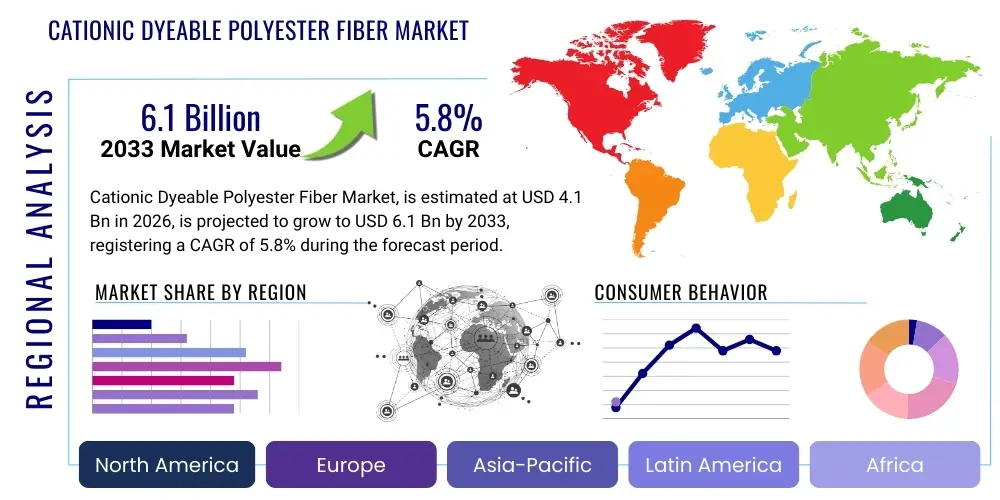

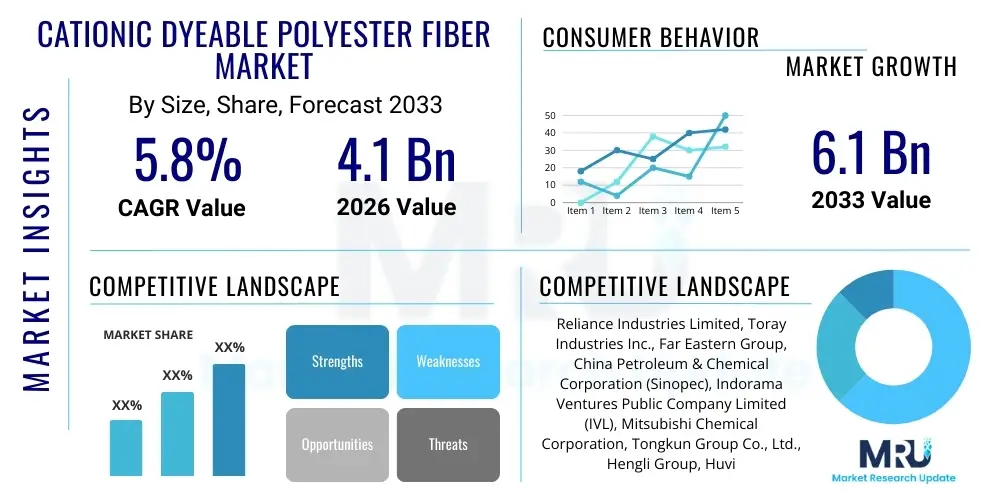

Cationic Dyeable Polyester Fiber Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 431422 | Date : Dec, 2025 | Pages : 257 | Region : Global | Publisher : MRU

Cationic Dyeable Polyester Fiber Market Size

The Cationic Dyeable Polyester Fiber Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 4.1 Billion in 2026 and is projected to reach USD 6.1 Billion by the end of the forecast period in 2033.

Cationic Dyeable Polyester Fiber Market introduction

The Cationic Dyeable Polyester (CDP) fiber market involves specialized synthetic fibers derived from polyethylene terephthalate (PET) modified during polymerization to incorporate sulfoisophthalate groups. These modifications introduce anionic sites that exhibit high affinity for cationic dyes, which are typically used for acrylic fibers. Standard polyester (PET) is non-dyeable with cationic dyes, requiring disperse dyes, which often results in lower color brilliance and poor deep shade reproducibility. CDP fibers overcome these limitations, offering improved dyeability, vibrant colors, and compatibility with low-temperature dyeing processes, leading to energy savings and reduced processing costs in the textile industry. The enhanced aesthetic appeal, particularly the deep, brilliant shades achievable, makes CDP fibers highly desirable in fashion and high-performance apparel sectors. Furthermore, CDP fibers often exhibit better moisture management properties compared to conventional polyester, enhancing wearer comfort in sportswear and intimate wear applications. This versatility drives their growing adoption across various end-use industries, including textiles, home furnishings, and automotive fabrics.

The core product characteristic of CDP is its chemical structure, which allows it to be cross-dyed with regular polyester and other fabrics (like nylon or cotton) in the same dyebath, enabling multi-color effects in a single step without the need for complex and separate dyeing procedures. This unique feature substantially streamlines manufacturing processes, reducing time and material waste. Major applications include high-end apparel, such functional outdoor wear, casual clothing, and professional uniforms, where colorfastness and durability are critical. The inherent cost-effectiveness of polyester coupled with the aesthetic benefits imparted by cationic dyeability positions CDP as a premium, yet economically viable, alternative to natural fibers or complex dyeing routes for standard PET. The market's growth is fundamentally driven by the escalating demand for high-performance textiles that offer both visual appeal and superior functional properties like resilience and chemical resistance, particularly in developing economies experiencing rapid urbanization and increased discretionary spending on textiles.

Cationic Dyeable Polyester Fiber Market Executive Summary

The global Cationic Dyeable Polyester Fiber market is characterized by robust growth, primarily fueled by shifting consumer preferences toward synthetic textiles that offer enhanced color vibrancy, superior functional performance, and environmental processing advantages, particularly energy efficiency in dyeing. Key business trends indicate a strong focus on capacity expansion and vertical integration by major Asian manufacturers, aiming to capitalize on the sustained demand from the fast-fashion and technical textile segments. Innovation in bi-component and multi-functional CDP fibers is a crucial strategic area, allowing manufacturers to cater to niche markets requiring specialized properties, such as flame retardancy or enhanced UV protection. Furthermore, sustainable practices, including the development of recycled CDP fibers and low-impact dyeing auxiliaries, are gaining prominence as regulatory pressures increase and consumer awareness of textile sustainability grows, defining the competitive landscape and influencing partnership formation between fiber producers and large textile mills globally.

Regional trends highlight the Asia Pacific region, specifically China and India, as the dominant consumer and producer due to massive manufacturing bases for textiles and cost-effective production capabilities, coupled with substantial domestic demand for apparel. North America and Europe, while representing mature markets, focus heavily on premium CDP products used in sportswear, automotive interiors, and specialized industrial textiles, emphasizing technological differentiation and compliance with stringent performance standards. Segment trends reveal that the apparel sector remains the largest application, driven by the fiber’s aesthetic properties and cost structure, while the industrial and home furnishing segments are showing accelerated growth due to the superior resilience and ease of maintenance offered by CDP fibers. Fiber manufacturers are increasingly specializing in dope-dyed CDP to meet rising demand for superior color consistency and reduced water usage, streamlining the supply chain and enhancing the overall value proposition of the end-product.

AI Impact Analysis on Cationic Dyeable Polyester Fiber Market

User inquiries regarding AI's influence on the Cationic Dyeable Polyester Fiber market frequently center on operational efficiency, supply chain resilience, and the potential for AI-driven textile design innovation. Consumers and industry stakeholders are keen to understand how artificial intelligence can optimize the complex spinning and dyeing processes unique to CDP, especially regarding color matching accuracy, minimizing waste, and predicting fiber quality fluctuations caused by raw material variability. Key concerns revolve around the initial investment required for integrating sophisticated AI and machine learning systems into existing legacy manufacturing plants and the need for specialized data scientists in a traditionally manufacturing-heavy sector. Expectations are high that AI will lead to predictive maintenance, radically reducing unplanned downtime, and enabling 'smart factories' that can dynamically adjust production parameters—such as temperature, tension, and chemical feed rates—to ensure optimal molecular structure for cationic dye uptake, thereby maximizing yields and maintaining consistent fiber quality across large production batches, fundamentally reshaping quality control methodologies.

- AI-driven optimization of polymerization kinetics and fiber spinning parameters to maximize cationic dye uptake efficiency and molecular uniformity.

- Predictive maintenance analytics for high-speed texturing and drawing machinery, reducing downtime and operational costs in CDP fiber production lines.

- Implementation of machine vision systems for automated, real-time quality control, instantly detecting minor imperfections or variations in fiber luster and denier.

- Enhanced supply chain forecasting and inventory management using deep learning algorithms to predict textile mill demand for specific CDP types and titers.

- Development of AI tools for simulating and predicting the final color outcome and fastness properties of CDP fabrics before large-scale dyeing, reducing material waste and sampling time.

DRO & Impact Forces Of Cationic Dyeable Polyester Fiber Market

The Cationic Dyeable Polyester Fiber market is significantly influenced by a dynamic interplay of drivers, restraints, and opportunities, collectively forming critical impact forces. A primary driver is the accelerating consumer demand for vibrant, deep colors and cross-dyeing capabilities in performance textiles, especially in the booming athletic and athleisure wear segments where aesthetics and functionality must coexist. Additionally, the fiber’s ability to be dyed at lower temperatures compared to standard polyester reduces energy consumption and shortens dyeing cycle times, providing a substantial economic incentive for textile manufacturers facing increasing energy costs and environmental regulations. The opportunity landscape is robust, centered on integrating CDP fibers into novel textile structures, such as microfibers and recycled blends, expanding their usage beyond traditional apparel into advanced composites and filtration media, while also exploring penetration into high-value specialized protective clothing markets demanding superior color retention after repeated cleaning cycles.

However, the market faces notable restraints, including the complex chemical modification process required for polymerization, which leads to higher production costs compared to conventional PET, potentially limiting adoption in extremely price-sensitive commodity textile markets. Furthermore, the specialized nature of cationic dyes requires specific handling and effluent treatment protocols, which can pose environmental challenges, particularly in regions with less stringent waste management infrastructure. The impact forces driving market evolution include intense global competition, particularly from large-scale Asian manufacturers who leverage economies of scale, putting pressure on pricing and technological innovation. The industry must navigate the countervailing forces of sustainability demands, pushing for eco-friendly CDP production, against the technical complexities inherent in maintaining quality and consistent performance while utilizing recycled feedstocks, which require continuous research and development to overcome molecular degradation issues during recycling and subsequent modification for dyeability.

- Drivers: Growing demand for vibrant and deep-colored textiles; energy savings through low-temperature dyeing processes; versatility in cross-dyeing with other fiber types; expansion of the high-performance and athleisure apparel markets.

- Restraints: Higher production cost compared to standard polyester; reliance on specialized raw materials (sulfoisophthalate compounds); potential effluent management issues related to specialized cationic dyes; market saturation in basic apparel applications.

- Opportunities: Development of recycled and sustainable CDP variants; increasing application in automotive textiles and home furnishings; potential for smart textile integration; leveraging bi-component fiber technology for enhanced performance characteristics.

- Impact Forces: Intense competition driving price reduction and technological innovation; tightening global environmental regulations promoting low-impact dyeing; consumer demand for sustainable and high-durability products; fluctuating petrochemical raw material prices impacting manufacturing costs.

Segmentation Analysis

The Cationic Dyeable Polyester Fiber market is segmented primarily based on product type, end-use application, and distribution channel, providing a multifaceted view of market dynamics and specialized demand pockets. Segmentation by product type typically differentiates between the fineness of the fiber, such as staple fiber and filament fiber. Filament CDP fibers, valued for their strength, uniformity, and luster, dominate high-end applications like fashion apparel and specialty industrial fabrics. Staple fibers, being easier to blend with natural fibers like cotton or wool, find extensive use in weaving, knitting, and non-woven applications, particularly for items requiring bulk, softness, and natural aesthetics. This foundational distinction reflects varying manufacturing complexities and target performance characteristics, allowing producers to tailor their product offerings to specific textile industry requirements and processing capabilities, ensuring optimal performance across a spectrum of final products.

The end-use application segment is critical in defining market value, with textiles and apparel consistently holding the largest share due to the consumer-facing benefits of CDP, including superior color aesthetics and durability. However, non-apparel applications, such as home textiles (drapery, upholstery), automotive fabrics (seat covers, interior linings), and industrial uses (ropes, belts, filtration), are exhibiting faster growth trajectories, driven by the need for materials that offer high resilience and colorfastness under harsh conditions. The geographical segmentation underscores the pivotal role of Asian economies in manufacturing and consumption, contrasting with the high-value, niche demand originating from established markets in North America and Europe. Comprehensive segmentation analysis provides a strategic roadmap for market players to prioritize investment in high-growth segments, optimize supply chain logistics based on regional demand concentration, and adapt product specifications to meet the rigorous performance standards specific to the target end-use sector.

- By Product Type:

- Filament Fiber (Fully Drawn Yarn (FDY), Drawn Textured Yarn (DTY), Partially Oriented Yarn (POY))

- Staple Fiber

- Microfiber

- By Application:

- Apparel and Textile (Knitting, Weaving)

- Home Furnishings (Upholstery, Carpets, Drapery)

- Automotive Textiles (Interior Trims, Seat Covers)

- Industrial and Technical Textiles (Ropes, Filtration, Geotextiles)

- By Grade:

- Standard CDP (Easy Dyeable)

- Deep Dyeable CDP

- Cationic Dyeable Low-Shrinkage Fiber

- By Region:

- North America (U.S., Canada, Mexico)

- Europe (Germany, U.K., France, Italy, Spain, Rest of Europe)

- Asia Pacific (China, India, Japan, South Korea, Southeast Asia, Rest of APAC)

- Latin America (Brazil, Argentina, Rest of Latin America)

- Middle East and Africa (UAE, Saudi Arabia, South Africa, Rest of MEA)

Value Chain Analysis For Cationic Dyeable Polyester Fiber Market

The value chain for Cationic Dyeable Polyester Fiber is complex, beginning with the upstream segment involving the synthesis of specialized raw materials. This stage focuses on the production of Purified Terephthalic Acid (PTA) and Ethylene Glycol (EG), the primary precursors for standard PET, alongside the crucial intermediate chemical, such as Dimethyl 5-Sulfoisophthalate (DMSIP) or its derivatives, which imparts the cationic dyeability characteristic. Upstream suppliers hold significant leverage as the quality and consistent availability of these specialized modifying agents directly impact the physical and chemical properties of the resulting CDP fiber. Efficient sourcing and stable pricing of these petrochemical derivatives are essential for maintaining competitive manufacturing costs. Research and development activities at this stage focus on enhancing the stability and efficiency of the modification process during polymerization, ensuring high-quality output before the material proceeds to fiber extrusion.

The middle segment involves the core manufacturing process: polymerization, spinning, and post-processing (drawing, texturing). Fiber producers transform the raw materials into various CDP formats—filament, staple, or microfiber. The efficiency of distribution channels is vital; direct sales models are common for large volume orders to major textile mills and integrated garment manufacturers, facilitating customization and technical support. Indirect channels, involving agents, distributors, and trading houses, typically serve smaller mills or handle international trade logistics. The downstream segment encompasses the textile mills, garment manufacturers, and end-use application industries. These buyers utilize the CDP fibers for weaving, knitting, and garment production. The final product reaches the consumer through various retail channels, including departmental stores, specialized apparel retailers, and rapidly growing e-commerce platforms. The overall value chain emphasizes vertical collaboration, particularly between fiber producers and large textile dyeing houses, to ensure precise control over dyeing compatibility and color matching, ultimately benefiting the end consumer with a superior, vibrantly colored product.

Cationic Dyeable Polyester Fiber Market Potential Customers

The primary customers for Cationic Dyeable Polyester Fiber are large-scale textile manufacturers, integrated apparel companies, and specialized technical textile producers seeking advanced materials for high-performance applications. Textile mills are key buyers because CDP fibers allow them to achieve multi-color patterns and deep, brilliant shades through efficient cross-dyeing processes, significantly reducing production time and resource consumption compared to piece dyeing using standard polyester. These customers value the fiber for its improved dye fastness, resilience, and its ability to blend seamlessly with other natural and synthetic fibers, enabling the creation of complex and aesthetically appealing fabrics that cater to the demanding fashion market and technical specifications for protective wear.

Beyond traditional apparel, potential customers include manufacturers focused on home furnishings, particularly those producing high-end upholstery, carpets, and window treatments where color retention under UV exposure and durability are paramount. The automotive sector represents a rapidly growing customer base, requiring CDP fibers for interior fabrics (e.g., seat covers and door panels) that need superior resistance to fading, abrasion, and harsh cleaning agents while maintaining vibrant, consistent color palettes throughout the vehicle’s lifespan. Furthermore, industrial textile companies utilizing non-woven and technical fabrics for filtration, geotextiles, and specialized webbing are increasingly adopting CDP due to its consistent quality and ability to handle specialized industrial dyeing processes, ensuring high performance in demanding, long-life applications.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 4.1 Billion |

| Market Forecast in 2033 | USD 6.1 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Reliance Industries Limited, Toray Industries Inc., Far Eastern Group, China Petroleum & Chemical Corporation (Sinopec), Indorama Ventures Public Company Limited (IVL), Mitsubishi Chemical Corporation, Tongkun Group Co., Ltd., Hengli Group, Huvis Corporation, Trelleborg AB, Xiamen Xiangyu Group, Zhejiang Guxiandao Industrial Fiber Co., Ltd., Bombay Dyeing and Manufacturing Company Limited, Sateri (RGE Group), DAK Americas (Alpek), Teijin Limited, Alok Industries Limited, JBF Industries Ltd., W. L. Gore & Associates, Kairui Fiber Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Cationic Dyeable Polyester Fiber Market Key Technology Landscape

The technological landscape for Cationic Dyeable Polyester (CDP) fiber production is centered on advanced chemical modification techniques during the polymerization and spinning stages to ensure consistent quality and maximum dye uptake. Key technologies involve the controlled co-polymerization of standard PET precursors (PTA and EG) with anionic monomers, typically sodium 5-sulfoisophthalate (NaSIP) or its derivatives, which introduce the necessary sulfonated groups. Precision metering and mixing technologies are crucial at the melt stage to ensure the modifier is uniformly incorporated into the polymer backbone without causing molecular weight degradation or inconsistent fiber cross-sections. Furthermore, high-speed spinning and sophisticated drawing technologies are employed to align the polymer chains, optimize crystallization, and enhance the physical properties—such as tenacity and elongation—while preserving the integrity of the chemically modified structure, which is vital for the final textile processing.

A significant technological focus is placed on enhancing the functionality of CDP through bi-component spinning and composite fiber formation. Bi-component technology allows for the creation of fibers with a CDP core and a standard PET sheath (or vice versa), which facilitates differential shrinkage, creating novel textures and improved handling characteristics in textiles. Advances in dope dyeing (solution dyeing) technology, where the color pigment is added directly to the polymer melt before spinning, are also critical. This process reduces the reliance on traditional dyeing houses, conserves water, and delivers superior color fastness compared to conventional post-dyeing methods, aligning with global sustainability mandates and the rising demand for high-durability, fade-resistant products in automotive and outdoor applications. Continuous process automation, driven by sensor technology and process control software, is standard practice to maintain the tight tolerance required for specialty fiber manufacturing.

Regional Highlights

The Cationic Dyeable Polyester Fiber market exhibits distinct regional dynamics, with Asia Pacific (APAC) maintaining its undisputed leadership position in terms of both production capacity and consumption volume. This dominance is attributed to the presence of the world’s largest textile and garment manufacturing hubs in countries like China, India, Vietnam, and South Korea, which benefit from favorable government policies, abundant labor, and established infrastructure for large-scale fiber production. The region’s burgeoning middle class also fuels domestic demand for modern, aesthetically appealing textiles and apparel, driving consumption of CDP fibers for fashion and functional wear. Strategic investments in new fiber technologies and vertical integration across the supply chain—from petrochemicals to finished garments—further solidify APAC’s market concentration and competitive edge, allowing regional players to dictate global pricing and supply trends.

North America and Europe represent mature, high-value markets characterized by demand for premium, specialized CDP products, often integrated into high-performance technical textiles, luxury fashion, and stringent automotive applications. In these regions, growth is less driven by volume and more by innovation, focusing on sustainable CDP variants, advanced microfiber technologies, and fibers engineered for specific functionalities like moisture-wicking or microbial resistance. European manufacturers prioritize compliance with strict environmental regulations, spurring demand for eco-friendly dyeing solutions and recycled feedstocks, thus promoting research into bio-based and sustainable CDP synthesis. The Middle East and Africa (MEA) and Latin America (LATAM) markets, while smaller, offer promising growth trajectories, particularly in industrial textiles and regional apparel manufacturing, as these economies modernize their textile sectors and increase their participation in global supply chains, presenting significant opportunities for targeted market expansion and technology transfer.

- Asia Pacific (APAC): Dominates the market due to expansive textile manufacturing bases, low operational costs, and significant domestic demand from China, India, and Southeast Asian nations. APAC is the primary global exporter and innovator in high-volume CDP production, focusing heavily on filament yarn for apparel.

- Europe: Characterized by high environmental standards and demand for high-quality, niche products, particularly in specialized technical textiles and high-fashion segments. Growth is driven by the shift towards sustainable, low-impact dyeing methods and compliance with REACH regulations.

- North America: A significant consumer, driven by the massive sportswear, athleisure, and automotive sectors. Focuses on premium CDP applications, emphasizing innovation in functional properties like enhanced wicking and durability, often sourcing specialized fibers from global suppliers.

- Latin America (LATAM): Emerging market with increasing industrialization in Brazil and Mexico, driving localized demand for CDP in technical textiles, uniforms, and casual wear. Market growth is sensitive to macroeconomic stability and foreign direct investment in textile infrastructure.

- Middle East and Africa (MEA): Growth is primarily concentrated in industrial applications, protective wear, and domestic textile production in countries like Turkey and the UAE. Focuses on imported fibers but is gradually developing localized production capabilities, particularly in non-woven and durable textile sectors.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Cationic Dyeable Polyester Fiber Market.- Reliance Industries Limited

- Toray Industries Inc.

- Far Eastern Group

- China Petroleum & Chemical Corporation (Sinopec)

- Indorama Ventures Public Company Limited (IVL)

- Mitsubishi Chemical Corporation

- Tongkun Group Co., Ltd.

- Hengli Group

- Huvis Corporation

- Trelleborg AB

- Xiamen Xiangyu Group

- Zhejiang Guxiandao Industrial Fiber Co., Ltd.

- Bombay Dyeing and Manufacturing Company Limited

- Sateri (RGE Group)

- DAK Americas (Alpek)

- Teijin Limited

- Alok Industries Limited

- JBF Industries Ltd.

- W. L. Gore & Associates

- Kairui Fiber Co., Ltd.

Frequently Asked Questions

Analyze common user questions about the Cationic Dyeable Polyester Fiber market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary chemical and functional differences between Cationic Dyeable Polyester (CDP) and standard Polyester (PET)?

Standard PET has a non-ionic structure and requires high-temperature dyeing with disperse dyes. CDP is chemically modified during polymerization by incorporating anionic sulfoisophthalate groups, creating reactive sites that attract cationic dyes. This modification allows CDP to achieve deeper, more brilliant colors at lower dyeing temperatures, leading to significant energy and cost savings in textile processing.

How does the use of CDP fiber contribute to sustainability in the textile industry?

CDP enhances sustainability primarily through energy efficiency. Its ability to be dyed at lower temperatures (around 100-110°C compared to 130°C for PET) reduces energy consumption during dyeing. Furthermore, CDP enables single-bath cross-dyeing with other fiber types, simplifying complex processes, reducing water consumption, and decreasing the use of multiple dyeing chemicals.

Which end-use application segments are expected to drive the fastest growth in the CDP fiber market through 2033?

The fastest growth is anticipated in the automotive textiles and performance/athleisure apparel segments. Automotive interiors require materials with high colorfastness, abrasion resistance, and aesthetic appeal, characteristics perfectly matched by CDP. The athleisure sector values CDP for its vibrant color capabilities and suitability for blending with wicking fibers, meeting the demand for functional and fashionable sportswear.

What technological challenges are currently restraining widespread adoption of Cationic Dyeable Polyester?

The main challenges include the specialized and often higher cost of raw material precursors (like NaSIP) compared to standard PET ingredients, leading to increased fiber production costs. Additionally, maintaining chemical consistency and quality control during the complex co-polymerization process remains a technical hurdle, requiring advanced process monitoring and specialized manufacturing expertise to ensure optimal dyeability.

How do fluctuations in petrochemical prices affect the cost and supply chain of Cationic Dyeable Polyester fiber?

CDP fiber production relies heavily on petrochemical derivatives like PTA and EG, whose costs are volatile. Price increases in these upstream raw materials directly inflate the manufacturing cost of CDP, impacting pricing strategies for fiber producers. Given that specialized modifiers are also petrochemical-derived, price instability requires robust risk management in the supply chain to maintain competitive pricing for downstream textile buyers.

This report contains 29681 characters including spaces.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager