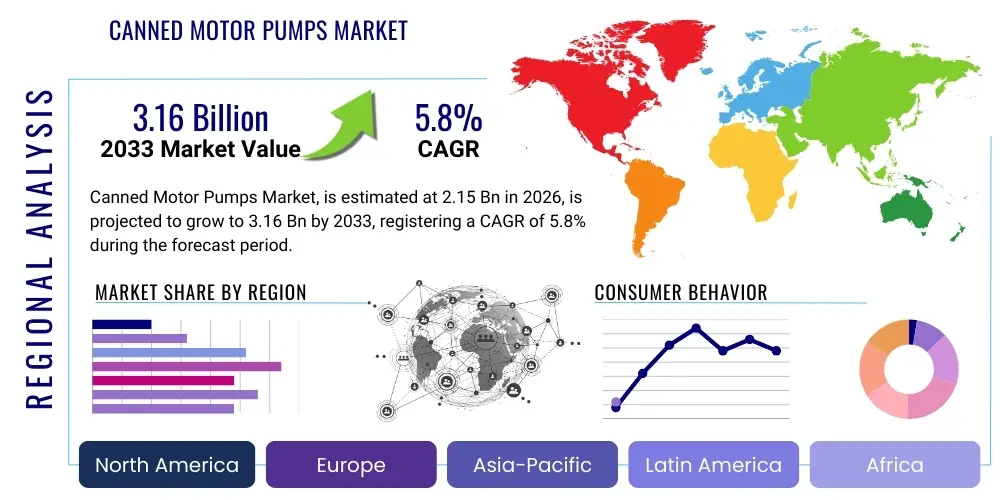

Canned Motor Pumps Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440542 | Date : Jan, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Canned Motor Pumps Market Size

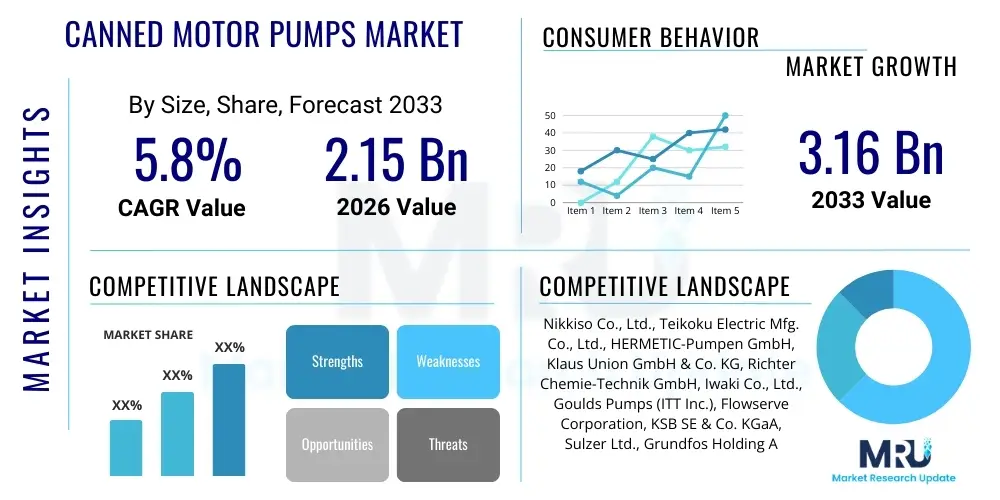

The Canned Motor Pumps Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 2.15 Billion in 2026 and is projected to reach USD 3.16 Billion by the end of the forecast period in 2033.

Canned Motor Pumps Market introduction

Canned motor pumps represent a specialized class of centrifugal pumps where the motor and pump are integrated into a single, hermetically sealed unit, eliminating the need for mechanical seals. This unique design prevents leakage of hazardous, toxic, volatile, or precious fluids, making them indispensable in applications demanding zero emissions and absolute containment. Their major applications span across the chemical and petrochemical industries, oil and gas, refrigeration, nuclear power plants, and pharmaceutical manufacturing, where the safe and reliable transfer of critical fluids is paramount. The inherent benefits of canned motor pumps include enhanced safety due to leak-free operation, reduced maintenance requirements, quiet operation, and a compact footprint. Key driving factors for their adoption include stringent environmental regulations promoting emission control, increasing demand for safer handling of aggressive and high-value fluids, and the expansion of industries requiring high operational reliability and minimal downtime for critical processes.

Canned Motor Pumps Market Executive Summary

The global Canned Motor Pumps Market is characterized by robust business trends driven by industrial safety mandates and environmental compliance. Companies are investing in R&D to enhance pump efficiency, expand material compatibility, and integrate smart monitoring capabilities. Regionally, Asia Pacific continues its dominance due to rapid industrialization, particularly in chemical and petrochemical sectors in China and India, while North America and Europe demonstrate steady growth fueled by technological advancements and the upgrading of existing infrastructure. Segment-wise, the chemical and petrochemical industries remain the largest application area, demanding pumps capable of handling corrosive and high-temperature media. There is also a discernible trend towards high-pressure and high-temperature variants, reflecting the evolving requirements of modern industrial processes, alongside a growing emphasis on energy efficiency and predictive maintenance solutions to optimize operational costs and enhance asset longevity across various end-user industries.

AI Impact Analysis on Canned Motor Pumps Market

Users frequently inquire about how artificial intelligence (AI) can enhance the operational efficiency, predictive maintenance capabilities, and overall safety of canned motor pumps. Common questions revolve around AI's role in real-time monitoring, anomaly detection, optimization of pump performance, and integration with broader smart factory initiatives. There's a strong interest in understanding how AI algorithms can analyze vibration data, temperature fluctuations, and flow rates to anticipate potential failures before they occur, thereby reducing unplanned downtime and maintenance costs. Users also express curiosity regarding AI's ability to optimize energy consumption and automate pump control parameters for specific process conditions, ultimately leading to greater reliability and a prolonged operational lifespan of these critical assets. The core expectation is that AI will transform canned motor pump management from reactive to proactive, ensuring safer and more efficient industrial operations.

- AI-driven predictive maintenance for early fault detection based on sensor data analysis.

- Optimization of pump operational parameters in real-time for energy efficiency and performance.

- Enhanced anomaly detection and diagnostics through machine learning algorithms.

- Integration with industrial IoT platforms for remote monitoring and control.

- Improved safety protocols through AI-powered risk assessment and mitigation strategies.

- Automated performance reporting and lifecycle management recommendations.

- Simulation and digital twinning for design optimization and operational planning.

DRO & Impact Forces Of Canned Motor Pumps Market

The Canned Motor Pumps Market is primarily driven by the imperative for leak-free fluid transfer in hazardous environments, stringent environmental and safety regulations, and the expansion of industries such as chemical, petrochemical, and nuclear power. Restraints include the high initial capital investment and the specialized maintenance expertise required, coupled with limited repairability compared to conventional pumps. Opportunities arise from technological advancements leading to more efficient and durable pump designs, increasing adoption in niche applications like LNG and renewables, and the growing demand for energy-efficient pumping solutions. These forces collectively shape market dynamics, influencing investment decisions, product development, and competitive strategies within the industry.

One of the primary drivers propelling the canned motor pumps market is the escalating global focus on environmental protection and industrial safety. Regulatory bodies worldwide are implementing stricter emission control standards and occupational safety guidelines, particularly for industries handling volatile, toxic, or corrosive substances. Canned motor pumps, with their hermetically sealed design, offer a zero-leakage solution, inherently preventing fugitive emissions and safeguarding personnel from exposure to hazardous fluids. This intrinsic safety feature makes them a preferred choice over conventional pumps with mechanical seals, which are prone to leakage over time, necessitating costly maintenance and potentially leading to environmental contamination or safety incidents. As industries continue to prioritize operational integrity and compliance, the demand for inherently safer pumping technologies like canned motor pumps is expected to surge.

Conversely, significant restraints hinder the broader adoption of canned motor pumps, primarily their higher initial acquisition cost and specialized maintenance requirements. The integrated motor and pump design, while offering advantages in terms of leakage prevention, also means that the entire unit often needs specialized servicing or replacement even for minor issues, unlike conventional pumps where seals or bearings can be replaced independently. This translates into potentially higher total cost of ownership for some applications, especially for businesses operating with tight capital expenditure budgets. Furthermore, the limited availability of specialized technicians and repair facilities for canned motor pumps in certain regions poses a logistical challenge, impacting operational readiness and increasing downtime during maintenance cycles. Addressing these cost and serviceability concerns through modular designs or enhanced diagnostic tools remains a critical factor for market expansion.

Despite these restraints, the market is poised for significant opportunities driven by technological innovations and expanding application horizons. Advances in material science are enabling the development of canned motor pumps capable of handling even more aggressive fluids at higher temperatures and pressures, thereby opening up new applications in specialized chemical processing and high-performance manufacturing. Furthermore, the growing global investment in renewable energy projects, such as concentrated solar power and advanced geothermal systems, which require reliable heat transfer fluids, presents a fertile ground for canned motor pump deployment. The integration of smart monitoring technologies, including IoT sensors and AI-driven diagnostics, is also enhancing their appeal by offering predictive maintenance capabilities, reducing operational risks, and improving overall system efficiency. These innovations are critical for unlocking new market segments and reinforcing the value proposition of canned motor pumps in a rapidly evolving industrial landscape.

- Drivers:

- Stringent environmental regulations demanding zero-emission pumping.

- Increased focus on industrial safety for hazardous and toxic fluid handling.

- Growing demand from chemical, petrochemical, and nuclear power industries.

- Need for high reliability and low maintenance in critical applications.

- Technological advancements improving pump efficiency and material compatibility.

- Restraints:

- High initial capital investment compared to conventional pumps.

- Specialized maintenance and limited repairability due to integrated design.

- Complexity in diagnostics and repair requiring expert technicians.

- Relatively lower energy efficiency in certain configurations compared to some conventional pumps.

- Opportunities:

- Expansion into niche applications like LNG, supercritical fluids, and renewable energy.

- Development of smart, IoT-enabled canned motor pumps for predictive maintenance.

- Advancements in materials science allowing handling of more aggressive and extreme conditions.

- Increasing demand for compact and quiet pumping solutions in space-constrained environments.

- Retrofitting older facilities with advanced, leak-free pumping solutions.

Segmentation Analysis

The Canned Motor Pumps Market is comprehensively segmented by various parameters to provide a detailed understanding of its dynamics and growth prospects. Key segmentation criteria include pump type, the materials used in construction, the specific applications they serve, and the end-user industries that adopt them. This granular analysis helps in identifying high-growth areas, understanding customer preferences, and tailoring product development and marketing strategies. The diverse operational requirements across different industries necessitate a range of specialized canned motor pump configurations, from standard models for general chemical transfer to highly specialized units designed for extreme temperatures, pressures, or abrasive slurries, each catering to unique industrial demands and regulatory compliance.

- By Type:

- Standard Canned Motor Pumps

- High Temperature/Pressure Canned Motor Pumps

- Submersible Canned Motor Pumps

- Slurry Canned Motor Pumps

- Cryogenic Canned Motor Pumps

- By Material:

- Stainless Steel Canned Motor Pumps

- Cast Iron Canned Motor Pumps

- Alloy Steel Canned Motor Pumps

- Non-Metallic Lined Canned Motor Pumps

- Special Alloys (e.g., Hastelloy, Monel)

- By Application:

- Chemical & Petrochemical Processing

- Oil & Gas (upstream, midstream, downstream)

- Refrigeration & HVAC Systems

- Nuclear Power Plants

- Pharmaceutical & Biotechnology

- Food & Beverage Processing

- Water and Wastewater Treatment

- Renewable Energy (e.g., Concentrated Solar Power)

- General Industrial Transfer

- By End-User Industry:

- Chemical Manufacturing

- Petrochemical Industry

- Oil & Gas Refineries

- Power Generation (Thermal, Nuclear)

- Pharmaceutical Sector

- HVAC (Industrial & Commercial)

- Food & Beverage Production

- Water Utilities

- Semiconductor Industry

Value Chain Analysis For Canned Motor Pumps Market

The value chain for the Canned Motor Pumps Market encompasses several critical stages, starting from raw material procurement and extending through manufacturing, assembly, distribution, and post-sales services. Upstream activities involve sourcing specialized materials such as high-grade stainless steel, exotic alloys for corrosive media, and advanced electrical components. Midstream activities focus on precision engineering, machining, motor winding, and the assembly of the integrated pump-motor unit, often involving complex manufacturing processes to ensure hermetic sealing and operational integrity. Downstream activities are crucial for market penetration, including establishing robust distribution channels that can cater to diverse industrial requirements, offering direct sales, and collaborating with system integrators. The effectiveness of this value chain is determined by seamless coordination between all stakeholders, ensuring quality, efficiency, and timely delivery of specialized pumping solutions to end-users.

Upstream analysis in the canned motor pumps value chain highlights the importance of reliable suppliers for specialized raw materials and components. Manufacturers heavily rely on high-quality metals, such as various grades of stainless steel (e.g., 304, 316, duplex) and nickel-based alloys (e.g., Hastelloy, Inconel), to construct pump casings, impellers, and motor components that can withstand corrosive, abrasive, or high-temperature fluids. Furthermore, precision electrical components, bearings, and insulation materials are critical for the motor's performance and longevity within the sealed unit. Supplier relationships are strategic, often involving long-term contracts and quality control agreements to ensure consistency and compliance with stringent industrial standards. Disruptions in the supply of these specialized materials can significantly impact production schedules and costs, making supply chain resilience a key competitive advantage for pump manufacturers.

Downstream activities are equally vital, focusing on getting the finished canned motor pumps to the end-user efficiently and with adequate support. Distribution channels typically involve a mix of direct sales teams, authorized distributors, and value-added resellers who provide localized sales, technical support, and after-sales services. Due to the specialized nature and high value of these pumps, direct sales and highly trained distributors are often preferred, especially for large industrial projects where custom solutions and extensive technical consultation are required. The indirect channel, through system integrators and engineering procurement construction (EPC) firms, also plays a significant role, as canned motor pumps are often part of larger process systems. Effective post-sales support, including installation assistance, commissioning, maintenance services, and spare parts availability, forms a crucial part of the value proposition, ensuring customer satisfaction and long-term operational success for industrial clients.

- Upstream Analysis:

- Sourcing of high-grade stainless steel, exotic alloys, and specialized non-metallic materials.

- Procurement of precision electrical components, insulation materials, and bearings.

- Reliance on specialized foundries and machining partners.

- Midstream (Manufacturing & Assembly):

- Precision machining and fabrication of pump components.

- Motor winding and electrical assembly within the hermetic casing.

- Integrated pump-motor unit assembly and sealing.

- Rigorous testing and quality control for leak-free operation and performance.

- Compliance with international standards (e.g., API, ISO).

- Downstream (Distribution & Sales):

- Direct sales channels to large industrial clients and OEMs.

- Network of authorized distributors and value-added resellers.

- Collaboration with Engineering, Procurement, and Construction (EPC) firms.

- E-commerce platforms for spare parts and standard models (emerging trend).

- Post-Sales Services:

- Installation and commissioning support.

- Maintenance, repair, and overhaul (MRO) services.

- Availability of genuine spare parts.

- Technical support and training.

- Warranty and extended service agreements.

Canned Motor Pumps Market Potential Customers

The potential customers for canned motor pumps are predominantly industrial entities operating in sectors where the safe, reliable, and emission-free transfer of fluids is critical. These end-users are typically involved in processes that handle hazardous, toxic, volatile, high-temperature, or high-pressure liquids, where any leakage could pose significant safety risks, environmental damage, or economic losses due to product contamination or material waste. Therefore, industries with stringent regulatory compliance requirements and a high emphasis on operational integrity form the core customer base. The decision-making units within these organizations often include process engineers, plant managers, safety officers, and procurement specialists who prioritize long-term reliability, low maintenance, and environmental performance over initial acquisition cost.

The chemical and petrochemical industries represent a cornerstone of the canned motor pump market's potential customer base. Within these sectors, processes often involve the transfer of highly corrosive acids, flammable solvents, or toxic intermediates that demand absolute containment. Refineries, chemical plants, and specialized processing units rely on canned motor pumps for applications such as catalyst circulation, chemical injection, and handling of liquid gases, where mechanical seals would be a continuous point of failure and a source of potential leaks. The cost associated with environmental fines, clean-up operations, and production downtime due to pump failures in these high-stakes environments makes the leak-proof and robust design of canned motor pumps an invaluable investment, providing a strong incentive for their adoption and continuous upgrading.

Beyond chemicals and petrochemicals, other significant potential customers include nuclear power generation facilities, where absolute containment of radioactive fluids is non-negotiable for safety and regulatory reasons. Refrigeration and HVAC industries also increasingly utilize canned motor pumps for handling refrigerants like ammonia and various hydrofluorocarbons, seeking to minimize leaks and improve energy efficiency in large-scale cooling systems. Furthermore, the pharmaceutical and biotechnology sectors are emerging as key potential customers, as they require sterile and contaminant-free fluid transfer for manufacturing active pharmaceutical ingredients and sensitive biological products. The ability of canned motor pumps to provide a clean, seal-less, and reliable pumping solution aligns perfectly with the stringent quality and safety standards mandated in these specialized industrial environments.

- Chemical Manufacturing Plants (for acids, bases, solvents, polymers)

- Petrochemical Refineries (for crude oil, naphtha, various hydrocarbons, liquefied gases)

- Oil & Gas Industry (offshore platforms, onshore processing, gas liquefaction plants)

- Nuclear Power Generation Facilities (for primary and secondary cooling circuits, waste treatment)

- Pharmaceutical and Biotechnology Companies (for sterile media transfer, API production)

- Refrigeration and HVAC Systems (for ammonia, CO2, and other refrigerants)

- Semiconductor Manufacturing (for ultra-pure water and specialty chemicals)

- Food & Beverage Industry (for hygienic transfer of sensitive liquids in specific applications)

- Specialty Gases Production (for handling liquefied gases)

- Water and Wastewater Treatment Plants (for specific chemical dosing where zero leakage is critical)

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 2.15 Billion |

| Market Forecast in 2033 | USD 3.16 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Nikkiso Co., Ltd., Teikoku Electric Mfg. Co., Ltd., HERMETIC-Pumpen GmbH, Klaus Union GmbH & Co. KG, Richter Chemie-Technik GmbH, Iwaki Co., Ltd., Goulds Pumps (ITT Inc.), Flowserve Corporation, KSB SE & Co. KGaA, Sulzer Ltd., Grundfos Holding A/S, Wilo SE, Ebara Corporation, Sundyne, Lewa GmbH |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Canned Motor Pumps Market Key Technology Landscape

The technological landscape of the Canned Motor Pumps Market is continuously evolving, driven by the need for enhanced performance, greater energy efficiency, and extended operational lifespans in demanding industrial environments. Key technological advancements center around optimizing motor efficiency, improving hydraulic design, developing advanced materials for wetted parts, and integrating smart monitoring and control systems. Innovations in computational fluid dynamics (CFD) and finite element analysis (FEA) are enabling manufacturers to design pumps with superior hydraulic efficiency and mechanical integrity, capable of handling a wider range of fluid properties and operating conditions more effectively. The focus is also shifting towards creating pumps that are more modular in design, facilitating easier maintenance and reducing the total cost of ownership over their lifecycle.

Material science plays a pivotal role in shaping the capabilities of canned motor pumps, especially for applications involving corrosive, abrasive, or extremely hot fluids. Manufacturers are increasingly utilizing advanced alloys such as Hastelloy, Monel, Inconel, and various grades of duplex and super duplex stainless steels to enhance the chemical resistance and mechanical strength of pump components like impellers, casings, and shafts. Furthermore, the development of non-metallic liners and coatings, such as PFA and PVDF, allows canned motor pumps to handle highly aggressive chemicals that would typically corrode metallic parts. These material innovations are crucial for expanding the application scope of canned motor pumps into new chemical processes and industries, ensuring long-term reliability and reducing the frequency of component replacement in harsh operating environments.

The integration of smart technologies, including sensors, Industrial Internet of Things (IIoT), and advanced control systems, represents another significant aspect of the canned motor pumps' technological landscape. These pumps are increasingly equipped with embedded sensors that monitor critical parameters such as temperature, vibration, pressure, and motor current in real-time. This data is then transmitted to central control systems or cloud-based platforms, enabling sophisticated diagnostics, predictive maintenance, and performance optimization through analytics and machine learning algorithms. The ability to remotely monitor pump health and anticipate potential failures before they lead to downtime not only enhances operational reliability and safety but also significantly reduces maintenance costs and extends the useful life of the equipment, aligning with the growing demand for smart, connected industrial assets.

- Advanced Material Science: Use of corrosion-resistant alloys (Hastelloy, Monel, Duplex Stainless Steel) and non-metallic linings (PFA, PVDF) for wetted parts.

- Computational Fluid Dynamics (CFD): For optimizing hydraulic design, improving efficiency, and reducing cavitation.

- Finite Element Analysis (FEA): For structural integrity, thermal management, and stress analysis of hermetic casings.

- Magnetic Bearings & Hydrodynamic Bearings: Enhancing bearing life, reducing friction, and improving pump stability.

- Variable Speed Drives (VSDs): For precise flow control, energy efficiency, and operational flexibility.

- Smart Sensors & IIoT Integration: Real-time monitoring of vibration, temperature, pressure, and current for predictive maintenance and diagnostics.

- Modular Design: Facilitating easier assembly, disassembly, and maintenance procedures.

- AI & Machine Learning for Predictive Analytics: Analyzing operational data to forecast failures and optimize performance.

- Noise & Vibration Reduction Technologies: Improving operational environment and extending component life.

- Energy-Efficient Motors: Incorporating high-efficiency motor designs to reduce power consumption.

Regional Highlights

- North America: This region exhibits mature industrial infrastructure with a strong emphasis on safety and environmental regulations, particularly in the chemical, petrochemical, and oil & gas sectors. The demand for canned motor pumps is driven by the need to upgrade existing facilities with leak-proof technology and comply with stringent emission standards. Innovation in smart pumping solutions and robust after-sales service networks are key market differentiators in the United States and Canada, reflecting a consistent demand for high-reliability equipment.

- Europe: European countries, especially Germany, France, and the UK, are characterized by highly developed chemical, pharmaceutical, and nuclear industries. Strict environmental legislation and a focus on energy efficiency drive the adoption of high-performance canned motor pumps. The region is a hub for technological innovation, with several key manufacturers investing in R&D to develop advanced materials and integrated smart features, addressing the specific demands of specialized industrial processes and promoting sustainable operations.

- Asia Pacific (APAC): APAC is the fastest-growing market for canned motor pumps, primarily fueled by rapid industrialization and significant investments in chemical, petrochemical, and power generation sectors across China, India, Japan, and South Korea. The region benefits from expanding manufacturing capacities and increasing awareness regarding industrial safety and environmental compliance. While price sensitivity can be a factor, the long-term benefits of reduced maintenance and enhanced safety are increasingly recognized, leading to robust market expansion and local manufacturing initiatives.

- Latin America: The market in Latin America is witnessing steady growth, particularly in countries like Brazil and Mexico, driven by investments in the oil & gas and chemical industries. The region presents opportunities for canned motor pump manufacturers as industries seek to modernize their infrastructure and improve operational safety and efficiency. Economic stability and governmental support for industrial development play crucial roles in market growth, although market penetration can be influenced by local economic conditions and import tariffs.

- Middle East and Africa (MEA): The MEA region is a significant market due to its extensive oil & gas and petrochemical industries, especially in Saudi Arabia, UAE, and Qatar. The demand for canned motor pumps is primarily driven by the need for reliable and safe fluid handling in volatile environments, alongside investments in new refinery projects and capacity expansions. While the market is highly influenced by global oil prices, the imperative for operational safety and maintenance cost reduction ensures a consistent demand for specialized leak-proof pumping solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Canned Motor Pumps Market.- Nikkiso Co., Ltd.

- Teikoku Electric Mfg. Co., Ltd.

- HERMETIC-Pumpen GmbH

- Klaus Union GmbH & Co. KG

- Richter Chemie-Technik GmbH

- Iwaki Co., Ltd.

- Goulds Pumps (ITT Inc.)

- Flowserve Corporation

- KSB SE & Co. KGaA

- Sulzer Ltd.

- Grundfos Holding A/S

- Wilo SE

- Ebara Corporation

- Sundyne

- Lewa GmbH

Frequently Asked Questions

What are the primary benefits of using canned motor pumps over conventional pumps?

Canned motor pumps offer significant advantages including absolute leak-free operation, ensuring zero emissions and enhanced safety for hazardous fluids. They also provide lower maintenance requirements due to the absence of mechanical seals, quieter operation, and a compact design, making them ideal for critical industrial applications.

Which industries are the major end-users of canned motor pumps?

The primary end-user industries include chemical and petrochemical processing, oil & gas (refineries and offshore platforms), nuclear power generation, pharmaceutical manufacturing, and specialized refrigeration/HVAC systems, where fluid containment and reliability are paramount.

What challenges does the canned motor pumps market face?

Key challenges include higher initial capital investment compared to traditional pumps, specialized knowledge required for maintenance and repair due to their integrated design, and the need for highly specific spare parts which can affect repair times and overall operational costs.

How is AI impacting the Canned Motor Pumps Market?

AI is transforming the market by enabling advanced predictive maintenance through real-time sensor data analysis, optimizing pump performance and energy efficiency, and enhancing anomaly detection. This leads to reduced downtime, extended pump life, and more proactive operational management.

What are the key technological advancements driving the market?

Technological advancements include the use of advanced corrosion-resistant materials, sophisticated hydraulic designs leveraging CFD and FEA, integration of smart sensors and IIoT for remote monitoring, and variable speed drives for improved energy efficiency and precise control.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager