direct downstream beneficiaries are the food and beverage processing companies, pharmaceutical manufacturers, and chemical industries that utilize these machines for sealing their products. The sealed cans then move through further stages of packaging, labeling, warehousing, and logistics before reaching distributors and retailers, and finally, the end consumers. Can seamer manufacturers often work closely with these downstream players to ensure machine compatibility with existing lines, provide training, and offer maintenance services, thus playing a vital role in ensuring the overall efficiency and reliability of the entire product journey to market.

Distribution channels for can seamers are varied, typically involving a mix of direct sales, authorized distributors, and agents. Direct sales are common for large, custom-engineered projects, where manufacturers engage directly with major clients to offer tailored solutions, installation, and comprehensive support. For broader market reach, particularly to SMEs and international markets, manufacturers rely on a network of distributors and agents. These intermediaries provide local market expertise, sales and technical support, and often manage after-sales services, bridging the geographical and logistical gaps between the manufacturer and diverse customer bases. The effectiveness of these distribution channels is paramount for market penetration, customer satisfaction, and timely delivery of complex machinery. The strategic selection and management of these channels are critical for competitive success.

Can Seamers Market Potential Customers

The potential customers for the Can Seamers Market are diverse and span a wide array of industries, each with specific packaging needs and operational scales, united by the fundamental requirement for reliable, hermetic sealing of cans. These end-users are primarily manufacturers and processors of products that benefit from the extended shelf-life, protective barriers, and transport stability afforded by canned packaging. Identifying and understanding the distinct characteristics and demands of these customer segments is crucial for can seamer manufacturers to develop targeted solutions, marketing strategies, and provide appropriate technical support and service offerings that align with their varied production environments and business objectives.

Among the most significant segments of potential customers are food processing companies, ranging from multinational conglomerates to regional producers and specialized artisanal businesses. This includes manufacturers of canned fruits, vegetables, meats, seafood, sauces, ready-to-eat meals, and pet food. These customers prioritize machines that can handle high volumes at speed, ensure absolute food safety through impeccable seal integrity, and comply with stringent regulatory standards. Their demand often involves versatility to accommodate various can sizes and product textures, coupled with efficiency to minimize product waste and maximize throughput in continuous operation lines, making them key drivers for innovation in automatic can seaming technology.

Another major customer base lies within the vast beverage industry, encompassing producers of carbonated soft drinks, beer, juices, energy drinks, and dairy-based beverages. These companies require high-speed, precision can seamers capable of handling delicate aluminum cans and maintaining optimal pressure integrity, especially for carbonated products. Consistency, speed, and minimal oxygen ingress are paramount for preserving product quality and taste, directly impacting brand reputation and consumer satisfaction. Additionally, the pharmaceutical and chemical industries represent significant, albeit more niche, potential customers. Pharmaceutical firms require highly sterile and tamper-evident sealing for medical products, while chemical manufacturers need robust, corrosion-resistant seamers for paints, aerosols, and industrial chemicals, emphasizing safety and compliance with hazardous material regulations. Each segment demands tailored features and robust performance from their can seaming solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $4.5 Billion |

| Market Forecast in 2033 | $6.8 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Angelus Sanitary Can Machine Company, Canco (Can-Pack), FMC Corporation, Krones AG, GEA Group Aktiengesellschaft, SEAMTECH, Dixie Canner Company, Shin-I Machinery Works Co., Ltd., Busch Maschinenbau GmbH, COMAC S.r.l., PAMA S.r.l., Belvac Production Machinery Inc., Ferrum AG, FBR ELPO S.p.A., Pneumatic Scale Angelus (Barry-Wehmiller), SOLTEC System, JBT Corporation, Zacmi S.p.A., CFT Group, Wild Goose Filling |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Can Seamers Market Key Technology Landscape

The Can Seamers Market is continuously reshaped by an evolving technology landscape, characterized by innovations aimed at enhancing precision, speed, reliability, and integration within modern manufacturing environments. A pivotal aspect of this landscape is the advanced double seaming mechanism itself, which has seen developments in tooling design, cam profiles, and seaming roll materials to achieve tighter tolerances and more consistent, hermetic seals across a wider range of can materials and sizes. Servo motor technology has become standard, replacing traditional mechanical drives, offering superior control over seaming cycles, reducing wear and tear, and enabling quicker changeovers between different product specifications, thereby significantly boosting operational flexibility and efficiency on the production floor.

The integration of Industry 4.0 principles, including the Internet of Things (IoT) and artificial intelligence (AI), is transforming can seaming operations. IoT sensors embedded in machines collect real-time data on parameters such as seaming force, speed, temperature, and vibration, providing invaluable insights into machine performance and potential issues. This data, when analyzed by AI algorithms, enables predictive maintenance, allowing manufacturers to anticipate equipment failures before they occur, reducing unscheduled downtime and optimizing maintenance schedules. Furthermore, AI-powered vision systems are revolutionizing quality control by performing high-speed, non-invasive inspection of every seam, detecting even microscopic defects that would be undetectable by conventional methods, ensuring unparalleled product safety and reducing waste from faulty seals.

Beyond core seaming mechanisms and smart connectivity, the technology landscape includes sophisticated Human Machine Interface (HMI) systems that provide intuitive control and comprehensive diagnostics, empowering operators with real-time feedback and simplifying troubleshooting. Robotic automation is also increasingly being deployed for precise can feeding, handling, and post-seaming inspection, minimizing human intervention, enhancing safety, and further boosting line efficiency. Innovations in lubrication systems, energy recovery technologies, and hygienic design principles further contribute to the market’s technological advancement, making can seamers more sustainable, easier to clean, and capable of meeting the stringent requirements of food, beverage, and pharmaceutical industries, ensuring a highly productive and resilient packaging operation.

Regional Highlights

- North America: This region represents a mature yet highly dynamic market for can seamers, characterized by robust demand for automated and high-speed machinery. The emphasis here is on technological upgrades, integration of Industry 4.0 solutions, and a strong focus on enhancing existing production efficiencies and meeting stringent food safety regulations. Manufacturers are keen on reducing labor costs through advanced automation and adopting sustainable packaging solutions. The dominance of large food and beverage conglomerates drives significant investment in state-of-the-art seaming equipment.

- Europe: The European market is defined by a strong inclination towards innovation, sustainability, and adherence to rigorous environmental and quality standards. There is a high demand for energy-efficient can seamers, machines capable of handling lighter-gauge and recycled materials, and those offering high flexibility for various can sizes and product types to cater to diverse consumer preferences. The region is a hub for advanced packaging machinery manufacturers, fostering continuous technological development and adoption of smart factory concepts in can seaming operations.

- Asia Pacific (APAC): APAC stands out as the fastest-growing market for can seamers, propelled by rapid urbanization, increasing disposable incomes, and the expansion of the food and beverage processing industries, particularly in countries like China, India, and Southeast Asian nations. The region is witnessing significant investments in new production facilities and a surge in demand for both automatic and semi-automatic machines to cater to growing domestic consumption and export markets. Cost-effectiveness, robust construction, and high throughput are key considerations for buyers in this region.

- Latin America: This region presents a developing yet promising market for can seamers, driven by the expansion of local food and beverage industries and increasing consumer demand for packaged goods. Growth is supported by foreign direct investments in manufacturing and processing capabilities. While price sensitivity can be a factor, there is a growing trend towards adopting more automated and reliable seaming solutions to improve product quality and compete in international markets. Modernization of existing production lines is a significant market activity.

- Middle East and Africa (MEA): The MEA region is emerging as a significant market, fueled by population growth, diversifying economies, and investments in food security initiatives and local manufacturing capabilities. Demand for can seamers is steadily rising, particularly in the beverage and dairy sectors. The market is characterized by a mix of new installations and upgrades to existing infrastructure, with a focus on durable and efficient machines that can operate reliably in challenging environmental conditions, while meeting evolving regional food safety standards and expanding distribution networks.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Can Seamers Market.- Angelus Sanitary Can Machine Company

- Canco (Can-Pack)

- FMC Corporation

- Krones AG

- GEA Group Aktiengesellschaft

- SEAMTECH

- Dixie Canner Company

- Shin-I Machinery Works Co., Ltd.

- Busch Maschinenbau GmbH

- COMAC S.r.l.

- PAMA S.r.l.

- Belvac Production Machinery Inc.

- Ferrum AG

- FBR ELPO S.p.A.

- Pneumatic Scale Angelus (Barry-Wehmiller)

- SOLTEC System

- JBT Corporation

- Zacmi S.p.A.

- CFT Group

- Wild Goose Filling

Frequently Asked Questions

Analyze common user questions about the Can Seamers market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is a can seamer and how does it work?

A can seamer is a specialized machine used in the packaging industry to create an airtight, hermetic seal between a can body and its lid. It operates by performing a double seaming process, which precisely interlocks the curled edge of the lid with the flanged edge of the can body in two distinct operations. The first operation forms a loose hook, while the second operation irons this hook into a tight, secure seam, essential for preserving product integrity and extending shelf-life by preventing contamination and leakage.

What are the primary applications of can seamers?

Can seamers are predominantly used in the food and beverage industry for packaging a wide variety of products, including canned fruits, vegetables, meats, seafood, carbonated soft drinks, beer, and juices. Beyond consumables, they also play a crucial role in pharmaceutical packaging for sterile medical supplies and in the chemical industry for sealing containers of paints, aerosols, and various industrial liquids, ensuring product safety, preservation, and compliance with packaging standards across diverse sectors.

What are the key factors driving the growth of the Can Seamers Market?

Key drivers include the escalating global demand for convenience food and beverages, an increasing emphasis on automation in packaging lines to boost efficiency and reduce labor costs, and continuous technological advancements in seaming precision and speed. Additionally, stringent food safety regulations, the need for extended product shelf-life, and growing consumer preference for sustainably packaged and recyclable materials like aluminum and steel cans significantly contribute to market expansion and innovation in can seamer technology.

How is AI impacting the efficiency and quality control of can seamers?

AI is profoundly impacting can seamers by enhancing both efficiency and quality control. AI-powered vision systems enable real-time, high-speed detection of microscopic defects in can seams, significantly improving product safety and reducing waste from faulty seals. Furthermore, AI algorithms facilitate predictive maintenance by analyzing machine data to anticipate equipment failures, thereby minimizing unscheduled downtime, optimizing operational schedules, and ensuring consistent, high-quality production without manual intervention.

What are the main types of can seamers available in the market?

The Can Seamers Market primarily offers three types of machines: Automatic, Semi-Automatic, and Manual. Automatic can seamers are designed for high-volume, continuous production lines, offering maximum speed and integration capabilities. Semi-automatic machines provide a balance of automation and manual control, suitable for medium-volume production or specialized runs. Manual can seamers are typically used for very low-volume applications, artisanal products, or research purposes, requiring significant operator involvement but offering cost-effectiveness for niche needs.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Can Seamers Market Statistics 2025 Analysis By Application (Canned Food, Canned Beverage), By Type (Less than 300 CPM, 300-1000 CPM, More than 1000 CPM), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Can Seamers Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Round Can Seamer, Irregular (Non- round) Can Seamers), By Application (Canned meat, Canned fish, Canned food, Other products), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager