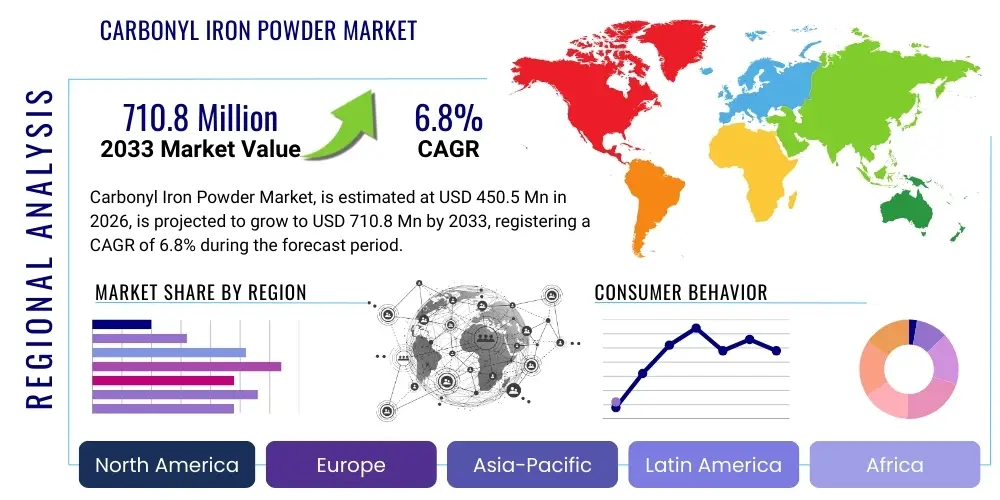

Carbonyl Iron Powder Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438957 | Date : Dec, 2025 | Pages : 248 | Region : Global | Publisher : MRU

Carbonyl Iron Powder Market Size

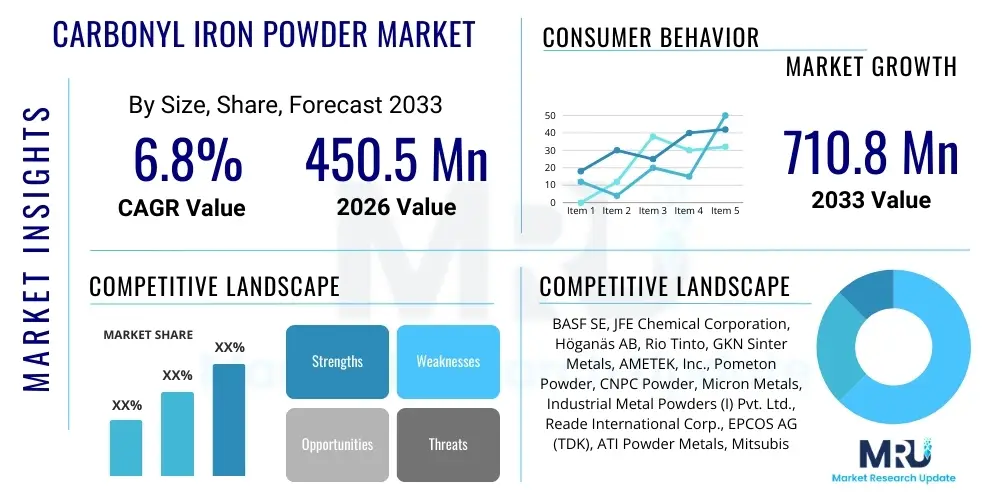

The Carbonyl Iron Powder Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 450.5 Million in 2026 and is projected to reach USD 710.8 Million by the end of the forecast period in 2033.

Carbonyl Iron Powder Market introduction

Carbonyl Iron Powder (CIP) is a highly specialized grade of iron powder characterized by its extremely high purity, spherical shape, and unique fine particle size distribution, typically ranging from 1 to 10 micrometers. Produced through the thermal decomposition of iron pentacarbonyl, this material exhibits exceptional magnetic and dielectric properties, making it indispensable in high-frequency applications. Its high chemical purity, often exceeding 99.5%, combined with its characteristic structure, allows for minimal eddy current losses and high permeability, crucial for advanced electronic components and electromagnetic shielding applications.

Major applications of CIP span across several high-growth industries, most notably electronics, telecommunications, and automotive sectors. In electronics, it is vital for manufacturing power inductors, chokes, transformers, and cores used in power supply units and noise suppression components. Furthermore, its ability to absorb electromagnetic radiation positions it as a key material in stealth technologies and electromagnetic interference (EMI) shielding. The increasing demand for miniaturization and high efficiency in electronic devices, particularly those supporting 5G technology, acts as a profound driving factor for market expansion.

The primary benefits of utilizing CIP include superior magnetic performance at high frequencies, excellent compaction properties for powder metallurgy, and homogeneity required for precise component manufacturing, such as metal injection molding (MIM). Driving factors for market growth include the massive global rollout of 5G infrastructure requiring advanced magnetic components, the accelerating electrification of vehicles (EVs) necessitating high-performance inductors, and continuous innovation in medical devices and pharmaceuticals where CIP is used in drug delivery systems and MRI shielding materials.

Carbonyl Iron Powder Market Executive Summary

The Carbonyl Iron Powder Market is undergoing significant evolution driven primarily by global technological shifts towards miniaturization and higher operating frequencies in electronics. Business trends indicate a strong focus on developing ultra-fine and surface-modified CIP grades to meet stringent performance requirements in 5G smartphones, data centers, and sophisticated radar systems. Leading market players are investing heavily in optimizing the complex manufacturing process to reduce production costs and improve yield, thereby stabilizing supply chains. Furthermore, strategic partnerships between CIP producers and specialty chemical companies are emerging to secure raw material supply (iron pentacarbonyl) and develop tailored application solutions for metal additive manufacturing (AM).

Regionally, the Asia Pacific (APAC) continues to dominate the market share, largely due to the presence of major electronics manufacturing hubs in countries like China, South Korea, Japan, and Taiwan. The robust production and consumption of consumer electronics and passive components in this region solidify its leading position. However, North America and Europe are exhibiting rapid growth rates, fueled by increased expenditure on defense applications, electric vehicle infrastructure development, and the expansion of biomedical technologies. Regulatory environments pertaining to material toxicity and recycling are also influencing regional strategies, compelling European and North American producers to prioritize sustainable manufacturing processes.

Segment trends highlight the ultra-fine powder category as the fastest-growing segment by type, driven by the demand for high-density, low-loss magnetic cores essential for high-frequency power management. By application, the Electronics & Electrical segment holds the largest market share, while the Automotive sector is projected to register the highest Compound Annual Growth Rate (CAGR). This accelerating growth in automotive applications is directly linked to the burgeoning electric vehicle market, where CIP is critical for high-efficiency motors, battery management systems, and on-board charging components, necessitating materials that perform reliably under high thermal stress and stringent vibration standards.

AI Impact Analysis on Carbonyl Iron Powder Market

Common user questions regarding AI's impact on the Carbonyl Iron Powder market often revolve around efficiency gains, predictive quality assurance, and accelerating material discovery. Users are keenly interested in how AI can manage the highly complex and sensitive decomposition process of iron pentacarbonyl to ensure consistent particle morphology and size distribution, which are critical performance metrics. Furthermore, inquiries focus on using machine learning algorithms to predict material degradation or optimize formulations for novel applications, such such as high-frequency antennas or specialized electromagnetic shields for satellite communication systems. The overarching theme is the integration of smart manufacturing protocols to reduce waste, lower production costs, and enhance the competitive edge of high-purity powder manufacturers.

AI technologies are being deployed in CIP manufacturing facilities primarily for process optimization and quality control, addressing the inherent challenges associated with maintaining uniformity in micron-scale powders. By leveraging real-time sensor data from the reaction chambers, AI algorithms can instantly adjust temperature, pressure, and gas flow rates, minimizing batch variation and maximizing yield. This level of precision is unattainable through traditional manual or conventional automation systems, ensuring that the resulting CIP meets the exacting specifications required by sophisticated end-users in the aerospace and advanced electronics industries.

Moreover, the integration of deep learning models significantly enhances research and development efforts in material science related to CIP. AI assists in simulating the properties of composite materials incorporating CIP, predicting the magnetic permeability and coercivity based on slight variations in particle size or surface coating. This predictive capability drastically cuts down the time and cost associated with experimental trials, leading to the faster introduction of next-generation CIP products specifically tailored for emerging technologies like 6G communication components and advanced medical imaging devices, solidifying AI’s role as an innovation accelerator.

- AI-driven optimization of iron pentacarbonyl decomposition process for size uniformity.

- Machine learning models used for predictive maintenance of reactors, minimizing downtime.

- Enhanced quality control through automated particle shape and size analysis (computer vision).

- Accelerated R&D for CIP-polymer composites and magnetic material formulation.

- Optimization of energy consumption during high-temperature manufacturing phases.

DRO & Impact Forces Of Carbonyl Iron Powder Market

The Carbonyl Iron Powder Market is significantly influenced by a confluence of powerful drivers (D), persistent restraints (R), and compelling opportunities (O), creating complex impact forces. Key drivers include the exponential increase in demand for compact and high-performance passive electronic components necessitated by the proliferation of 5G networks, IoT devices, and advanced driver-assistance systems (ADAS) in the automotive sector. These applications rely on the low-loss characteristics and high magnetic permeability unique to CIP, ensuring efficient power management and signal integrity. However, the market faces structural restraints primarily related to the high capital expenditure required for establishing and maintaining CIP production facilities, coupled with the stringent environmental and health regulations surrounding the handling of toxic carbonyl intermediates.

The primary opportunities for growth stem from disruptive technologies such as additive manufacturing (AM), specifically binder jetting and selective laser sintering, where ultra-fine iron powders are required for creating complex, high-precision metallic components. Furthermore, the burgeoning biomedical field presents a lucrative avenue, utilizing CIP in targeted drug delivery systems and medical diagnostics, capitalizing on its biocompatibility and magnetic responsiveness. These opportunities are tempered by the potential threat of substitution from alternative magnetic materials, such as amorphous metals or specialized ferrites, which may offer cost advantages or easier processing in certain low-to-mid frequency applications, thereby defining the competitive impact forces.

The impact forces driving market dynamics are heavily skewed towards technological advancements and regulatory pressures. The necessity for higher frequency components in modern communication infrastructure acts as a powerful accelerating force. Conversely, the high cost of raw material procurement and the complexity of synthesizing ultra-high purity CIP exert restraining forces on mass adoption, particularly in cost-sensitive markets. Navigating these forces requires producers to focus on process efficiency (to mitigate costs) and product differentiation (to justify premium pricing), ensuring continuous innovation remains the central axis for market strategy.

Segmentation Analysis

The Carbonyl Iron Powder market is intricately segmented based on Type, Application, and End-User, reflecting the diverse requirements of downstream industries. The segmentation by type—Ultra-fine, Fine, and Coarse—is crucial as particle size directly correlates with magnetic properties, with ultra-fine powders catering to the highest frequency and most demanding applications. Application segmentation focuses on end-use component production, primarily dividing the market into magnetic cores, radar absorbing materials, and specialized powder metallurgy processes, each demanding unique physical and chemical characteristics from the CIP.

The dominant application segment remains Electronics & Electrical, encompassing a vast array of passive components essential for modern power electronics, including inductors, chokes, and specialized magnetic shielding materials. The rapid expansion of electric vehicles drives the growth in the Automotive segment, requiring high-thermal stability and low-loss materials for electric motor components and battery charging infrastructure. Furthermore, the specialized nature of CIP makes it indispensable in the Defense sector for stealth coatings and microwave absorption, representing a high-value, albeit lower volume, segment.

The granularity of the segmentation allows market participants to tailor their offerings and strategic investments. Manufacturers increasingly focus on developing composite powders, mixing CIP with polymers or other metals, to create specialized compounds that address specific performance gaps, such as enhancing thermal dissipation or improving mechanical strength, further diversifying the product landscape and addressing the evolving needs of advanced manufacturing techniques like Metal Injection Molding (MIM).

- Type: Ultra-fine powder (1-3 µm), Fine powder (3-6 µm), Coarse powder (6-10 µm)

- Application: Electronics & Electrical (Inductors, Chokes, Cores), Magnetic Core (Power Inductors, Transformers), Automotive (EV Motors, Charging Components), Medical & Pharmaceutical (Drug Delivery, MRI Shielding), Radar Absorbing Material (RAM), Powder Metallurgy, Others

- End-User: Powder Metallurgy Industry, Electrical Components Manufacturers, Automotive OEM Suppliers, Defense and Aerospace, Chemical and Pharmaceutical Industry

Value Chain Analysis For Carbonyl Iron Powder Market

The Carbonyl Iron Powder value chain is characterized by high technological barriers and strict control over feedstock, beginning with the highly specialized upstream analysis. The upstream phase centers on the reliable sourcing and preparation of high-purity iron metal and carbon monoxide to synthesize the intermediate compound, iron pentacarbonyl (Fe(CO)5). This synthesis process is hazardous, capital-intensive, and requires specialized pressure vessels and safety protocols, restricting the number of companies capable of vertically integrating this crucial step. Suppliers must ensure the highest purity standards for the raw materials, as contaminants can severely compromise the magnetic performance of the final CIP product.

The core manufacturing stage involves the thermal decomposition of the iron pentacarbonyl under carefully controlled conditions to yield the spherical CIP particles. This stage determines the final product's physical characteristics, including particle size, morphology, and purity, which are the primary determinants of market value. Downstream analysis involves post-processing steps such as surface treatment, blending with polymer binders to create composite materials (e.g., magnetic paints or injection molding feedstocks), and rigorous quality testing. Component manufacturers then utilize these specialized powders to produce magnetic cores, filters, and electromagnetic shielding solutions.

The distribution channel is predominantly direct or via highly specialized distributors. Due to the technical nature of the product and the need for application-specific formulations, direct sales to large end-users (like major electronics component manufacturers or defense contractors) are common, facilitating technical support and customization. Indirect channels involve specialized chemical distributors who possess expertise in handling high-purity powders and supplying smaller powder metallurgy firms or research institutions. The complexity of handling and the precise specifications required necessitate a high degree of technical sales expertise throughout the distribution network.

Carbonyl Iron Powder Market Potential Customers

The primary potential customers and end-users of Carbonyl Iron Powder are entities demanding materials with exceptional magnetic permeability, high saturation magnetization, and low power loss at elevated frequencies. The most significant customer base resides within the electronics manufacturing industry, particularly companies specializing in the production of power electronics, DC-DC converters, and specialized inductors used in computing, communication, and power supply management. These customers require ultra-fine CIP grades to enable the miniaturization of components while maintaining, or improving, efficiency.

Another crucial segment comprises automotive original equipment manufacturers (OEMs) and their Tier 1 suppliers, driven by the shift towards electric mobility. These customers utilize CIP in high-performance magnetic cores for electric motors, crucial components in battery management systems (BMS), and charging infrastructure, where the material’s thermal stability and low-loss characteristics contribute directly to overall vehicle efficiency and range. The demand from this sector is characterized by requirements for high volume and stringent quality assurance standards (e.g., AEC-Q200 certification for automotive components).

Furthermore, the powder metallurgy industry constitutes a foundational customer base, using CIP, often mixed with other metallic powders, to create highly precise, complex-shaped parts via Metal Injection Molding (MIM). This includes components for medical devices, mechanical parts for consumer electronics, and specialized gears. The Defense and Aerospace sectors represent high-value customers, requiring CIP for radar-absorbing coatings (stealth technology) and electromagnetic shielding in sensitive avionics, where material reliability and performance in extreme environments are non-negotiable criteria.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450.5 Million |

| Market Forecast in 2033 | USD 710.8 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | BASF SE, JFE Chemical Corporation, Höganäs AB, Rio Tinto, GKN Sinter Metals, AMETEK, Inc., Pometon Powder, CNPC Powder, Micron Metals, Industrial Metal Powders (I) Pvt. Ltd., Reade International Corp., EPCOS AG (TDK), ATI Powder Metals, Mitsubishi Materials Corporation, Sumitomo Electric Industries, Ltd., Toho Titanium Co., Ltd., China Minmetals Corporation, Saint-Gobain, Alfa Aesar (Thermo Fisher Scientific), Erasteel SAS |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Carbonyl Iron Powder Market Key Technology Landscape

The key technology landscape in the Carbonyl Iron Powder market is dominated by advancements in controlled decomposition processes, aimed at achieving narrower particle size distribution (PSD) and enhanced purity levels. The core manufacturing technology involves the thermal or catalytic decomposition of high-purity iron pentacarbonyl vapor under precise temperature and pressure regimes. Recent technological innovations focus on plasma-assisted decomposition methods and fluidized bed reactors, which offer better control over reaction kinetics, resulting in ultra-fine, highly spherical particles essential for high-frequency magnetic applications. These technological refinements are critical for reducing agglomeration and ensuring superior flow characteristics needed for complex component fabrication.

Beyond the synthesis phase, surface modification technologies are increasingly important. Manufacturers are employing specialized surface coatings, often involving silanes, oxides, or polymer layers, to insulate the iron particles. This insulating layer is critical for reducing eddy current losses in compacted cores, especially when the material is used in composite form (CIP mixed with resin). Enhancing the dielectric strength and magnetic performance through controlled surface chemistry allows for the creation of superior magnetic components suitable for harsh operating conditions found in automotive electronics and high-power industrial applications.

Furthermore, the integration of Carbonyl Iron Powder into additive manufacturing (AM) processes represents a significant technological frontier. Fine CIP is being specifically engineered to be compatible with Metal Injection Molding (MIM) and Binder Jetting technologies. The focus is on developing highly homogeneous feedstock powders (metal-polymer blends) that possess exceptional flowability and high packing density. This allows for the production of geometrically complex magnetic components that are impossible to fabricate using traditional pressing and sintering methods, thereby expanding the potential scope and market size for high-purity iron powders in customized, low-volume, high-performance applications.

Regional Highlights

- Asia Pacific (APAC): APAC is the global leader in both production and consumption of Carbonyl Iron Powder, primarily due to its overwhelming dominance in the global electronics manufacturing sector. Countries like China, Japan, South Korea, and Taiwan house the world’s largest producers of consumer electronics, passive components, and automotive electronics. The aggressive build-out of 5G infrastructure and the localization of electric vehicle supply chains in these countries ensure sustained high demand for high-performance magnetic materials, solidifying APAC's market leadership throughout the forecast period.

- North America: This region is characterized by high-value, specialized demand, especially from the Defense, Aerospace, and Advanced Medical sectors. North American companies utilize CIP for high-specification applications such as radar absorbing materials (RAM) for military aircraft and specialized magnetic components in medical imaging equipment (MRI). The presence of key automotive innovation centers and stringent requirements for high-efficiency power converters also drive the demand for premium, ultra-fine CIP grades.

- Europe: Europe represents a significant growth market, propelled largely by the rapid adoption and production of electric vehicles (EVs) and strong investment in renewable energy infrastructure. CIP is essential for high-efficiency inductors and magnetic shielding components within EV batteries and charging stations, aligning with the EU’s strict climate and efficiency targets. Germany, France, and the UK are key markets, focusing heavily on R&D for advanced powder metallurgy techniques and composite materials for industrial automation and machinery.

- Latin America (LATAM): The LATAM market is relatively smaller but growing steadily, driven by increasing industrialization and foreign direct investment in electronics assembly and automotive manufacturing, particularly in Mexico and Brazil. Demand is focused on standard and fine grades of CIP used in traditional electrical components and for cost-effective magnetic shielding solutions across various consumer goods sectors.

- Middle East and Africa (MEA): Growth in the MEA region is nascent but accelerating, linked to infrastructure projects, increasing defense spending, and emerging telecommunication networks. Demand is project-based, centered around large-scale construction, telecommunication upgrades (especially 5G rollout), and specialized oil & gas exploration equipment requiring robust magnetic properties under extreme conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Carbonyl Iron Powder Market.- BASF SE

- JFE Chemical Corporation

- Höganäs AB

- Rio Tinto

- GKN Sinter Metals

- AMETEK, Inc.

- Pometon Powder

- CNPC Powder

- Micron Metals

- Industrial Metal Powders (I) Pvt. Ltd.

- Reade International Corp.

- EPCOS AG (TDK)

- ATI Powder Metals

- Mitsubishi Materials Corporation

- Sumitomo Electric Industries, Ltd.

- Toho Titanium Co., Ltd.

- China Minmetals Corporation

- Saint-Gobain

- Alfa Aesar (Thermo Fisher Scientific)

- Erasteel SAS

Frequently Asked Questions

Analyze common user questions about the Carbonyl Iron Powder market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the demand for Ultra-fine Carbonyl Iron Powder?

The primary driver is the pervasive trend of miniaturization in modern electronics, particularly the rapid global adoption of 5G technology, which necessitates extremely compact, high-performance, and low-loss magnetic components (inductors and chokes) capable of operating efficiently at very high frequencies (VHF and UHF bands).

How is Carbonyl Iron Powder different from conventionally reduced iron powder?

Carbonyl Iron Powder (CIP) is manufactured through the high-purity chemical decomposition of iron pentacarbonyl, yielding spherical particles (1–10 µm) with exceptionally high purity (>99.5%). Conventional iron powder is typically irregular, larger, and lower in purity, making CIP superior for applications requiring low eddy current losses and high permeability in electromagnetic applications.

Which industry segment holds the largest market share for Carbonyl Iron Powder applications?

The Electronics and Electrical components segment holds the largest market share. CIP is critical for producing high-quality magnetic cores, chokes, and specialized inductors essential for power management systems in consumer electronics, telecommunications equipment, and computing infrastructure globally.

What are the main restraints hindering the growth of the CIP market?

The main restraints include the significantly high capital investment required for specialized manufacturing facilities and the high operational costs associated with maintaining the complex and energy-intensive chemical decomposition process. Additionally, strict environmental and safety regulations concerning the handling of toxic carbonyl precursors pose logistical challenges.

What role does Carbonyl Iron Powder play in the growing Electric Vehicle (EV) market?

In the EV market, CIP is essential for manufacturing high-efficiency, high-thermal stability magnetic components. These components are used in electric motor stators, specialized inductors within battery management systems (BMS), and power converters, contributing directly to increased vehicle range and charging efficiency.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Carbonyl Iron Powder Market Statistics 2025 Analysis By Application (Powder Metallurgy, Electronics Industry, Diamond Tools, Military Industry, Food and Drug Industry, Others), By Type (Fe?98%, Fe: 98-99%, Fe?99%), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Carbonyl Iron Powder Market Statistics 2025 Analysis By Application (Powder Metallurgy, Electronics Industry, Diamond Tools, Military Industry, Food and Drug Industry), By Type (Fe 98%, Fe: 98-99%, Fe 99%), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Carbonyl Iron Powder and Ultra Fine Iron Powder Market Statistics 2025 Analysis By Application (Powder Metallurgy, Electronics Industry, Diamond Tools, Military Industry, Food and Drug Industry), By Type (Carbonyl Iron Powder, Atomized Ultra Fine Iron Powder), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager