Cardboard Box Edge Protector Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 431752 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Cardboard Box Edge Protector Market Size

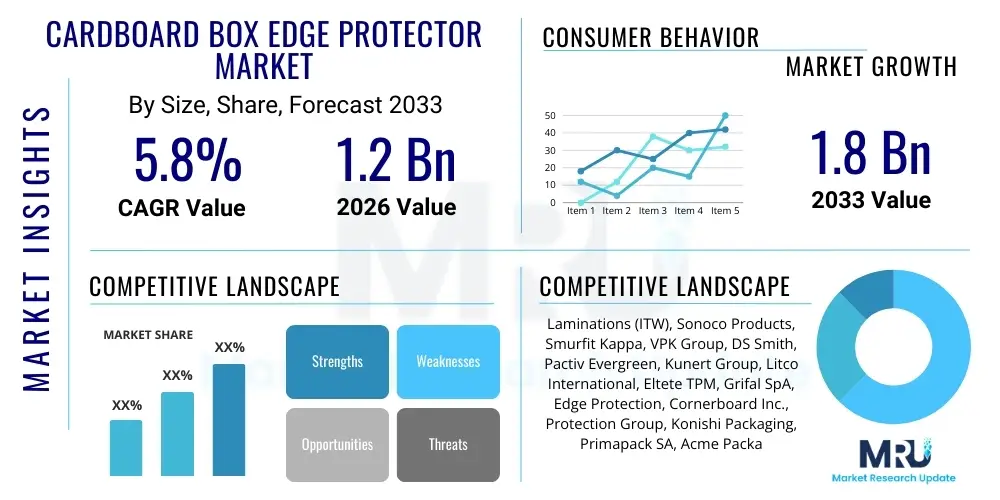

The Cardboard Box Edge Protector Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $1.2 Billion in 2026 and is projected to reach $1.8 Billion by the end of the forecast period in 2033.

Cardboard Box Edge Protector Market introduction

The Cardboard Box Edge Protector Market encompasses the manufacturing and distribution of protective angular strips made primarily from compressed, recycled paperboard or fiberboard. These L-shaped or U-shaped products, often termed corner boards or edge guards, are engineered to prevent damage to packaged goods during transit, storage, and handling. They function by reinforcing the structural integrity of palletized loads and cardboard cartons, distributing tension from strapping materials, and absorbing impact forces, thereby safeguarding corners and edges from crushing, scuffing, or breakage. The increasing global focus on efficient logistics, coupled with the rapid expansion of the e-commerce sector, drives the fundamental demand for reliable packaging protection solutions.

These essential packaging aids find major applications across diverse industries, including food and beverage, electronics, building and construction, and general manufacturing, where product integrity is paramount. Benefits derived from utilizing edge protectors include significantly reduced product damage claims, enhanced load stability, and optimization of storage density. Furthermore, the material composition—often recycled and recyclable fiber—aligns well with corporate sustainability initiatives, offering an environmentally conscious alternative to plastic or foam protectors. The primary driving factors for market growth include stringent quality control standards in supply chains, increasing container throughput in global trade, and the necessity to stabilize heavy or irregularly shaped loads.

Cardboard Box Edge Protector Market Executive Summary

The Cardboard Box Edge Protector Market is currently characterized by robust business trends driven by global supply chain optimization and the surging volume of e-commerce shipments. Key business activity includes strategic mergers and acquisitions aimed at expanding geographical reach and integrating sustainable material technologies. Manufacturers are increasingly focusing on customization, offering variable leg lengths, thicknesses, and moisture-resistant coatings to cater to specialized industry needs, particularly in cold chain logistics and construction materials handling. The competitive landscape is fragmented, featuring both large multinational packaging conglomerates and specialized regional players, all vying for efficiency and material innovation to reduce the total cost of ownership for end-users.

Regionally, Asia Pacific is anticipated to exhibit the fastest growth, primarily due to expanding manufacturing bases in countries like China and India, coupled with massive infrastructure projects and a rapidly digitalizing retail sector fueling e-commerce adoption. North America and Europe, while mature, maintain significant market shares, characterized by strong regulatory emphasis on safe transit and high adoption rates of automated palletizing systems requiring standardized and durable edge protection. Segment trends highlight the dominant position of heavy-duty protectors (thicker than 7mm) owing to their use in industrial sectors, while the sustainability segment, focusing on 100% recycled content and biodegradable glues, is experiencing exponential growth, influencing purchasing decisions across all end-use sectors.

AI Impact Analysis on Cardboard Box Edge Protector Market

User inquiries regarding AI's impact on the edge protector market generally revolve around optimizing packaging processes, predictive damage analysis, and enhancing supply chain efficiency rather than the manufacturing process itself. Users are concerned about how AI can minimize the *need* for excessive protection by predicting transit risks accurately, determining the optimal amount and placement of edge protectors, and automating quality control during production and palletization. The consensus theme is that AI will transform edge protector selection from a manual estimation process to a data-driven, highly efficient component of smart packaging systems. Key expectations include AI algorithms interpreting sensor data (shock, temperature, humidity) from shipments to refine packaging standards, leading to customized protector specifications and reduced material waste.

- AI-driven optimization of material usage, calculating the minimum required thickness and quantity of protectors based on simulated transit stressors.

- Predictive analytics for packaging damage, allowing logistics providers to dynamically adjust protection levels based on real-time route conditions and historical damage data.

- Automated quality control systems utilizing computer vision to ensure precise application and alignment of edge protectors on pallets, reducing manual errors.

- Integration of AI into warehouse management systems (WMS) to manage inventory levels of specialized edge protectors tailored for different product lines.

- Enhanced supply chain visibility and risk assessment, identifying specific points of failure in transit where edge protection is most critical.

DRO & Impact Forces Of Cardboard Box Edge Protector Market

The Cardboard Box Edge Protector Market is significantly influenced by macro-economic factors and micro-level packaging dynamics. Primary drivers include the massive global expansion of e-commerce, which necessitates durable and scalable packaging solutions for single-item and bulk shipments, and the mandatory requirement for load stabilization in high-speed, automated logistics facilities. Restraints predominantly stem from the volatility in raw material (pulp and paperboard) prices, which impacts manufacturing costs and profitability, along with the increasing preference for alternative, reusable packaging systems, such as plastic crates, in closed-loop supply chains. Opportunities lie in developing advanced, moisture-resistant, and fire-retardant edge protectors for specialized industrial applications, and integrating IoT tracking capabilities into packaging structures for enhanced monitoring.

The overarching impact forces shaping this market include stringent environmental regulations promoting the use of sustainable packaging materials (a positive force for cardboard) and the increasing complexity of international shipping routes requiring standardized yet robust protection (a stabilizing force). Price sensitivity in emerging markets acts as a powerful restraining influence, forcing manufacturers to focus relentlessly on cost-effective production methods. Conversely, the continuous pressure from end-users to minimize product damage during transit—a direct consequence of brand reputation and high shipping insurance costs—serves as the most substantial long-term driver, ensuring persistent demand for high-quality edge protection solutions.

Segmentation Analysis

Segmentation analysis of the Cardboard Box Edge Protector Market reveals distinct consumer preferences and technological requirements across various applications and end-use industries. The market is primarily segmented based on the type of material used, the thickness of the protector, the application method (e.g., palletizing vs. strapping), and the specific industry utilizing the product. Analysis of these segments is crucial for manufacturers to tailor their production capacities and product specifications to meet the nuanced demands of sectors ranging from delicate electronics to bulk construction materials, optimizing for factors like compression strength, flexibility, and resistance to environmental factors like humidity.

- By Material:

- Recycled Paperboard

- Virgin Kraft Linerboard

- By Thickness:

- 3mm - 6mm (Light Duty)

- 7mm - 10mm (Medium Duty)

- Above 10mm (Heavy Duty)

- By Application:

- Palletizing and Load Unitization

- Strapping Protection (Under Straps)

- Internal Reinforcement (Box Corners)

- Load Stabilization and Void Filling

- By End-Use Industry:

- Food & Beverage (Including Cold Chain)

- Electronics and High-Value Goods

- Building & Construction Materials

- E-commerce & Logistics (3PLs)

- Manufacturing (Automotive, Machinery)

Value Chain Analysis For Cardboard Box Edge Protector Market

The value chain for the Cardboard Box Edge Protector Market begins with upstream analysis involving raw material suppliers, predominantly recycled paper pulp, virgin fiber, and specialized adhesives. Efficiency in this stage is critical, as the cost structure of the final product is highly sensitive to fluctuations in global paper commodity prices. Key upstream activities include sorting, pulping, and the production of multi-ply paperboard rolls which serve as the base input. Optimization here focuses on securing high-quality, sustainable inputs and implementing resource-efficient manufacturing processes to maintain competitive pricing in the highly commoditized packaging sector.

The core manufacturing and distribution stage involves converting the paperboard into angle boards via lamination, pressing, and cutting processes, often requiring specialized machinery for high-volume production. Distribution channels are varied: direct sales to large manufacturing corporations and logistics providers represent a significant portion, particularly for customized or heavy-duty products, while indirect channels rely on packaging distributors, wholesalers, and third-party logistics (3PL) providers to reach small-to-medium enterprises (SMEs). Downstream analysis focuses on the end-users—large consumer goods companies, construction firms, and e-commerce fulfillment centers—who integrate these protectors into their automated or manual packaging lines to ensure safe transit.

The competitive advantage in the value chain is increasingly shifting towards logistics integration and service quality. Companies that offer inventory management, just-in-time delivery, and specialized technical consultation on optimal protector dimensions and placement demonstrate higher value capture. The interplay between direct sales (offering control and deep customization) and indirect channels (offering broad market penetration and accessibility) defines the market reach. As sustainability becomes a core purchasing criterion, traceability and certifications regarding recycled content and eco-friendly manufacturing processes are crucial checkpoints in the value chain, influencing procurement decisions at the downstream level.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $1.2 Billion |

| Market Forecast in 2033 | $1.8 Billion |

| Growth Rate | CAGR 5.8% |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Laminations (ITW), Sonoco Products, Smurfit Kappa, VPK Group, DS Smith, Pactiv Evergreen, Kunert Group, Litco International, Eltete TPM, Grifal SpA, Edge Protection, Cornerboard Inc., Protection Group, Konishi Packaging, Primapack SA, Acme Packaging, Shijiazhuang Liantong, Mondi Group, L.G.R. Packaging, Packaging Strategies Inc. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Cardboard Box Edge Protector Market Potential Customers

Potential customers for Cardboard Box Edge Protectors span a vast array of industries characterized by the need to ship goods securely and maintain product quality during complex transit processes. The largest end-users include third-party logistics (3PL) providers and major e-commerce fulfillment centers, who utilize protectors extensively for unitizing high volumes of diverse products onto pallets destined for last-mile delivery. These customers prioritize standardized, cost-effective solutions that are easily integrated into high-speed automated packaging lines, viewing edge protectors as a critical tool for minimizing costly damage returns and insurance claims, which directly impact profitability and customer satisfaction metrics.

Another significant segment comprises the Building and Construction industry, which requires heavy-duty protectors (often exceeding 10mm thickness) to safeguard oversized, heavy, or irregularly shaped materials such as drywall, steel coils, metal sheeting, and lumber. For this sector, the protectors must offer superior compression strength and often require specialized coatings to withstand harsh external environments, including moisture and extreme temperature fluctuations encountered on construction sites. Similarly, the Manufacturing sector, particularly automotive and heavy machinery components, relies on edge protectors to stabilize high-value, fragile parts that are susceptible to damage from strapping tension or side impacts during intermodal transport.

Furthermore, the Food and Beverage industry, especially those dealing with perishable goods and cold chain logistics, constitutes a growing customer base. Here, the emphasis is on moisture-resistant or poly-coated protectors that prevent mold and maintain structural integrity in refrigerated or frozen conditions. Electronics manufacturers also represent high-value buyers, seeking specialized, often anti-static or finely finished edge protectors to ensure the pristine condition of sensitive consumer electronics and display screens. Procurement managers across all these sectors evaluate suppliers based on reliability, material sustainability certifications, and the ability to customize dimensions (e.g., asymmetrical legs) for unique packaging challenges.

Cardboard Box Edge Protector Market Key Technology Landscape

The Cardboard Box Edge Protector Market, while rooted in traditional paper manufacturing, is evolving through process optimization and material science innovations. The key technology centers around high-speed lamination and precise forming machinery, which uses multiple layers of paperboard and industrial adhesives to create the strong, rigid L- or U-profiles. Advanced technology ensures uniform thickness and consistent compression strength across long production runs, vital for products used in automated pallet wrappers and strapping machines. Modern machinery also incorporates quick-change tooling to efficiently switch between different dimensions and thicknesses, meeting the customization demands of the market.

Material technology is another critical area. This involves the development of specialized coatings—such as wax, polyethene, or silicone—to enhance moisture resistance, an essential requirement for outdoor storage or cold chain applications. Furthermore, there is a substantial technological push towards developing high-performance, water-based, and starch-based adhesives that offer superior bonding strength while remaining environmentally friendly and fully recyclable. Manufacturers are also experimenting with proprietary fiber blending techniques to maximize the strength-to-weight ratio, allowing for lighter, yet equally protective, solutions, which directly reduces shipping weight and costs for the end-user.

The adoption of Industry 4.0 principles, including sensor integration and process automation, is increasingly relevant, primarily in the quality control and downstream application phases. Although the edge protector itself is low-tech, its application is becoming high-tech. Innovations include automated systems that precisely cut, position, and affix edge protectors to pallets using robotic arms, minimizing waste and maximizing load stability. The future landscape will likely involve integrating simple RFID or printed electronics into the protectors for basic tracking and condition monitoring, transforming them from passive protective elements into components of a smart packaging ecosystem.

Regional Highlights

Regional dynamics play a significant role in shaping the demand and manufacturing footprint of the Cardboard Box Edge Protector Market, driven by differential economic growth, regulatory environments, and logistics infrastructure maturity.

- Asia Pacific (APAC): This region is forecast to experience the highest growth rate, fueled by robust industrial output, massive investment in infrastructure and construction, and the explosive growth of e-commerce markets, particularly in China, India, and Southeast Asia. Manufacturing capacity is rapidly increasing, focusing both on domestic consumption and global export requirements. The competitive intensity is high, prioritizing large volumes and cost-efficiency.

- North America: A mature but highly valuable market, characterized by advanced logistics networks and a strong emphasis on supply chain integrity and worker safety. Demand is consistently high across the manufacturing, automotive, and food sectors. Innovation here focuses on developing high-performance, specialized, and highly customizable protectors tailored to automated material handling systems and stringent quality standards.

- Europe: This region exhibits stable growth, driven largely by regulatory pressures mandating sustainable packaging solutions and strong adherence to pallet standardization (e.g., EPAL standards). European manufacturers lead in sustainable practices, emphasizing recycled content, closed-loop systems, and bio-degradable adhesives, making AEO and sustainability credentials vital competitive factors.

- Latin America (LATAM): Growth is moderate but accelerating, linked to expanding trade agreements and modernization of logistics infrastructure in key economies such as Brazil and Mexico. Price sensitivity remains a defining factor, driving demand for cost-effective, medium-duty protectors for exports of agricultural products and manufactured goods.

- Middle East and Africa (MEA): Emerging market for edge protectors, primarily driven by large-scale construction projects (requiring heavy-duty protection) and developing port infrastructure. The demand is often sporadic but significant, focusing on specialized protectors resistant to high heat and humidity typical of the region's climate.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Cardboard Box Edge Protector Market.- Laminations (ITW)

- Sonoco Products

- Smurfit Kappa

- VPK Group

- DS Smith

- Pactiv Evergreen

- Kunert Group

- Litco International

- Eltete TPM

- Grifal SpA

- Edge Protection

- Cornerboard Inc.

- Protection Group

- Konishi Packaging

- Primapack SA

- Acme Packaging

- Shijiazhuang Liantong

- Mondi Group

- L.G.R. Packaging

- Packaging Strategies Inc.

Frequently Asked Questions

Analyze common user questions about the Cardboard Box Edge Protector market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the growth of the Cardboard Box Edge Protector Market?

The primary factor driving market growth is the exponential expansion of the global e-commerce sector, which necessitates secure and standardized protective packaging solutions to minimize product damage and ensure efficient transit in complex logistics environments.

How does the thickness of the edge protector impact its application and cost?

Thicker edge protectors (Above 10mm) provide higher compression strength and are utilized for heavy industrial applications (e.g., construction materials), resulting in a higher unit cost. Thinner protectors (3mm-6mm) are generally used for lighter loads and internal box reinforcement, prioritizing cost-efficiency and reduced weight.

Are cardboard box edge protectors considered sustainable or recyclable?

Yes, the vast majority of cardboard box edge protectors are made from multiple layers of recycled paperboard and fiber, making them highly sustainable and easily recyclable through existing paper waste streams, aligning with corporate environmental goals.

Which geographical region holds the largest market share for edge protectors?

North America and Europe currently hold the largest market shares due to advanced logistics infrastructure and high volumes of industrial manufacturing and trade, although the Asia Pacific region is projected to register the fastest growth rate in the forecast period.

What is the main role of AI in the future of the edge protector market?

AI's main role will be optimization, specifically using predictive analytics to determine the optimal size, strength, and quantity of edge protectors needed for specific shipments based on real-time and historical transit data, leading to reduced material waste and improved packaging efficiency.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager