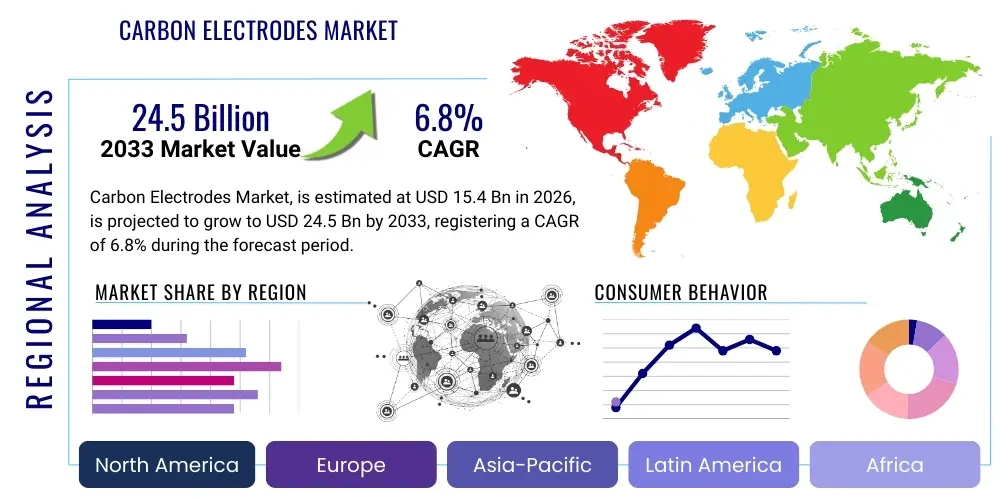

Carbon Electrodes Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435149 | Date : Dec, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Carbon Electrodes Market Size

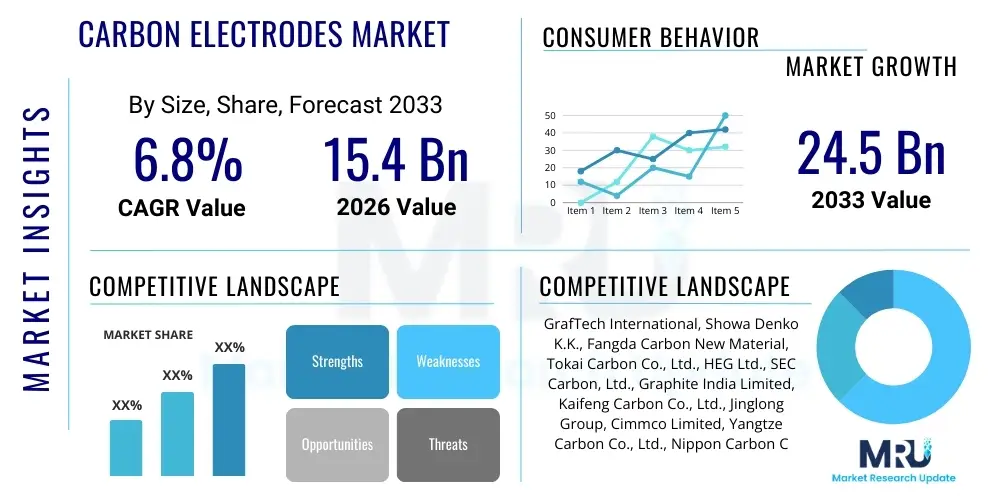

The Carbon Electrodes Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 15.4 Billion in 2026 and is projected to reach USD 24.5 Billion by the end of the forecast period in 2033. This robust expansion is primarily driven by the escalating demand for steel production, particularly through Electric Arc Furnaces (EAFs), which are heavily reliant on high-quality graphite electrodes. Furthermore, the persistent growth in global infrastructure development and the increasing adoption of lightweight materials in the automotive and aerospace sectors contribute significantly to the underlying market momentum, positioning carbon electrodes as an indispensable component in high-temperature industrial processes.

Carbon Electrodes Market introduction

The Carbon Electrodes Market encompasses specialized conductive materials used predominantly in metallurgical processes, chemical manufacturing, and the production of advanced materials. These electrodes, crafted primarily from petroleum coke, coal tar pitch, and needle coke, exhibit exceptional thermal stability, high electrical conductivity, and chemical resistance, making them essential consumables in environments subjected to extreme heat and corrosive agents. The fundamental product categories include graphite electrodes, which command high prices due to their superior purity and performance in EAFs, and amorphous or baked carbon electrodes, commonly utilized in submerged arc furnaces and aluminum reduction cells. The performance of these electrodes directly influences the operational efficiency, energy consumption, and overall yield of the smelting and refining processes they support.

Major applications of carbon electrodes span several heavy industries. The steel industry represents the largest consumer, where graphite electrodes are crucial for melting scrap steel in Electric Arc Furnaces, a process rapidly gaining traction globally due to its lower environmental footprint compared to traditional blast furnaces. Additionally, these materials are vital in the primary aluminum production sector (Hall-Héroult process), where baked carbon anodes are consumed continuously. Beyond metallurgy, carbon electrodes find significant roles in producing ferroalloys, silicon metal, and various industrial chemicals, demonstrating their versatility and foundational importance to the global manufacturing ecosystem. The growing focus on high-purity metal production for high-tech applications is further solidifying the market position of advanced carbon electrode variants.

Key driving factors accelerating market expansion include the global shift towards EAF steel production, supported by favorable regulatory policies emphasizing recycling and reduced carbon emissions. Moreover, persistent urbanization and infrastructure development, particularly in Asia Pacific economies like China and India, necessitate vast quantities of steel, directly fueling electrode demand. The inherent benefits offered by carbon electrodes—such as durability, excellent thermal shock resistance, and efficient energy transfer—ensure their continued preference over alternative materials. Continuous advancements in electrode manufacturing technology, aimed at improving density and reducing consumption rates, also contribute to market vitality by offering enhanced operational lifetimes and cost-effectiveness to end-users.

Carbon Electrodes Market Executive Summary

The Carbon Electrodes Market is poised for substantial growth, characterized by significant shifts in business dynamics, pronounced regional diversification, and evolving segment consumption patterns. Business trends indicate a heightened focus on vertical integration among key players, securing consistent access to high-quality raw materials such as needle coke, which is critical for producing ultra-high power (UHP) graphite electrodes. Furthermore, strategic alliances and long-term supply contracts between electrode manufacturers and major steel producers are becoming common strategies to mitigate supply chain volatility and stabilize pricing structures. Technological innovation centers around enhancing electrode longevity and optimizing manufacturing processes to achieve higher quality while minimizing energy inputs, addressing both cost pressures and environmental sustainability concerns across the industrial value chain.

Regional trends unequivocally highlight Asia Pacific (APAC) as the dominant market, driven by massive domestic steel production capacity in China and rapid industrialization across Southeast Asia. While APAC accounts for the largest share in terms of volume and value, North America and Europe are exhibiting accelerated growth rates, primarily fueled by stringent environmental regulations prompting the rapid retirement of older basic oxygen furnaces (BOFs) in favor of EAFs. This structural transition is creating sustained high demand for UHP graphite electrodes in these established markets. Simultaneously, the Middle East and Africa (MEA) are emerging as high-potential regions, leveraging abundant energy resources to establish competitive primary aluminum and steel production facilities, thereby increasing regional consumption of both carbon anodes and cathodes.

Segment trends underscore the supremacy of graphite electrodes, specifically the UHP grade, which remains the fastest-growing segment owing to the proliferation of EAF technology globally. Within applications, the steel industry maintains its position as the primary end-user, though the aluminum industry segment presents substantial, steady demand for prebaked anodes and cathodes. The market is also observing increasing specialization within product types, such as composite electrodes designed for improved performance in specific furnace conditions, and the growing adoption of specialized carbon blocks in chemical and metallurgical processes requiring superior corrosion resistance. This fragmentation by end-use application allows manufacturers to tailor product specifications, driving profitability within specific niches.

AI Impact Analysis on Carbon Electrodes Market

Users frequently inquire about how Artificial Intelligence (AI) can optimize the notoriously complex and energy-intensive manufacturing process of carbon electrodes, particularly concerning raw material variability and quality control. Key concerns revolve around the potential for AI to predict defects during baking and graphitization, minimize costly energy consumption in UHP electrode production, and enhance supply chain resilience by forecasting needle coke availability and pricing fluctuations. Stakeholders seek confirmation on AI's capability to implement predictive maintenance for extrusion presses and graphitization furnaces, ensuring maximum operational uptime. The overall expectation is that AI will act as a pivotal technology, transitioning the industry towards a more efficient, higher-yield, and data-driven operational model, thereby stabilizing output quality and reducing manufacturing overheads, ultimately impacting the final cost structure of these essential industrial consumables.

- AI-powered predictive maintenance optimizes furnace scheduling and minimizes unplanned downtime in energy-intensive graphitization processes.

- Machine learning algorithms analyze raw material batches (coke and pitch quality) to predict optimal mixing ratios, ensuring consistent electrode density and purity.

- Real-time quality control systems use computer vision and sensor data during extrusion and baking to detect micro-defects, reducing reject rates significantly.

- AI enhances supply chain management by forecasting demand variability and optimizing inventory levels for critical precursors like needle coke.

- Energy consumption models driven by neural networks adjust furnace temperatures and power input dynamically, leading to substantial energy savings in the graphitization stage.

DRO & Impact Forces Of Carbon Electrodes Market

The Carbon Electrodes Market dynamics are influenced by a complex interplay of strong demand drivers, operational constraints, clear growth opportunities, and impactful external forces. The primary driver is the accelerating global adoption of Electric Arc Furnaces (EAFs) in steelmaking, replacing traditional, more polluting methods, thereby creating a sustained and high-growth requirement for Ultra-High Power (UHP) graphite electrodes. This demand is further amplified by continuous global urbanization and extensive government investments in infrastructure, particularly in developing economies, which require vast quantities of steel and aluminum. However, the market faces significant restraints, chiefly the volatile and often high cost of key raw materials, particularly high-grade needle coke, which is highly dependent on the petrochemical industry cycle. Furthermore, stringent environmental regulations regarding emissions and waste disposal during the baking and graphitization processes impose substantial compliance costs on manufacturers, limiting capacity expansion for smaller players.

Opportunities for market players are abundant, focusing primarily on sustainable solutions and advanced material science. The green steel movement, aiming for decarbonized metal production, presents a unique chance for innovation in low-consumption electrodes and alternative raw material sourcing. The expanding electric vehicle (EV) battery market, which requires high-purity carbon materials, also represents a burgeoning opportunity for specialized carbon product manufacturers to diversify their portfolios. The impact forces shaping the market include technological advancements aimed at improving electrode performance parameters, such as reducing oxidation rates and enhancing mechanical strength. Economic stability in major industrialized regions directly influences steel and aluminum production cycles, while geopolitical tensions can disrupt the supply of critical raw materials, leading to sudden price spikes and supply chain instability. The shift in global manufacturing dominance towards Asia Pacific countries continuously realigns the competitive landscape and trade flows of finished electrode products.

The combined effect of these forces suggests a market trajectory characterized by moderate to high growth, underscored by necessary technological adaptations. Manufacturers are heavily investing in Research and Development to optimize material consumption and improve energy efficiency, addressing the twin challenges of raw material costs and environmental compliance. The necessity for reliable, high-performing electrodes in mission-critical processes ensures inelastic demand, maintaining the pricing power of specialized manufacturers. The market's future vitality relies significantly on innovations that stabilize the raw material supply chain and develop electrodes compatible with emerging sustainable metallurgical technologies, thus ensuring long-term profitability amidst increasingly complex operational environments.

Segmentation Analysis

The Carbon Electrodes Market is rigorously segmented based on product type, grade, application, and geography, reflecting the diverse requirements of end-user industries and the variations in manufacturing complexity. The segmentation by product type typically differentiates between graphite electrodes and carbon electrodes (including amorphous and baked carbon blocks), each serving distinct functions and temperature requirements. Grade segmentation, particularly for graphite electrodes, distinguishes between Regular Power (RP), High Power (HP), and Ultra-High Power (UHP) categories, with UHP electrodes commanding the highest prices and exhibiting the fastest growth due to their essential role in modern, high-efficiency Electric Arc Furnaces. Analyzing these segments provides strategic insights into investment priorities, indicating where technological advancements and capacity expansion are most concentrated.

- By Product Type:

- Graphite Electrodes

- Ultra-High Power (UHP)

- High Power (HP)

- Regular Power (RP)

- Carbon Electrodes

- Amorphous Carbon Electrodes

- Prebaked Anodes (PBA)

- Cathodes (Carbon Blocks)

- By Application:

- Steel Industry (Electric Arc Furnaces, Ladle Furnaces)

- Aluminum Industry (Smelting and Refining)

- Ferroalloy Production

- Silicon Metal Production

- Chemical and Industrial Processes

- Other Metallurgical Applications

- By Region:

- North America (US, Canada, Mexico)

- Europe (Germany, UK, France, Italy, Rest of Europe)

- Asia Pacific (China, India, Japan, South Korea, Rest of APAC)

- Latin America (Brazil, Argentina, Rest of LAMEA)

- Middle East and Africa (GCC Countries, South Africa, Rest of MEA)

Value Chain Analysis For Carbon Electrodes Market

The value chain of the Carbon Electrodes Market is highly structured, beginning with the sourcing of specialized raw materials and extending through complex manufacturing processes to final delivery to heavy industrial end-users. The upstream segment is critical, dominated by the supply of high-purity carbon sources, predominantly calcined petroleum coke (CPC), coal tar pitch, and, most importantly for high-end electrodes, needle coke. Fluctuations in the refining and petrochemical industries directly impact the availability and price volatility of these precursors, making stable supply agreements a competitive advantage. Manufacturers often engage in rigorous quality testing and pre-treatment of raw materials to ensure the final product meets stringent performance specifications required for UHP applications, where even minor impurities can compromise electrode integrity under extreme furnace conditions.

The core manufacturing process involves several energy-intensive and technically challenging stages, including mixing, kneading, forming (extrusion or molding), baking (carbonization), and graphitization, the latter requiring temperatures exceeding 2,500 degrees Celsius. Downstream analysis focuses on the efficient distribution and consumption of the finished electrodes. Given the bulk and sensitivity of these products (especially the susceptibility of graphite electrodes to thermal shock during handling), specialized logistics and warehousing are essential. Distribution channels are typically a mix of direct sales to large steel and aluminum producers, particularly for high-volume contracts, and indirect sales facilitated by specialized industrial distributors who provide localized inventory, technical support, and smaller lot deliveries to ferroalloy and specialty chemical manufacturers.

The relationship between manufacturers and end-users is often characterized by long-term strategic partnerships, as the electrode is a critical, high-cost consumable impacting furnace uptime and productivity. Direct sales channels enable manufacturers to offer customized dimensions and material specifications tailored to specific furnace geometries and operational cycles, reinforcing customer loyalty. The increasing complexity of modern metallurgical processes necessitates strong technical collaboration throughout the distribution channel, ensuring that the correct electrode grade and handling procedures are implemented. The efficiency of the entire value chain—from stable raw material procurement to optimized manufacturing throughput and reliable just-in-time delivery—is paramount for maintaining market competitiveness and mitigating the impact of fluctuating demand from the cyclic steel industry.

Carbon Electrodes Market Potential Customers

Potential customers for the Carbon Electrodes Market primarily consist of large industrial entities engaged in high-temperature processing and electrochemical reduction, where carbon materials serve as indispensable conductive and structural components. The most significant customer segment is the global steel industry, specifically operators of Electric Arc Furnaces (EAFs) and Ladle Furnaces (LFs). EAF steelmakers require continuous supplies of high-quality Ultra-High Power (UHP) graphite electrodes to sustain intensive melting cycles, making electrode consumption a major operational expenditure. Demand from this sector is driven by scrap steel availability and global infrastructure spending, ensuring persistent, high-volume procurement cycles based on tonnage throughput.

Another major segment encompasses the primary aluminum industry, which relies heavily on prebaked carbon anodes and carbon cathodes for the Hall-Héroult reduction process. These customers, predominantly large-scale smelters, consume anodes continuously as they are oxidized during the electrolysis process. Customer requirements in this segment emphasize consistency, density, and low impurity levels to maximize current efficiency and minimize greenhouse gas emissions. Beyond these two giants, potential customers include producers of various ferroalloys (such as ferrosilicon and ferrochrome), silicon metal manufacturers, and specialized chemical companies requiring carbon components for electrolytic production processes. These diverse customer bases require tailored product specifications, ranging from standard amorphous carbon blocks to specialized high-ppurity graphite rods.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 15.4 Billion |

| Market Forecast in 2033 | USD 24.5 Billion |

| Growth Rate | CAGR 6.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | GrafTech International, Showa Denko K.K., Fangda Carbon New Material, Tokai Carbon Co., Ltd., HEG Ltd., SEC Carbon, Ltd., Graphite India Limited, Kaifeng Carbon Co., Ltd., Jinglong Group, Cimmco Limited, Yangtze Carbon Co., Ltd., Nippon Carbon Co., Ltd., SGL Carbon SE, DTR Corporation, Shaanxi Lige Carbon Co., Ltd., Jilin Carbon Co., Ltd., Resorcinol Global, Mitsubishi Chemical Corporation, Chemence Corporation. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Carbon Electrodes Market Key Technology Landscape

The Carbon Electrodes Market is continuously shaped by technological advancements focused primarily on improving material performance, reducing manufacturing time, and increasing energy efficiency. One of the most critical technological areas is the refinement of graphitization techniques, moving towards optimized Acheson furnace technology and potentially graphitization by induction heating, which promises higher throughput and reduced specific energy consumption compared to older methods. Additionally, sophisticated extrusion and vibration molding processes are being implemented to achieve extremely high densities and low porosity in UHP electrodes, directly enhancing mechanical strength and reducing oxidation rates during intense furnace operations. Manufacturers are leveraging precise control systems, often integrated with AI and sensor technology, to monitor and adjust the pitch binder and coke aggregate mixing ratios in real-time, thereby ensuring homogenous structure and minimal internal stress during baking.

Another pivotal technological development involves surface treatment and coating technologies designed to extend electrode life. Advanced anti-oxidation coatings, often incorporating ceramic or specialized carbon compounds, are applied to the electrode surface to minimize carbon loss in the oxidizing EAF environment, significantly reducing consumption rates per ton of steel produced. Furthermore, there is ongoing research into alternative or synthetic needle coke precursors to mitigate dependence on volatile petroleum coke markets. Innovations in joining technology, such as optimized nipple and socket design, are crucial for UHP electrodes operating under high mechanical and thermal stress, ensuring minimal joint resistance and preventing breakage, which can cause significant operational disruptions and costly downtime in steel mills.

The convergence of material science and digital technology is defining the current landscape. Non-destructive testing methods, including advanced ultrasound and eddy current testing, are increasingly employed to ensure internal integrity and detect hairline cracks before shipment, guaranteeing product reliability under operational extremes. For carbon anodes used in aluminum smelting, technological focus is on optimizing anode paste composition and baking temperature profiles to minimize 'anode effect' occurrences, improve current efficiency, and reduce associated perfluorocarbon (PFC) emissions, aligning with stringent global climate goals. The sustained investment in these high-precision manufacturing and quality control technologies is essential for maintaining a competitive edge, especially in the premium UHP graphite segment.

Regional Highlights

- Asia Pacific (APAC) Dominance: APAC constitutes the largest and fastest-growing market for carbon electrodes, driven overwhelmingly by the colossal steel and aluminum production capacities of China and India. China, being the world's largest steel producer, dictates global demand dynamics for both graphite electrodes (for its increasing EAF base) and carbon anodes (for its primary aluminum smelters). Rapid urbanization, massive infrastructure projects, and robust manufacturing growth across emerging economies like Vietnam and Indonesia ensure sustained high consumption. The regional landscape is characterized by intense competition among large domestic producers who benefit from localized raw material sourcing and scale economies, often resulting in competitive export pricing.

- North America (NA) Structural Shift: The North American market is distinguished by a mature and highly advanced steel sector undergoing a significant transition toward scrap-based production using EAF technology. This structural shift is the primary driver for high demand for UHP graphite electrodes, as EAFs require maximum efficiency and output. Environmental regulations and the strong push towards domestic recycling and reduced reliance on imports further solidify the consumption base. The region emphasizes premium quality and consistent performance, favoring long-term contracts with global leaders who can ensure supply chain reliability and technical support.

- Europe’s Decarbonization Imperative: The European market growth is highly influenced by aggressive climate targets and the Green Deal, necessitating the rapid replacement of blast furnaces with EAFs. This regulatory pressure generates predictable, high demand for high-specification graphite electrodes. Furthermore, Europe is a major hub for specialized metallurgy and chemical processing, driving demand for specific, high-purity carbon blocks and cathodes. The regional market focus is increasingly placed on sustainable manufacturing practices, favoring suppliers demonstrating low-carbon footprint production methods and robust environmental compliance.

- Middle East and Africa (MEA) Expansion: The MEA region is emerging as a significant market due to substantial investments in energy-intensive industries, particularly primary aluminum smelting and steel production, often leveraging abundant, low-cost natural gas resources. Saudi Arabia, UAE, and Qatar are key players in aluminum production, ensuring a steady, long-term requirement for prebaked carbon anodes. The demand is project-driven, tied to large-scale industrialization plans and national economic diversification strategies, offering opportunities for specialized carbon electrode suppliers who can manage complex logistics and provide large contract volumes.

- Latin America (LAMEA) Stability: The LAMEA market, led by Brazil and Mexico, exhibits stable demand linked to domestic automotive production and agricultural infrastructure development, necessitating steady steel output. While growth rates are generally moderate compared to APAC, the reliance on hydroelectric power in regions like Brazil supports EAF steelmaking, ensuring consistent consumption of graphite electrodes. The market often seeks cost-effective solutions but prioritizes durability given potential logistical challenges and maintenance costs.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Carbon Electrodes Market.- GrafTech International

- Showa Denko K.K.

- Fangda Carbon New Material

- Tokai Carbon Co., Ltd.

- HEG Ltd.

- SEC Carbon, Ltd.

- Graphite India Limited

- Kaifeng Carbon Co., Ltd.

- Jinglong Group

- Nippon Carbon Co., Ltd.

- SGL Carbon SE

- DTR Corporation

- China Steel Chemical Corporation

- Lanzhou Carbon Co., Ltd.

- Resorcinol Global

- Mitsubishi Chemical Corporation

- Cimmco Limited

- Yangtze Carbon Co., Ltd.

- Nantong Yangzi Carbon Co., Ltd.

- Jilin Carbon Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Carbon Electrodes market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the demand for Ultra-High Power (UHP) graphite electrodes?

The primary driver is the accelerating global transition towards Electric Arc Furnace (EAF) steel production. EAFs require UHP electrodes for rapid, energy-efficient melting of scrap steel, facilitating higher throughput and operational cost reduction compared to traditional blast furnaces.

How does the volatility of needle coke pricing impact the Carbon Electrodes Market?

Needle coke is a high-purity precursor essential for UHP graphite electrodes. Its price volatility, driven by supply constraints in the petrochemical industry, significantly increases the manufacturing cost for electrodes and leads to unpredictable pricing and reduced profit margins across the value chain.

Which application segment holds the largest share in the Carbon Electrodes Market?

The steel industry remains the dominant application segment, accounting for the largest share. Carbon electrodes, especially graphite variants, are mission-critical consumables for both Electric Arc Furnaces (EAFs) and Ladle Furnaces (LFs) used in steel refining.

What role does the 'Green Steel' movement play in the future of the Carbon Electrodes Market?

The Green Steel movement accelerates the adoption of EAFs, which use scrap or direct reduced iron (DRI), creating substantial demand for electrodes. It also mandates the development of more sustainable electrode manufacturing processes and high-efficiency electrode grades that reduce energy consumption and environmental impact.

How are manufacturers technologically addressing the challenge of electrode consumption rates?

Manufacturers are focusing on advanced technological solutions such as applying anti-oxidation coatings, optimizing electrode density and microstructure through precise extrusion, and improving the design of electrode joints (nipples) to enhance mechanical strength and minimize burn rate during operation.

What are carbon anodes primarily used for, and how often are they consumed?

Carbon anodes are primarily used in the aluminum industry for the Hall-Héroult electrolytic reduction process. They are continuously consumed during the smelting process as they react with oxygen to produce carbon dioxide, requiring constant replacement in aluminum reduction cells.

Why is Asia Pacific considered the most significant geographical market for carbon electrodes?

APAC holds market dominance due to high concentration of heavy industries, particularly in China and India. These countries have immense capacities for both steel production (driving graphite electrode demand) and primary aluminum smelting (driving carbon anode demand), coupled with ongoing massive infrastructure expansion.

How does AI contribute to improving the quality of carbon electrode manufacturing?

AI improves quality by analyzing sensor data in real-time during critical phases like baking and graphitization, allowing for predictive defect detection and optimization of furnace parameters. Machine learning models ensure consistent structural integrity by precisely controlling raw material mixing ratios.

Are carbon electrodes used in the production of specialized chemicals?

Yes, carbon electrodes are vital in various chemical and industrial processes, particularly in the production of caustic soda, chlorine, and other specialized electrolytic products where high electrical conductivity and chemical inertness are prerequisites for the electrode material.

What is the main restraint impacting smaller players in the Carbon Electrodes Market?

Smaller market players face significant restraints primarily due to high capital expenditure required for advanced graphitization furnaces and the difficulty in securing long-term, stable access to high-grade, expensive raw materials, especially needle coke, at competitive prices.

What is the difference between Graphite Electrodes and Amorphous Carbon Electrodes in terms of application?

Graphite Electrodes (UHP/HP) are used in high-heat processes like Electric Arc Furnaces (EAFs) due to their superior conductivity and purity. Amorphous Carbon Electrodes (like prebaked anodes) are generally used in lower-temperature, high-current density applications such as aluminum smelting and ferroalloy production.

How do carbon cathodes function in the aluminum smelting process?

Carbon cathodes form the bottom lining of the electrolytic cell (pot) in aluminum smelting. They serve as the negative electrode, collecting the electrical current, and must possess high resistance to chemical erosion by molten cryolite and mechanical stress for long operational life.

What are the key risks associated with supply chain management in this market?

Key risks include dependency on a limited number of needle coke suppliers globally, geopolitical instability affecting transport routes, and the cyclical nature of the steel industry causing sudden demand spikes or dips that challenge inventory optimization.

How does electrode density relate to performance in an EAF?

Higher density in UHP graphite electrodes correlates directly with enhanced performance. Increased density reduces porosity, leading to greater mechanical strength, lower electrical resistivity, and superior resistance to oxidation, thus extending electrode lifetime and improving furnace efficiency.

Why is environmental compliance a growing concern for carbon electrode manufacturers?

Environmental compliance is crucial due to the energy intensity of the graphitization process and the potential for volatile organic compound (VOC) and particulate emissions during baking. Strict regulations require substantial investment in advanced air filtration and emission reduction technologies, particularly in North America and Europe.

What distinguishes the High Power (HP) grade from the Regular Power (RP) grade of graphite electrodes?

HP electrodes can handle higher current loads and are utilized in more intensive melting operations than RP electrodes. HP manufacturing involves higher quality raw materials (like intermediate-grade needle coke) and more rigorous baking/graphitization to achieve better mechanical and electrical properties necessary for high-throughput furnaces.

Is there an increasing trend towards customized electrode solutions?

Yes, the trend towards customization is strong, particularly for large EAF operators. Manufacturers offer tailored electrode diameters, lengths, and specific nipple thread designs to match unique furnace power ratings, operational requirements, and specific steel grades being produced, maximizing melt efficiency.

How do technological advancements influence the energy efficiency of electrode production?

Advancements, such as optimizing furnace lining materials, implementing computerized control of heating cycles, and potentially utilizing induction graphitization methods, reduce the specific energy consumption per ton of electrode produced. This addresses operational costs and aligns with sustainability goals.

What are the typical distribution channels used for carbon electrodes?

Distribution primarily occurs through direct sales to major integrated steel and aluminum producers under long-term contracts. For smaller customers and specialized markets, indirect channels involving industrial distributors and agents who provide technical support and local inventory management are common.

What strategic actions are key players taking to secure market leadership?

Key players are focusing on vertical integration to secure stable needle coke supply, investing heavily in UHP electrode production capacity expansion, and utilizing intellectual property (IP) protection related to specialized anti-oxidation coatings and joint technologies to maintain a competitive advantage in performance.

What material is primarily used as the binder in carbon electrode manufacturing?

Coal tar pitch is the primary binder material used to agglutinate the coke particles during the mixing and forming stages. The quality and chemical composition of the pitch are crucial as they significantly influence the final density, structure, and carbon yield after baking.

How do global infrastructure projects affect the Carbon Electrodes Market?

Large-scale global infrastructure projects (roads, bridges, rail networks, power grids) directly translate into increased demand for steel and aluminum, thus creating a stable, high baseline demand for both graphite electrodes in steel production and carbon anodes in aluminum smelting.

What is the significance of the graphitization process for electrode performance?

Graphitization is the heat treatment process where amorphous carbon is converted into highly crystalline graphite at temperatures up to 3000°C. This process dramatically increases electrical conductivity and thermal resistance, which are critical performance metrics for high-power furnace operations.

Is the use of carbon electrodes expected to decline with the adoption of greener technologies?

No, the demand is expected to grow. While greener technologies are changing metallurgy, the shift is towards EAFs (which rely heavily on graphite electrodes) over traditional methods. Furthermore, new green processes like H-DRI steel still require high-purity carbon sources, ensuring sustained market relevance.

Which regional market shows the fastest percentage growth rate for carbon electrodes?

While Asia Pacific holds the largest market share, markets in North America and Europe are showing accelerated growth rates, driven by the rapid, mandated transition away from older, high-emission steel production methods towards modern EAF facilities requiring high volumes of UHP electrodes.

What are the typical dimensions of a modern Ultra-High Power graphite electrode?

UHP graphite electrodes used in high-capacity EAFs typically range in diameter from 500 mm (20 inches) up to 750 mm (30 inches) or more, with lengths often exceeding 2,800 mm, designed to handle extreme current densities and mechanical stresses.

How does the production of ferroalloys contribute to the demand for carbon electrodes?

Ferroalloys (such as ferrochrome, ferromanganese) are produced in submerged arc furnaces (SAFs) which utilize large, amorphous carbon electrodes or Söderberg electrodes. The increasing global demand for specialized alloys in manufacturing necessitates a steady supply of these carbon products.

What is the primary technical challenge manufacturers face when producing large-diameter electrodes?

The primary technical challenge is achieving uniform heating and structural homogeneity throughout the large volume during the baking and graphitization phases. Inadequate uniformity can lead to internal stresses, cracks, and subsequent failure when the electrode is subjected to thermal shock in the furnace.

How is the aerospace industry indirectly impacting the Carbon Electrodes Market?

The aerospace industry drives demand for specialized, high-performance alloys and composite materials (like titanium and high-purity silicon metal) that require specific metallurgical processing steps often involving specialized carbon electrodes and ferroalloys during their refinement stage.

What distinguishes calcined petroleum coke (CPC) from needle coke?

Needle coke is a highly crystalline, highly oriented form of petroleum coke derived from specific refinery streams, used almost exclusively for high-grade graphite electrode production. CPC is a lower-purity, less organized structure primarily used for general carbon electrodes and prebaked anodes in aluminum smelting.

What are the implications of the Electric Vehicle (EV) battery market on carbon material suppliers?

The EV battery market requires vast quantities of high-purity synthetic graphite for lithium-ion battery anodes. While distinct from furnace electrodes, this burgeoning demand creates competition for precursor materials and stimulates specialized carbon material research among electrode manufacturers, potentially leading to portfolio diversification.

Do regulatory standards exist for the quality and performance of carbon electrodes?

Yes, regulatory and industry standards, often set by bodies like ASTM or major steel/aluminum consortia, dictate minimum requirements for electrical resistivity, apparent density, flexural strength, and oxidation resistance to ensure safety, reliability, and guaranteed performance parameters for industrial use.

What are the financial implications of electrode breakage during EAF operation?

Electrode breakage causes significant financial losses due to immediate costs of replacement, loss of production time (downtime), potential damage to the furnace lining or structure, and the safety hazards associated with molten metal splashing and handling broken conductive materials.

How is competition structured among the top global carbon electrode manufacturers?

Competition is highly oligopolistic in the UHP graphite segment, dominated by a few integrated global players (e.g., GrafTech, Showa Denko, Fangda) who control proprietary technology and raw material sourcing. The amorphous carbon segment, however, is more fragmented, particularly within the APAC region.

What long-term opportunity exists in recycling carbon electrode remnants?

A long-term opportunity lies in efficient recycling programs for used or broken electrode butts. These remnants, still possessing high carbon content, can be processed and reused as high-quality raw material substitutes in certain metallurgical processes, improving sustainability and reducing material costs.

What is the significance of low thermal expansion coefficient in graphite electrodes?

A low thermal expansion coefficient is critical because it ensures the electrode can withstand extreme and rapid temperature changes within the EAF without cracking or spalling (thermal shock resistance). This property is essential for the long operational life and reliability of UHP electrodes.

How is automation improving consistency in the mixing and kneading phase?

Automation ensures highly precise metering of raw materials (coke, pitch, additives) and consistent pressure and temperature control during mixing and kneading. This guarantees homogeneity in the electrode mixture, a fundamental requirement for achieving uniform density and eliminating weak spots in the final product.

What impact do energy prices have on the Carbon Electrodes Market?

Energy prices have a dual impact: high electricity prices increase the operational cost for electrode manufacturers (due to energy-intensive graphitization) and simultaneously impact the operational costs and profitability of steel and aluminum producers, affecting their overall capacity utilization and electrode demand.

What measures are taken to protect carbon anodes from oxidation before use?

Prebaked carbon anodes are typically stored in controlled environments and are often protected by thin surface layers or coatings (sometimes involving pitch) to prevent premature oxidation and moisture absorption, which could compromise their integrity and performance once immersed in the molten cryolite bath.

How does geopolitical instability influence the market for carbon electrodes?

Geopolitical instability can disrupt the supply chain of primary raw materials like needle coke, which is often sourced from specific global regions. Such disruptions lead to immediate market tightening, sharp price hikes, and increased reliance on regional stockpiles or alternative sourcing strategies.

What are the technological challenges associated with developing substitute materials for needle coke?

The main challenges involve replicating needle coke's highly ordered crystalline structure and low sulfur content using alternative carbon precursors, such as synthetic pitch or biomass derivatives, while ensuring the resulting graphite electrode maintains the ultra-high electrical and mechanical performance required by modern EAFs.

How does the shift from primary steel production to recycled steel influence electrode demand?

The shift heavily favors electrode demand, as primary steel is typically produced in blast furnaces (not requiring electrodes), whereas recycled steel is produced in EAFs, which are entirely dependent on high-volume consumption of graphite electrodes for their operation.

What is the primary function of the nipple connection between graphite electrodes?

The nipple functions to join individual electrode sections into a long column for the furnace. Its primary function is to provide mechanical strength to the column while maintaining exceptionally low electrical resistance to efficiently transfer current to the molten charge.

Why is the quality of carbon electrodes especially critical in Ladle Furnaces (LFs)?

In Ladle Furnaces, electrodes are used for secondary refining (heating and alloying). High-quality electrodes are crucial here because they prevent carbon pick-up and contamination of specialized, high-purity steel grades, ensuring the final product meets stringent specifications.

What factors determine the operational life of a carbon electrode?

Operational life is determined by factors including the electrode grade (UHP lasts longer), the specific current density applied, the frequency of thermal cycling, the type of anti-oxidation coating used, and the quality of the electrode joints (nipples).

How are carbon electrodes utilized in the production of silicon metal?

Silicon metal production uses submerged arc furnaces, where large carbon electrodes (often Söderberg type or prebaked carbon blocks) provide the heat source and act as a reducing agent, reacting with quartz to yield high-purity silicon metal required for solar panels and electronic components.

What is the current market trend regarding the size and capacity of EAFs globally?

The trend is towards larger, more powerful EAFs, often exceeding 150-ton capacity, operating at Ultra-High Power inputs. This mandates the use of larger diameter, highest-specification UHP graphite electrodes to maximize melting speed and energy efficiency, further segmenting the premium market.

What role does digitalization play in the downstream logistics of carbon electrodes?

Digitalization optimizes logistics by using sensors and tracking to monitor handling conditions, ensuring that sensitive electrodes are not subjected to excessive shocks or moisture during transport, minimizing the risk of breakage or degradation before they reach the highly mechanized storage facilities of end-users.

How is the market addressing the environmental impact of waste carbon materials?

The market is addressing this by enhancing recycling programs, developing technologies to process used electrode butts into value-added carbon products, and focusing on improving material yield during manufacturing to minimize industrial waste streams and overall environmental footprint.

What is the projected CAGR for the Carbon Electrodes Market between 2026 and 2033?

The Carbon Electrodes Market is projected to exhibit a Compound Annual Growth Rate (CAGR) of 6.8% during the forecast period from 2026 to 2033, driven largely by sustained growth in global steel production and technological shifts in metallurgy.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager