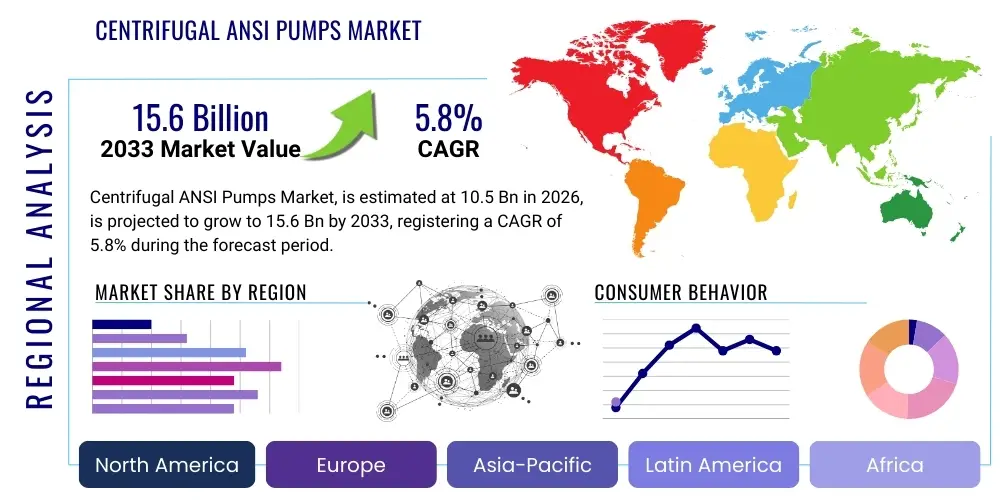

Centrifugal ANSI Pumps Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440048 | Date : Jan, 2026 | Pages : 245 | Region : Global | Publisher : MRU

Centrifugal ANSI Pumps Market Size

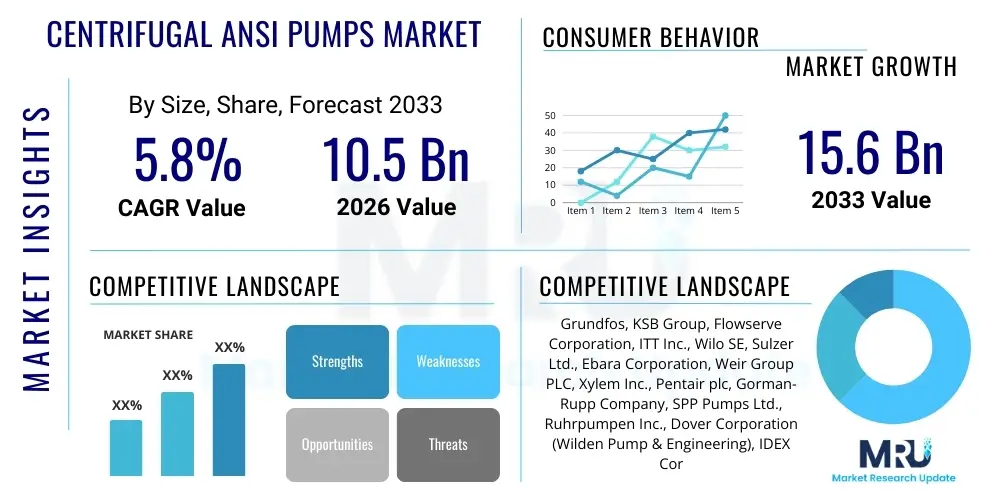

The Centrifugal ANSI Pumps Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 10.5 billion in 2026 and is projected to reach USD 15.6 billion by the end of the forecast period in 2033.

Centrifugal ANSI Pumps Market introduction

The Centrifugal ANSI Pumps Market encompasses a vital segment of industrial fluid handling, characterized by pumps designed and manufactured to adhere strictly to the dimensional and performance standards set by the American National Standards Institute (ANSI) / American Society of Mechanical Engineers (ASME) B73.1. These pumps are robust, reliable, and predominantly used for transferring a wide array of liquids in demanding industrial environments, ranging from water and chemicals to slurries and corrosive substances. Their standardized design ensures interchangeability between different manufacturers' pumps, simplifying maintenance and reducing operational complexities for end-users globally. The product's inherent reliability and ease of integration into existing systems make it a preferred choice across various sectors requiring consistent and efficient fluid transfer operations.

Major applications for Centrifugal ANSI Pumps span across critical industries such as chemical processing, where they handle acids, bases, and solvents; petrochemical and oil & gas, for crude oil, refined products, and various process fluids; and pulp & paper manufacturing, managing slurries and pulps. They are also indispensable in water and wastewater treatment plants for moving large volumes of water and effluents, food & beverage processing for hygienic liquid transfer, and pharmaceutical production for precise chemical dosing and utility services. The primary benefits driving their adoption include high operational efficiency, exceptional durability, lower total cost of ownership due to standardization, and reduced downtime because of easy parts replacement. These factors collectively contribute to their sustained demand in capital-intensive industries where operational continuity and safety are paramount.

Key driving factors propelling the Centrifugal ANSI Pumps Market include rapid industrialization and infrastructure development, particularly in emerging economies, which fuels the demand for new installations and system upgrades. The expansion of chemical manufacturing facilities and the increasing complexity of chemical processes necessitate reliable and standardized pumping solutions. Furthermore, the growing focus on energy efficiency and environmental compliance worldwide encourages industries to replace older, less efficient pump systems with modern ANSI-compliant models that offer improved performance and reduced energy consumption. The robust replacement market, driven by the lifecycle of existing industrial equipment and the continuous need for facility modernization, also plays a significant role in sustaining market growth. These dynamics underscore the enduring relevance and critical role of Centrifugal ANSI Pumps in global industrial operations.

Centrifugal ANSI Pumps Market Executive Summary

The Centrifugal ANSI Pumps Market is currently navigating a dynamic landscape characterized by several key business trends. Manufacturers are increasingly focusing on incorporating smart technologies such as IoT sensors and predictive analytics capabilities into their pump designs, enhancing operational efficiency and enabling proactive maintenance strategies. This shift towards intelligent pumping solutions aims to minimize downtime, optimize energy consumption, and provide real-time performance data. Furthermore, there's a notable trend towards customization and specialized material construction to meet the unique demands of highly corrosive, abrasive, or high-temperature applications, particularly in the chemical and petrochemical industries. Supply chain resilience and localization efforts are also gaining traction, driven by recent global disruptions, leading to a re-evaluation of manufacturing and distribution networks to ensure consistent product availability and reduced lead times. Strategic mergers and acquisitions continue to reshape the competitive landscape, as companies seek to expand their product portfolios, technological capabilities, and geographical reach, consolidating market share and fostering innovation.

Regionally, the market exhibits varied growth patterns and drivers. Asia Pacific remains the fastest-growing region, fueled by extensive industrialization, significant infrastructure investments, and a burgeoning chemical manufacturing sector, particularly in countries like China and India. This region benefits from both new project installations and an expanding base of existing industries requiring upgrades. North America and Europe, while more mature markets, demonstrate steady demand driven primarily by replacement cycles, stringent environmental regulations necessitating upgrades to more efficient systems, and the ongoing modernization of industrial facilities. These regions also lead in the adoption of advanced pumping technologies and digitalization initiatives. Latin America, the Middle East, and Africa are emerging as promising markets, propelled by growth in the oil & gas, mining, and water infrastructure sectors. However, these regions often face challenges related to economic volatility and infrastructure development, which can impact the pace of market expansion.

Segmentation trends within the Centrifugal ANSI Pumps Market highlight shifts in demand across different product types and applications. The segment for pumps constructed from exotic alloys and specialized non-metallic materials is experiencing robust growth due to increasing requirements from industries handling aggressive chemicals and corrosive fluids, where standard materials are inadequate. This reflects a broader industry move towards extending equipment lifespan and improving process safety. Application-wise, the chemical processing industry continues to be a dominant consumer, but the water and wastewater treatment sector is also showing significant growth, driven by global efforts to enhance water infrastructure and improve sanitation. Moreover, there's a discernible trend towards pumps with higher energy efficiency ratings, prompted by rising energy costs and environmental mandates, influencing purchasing decisions across all end-user industries. This collective evolution across business trends, regional dynamics, and segmentation reflects a market that is both mature in its core offering and innovative in its adaptation to modern industrial demands.

AI Impact Analysis on Centrifugal ANSI Pumps Market

The integration of Artificial intelligence (AI) is poised to significantly transform the Centrifugal ANSI Pumps market, primarily by enhancing operational efficiency, revolutionizing maintenance practices, and optimizing the entire lifecycle of these critical industrial assets. Users are particularly interested in how AI can extend pump lifespan, minimize unexpected breakdowns, and contribute to more sustainable and energy-efficient operations. The widespread adoption of AI-driven solutions is expected to reduce the total cost of ownership by enabling predictive maintenance, where algorithms analyze sensor data to anticipate potential failures before they occur, thus scheduling maintenance proactively rather than reactively. This shift not only prevents costly downtime but also optimizes resource allocation for maintenance activities, ensuring pumps operate at peak performance for longer periods. Additionally, AI is influencing design and manufacturing processes, with generative design tools exploring optimal pump geometries for improved efficiency and smart manufacturing systems monitoring production lines for quality control and process optimization.

The transformative power of AI extends to real-time operational optimization, where intelligent algorithms can adjust pump parameters based on varying fluid properties, flow rates, and energy costs, ensuring maximum efficiency under diverse operating conditions. This capability is particularly valuable in dynamic industrial environments where process requirements frequently change. Users are also keen to understand how AI can facilitate better decision-making through comprehensive data analysis, turning vast amounts of operational data into actionable insights for facility managers and engineers. This includes identifying anomalous behavior, optimizing system configurations, and even forecasting future demand for spare parts. The ability of AI to create 'digital twins' of physical pumps allows for virtual testing, simulation of various scenarios, and continuous monitoring, providing a holistic view of the pump's health and performance without physically impacting the operational unit.

- Predictive Maintenance: AI algorithms analyze sensor data (vibration, temperature, pressure) to forecast equipment failures, reducing unplanned downtime and maintenance costs by up to 30%.

- Operational Optimization: Real-time AI adjustments to pump speed and flow rates based on demand, fluid properties, and energy tariffs, leading to significant energy savings (5-15%).

- Generative Design: AI assists engineers in designing more efficient impellers, casings, and other components by exploring thousands of design iterations to meet specific performance criteria and material constraints.

- Smart Manufacturing: AI-powered vision systems and robotics enhance quality control during pump production, detect defects early, and optimize assembly processes, improving product consistency.

- Supply Chain Optimization: AI predicts demand for spare parts, optimizes inventory levels, and streamlines logistics for pump components, enhancing responsiveness and reducing carrying costs.

- Digital Twins: Creation of virtual models of pumps that continuously receive real-time data, allowing for simulations, performance monitoring, and fault diagnosis without interrupting operations.

- Energy Efficiency Management: AI systems identify patterns in energy consumption and suggest operational changes or maintenance interventions to maximize energy efficiency and reduce carbon footprint.

- Remote Monitoring and Control: AI-enabled platforms allow for remote oversight and control of pump operations, particularly beneficial for geographically dispersed installations or hazardous environments.

DRO & Impact Forces Of Centrifugal ANSI Pumps Market

The Centrifugal ANSI Pumps Market is significantly influenced by a complex interplay of drivers, restraints, opportunities, and external impact forces that collectively shape its growth trajectory and competitive landscape. Key drivers include robust industrial growth, particularly in developing economies, leading to increased demand for new pump installations and system expansions across sectors like chemical processing, oil & gas, and water infrastructure. The global push for energy efficiency and sustainable operations also acts as a powerful driver, compelling industries to upgrade to modern, high-efficiency ANSI-compliant pumps to reduce operational costs and environmental impact. Furthermore, the inherent standardization of ANSI pumps ensures interchangeability and ease of maintenance, making them a preferred choice for industries seeking reliability and reduced downtime, which consistently fuels replacement demand. Stringent environmental regulations in developed regions, mandating safer and more efficient fluid handling, also stimulate market expansion.

However, several restraints challenge market growth. The high initial capital investment required for Centrifugal ANSI Pumps, especially those made from specialized materials for corrosive applications, can deter smaller enterprises or projects with limited budgets. Intense competition from non-ANSI standard pumps, which may offer lower upfront costs or custom solutions for niche applications, presents a significant alternative. Volatility in raw material prices, particularly for metals like stainless steel and specialized alloys, directly impacts manufacturing costs and can lead to price fluctuations, affecting market stability. Additionally, global economic slowdowns, trade protectionism, and geopolitical uncertainties can lead to reduced industrial investments, directly impacting demand for new pumps and facility upgrades. The long operational lifespan of existing pumps also sometimes delays replacement cycles, posing another restraint to consistent new sales.

Despite these restraints, numerous opportunities exist for market expansion. The growing adoption of smart pump technologies, integrating IoT and AI for predictive maintenance and operational optimization, presents a significant growth avenue, allowing manufacturers to offer higher-value solutions. Expanding into emerging economies, where industrialization is still in its nascent stages, offers substantial untapped potential for new installations. Moreover, the increasing demand for customized solutions tailored for specific, challenging fluid applications—such as highly abrasive slurries or extremely high-temperature processes—opens doors for innovation in material science and engineering. The market also benefits from opportunities in retrofitting existing industrial facilities with more efficient and digitally integrated ANSI pump systems to meet evolving regulatory standards and achieve sustainability goals. Technological advancements and environmental concerns serve as continuous impact forces, driving innovation towards more efficient, durable, and environmentally friendly pump designs, ensuring the market's long-term relevance and evolution.

Segmentation Analysis

The Centrifugal ANSI Pumps Market is intricately segmented across various parameters, allowing for a granular understanding of demand patterns, technological preferences, and regional dynamics. This segmentation helps identify specific market niches and growth opportunities within the broader industrial pump landscape. Key segmentation criteria include the type of material used for pump construction, which dictates suitability for different fluid types and operating conditions; the application areas, reflecting the diverse industrial processes where these pumps are deployed; and the end-user industries, which highlights the primary economic sectors driving demand. Understanding these segments is crucial for manufacturers to tailor their product offerings, marketing strategies, and R&D efforts to meet the specific requirements of various customer groups, optimizing market penetration and competitive positioning. Each segment represents a unique set of challenges and opportunities, influencing design considerations, pricing strategies, and distribution channels.

- By Material

- Cast Iron

- Stainless Steel

- Ductile Iron

- Exotic Alloys (e.g., Hastelloy, Titanium)

- Non-Metallic (e.g., FRP, PVDF)

- By Application

- Chemical Processing

- Oil & Gas

- Pulp & Paper

- Water & Wastewater Treatment

- Food & Beverage

- Pharmaceuticals

- Power Generation

- Mining

- General Industrial

- By End-User Industry

- Manufacturing

- Utilities

- Infrastructure

- Commercial

- By Capacity

- Small Capacity (Up to 200 GPM)

- Medium Capacity (201 - 1000 GPM)

- Large Capacity (Above 1000 GPM)

- By Type

- Single Stage

- Multi-Stage

Value Chain Analysis For Centrifugal ANSI Pumps Market

The value chain for the Centrifugal ANSI Pumps Market begins with a robust upstream analysis, focusing on the sourcing and processing of essential raw materials and components. This segment involves suppliers of high-quality metals such as cast iron, stainless steel, and specialized alloys like Hastelloy and titanium, which are critical for manufacturing pump casings, impellers, and shafts to withstand corrosive and abrasive fluids. Additionally, it includes manufacturers of crucial ancillary components such as mechanical seals, bearings, motors, and couplings. The efficiency and quality of these upstream suppliers directly impact the final product's performance, durability, and cost-effectiveness. Relationships with these suppliers are often long-term, built on trust, quality assurance, and consistent delivery, as any disruption or compromise in component quality can have significant downstream effects on pump manufacturing and reliability. Innovation in material science, particularly in developing more resistant and lighter materials, is a key focus area in this upstream segment.

Moving downstream, the value chain encompasses the manufacturing, assembly, distribution, and end-user adoption phases. After the procurement of raw materials and components, manufacturers engage in precision machining, casting, welding, and assembly processes to construct the Centrifugal ANSI Pumps according to stringent ANSI/ASME B73.1 standards. This stage often involves advanced manufacturing techniques, quality control checks, and performance testing to ensure compliance and reliability. The distribution channel then plays a pivotal role in connecting manufacturers with a diverse range of industrial end-users. This typically involves a mix of direct sales channels for large, complex projects and strategic partnerships with authorized distributors, wholesalers, and system integrators who possess regional expertise and provide localized support, warehousing, and often, value-added services like installation and commissioning. The effectiveness of this distribution network is crucial for market reach and customer service responsiveness.

Both direct and indirect distribution strategies are employed within the market. Direct sales are often preferred for highly specialized or large-scale industrial projects where manufacturers can offer tailored engineering solutions, direct technical support, and comprehensive project management. This approach allows for closer client relationships and deeper understanding of specific application requirements. In contrast, indirect distribution channels, through a network of distributors and resellers, are vital for reaching a broader customer base, particularly small to medium-sized enterprises (SMEs), and for providing off-the-shelf standard ANSI pump models and spare parts. These indirect partners often provide initial sales, post-sales support, and essential maintenance services, acting as the primary point of contact for many end-users. The blend of direct and indirect channels ensures broad market coverage, efficient logistics, and varied customer support, optimizing market penetration and responsiveness across different customer segments and geographical regions.

Centrifugal ANSI Pumps Market Potential Customers

The Centrifugal ANSI Pumps Market caters to a wide spectrum of potential customers across various heavy and light industrial sectors, all requiring reliable and efficient fluid transfer solutions that adhere to standardized performance and dimensional specifications. The primary end-users and buyers of these products are industries that depend on continuous and safe operations for handling a diverse range of liquids, often under challenging conditions involving corrosive chemicals, abrasive slurries, high temperatures, or volatile substances. These customers prioritize durability, maintainability, and the ability to minimize downtime, making the standardized and robust design of ANSI pumps particularly appealing. Their purchasing decisions are often influenced by the total cost of ownership, including initial capital outlay, energy efficiency, maintenance costs, and the availability of readily interchangeable spare parts, which is a hallmark benefit of ANSI-compliant designs.

Key sectors representing significant potential customers include the chemical processing industry, where pumps are essential for transferring acids, bases, solvents, and other reactive compounds in manufacturing processes. Petrochemical and oil & gas facilities are major consumers, utilizing ANSI pumps for crude oil transfer, refining processes, and wastewater management within their operations. Pulp & paper mills rely on these pumps for handling fibrous slurries and various process liquors. Furthermore, municipal and industrial water and wastewater treatment plants constitute a substantial customer base, needing robust pumps for moving large volumes of water, sludge, and effluents. Pharmaceutical companies use them for utility applications and specific chemical transfers, while the food & beverage industry employs them for utility services and certain non-hygienic process applications where material compatibility is crucial. Power generation plants, particularly those using fossil fuels or nuclear energy, also represent critical customers for cooling water circulation and other auxiliary services.

Beyond these core industrial applications, other significant potential customers include mining operations for dewatering and slurry transportation, general manufacturing facilities for cooling systems and process fluid handling, and various utility services. The demand from these end-users is often cyclical, tied to global economic conditions, commodity prices, and infrastructure spending. However, the continuous need for replacement of aging equipment, coupled with expansions in industrial capacity globally, ensures a sustained demand base. Moreover, the increasing adoption of smart technologies within these industries means that customers are increasingly seeking not just pumps, but integrated pumping solutions that offer advanced monitoring, predictive maintenance capabilities, and higher energy efficiency, thereby evolving the customer profile to one that values technological innovation alongside traditional reliability and standardization.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 10.5 billion |

| Market Forecast in 2033 | USD 15.6 billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces | >|

| Segments Covered | >|

| Key Companies Covered | Grundfos, KSB Group, Flowserve Corporation, ITT Inc., Wilo SE, Sulzer Ltd., Ebara Corporation, Weir Group PLC, Xylem Inc., Pentair plc, Gorman-Rupp Company, SPP Pumps Ltd., Ruhrpumpen Inc., Dover Corporation (Wilden Pump & Engineering), IDEX Corporation, Tsurumi Manufacturing Co., Ltd., Franklin Electric Co., Inc., Seepex GmbH, Gardner Denver (Ingersoll Rand), All-Flo Pump Co. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Centrifugal ANSI Pumps Market Key Technology Landscape

The Centrifugal ANSI Pumps Market is undergoing a significant transformation driven by advancements in digital and material technologies, moving beyond traditional mechanical designs to incorporate smart and integrated solutions. A primary technological focus involves the integration of Internet of Things (IoT) sensors and connectivity into pump systems. These sensors collect real-time data on critical operational parameters such as vibration, temperature, pressure, flow rate, and power consumption. This data is then transmitted to cloud-based platforms for analysis, enabling predictive maintenance strategies and real-time performance monitoring. The shift from reactive to proactive maintenance minimizes unplanned downtime, extends pump lifespan, and significantly reduces overall operational costs, providing a substantial return on investment for end-users and enhancing the reliability of industrial processes. Furthermore, the adoption of variable frequency drives (VFDs) is becoming standard, optimizing pump speed and energy consumption based on actual process demand, leading to considerable energy savings and a reduced environmental footprint, aligning with global sustainability goals.

Another crucial aspect of the evolving technology landscape is the development and application of advanced materials. While traditional materials like cast iron and stainless steel remain prevalent, there is an increasing demand for pumps made from exotic alloys (e.g., Hastelloy, Titanium, Duplex Stainless Steel) and high-performance non-metallic composites (e.g., FRP, PVDF, PFA). These materials offer superior resistance to highly corrosive chemicals, extreme temperatures, and abrasive slurries, extending the operational envelope of ANSI pumps into more challenging and specialized applications within the chemical, petrochemical, and mining industries. Furthermore, additive manufacturing, or 3D printing, is gaining traction for producing complex pump components, such as impellers and casings, with intricate geometries that were previously difficult or impossible to achieve with conventional manufacturing methods. This technology enables rapid prototyping, cost-effective customization, and the creation of parts with optimized hydraulic performance, enhancing efficiency and reducing material waste.

The rise of digital twins and advanced analytics platforms is also revolutionizing the way Centrifugal ANSI Pumps are managed and optimized. Digital twins are virtual replicas of physical pumps that continuously receive real-time data, allowing engineers to simulate various operating scenarios, predict potential failures, and optimize performance without impacting actual operations. This capability is invaluable for complex industrial facilities seeking to maximize asset utilization and minimize risks. Coupled with sophisticated predictive analytics, these digital tools can identify subtle performance deviations, diagnose root causes of issues, and recommend corrective actions before they escalate. The integration of artificial intelligence (AI) and machine learning (ML) algorithms further enhances these platforms, enabling autonomous optimization, anomaly detection, and advanced fault diagnostics. These technologies collectively contribute to a more intelligent, efficient, and sustainable Centrifugal ANSI Pumps market, addressing the growing industry demand for higher reliability, lower lifecycle costs, and enhanced environmental performance.

Regional Highlights

- North America: This region represents a mature market for Centrifugal ANSI Pumps, characterized by steady demand driven primarily by the replacement and upgrade of aging infrastructure, stringent environmental regulations, and the robust chemical processing, oil & gas, and manufacturing sectors. The focus is heavily on efficiency, reliability, and the integration of smart technologies.

- Europe: Similar to North America, Europe is a mature market with a strong emphasis on energy efficiency, environmental compliance (such as REACH regulations), and advanced manufacturing practices. Demand is fueled by upgrades to meet strict regulatory standards and investments in industries like chemicals, pharmaceuticals, and water treatment.

- Asia Pacific (APAC): APAC is the fastest-growing market globally, propelled by rapid industrialization, massive infrastructure development projects, and expanding chemical and petrochemical industries in countries like China, India, and Southeast Asia. The region benefits from both new installations and increasing modernization efforts across various sectors.

- Latin America: This region shows significant potential due to its rich natural resources, leading to demand from the mining, oil & gas, and agriculture sectors. Infrastructure development and increasing investments in water and wastewater management also contribute to market growth, though economic volatility can influence the pace of expansion.

- Middle East & Africa (MEA): The MEA region's demand is largely driven by large-scale oil & gas projects, substantial investments in water management and desalination plants, and industrial diversification initiatives. Countries in the GCC region, in particular, are investing heavily in industrial and infrastructure development, boosting pump demand.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Centrifugal ANSI Pumps Market.- Grundfos

- KSB Group

- Flowserve Corporation

- ITT Inc.

- Wilo SE

- Sulzer Ltd.

- Ebara Corporation

- Weir Group PLC

- Xylem Inc.

- Pentair plc

- Gorman-Rupp Company

- SPP Pumps Ltd.

- Ruhrpumpen Inc.

- Dover Corporation (Wilden Pump & Engineering)

- IDEX Corporation

- Tsurumi Manufacturing Co., Ltd.

- Franklin Electric Co., Inc.

- Seepex GmbH

- Gardner Denver (Ingersoll Rand)

- All-Flo Pump Co.

Frequently Asked Questions

What defines a Centrifugal ANSI Pump?

A Centrifugal ANSI Pump is a type of pump that conforms to the American National Standards Institute (ANSI) / American Society of Mechanical Engineers (ASME) B73.1 standard, which specifies dimensional interchangeability, hydraulic performance, and material specifications for chemical process pumps. This standardization ensures parts from different manufacturers are interchangeable.

Why are Centrifugal ANSI Pumps preferred in industrial applications?

ANSI pumps are highly favored in industrial settings due to their standardized design, ensuring interchangeability of parts and easy maintenance. They offer high reliability, robustness for handling diverse fluids, excellent operational efficiency, and a lower total cost of ownership over their lifespan, minimizing downtime in critical processes.

Which industries are the primary users of Centrifugal ANSI Pumps?

The primary industries utilizing Centrifugal ANSI Pumps include chemical processing, petrochemical and oil & gas, pulp & paper, water and wastewater treatment, pharmaceuticals, and food & beverage. They are essential for transferring a wide range of liquids, often corrosive or abrasive, within these demanding industrial environments.

How does technological advancement impact the efficiency of ANSI pumps?

Technological advancements, particularly the integration of IoT sensors, variable frequency drives (VFDs), and AI-driven predictive analytics, significantly enhance ANSI pump efficiency. These innovations enable real-time monitoring, optimized operation based on demand, and proactive maintenance, leading to reduced energy consumption and prolonged operational life.

What are the key drivers for growth in the Centrifugal ANSI Pumps market?

Key growth drivers include global industrialization, increasing infrastructure development, the expansion of chemical and petrochemical industries, and growing emphasis on energy efficiency and environmental compliance. The ongoing need for replacement and upgrade of existing industrial equipment also contributes significantly to market expansion.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager