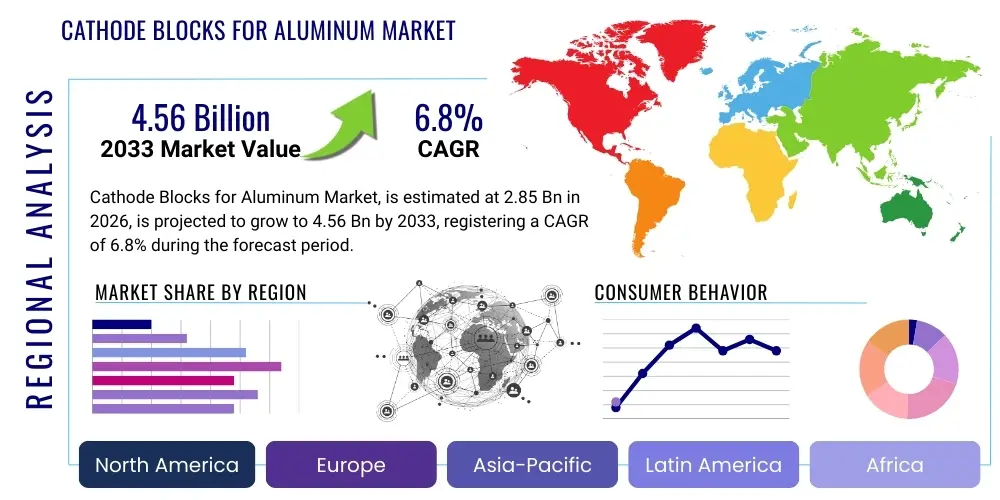

Cathode Blocks for Aluminum Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439597 | Date : Jan, 2026 | Pages : 257 | Region : Global | Publisher : MRU

Cathode Blocks for Aluminum Market Size

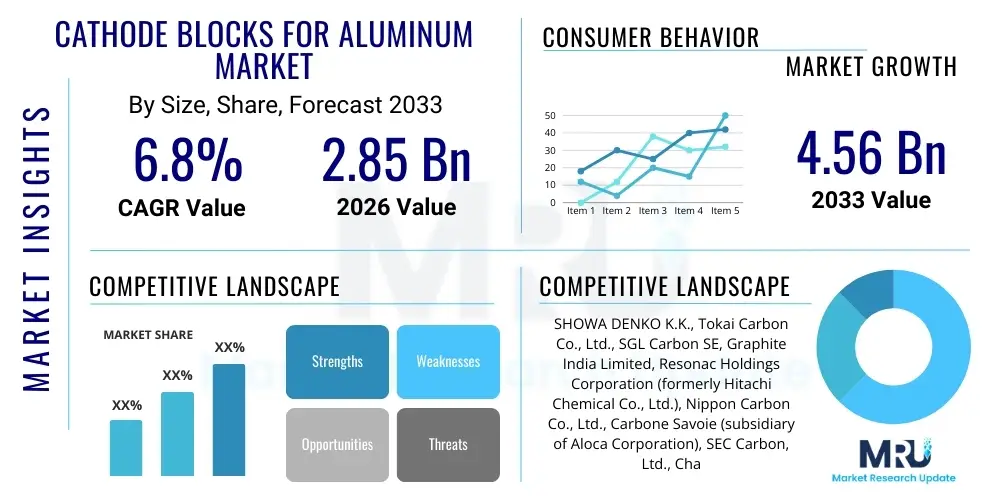

The Cathode Blocks for Aluminum Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 2.85 Billion in 2026 and is projected to reach USD 4.56 Billion by the end of the forecast period in 2033.

Cathode Blocks for Aluminum Market introduction

The Cathode Blocks for Aluminum Market plays a pivotal role in the global primary aluminum smelting industry, serving as critical components in electrolysis cells, often referred to as potlines. These blocks are manufactured from carbonaceous materials, primarily petroleum coke and coal tar pitch, and are engineered to withstand extreme thermal, chemical, and electrical stresses within reduction cells. Their primary function is to conduct electricity into the molten electrolyte (cryolite-alumina bath) and serve as the negative electrode where aluminum ions are reduced to molten aluminum metal. The quality, durability, and performance of cathode blocks directly impact the energy efficiency, productivity, and operational lifespan of aluminum smelters.

The product encompasses a range of specialized carbon materials, including graphitized, semi-graphitized, and amorphous carbon blocks, each offering distinct properties suited for various smelting processes and operational demands. Innovations in material science have led to the development of high-performance cathode blocks designed to minimize energy consumption and resist penetration by molten aluminum and electrolyte components, thereby extending cell life. Major applications are exclusively within primary aluminum production, forming the bottom lining of electrolytic cells where alumina is converted into aluminum.

Benefits derived from high-quality cathode blocks include enhanced energy efficiency, reduced maintenance downtime, extended cell life, and improved environmental performance through lower specific energy consumption. Driving factors for this market are intrinsically linked to the global demand for aluminum across diverse industries such as automotive, aerospace, construction, packaging, and electrical infrastructure. Furthermore, the increasing focus on energy efficiency in industrial processes, coupled with technological advancements aimed at improving smelter productivity and reducing operational costs, continues to fuel demand for advanced cathode block solutions.

Cathode Blocks for Aluminum Market Executive Summary

The Cathode Blocks for Aluminum Market is undergoing significant evolution, driven by a confluence of global economic shifts, technological advancements, and a heightened focus on sustainability within the aluminum industry. Key business trends indicate a strong emphasis on product innovation, with manufacturers investing heavily in R&D to develop cathode blocks that offer superior electrical conductivity, enhanced thermal shock resistance, and greater longevity. This push for higher performance is directly linked to smelters' continuous efforts to optimize energy consumption and reduce operational expenditure. Furthermore, market consolidation among cathode block producers is observed, as larger players leverage economies of scale and integrate vertically to secure raw material supplies and strengthen their market position. Strategic partnerships and collaborations between block manufacturers and aluminum producers are also becoming more prevalent, fostering co-development initiatives tailored to specific smelter requirements and emerging industry standards.

Regional trends reveal dynamic growth patterns, with the Asia Pacific region, particularly China, dominating both aluminum production and, consequently, cathode block consumption. This region benefits from robust industrial growth, extensive infrastructure development, and a large manufacturing base that drives significant demand for aluminum. In contrast, mature markets in North America and Europe exhibit stable demand, characterized by a focus on upgrading existing smelter capacities with more efficient and environmentally friendly cathode solutions, rather than significant new capacity additions. The Middle East and Africa (MEA) and Latin America are emerging as significant growth areas, driven by new smelter projects and expansion plans aimed at capitalizing on abundant energy resources and growing regional aluminum demand. These regions are attracting investment and technological transfer, contributing to the global shift in manufacturing landscapes.

Segment trends within the market highlight a continued preference for graphitized and semi-graphitized cathode blocks due to their superior electrical properties and resistance to corrosion, though innovations in amorphous and composite materials are gaining traction for niche applications. The demand for pre-baked cathode blocks remains dominant, given their established performance and widespread adoption. From an application perspective, primary aluminum smelting accounts for nearly all market activity, with little scope for secondary aluminum production to utilize these components. The market is also seeing a growing emphasis on "green" cathode block technologies that reduce carbon footprint during their manufacturing and improve the environmental profile of aluminum production. This includes exploring alternative binders and raw materials to minimize reliance on fossil-fuel derivatives, aligning with global decarbonization goals.

AI Impact Analysis on Cathode Blocks for Aluminum Market

The integration of Artificial Intelligence (AI) in the Cathode Blocks for Aluminum Market is poised to significantly transform various aspects of the industry, addressing common user questions related to efficiency, quality control, and predictive maintenance. Users are keenly interested in how AI can optimize the complex manufacturing processes of cathode blocks, reduce defects, and enhance material consistency, which directly impacts the performance and lifespan of these critical components in aluminum smelters. There's significant curiosity about AI's potential to drive down production costs through intelligent resource allocation and energy management, as well as its capacity to facilitate the development of novel materials with superior properties. Furthermore, smelter operators are exploring AI applications for real-time monitoring of cathode block performance within operational cells, aiming to predict failures, optimize maintenance schedules, and extend the overall potline efficiency. The overarching theme among user inquiries revolves around leveraging AI to achieve higher operational efficiency, enhanced product quality, and greater sustainability throughout the cathode block lifecycle and its end-use in aluminum production.

- AI-driven predictive maintenance optimizes the operational lifespan of cathode blocks within smelters by analyzing real-time performance data, preventing premature failures, and scheduling proactive replacements.

- Enhanced quality control during manufacturing through AI and machine learning algorithms identifies microscopic defects, ensuring consistent material properties and superior product reliability.

- Optimized raw material blending and formulation using AI models leads to more efficient use of resources, reducing waste and improving the specific characteristics of cathode blocks.

- AI algorithms contribute to process optimization in cathode block production, adjusting parameters such as baking temperature and compaction force to maximize output efficiency and minimize energy consumption.

- Development of advanced cathode materials is accelerated by AI, which can simulate material behaviors and predict optimal compositions for improved electrical conductivity, thermal shock resistance, and corrosion resistance.

- Supply chain optimization benefits from AI's ability to forecast demand accurately, manage inventory, and optimize logistics for raw materials (e.g., coke, pitch) and finished cathode blocks, enhancing market responsiveness.

- Environmental impact reduction is supported by AI in identifying opportunities for energy savings during manufacturing and by optimizing cell performance in smelters, leading to lower greenhouse gas emissions.

- AI-powered sensor networks within aluminum reduction cells can monitor the degradation patterns of cathode blocks, providing invaluable data for future design improvements and operational adjustments.

- Improved energy efficiency in aluminum smelting is achieved through AI models that fine-tune electrical current distribution across the cathode, reducing specific energy consumption per ton of aluminum produced.

- Remote monitoring and diagnostics capabilities are augmented by AI, allowing experts to assess cathode block health from anywhere, facilitating quicker decision-making and problem resolution.

- AI contributes to workforce safety by automating hazardous inspection tasks and predicting equipment malfunctions related to cathode blocks, reducing human exposure to risks.

DRO & Impact Forces Of Cathode Blocks for Aluminum Market

The Cathode Blocks for Aluminum Market is shaped by a complex interplay of Drivers, Restraints, and Opportunities, with various impact forces exerting influence on its trajectory. The primary driver is the inexorable growth in global aluminum demand, propelled by expanding industrialization, urbanization, and widespread application across key sectors such as automotive, construction, packaging, and electronics. As the world moves towards a greener economy, lightweight aluminum is increasingly favored in electric vehicles and sustainable infrastructure, directly fueling the need for efficient primary aluminum production, and consequently, high-quality cathode blocks. Additionally, the constant pressure on aluminum smelters to improve energy efficiency and reduce operational costs acts as a significant driver for innovation in cathode block technology, pushing manufacturers to develop more durable, conductive, and long-lasting solutions. Government policies supporting industrial growth and infrastructure projects in developing economies further stimulate this demand. The increasing focus on extending cell life and minimizing downtime in smelters also drives the adoption of premium cathode blocks.

However, the market faces several significant restraints. The high capital expenditure required for setting up and maintaining cathode block manufacturing facilities, coupled with the specialized technological know-how, creates substantial barriers to entry for new players. Volatility in raw material prices, particularly for petroleum coke and coal tar pitch, which are derivatives of the petrochemical industry, can significantly impact production costs and profit margins. Environmental regulations, especially those targeting carbon emissions from industrial processes, pose challenges for both cathode block manufacturers and aluminum smelters, necessitating investments in cleaner technologies and sustainable practices. The limited number of primary aluminum smelters globally means a concentrated customer base, which can lead to intense price competition among cathode block suppliers. Furthermore, the long replacement cycles of cathode blocks, typically several years, mean that demand is driven more by new smelter capacity additions and routine maintenance rather than rapid consumption.

Opportunities in this market are abundant for innovative and adaptable players. The development of advanced, high-performance cathode materials, including composite and carbon-nanostructure-enhanced blocks, presents avenues for superior product offerings that can command premium pricing. The growing emphasis on sustainable and eco-friendly manufacturing processes for cathode blocks, such as those utilizing recycled materials or alternative, lower-carbon binders, offers a competitive edge in a market increasingly sensitive to environmental concerns. Moreover, strategic collaborations and partnerships with leading aluminum producers can lead to co-development of customized solutions, securing long-term supply contracts and fostering technological leadership. Geographic expansion into emerging markets with planned smelter capacity expansions, particularly in regions like Southeast Asia, the Middle East, and Africa, also represents a significant growth opportunity. The market could also benefit from exploring digital solutions, such as AI and IoT, for optimized production, quality control, and predictive maintenance of cathode blocks throughout their lifecycle.

Impact forces such as the bargaining power of buyers (large aluminum smelters) are high due to the concentrated nature of the customer base, enabling them to exert pressure on pricing and quality. Conversely, the bargaining power of suppliers of critical raw materials (petroleum coke, pitch) is also significant, given the specialized nature and limited global supply, leading to potential cost pressures. The threat of new entrants is relatively low due to high capital requirements, technological expertise, and established relationships in the industry. The threat of substitutes is minimal as there is no viable alternative to carbon-based cathode blocks for aluminum electrolysis at present. Competitive rivalry within the market is moderate to high, driven by a few dominant players vying for market share through product differentiation, technological superiority, and cost efficiency. Environmental regulations and technological advancements continuously reshape the competitive landscape.

Segmentation Analysis

The Cathode Blocks for Aluminum Market is meticulously segmented to provide a granular understanding of its diverse components and drivers. This segmentation allows for precise market analysis, enabling stakeholders to identify specific growth opportunities, assess competitive landscapes, and formulate targeted strategies. The market is primarily segmented by type of material, which dictates the performance characteristics and cost structure of the blocks; by application, which overwhelmingly points to primary aluminum smelting; and by end-use industry, reflecting the ultimate consumers of the aluminum produced.

- By Type

- Graphitized Cathode Blocks: Characterized by high thermal and electrical conductivity, superior resistance to chemical attack, and longer service life due to their highly ordered graphitic structure.

- Semi-Graphitized Cathode Blocks: Offer a balance between the properties of amorphous and graphitized blocks, providing good performance at a more cost-effective point.

- Amorphous Cathode Blocks: Made from ungraphitized carbon, typically less conductive but robust, often used in specific cell designs or regions where cost is a primary consideration.

- Pre-baked Cathode Blocks: The predominant type, these blocks are fully baked and densified before installation in the reduction cell, ensuring stable performance from the outset.

- Carbon Composite Cathode Blocks: Emerging segment utilizing advanced materials and binding agents to enhance specific properties like erosion resistance or electrical conductivity.

- By Application

- Primary Aluminum Smelting: The sole significant application, where cathode blocks form the bottom lining of electrolytic cells for the Hall-Héroult process.

- By End-Use Industry

- Automotive: Lightweight aluminum is critical for fuel efficiency and electric vehicle components, driving demand for primary aluminum.

- Construction: Aluminum is extensively used in architectural applications, framing, and structural components due to its strength-to-weight ratio and corrosion resistance.

- Packaging: Aluminum cans and foils are widely used for food and beverage packaging, valued for their recyclability and barrier properties.

- Aerospace: High-strength, lightweight aluminum alloys are essential for aircraft structures and components.

- Electrical & Electronics: Aluminum is used in electrical conductors, heat sinks, and electronic casings due to its conductivity and thermal properties.

- Others: Includes machinery, consumer goods, and industrial equipment.

Value Chain Analysis For Cathode Blocks for Aluminum Market

The value chain for the Cathode Blocks for Aluminum Market is a complex and highly specialized ecosystem, beginning with the extraction and processing of raw materials and culminating in their integration into primary aluminum reduction cells. Upstream analysis involves a critical reliance on suppliers of high-purity carbonaceous materials, predominantly calcined petroleum coke (CPC) and coal tar pitch (CTP). CPC, derived from crude oil refining, and CTP, a byproduct of coal coking, form the fundamental building blocks of cathode materials. The quality and consistent supply of these raw materials are paramount, as they directly influence the final properties and performance of the cathode blocks. Suppliers in this segment often require significant capital investment in coking and calcination facilities, with adherence to stringent quality specifications being a key competitive differentiator. Other minor but important raw materials include anthracite, graphite scrap, and various additives, sourced from specialized chemical and material suppliers. Price volatility and geopolitical factors affecting crude oil and coal markets significantly impact the upstream segment, creating challenges for manufacturers in managing costs and ensuring supply security.

Midstream activities encompass the manufacturing process of the cathode blocks themselves. This involves multiple energy-intensive steps: raw material crushing and grinding, mixing with binders, compaction or pressing into green blocks, baking in specialized furnaces at extremely high temperatures (up to 1200-1300°C), and sometimes graphitization at even higher temperatures (up to 2800°C). Each stage requires precise control and specialized equipment to achieve the desired density, porosity, electrical conductivity, and mechanical strength. Manufacturers in this segment employ advanced material science and engineering expertise to optimize product performance for the demanding conditions of aluminum electrolysis. Quality control and assurance are critical at every step to meet the rigorous specifications set by aluminum smelters, as defects can lead to premature cell failure and significant financial losses for the end-user. Research and development efforts are concentrated on improving energy efficiency in production, enhancing material properties, and extending the lifespan of the blocks.

Downstream analysis focuses on the primary consumers of cathode blocks: aluminum smelters. These large-scale industrial facilities integrate the blocks into their electrolytic cells, where they function as the negative electrode for aluminum reduction. The efficiency and longevity of cathode blocks directly impact the smelter's operational costs, energy consumption, and environmental footprint. Distribution channels for cathode blocks are predominantly direct, given the specialized nature of the product, the high value of transactions, and the need for technical support and customization. Manufacturers often engage directly with aluminum producers, offering tailored solutions, technical consultancy, and after-sales service. Indirect channels, through distributors or agents, are less common but may be utilized for smaller regional smelters or for specific logistical arrangements. The relationship between cathode block manufacturers and aluminum smelters is often long-term and strategic, characterized by strong technical collaboration and a shared interest in optimizing aluminum production efficiency. This direct engagement ensures a robust feedback loop for continuous product improvement and adaptation to evolving smelter technologies and sustainability requirements.

Cathode Blocks for Aluminum Market Potential Customers

The primary and virtually exclusive potential customers for Cathode Blocks for Aluminum are the global primary aluminum producers and integrated aluminum companies. These entities operate large-scale aluminum reduction plants, commonly known as smelters, where the Hall-Héroult process is employed to convert alumina (aluminum oxide) into molten aluminum metal. Within these smelters, cathode blocks are indispensable components of the electrolytic cells (pots), forming the cathode lining that conducts electricity and serves as the site for the electrochemical reduction reaction. The demand for cathode blocks is therefore directly tied to the operational capacity, expansion plans, and maintenance schedules of these aluminum smelters worldwide. Companies such as Aluminum Corporation of China Limited (Chalco), Rio Tinto Alcan, Alcoa Corporation, Rusal, and Emirates Global Aluminium represent the core customer base, along with numerous other regional and national aluminum producers.

These customers are highly discerning, prioritizing several key factors when procuring cathode blocks. Performance characteristics such as electrical conductivity, thermal shock resistance, mechanical strength, and resistance to chemical corrosion by molten cryolite and aluminum are paramount. The longevity and reliability of cathode blocks directly impact the operational efficiency, energy consumption per ton of aluminum, and overall profitability of a smelter. Therefore, potential customers seek suppliers who can demonstrate consistent product quality, offer robust technical support, and provide solutions tailored to their specific cell designs and operational parameters. The initial investment in a potline is substantial, and the lifespan of cathode blocks is critical to maximizing that investment, making reliability a non-negotiable requirement. Furthermore, with increasing environmental regulations and a focus on sustainability, aluminum producers are also looking for cathode block manufacturers who can offer products with a lower carbon footprint in their production or those that contribute to more energy-efficient aluminum smelting processes.

The purchasing decisions of these potential customers are often driven by long-term supply agreements, technical partnerships, and the ability of suppliers to consistently deliver high-quality products on a global scale. Given the critical nature of cathode blocks to their core production process, aluminum smelters typically engage in rigorous qualification processes for potential suppliers. The relationship is often collaborative, involving joint research and development efforts to optimize block designs and material compositions for improved performance. The market is not characterized by a broad base of small buyers; rather, it is concentrated among a relatively small number of very large industrial entities that exert significant influence due to their purchasing power and the technical demands of their operations. Therefore, cathode block manufacturers must possess extensive industry experience, robust R&D capabilities, and strong customer service to succeed in this specialized market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 2.85 Billion |

| Market Forecast in 2033 | USD 4.56 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered |

|

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Cathode Blocks for Aluminum Market Key Technology Landscape

The Cathode Blocks for Aluminum Market is underpinned by a sophisticated array of technologies spanning material science, advanced manufacturing processes, and rigorous quality assurance protocols. At the core is the expertise in carbon technology, involving the precise selection and processing of raw materials like calcined petroleum coke and coal tar pitch. Key technological advancements in this domain focus on improving the purity, morphology, and particle size distribution of these carbon precursors, as even minor impurities can significantly impact the electrical conductivity and chemical resistance of the final product. Innovations include advanced calcination techniques to enhance crystalline structure and reduce volatile content, alongside optimized mixing and granulation technologies that ensure homogeneous distribution of binder within the carbon aggregate. These material engineering efforts are critical for achieving the desired density, mechanical strength, and pore structure necessary for long-lasting cathode blocks in the aggressive electrolytic environment of aluminum smelters.

Manufacturing processes leverage highly specialized equipment and methodologies to transform raw materials into high-performance cathode blocks. Key technologies here include high-pressure pressing or vibro-compacting techniques that achieve optimal green density and structural integrity before baking. The baking process itself, conducted in large ring furnaces or tunnel kilns, involves complex thermal profiles to slowly carbonize the binder and consolidate the block without cracking. Advanced furnace control systems, often incorporating predictive modeling and sensor-based feedback loops, are crucial for uniform temperature distribution and efficient energy utilization. For graphitized blocks, ultra-high temperature graphitization furnaces are employed, using technologies that can reach temperatures exceeding 2800°C to rearrange the carbon atoms into a highly ordered graphite lattice, significantly enhancing electrical and thermal conductivity. Continuous process monitoring using IoT devices and data analytics is increasingly being adopted to optimize production parameters, reduce energy consumption, and minimize waste.

Furthermore, the technology landscape includes innovations in cathode block design and composition aimed at improving specific performance characteristics. This encompasses the development of carbon composite blocks incorporating specialized additives or reinforcements to enhance erosion resistance, reduce sodium intercalation, or improve fracture toughness. Computational fluid dynamics (CFD) and finite element analysis (FEA) are utilized in the design phase to model thermal and electrical fields within the reduction cell, allowing for the optimization of cathode block geometry and connection configurations to maximize current efficiency and minimize energy losses. Non-destructive testing techniques, such as ultrasonic inspection and eddy current testing, are essential for quality control, detecting internal flaws or heterogeneities before blocks are shipped. Emerging technologies, such as AI and machine learning, are also being explored for predictive maintenance of manufacturing equipment, intelligent defect detection, and accelerating the R&D of next-generation cathode materials, signaling a future where data-driven insights will play an even more critical role in this highly technical market.

Regional Highlights

- Asia Pacific (APAC): Dominates the global Cathode Blocks for Aluminum Market, driven primarily by China's colossal primary aluminum production capacity. This region benefits from rapid industrialization, extensive infrastructure development, and burgeoning demand from automotive and construction sectors. Other significant contributors include India and countries in Southeast Asia, where new smelter projects and expansions are driving substantial demand. The region is characterized by both large-scale domestic production and significant import activity to support its vast aluminum industry. Innovation focuses on scaling up production efficiently while gradually improving environmental performance.

- Europe: Represents a mature but technologically advanced market. While new smelter capacity additions are limited, the emphasis is heavily on upgrading existing facilities with high-performance, energy-efficient, and sustainable cathode blocks. Strict environmental regulations and high energy costs drive innovation towards longer-lasting and more environmentally friendly solutions. Countries like Germany, France, and Norway, with established aluminum industries, continue to be key players, focusing on niche, high-value applications and advanced material research.

- North America: A stable market characterized by a focus on operational excellence, energy efficiency, and a drive towards reducing carbon footprint in aluminum production. The region's aluminum smelters prioritize sourcing high-quality cathode blocks that contribute to lower specific energy consumption and extended potline life. Investment in R&D for advanced carbon materials and process optimization is strong, with a push towards domestic sourcing where feasible. Canada, with its abundant hydropower, and the United States remain significant consumers.

- Middle East and Africa (MEA): Emerging as a major growth hub for primary aluminum production due to access to abundant and often low-cost energy resources. Countries such as UAE, Bahrain, Saudi Arabia, and Qatar have invested heavily in large-scale, modern aluminum smelters, making them significant consumers of cathode blocks. The market here is driven by new capacity additions and the continuous operation of highly efficient, state-of-the-art facilities. Strategic geographical location also supports exports to other regions.

- Latin America: Shows steady growth, with Brazil being a key player in aluminum production, supported by its bauxite reserves and energy resources. Other countries in the region are also contributing to the demand for cathode blocks through existing smelter operations and modest expansion projects. The market dynamics are influenced by regional economic stability and investment in industrial sectors. Focus is on maintaining competitive production costs and improving operational efficiency.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Cathode Blocks for Aluminum Market.- SHOWA DENKO K.K.

- Tokai Carbon Co., Ltd.

- SGL Carbon SE

- Graphite India Limited

- Resonac Holdings Corporation (formerly Hitachi Chemical Co., Ltd.)

- Nippon Carbon Co., Ltd.

- Carbone Savoie (subsidiary of Alcoa Corporation)

- SEC Carbon, Ltd.

- Chalco (Aluminum Corporation of China Limited)

- Puyang Lianzhong Carbon Co., Ltd.

- Fushun Carbon Co., Ltd.

- Liaoning Dashiqiao Shibo Carbon Co., Ltd.

- Jilin Carbon Co., Ltd.

- Inner Mongolia Xingye Carbon Co., Ltd.

- Envision AESC (a leading battery manufacturer, relevant for advanced carbon material expertise)

- Alu-Pro Srl

- ECL Carbon Technologies Co., Ltd.

- Mersen S.A.

- Graphtech International Ltd.

- Zhejiang Kaiyuan Carbon Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Cathode Blocks for Aluminum market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the projected growth rate for the Cathode Blocks for Aluminum Market?

The Cathode Blocks for Aluminum Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033, driven by increasing global aluminum demand and advancements in smelting technology. This steady growth reflects the critical and indispensable role of cathode blocks in primary aluminum production worldwide.

What are the main types of Cathode Blocks for Aluminum available in the market?

The primary types of Cathode Blocks for Aluminum include Graphitized, Semi-Graphitized, and Amorphous blocks, distinguished by their carbon structure and properties. Pre-baked cathode blocks are the most common manufacturing form, with Carbon Composite blocks representing an emerging category offering enhanced performance characteristics for specific applications.

Which factors are primarily driving the demand for Cathode Blocks for Aluminum?

Key drivers include the robust growth in global primary aluminum demand across industries like automotive, construction, and packaging. Additionally, the continuous industry-wide focus on improving energy efficiency, extending the lifespan of aluminum reduction cells, and reducing operational costs in smelters significantly fuels the demand for high-performance cathode blocks.

How does AI impact the Cathode Blocks for Aluminum Market?

AI significantly impacts the market by enhancing manufacturing quality control, optimizing raw material utilization, and improving process efficiency. Furthermore, AI-driven predictive maintenance for cathode blocks in smelters can extend their operational life and improve overall energy efficiency in aluminum production, leading to cost savings and reduced downtime.

What are the major challenges faced by manufacturers in this market?

Manufacturers face challenges such as high capital investment requirements, volatility in raw material prices (petroleum coke and coal tar pitch), and stringent environmental regulations concerning carbon emissions. The concentrated customer base of large aluminum smelters also exerts significant pressure on pricing and product specifications.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager