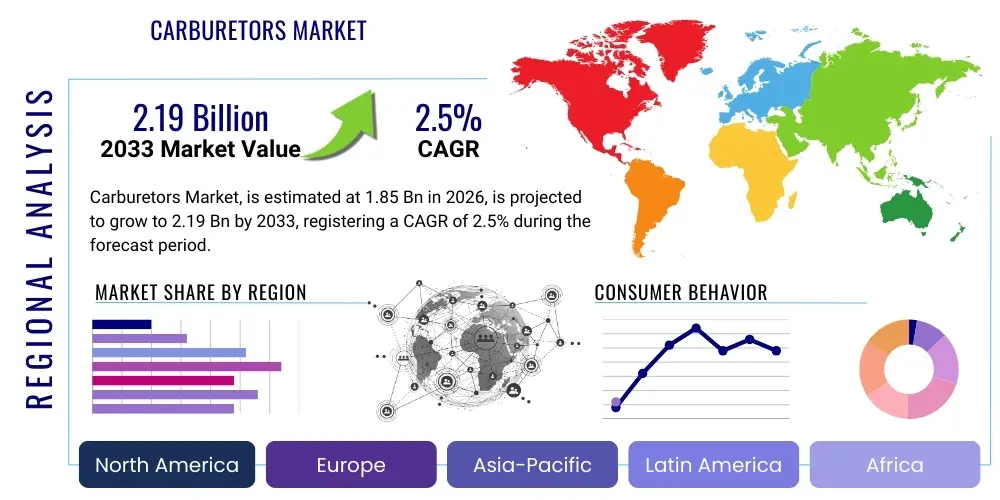

Carburetors Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440649 | Date : Jan, 2026 | Pages : 245 | Region : Global | Publisher : MRU

Carburetors Market Size

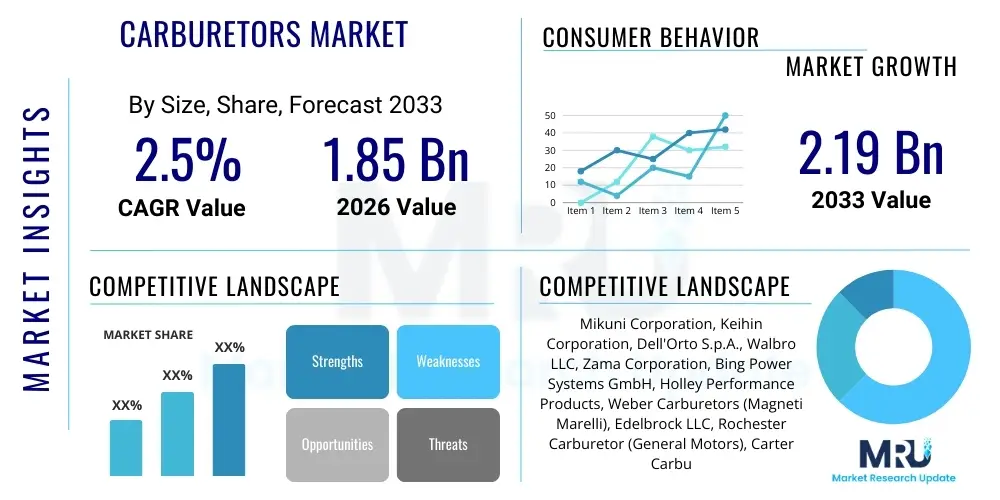

The Carburetors Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 2.5% between 2026 and 2033. The market is estimated at USD 1.85 Billion in 2026 and is projected to reach USD 2.19 Billion by the end of the forecast period in 2033.

Carburetors Market introduction

The carburetors market encompasses the manufacturing, distribution, and sale of devices responsible for mixing air and fuel in internal combustion engines before combustion. Historically a cornerstone of automotive technology, carburetors continue to find significant application in various segments, including small engines for lawnmowers, generators, and chainsaws, as well as in motorcycles, power sports vehicles, marine engines, and agricultural machinery. Their enduring appeal in these sectors stems from their relative simplicity, cost-effectiveness, and ease of maintenance compared to more complex fuel injection systems. The core function involves creating a vacuum to draw fuel into an airstream, atomizing it, and precisely controlling the air-fuel ratio delivered to the engine cylinders, thereby ensuring efficient combustion under varying operational conditions.

Major applications for carburetors extend beyond these traditional segments, holding a crucial place in the aftermarket for classic and vintage vehicles, where authenticity and specific performance characteristics are highly valued. The market is also sustained by regions where economic factors favor less complex, more repairable technologies, particularly in developing countries. Benefits include lower manufacturing costs for original equipment manufacturers (OEMs) in certain product categories, straightforward mechanical operation, and a robust ecosystem for parts and servicing. These advantages maintain their relevance despite the technological advancements seen in the broader internal combustion engine landscape, particularly where environmental regulations are less stringent or where the primary emphasis remains on initial affordability and operational resilience.

Driving factors for the continued market presence include consistent demand from the small engine sector, which powers a vast array of consumer and commercial equipment globally. The global population's increasing need for portable power solutions, coupled with the burgeoning popularity of recreational vehicles and marine sports in certain regions, further underpins this demand. Additionally, the enthusiastic community of classic car and motorcycle restorers actively seeks authentic carburetor components, ensuring a steady, albeit niche, aftermarket segment. The economic viability and accessibility of carburetor technology in emerging markets also play a significant role, as it provides a practical solution for power generation and transportation where advanced infrastructure for fuel injection diagnostics and maintenance might be lacking.

Carburetors Market Executive Summary

The Carburetors Market is characterized by a dichotomy: declining adoption in new automotive and high-performance applications due to stringent emission norms and the prevalence of fuel injection systems, contrasted with sustained demand in specific, resilient niche sectors. Business trends indicate a strategic pivot by leading manufacturers towards optimizing existing carburetor designs for improved efficiency, reliability, and emission compliance in their established segments, rather than broad innovation aimed at challenging fuel injection dominance. There is a notable emphasis on aftermarket support, including the production of replacement parts and performance-enhancing modifications, catering to a loyal base of users and enthusiasts. Furthermore, manufacturers are exploring advanced materials and manufacturing techniques to enhance durability and reduce production costs, ensuring competitive pricing in cost-sensitive markets. The consolidation of smaller players and strategic alliances among major manufacturers are also observed, aimed at leveraging economies of scale and expanding distribution networks in key geographic regions.

Regional trends reveal significant variances in market dynamics. Asia Pacific, particularly countries like China, India, and Southeast Asian nations, represents a substantial market for carburetors due to the high volume of two-wheelers, small commercial vehicles, and agricultural machinery, where cost-effectiveness and robustness are paramount. North America and Europe, while witnessing a decline in new installations for mainstream automotive, maintain a strong aftermarket for classic vehicles, power sports, and specific industrial small engine applications. Latin America and the Middle East & Africa regions are experiencing steady demand, driven by economic development and the continued reliance on more accessible and maintainable engine technologies for everyday use and light industrial applications. These regions often prioritize initial purchase cost and ease of repair, which carburetors inherently offer, over the sophisticated features of modern fuel injection systems.

Segmentation trends highlight the resilience of the motorcycle and small engine segments. Motorcycles, particularly in emerging economies, continue to rely on carburetors for their simplicity and lower production costs, although this trend is slowly being challenged by the introduction of budget-friendly fuel-injected models. The power sports market, encompassing ATVs, snowmobiles, and personal watercraft, also sustains demand, often due to performance tuning possibilities and the ruggedness required in demanding environments. The aftermarket segment, catering to repairs, maintenance, and performance upgrades for existing vehicles and equipment, forms a critical revenue stream, demonstrating consistent growth. This includes components for classic cars, vintage motorcycles, and older models of small engines. Conversely, the automotive OEM segment for new passenger vehicles has almost entirely transitioned away from carburetors, making their presence minimal and highly specialized, typically limited to high-performance racing applications or niche replica vehicles where specific engine characteristics are desired.

AI Impact Analysis on Carburetors Market

Common user questions regarding AI's impact on the Carburetors Market often revolve around concerns that AI-driven advancements, particularly in fuel system optimization, will render carburetors entirely obsolete or significantly diminish their niche appeal. Users frequently inquire about whether AI could improve carburetor performance, efficiency, or emission profiles, or if its influence will be limited to broader manufacturing and supply chain efficiencies rather than the core technology itself. There is also curiosity about how AI might impact the aftermarket, such as predictive maintenance for carburetor-equipped engines or AI-assisted diagnostic tools for tuning and repair. The underlying themes are centered on the future viability of a traditional technology in an increasingly intelligent and digitally integrated world, and whether AI can extend the lifespan or improve the functionality of carburetors in any meaningful way, or if its role is primarily to accelerate the transition to fuel injection systems.

While AI's direct influence on the fundamental operating principles of a mechanical carburetor is limited, its indirect impact can be transformative in several market dimensions. AI algorithms can significantly optimize manufacturing processes by predicting machine failures, identifying quality control issues in real-time, and streamlining assembly lines for carburetor components, leading to reduced waste and improved production efficiency. In the supply chain, AI can enhance demand forecasting for both OEM and aftermarket parts, optimize inventory management, and predict logistical bottlenecks, ensuring timely availability of components globally. This predictive capability is crucial for manufacturers dealing with fluctuating demand across diverse regional markets, from high-volume small engine production to niche vintage car restoration parts.

Furthermore, AI can play a crucial role in the aftermarket segment. AI-powered diagnostic tools can assist technicians in troubleshooting carburetor issues by analyzing symptom patterns and suggesting optimal tuning parameters more rapidly and accurately than traditional methods. Predictive maintenance models, leveraging data from engines, could forecast potential carburetor malfunctions before they occur, enabling proactive servicing and extending the operational lifespan of existing equipment. While AI won't reinvent the carburetor's core mechanism, it can refine its production, distribution, and maintenance ecosystem, contributing to cost reductions, improved reliability, and enhanced user experience in the segments where carburetors remain prevalent, thereby indirectly bolstering their market presence in an intelligent operational framework.

- AI optimizes carburetor manufacturing processes through predictive maintenance and quality control, reducing defects and improving efficiency.

- AI enhances supply chain management for carburetor components, improving demand forecasting, inventory optimization, and logistics for OEMs and the aftermarket.

- AI-powered diagnostic tools assist technicians in troubleshooting and precise tuning of carburetor-equipped engines, improving service efficiency and accuracy.

- AI can contribute to predictive maintenance for engines utilizing carburetors, extending equipment lifespan and minimizing unexpected downtime.

- AI analytics support market segmentation and trend analysis, helping manufacturers identify niche opportunities and tailor product offerings more effectively.

DRO & Impact Forces Of Carburetors Market

The Carburetors Market is shaped by a complex interplay of driving forces, inherent restraints, and emerging opportunities, all contributing to its dynamic evolution. A primary driver is the enduring demand for cost-effective and straightforward power solutions in the small engine sector, which includes applications such as lawn and garden equipment, portable generators, and light construction machinery. These segments prioritize initial purchase price and ease of maintenance, where carburetors offer a significant advantage over more complex and expensive fuel injection systems. Furthermore, the robust aftermarket demand, particularly from enthusiasts and restorers of classic automobiles, vintage motorcycles, and older recreational vehicles, provides a steady revenue stream. The simplicity of carburetor design also contributes to its appeal in developing economies, where access to advanced diagnostic tools and specialized technicians for fuel injection systems might be limited, making carburetors a practical and reliable choice for transportation and power generation needs.

Conversely, significant restraints hinder the broader expansion of the carburetors market. Foremost among these are increasingly stringent global emission regulations, which favor the precise fuel delivery and control offered by electronic fuel injection systems. Carburetors, being mechanical devices, struggle to meet the strict emission standards for hydrocarbons, carbon monoxide, and nitrogen oxides mandated in many regions for new vehicles and equipment. The continuous technological advancements in fuel injection systems, offering superior fuel efficiency, power output, and adaptability to varying atmospheric conditions, further erode the competitive edge of carburetors in many applications. Additionally, consumer preference in developed markets has largely shifted towards more sophisticated, electronically controlled engines that provide better performance, lower emissions, and enhanced diagnostic capabilities, marginalizing carburetors to specific niche uses.

Despite these challenges, opportunities exist for market participants. Niche applications, such as high-performance racing (where specific tuning capabilities are valued), vintage vehicle restoration, and certain specialized industrial equipment, continue to offer viable segments. There's also potential for innovation in materials and manufacturing processes to enhance the durability and cost-effectiveness of carburetors, making them more attractive for their established markets. Furthermore, the integration of basic electronic feedback loops or sensors, while not transforming them into fuel injection systems, could potentially help carburetors optimize air-fuel mixtures more effectively under varying conditions, addressing some emission concerns within their operational constraints. Exploring hybrid solutions for small engines, where a carburetor might be combined with other technologies to achieve better efficiency or emissions, could also present future avenues for growth. The continued growth of disposable income in emerging markets, driving demand for affordable motorcycles and small utility vehicles, also presents a substantial opportunity for carburetor manufacturers.

Segmentation Analysis

The Carburetors Market is broadly segmented based on several critical parameters, including type, component, application, and end-user, each reflecting distinct operational characteristics and market demands. This comprehensive segmentation allows for a detailed understanding of market dynamics, identifying specific growth areas, and recognizing where traditional carburetor technologies maintain competitive advantages. The varying requirements across different engine sizes, performance expectations, and regulatory environments dictate the predominant carburetor types and their specific applications, from simple single-barrel designs for small utility engines to complex multi-barrel configurations found in performance vehicles. The analysis provides granular insights into the market's structure, highlighting the diverse landscape from initial equipment manufacturing to the expansive aftermarket for repairs and modifications.

- By Type:

- Updraft Carburetors: Primarily for older or stationary engines, where gravity assists fuel flow.

- Downdraft Carburetors: Common in automotive, using gravity for fuel flow; offers good fuel distribution.

- Side-draft Carburetors: Often used in performance and sportier vehicles due to lower profile and direct airflow.

- Constant Velocity (CV) Carburetors: Utilizes a variable Venturi, common in motorcycles and ATVs for smooth power delivery.

- Fixed Jet Carburetors: Simplest design, common in small engines, with fixed orifices for fuel metering.

- By Component:

- Float Chamber: Regulates fuel level.

- Venturi: Creates vacuum to draw fuel.

- Throttle Valve: Controls engine speed.

- Choke Valve: Enriches mixture for cold starts.

- Fuel Jet: Meters fuel flow into the airstream.

- Air Bleeds: Control air emulsion.

- Accelerator Pump: Provides extra fuel during rapid acceleration.

- Idle Circuit: Supplies fuel at low engine speeds.

- By Application:

- Automotive: Limited to classic cars, racing, and some vintage models.

- Motorcycles: Widely used, especially in smaller displacement and cost-sensitive models, and older motorcycles.

- Power Sports: Includes ATVs, UTVs, snowmobiles, and personal watercraft.

- Marine: Used in smaller outboard motors and some leisure craft.

- Agricultural Equipment: Tractors, tillers, and other farm machinery.

- Small Engines/Generators: Lawnmowers, chainsaws, portable generators, leaf blowers, etc.

- Aircraft: Primarily in small, piston-engine general aviation aircraft.

- By End-User:

- OEM (Original Equipment Manufacturers): Supplying carburetors for new production vehicles and equipment.

- Aftermarket: Replacement parts, performance upgrades, and tuning components for existing vehicles and machinery.

- By Material:

- Aluminum: Lightweight, corrosion-resistant, common for body.

- Zinc Alloy: Cost-effective, good casting properties, often used for body.

- Brass: Used for precision components like jets and needles due to machinability and corrosion resistance.

- Plastics/Polymers: For gaskets, floats, and certain housing components.

Value Chain Analysis For Carburetors Market

The value chain for the Carburetors Market commences with the upstream activities involving the sourcing and processing of various raw materials. This includes manufacturers of aluminum and zinc alloys for carburetor bodies, brass for precision components like jets and needles, and specialized plastics and rubbers for gaskets, seals, and floats. These suppliers form the foundational layer, providing critical inputs whose quality directly impacts the performance and durability of the final carburetor product. Key considerations at this stage include material cost, availability, and adherence to specific metallurgical or chemical properties required for fuel compatibility and operational integrity. Relationships with these suppliers are often long-term, built on trust and consistent quality, ensuring a stable and reliable supply of materials essential for mass production as well as specialized niche components.

Moving downstream, the manufactured carburetor components are then supplied to Original Equipment Manufacturers (OEMs) across various industries such as motorcycle, power sports, small engine, and agricultural equipment manufacturing. These OEMs integrate carburetors into their complete engine assemblies, which are then installed in their final products like motorcycles, ATVs, lawnmowers, or generators. Parallel to the OEM channel, a significant portion of carburetor production flows into the aftermarket. This involves a complex network of distributors, wholesalers, and retailers who supply replacement parts, repair kits, and performance-enhancing carburetors to independent mechanics, service centers, automotive parts stores, and individual consumers. The aftermarket segment is particularly vital for sustaining older vehicles and equipment, as well as for catering to enthusiasts who seek specific tuning or upgrade options.

Distribution channels for carburetors are multifaceted, encompassing both direct and indirect routes. Direct sales are typically made from carburetor manufacturers to large OEMs, often through contractual agreements that specify volume, pricing, and delivery schedules. Indirect channels are more prevalent for the aftermarket, involving a tiered distribution network. This includes large-scale master distributors who serve regional wholesalers, who in turn supply smaller retail outlets, specialized tuning shops, and online platforms. The rise of e-commerce has significantly impacted this distribution, allowing direct-to-consumer sales for niche parts and broadening the reach of aftermarket suppliers globally. The effectiveness of these channels is crucial for ensuring product availability, managing inventory, and providing timely technical support across the diverse end-user base, from large industrial clients to individual hobbyists. Robust logistics and efficient inventory management are key to success in both OEM and aftermarket distribution, optimizing the flow from production to the end-user's point of need.

Carburetors Market Potential Customers

Potential customers for carburetors span a diverse range of industries and individual consumer segments, each driven by specific needs and priorities. The largest volume of demand typically originates from Original Equipment Manufacturers (OEMs) in sectors that produce small engines, motorcycles, power sports vehicles (such as ATVs, UTVs, and snowmobiles), marine engines, and agricultural machinery. These manufacturers select carburetors for new production runs based on factors like cost-effectiveness, simplicity of integration, and the ability to meet regional emission standards for specific engine classes. For these OEMs, carburetors often represent a balance between performance, reliability, and manufacturing cost, particularly in markets where price sensitivity is high and advanced fuel injection systems are deemed unnecessary or prohibitively expensive for the target consumer base.

Beyond the OEM segment, a substantial and highly loyal customer base exists within the aftermarket. This includes independent repair shops, automotive service centers, and specialized garages that service older vehicles and equipment still equipped with carburetors. These customers require a steady supply of replacement carburetors, repair kits, and individual components for routine maintenance and troubleshooting. Furthermore, enthusiasts and collectors of classic cars, vintage motorcycles, and historical power sports vehicles represent a significant niche. These individuals actively seek authentic or high-quality replica carburetors to maintain the originality, performance, and historical accuracy of their machines, often investing significantly in specialized parts and tuning expertise. This segment values precision, reliability, and the ability to finely tune carburetors for specific performance characteristics.

Finally, individual consumers who own small engine equipment, such as lawnmowers, generators, chainsaws, and leaf blowers, also constitute a broad customer group. These end-users, or the local repair technicians they employ, are potential buyers of replacement carburetors when their original units malfunction or require refurbishment. This segment prioritizes ease of installation, availability, and affordability of parts, often opting for direct replacements that require minimal adjustment. The agricultural sector, encompassing farmers and agricultural equipment operators, also relies on carburetor-equipped machinery for various tasks, creating consistent demand for durable and easily maintainable fuel systems. These diverse customer profiles underscore the multifaceted nature of the carburetors market, requiring manufacturers and distributors to cater to a wide spectrum of technical expertise, financial capacity, and specific application requirements.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.85 Billion |

| Market Forecast in 2033 | USD 2.19 Billion |

| Growth Rate | 2.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Mikuni Corporation, Keihin Corporation, Dell'Orto S.p.A., Walbro LLC, Zama Corporation, Bing Power Systems GmbH, Holley Performance Products, Weber Carburetors (Magneti Marelli), Edelbrock LLC, Rochester Carburetor (General Motors), Carter Carburetor, S&S Cycle, Inc., Lectron Fuel Systems, Tecumseh Products Company LLC, Tillotson Carburetors, Nikki Co., Ltd., Bendix Corporation (Honeywell), Zenith Carburetter Co., Ltd., SU Carburetters (Burlen Fuel Systems), Stromberg Carburetors |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Carburetors Market Key Technology Landscape

The key technology landscape for the Carburetors Market, while rooted in mechanical principles, has seen continuous, albeit subtle, advancements focused on improving efficiency, reliability, and emission compliance within its inherent limitations. Modern carburetor design emphasizes precision engineering and manufacturing techniques to ensure consistent fuel delivery and atomization, crucial for optimizing engine performance and reducing emissions. This includes sophisticated casting processes for carburetor bodies to achieve tighter tolerances and smoother internal passages, minimizing airflow restrictions and improving fuel mixing. Materials science also plays a significant role, with the adoption of advanced corrosion-resistant alloys for bodies and components, extending the operational life and reducing maintenance requirements, particularly in harsh environmental conditions such as marine or agricultural applications.

Further technological evolution in carburetors involves the refinement of internal components. This includes the development of more precise fuel jets and needles that can maintain optimal air-fuel ratios across a broader range of engine speeds and loads. Manufacturers are also integrating improved float designs and accelerator pump mechanisms to enhance responsiveness and prevent fuel starvation or enrichment issues. While fully electronic control remains the domain of fuel injection, some modern carburetors for small engines incorporate basic electronic elements, such as electronically controlled solenoids for idle speed or fuel cut-off, to marginally improve emission characteristics and cold-start performance. These advancements aim to bridge the gap between traditional mechanical simplicity and modern demands for better environmental performance and user experience without fully abandoning the core carburetor design.

Another area of technological focus involves modular design, allowing for easier assembly, disassembly, and servicing, which is a key selling point in the aftermarket and in regions where self-repair is common. This modularity also facilitates the development of application-specific carburetors that can be quickly adapted for different engine types and performance requirements without a complete redesign. Furthermore, in niche markets like racing or custom vehicle building, advanced tuning technologies such as adjustable air bleeds, interchangeable venturis, and sophisticated power valves allow for highly precise calibration to maximize engine output and efficiency under specific operating conditions. These innovations collectively ensure that carburetors, despite facing competition from more advanced systems, remain a viable and continuously refined solution for their established and niche market segments, upholding their reputation for robustness and adaptability in certain power applications.

Regional Highlights

- North America: This region represents a mature market for carburetors, predominantly driven by the robust aftermarket segment for classic cars, vintage motorcycles, and power sports vehicles (ATVs, snowmobiles, personal watercraft). Demand also persists in the small engine sector for lawn and garden equipment and portable generators. While new automotive installations are negligible, the emphasis on restoration, performance tuning, and outdoor recreational activities sustains a steady need for both replacement and performance carburetors.

- Europe: Similar to North America, Europe's carburetor market is largely sustained by the aftermarket, catering to a passionate community of classic vehicle enthusiasts and specialized motorsport segments. There's also consistent demand from the small engine market, particularly for agricultural machinery and professional landscaping equipment. Stringent emission regulations mean new OEM carburetor installations are rare in mainstream vehicles, pushing market focus towards high-quality replacement parts and niche performance applications.

- Asia Pacific (APAC): APAC is a dominant region for carburetor demand, primarily due to its vast motorcycle market, especially in countries like India, China, and Southeast Asian nations, where two-wheelers are a primary mode of transportation. The cost-effectiveness and simplicity of carburetors make them highly suitable for these price-sensitive markets. Additionally, the region's significant agricultural sector and widespread use of small utility engines for power generation and construction further contribute to substantial market volumes.

- Latin America: This region exhibits strong demand for carburetors, mirroring trends in APAC, driven by the affordability and durability required for motorcycles, small commercial vehicles, and agricultural equipment. Economic factors and less stringent emission standards in many countries contribute to the continued preference for carburetor-equipped engines over more expensive and complex fuel injection systems. The aftermarket for repairs and maintenance is also a crucial segment.

- Middle East and Africa (MEA): The MEA region represents a growing market, fueled by increasing infrastructure development and the need for affordable and reliable power solutions. Carburetors find extensive use in small generators, pumps, and basic transportation vehicles. The market is characterized by a strong emphasis on robust, easily repairable technology suitable for challenging operating environments, making carburetors a practical choice for a broad range of applications.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Carburetors Market.- Mikuni Corporation

- Keihin Corporation

- Dell'Orto S.p.A.

- Walbro LLC

- Zama Corporation

- Bing Power Systems GmbH

- Holley Performance Products

- Weber Carburetors (Magneti Marelli)

- Edelbrock LLC

- Rochester Carburetor (General Motors)

- Carter Carburetor

- S&S Cycle, Inc.

- Lectron Fuel Systems

- Tecumseh Products Company LLC

- Tillotson Carburetors

- Nikki Co., Ltd.

- Bendix Corporation (Honeywell)

- Zenith Carburetter Co., Ltd.

- SU Carburetters (Burlen Fuel Systems)

- Stromberg Carburetors

Frequently Asked Questions

What is the projected growth rate for the Carburetors Market?

The Carburetors Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 2.5% between 2026 and 2033, reaching an estimated USD 2.19 Billion by 2033.

Why are carburetors still used despite the prevalence of fuel injection systems?

Carburetors remain prevalent in segments like small engines, motorcycles, and power sports due to their cost-effectiveness, mechanical simplicity, ease of maintenance, and suitability for niche applications like vintage vehicle restoration, especially in developing regions.

What are the main drivers of the Carburetors Market?

Key drivers include consistent demand from the small engine sector, robust aftermarket demand for classic vehicles and repairs, cost-effectiveness, and continued adoption in emerging economies where affordability and easy repair are prioritized.

How do emission regulations impact the Carburetors Market?

Stringent global emission regulations are a significant restraint, as carburetors struggle to meet modern standards compared to precise fuel injection systems, leading to a decline in new installations for mainstream automotive applications.

Which regions are key markets for carburetors?

Asia Pacific is a dominant market due to high motorcycle and small engine adoption, while North America and Europe primarily rely on the aftermarket for classic vehicles and power sports. Latin America and MEA show steady demand driven by affordability and utility.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Carburetors Market Size Report By Type (Float-Feed Carburetor, Diaphragm Carburetor), By Application (Motorcycle & Powersports, Universal Gasoline Engines, Automotive, Others), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Outdoor Power Equipment Carburetors Market Statistics 2025 Analysis By Application (Lawn Mowers, Chainsaws, Leaf Blowers, Lawn Trimmers), By Type (Float-Feed Carburetor, Diaphragm Carburetor), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager