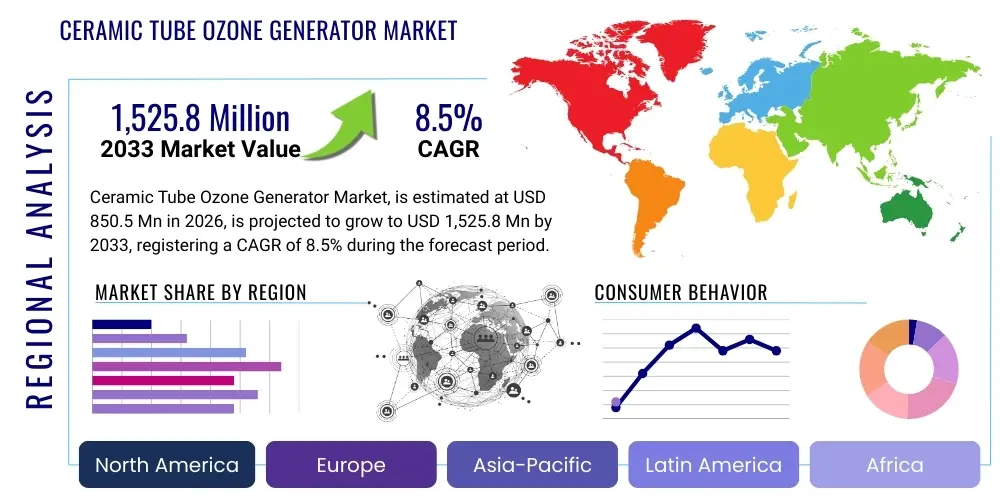

Ceramic Tube Ozone Generator Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436476 | Date : Dec, 2025 | Pages : 249 | Region : Global | Publisher : MRU

Ceramic Tube Ozone Generator Market Size

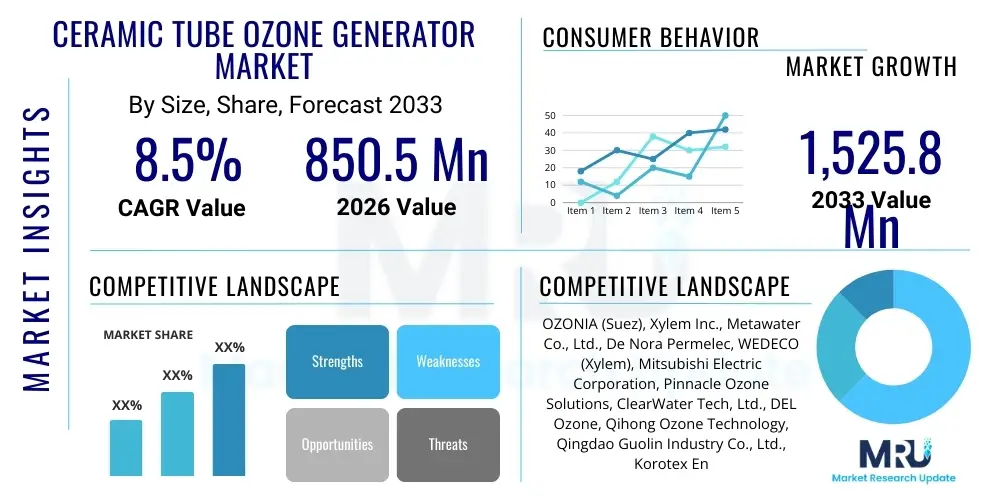

The Ceramic Tube Ozone Generator Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at $850.5 Million in 2026 and is projected to reach $1,525.8 Million by the end of the forecast period in 2033.

Ceramic Tube Ozone Generator Market introduction

The Ceramic Tube Ozone Generator Market encompasses the manufacturing, distribution, and utilization of devices designed to produce ozone (O3) gas using ceramic dielectric barrier discharge (DBD) technology. These generators rely on high-ppurity ceramic materials, known for their superior heat resistance and dielectric properties, which significantly enhance ozone output efficiency and system longevity compared to traditional glass or stainless steel counterparts. Ceramic tube generators are primarily favored in industrial and commercial applications requiring reliable, high-concentration ozone production, offering robust performance in demanding environments.

Product Description: Ceramic tube ozone generators utilize a silent electrical discharge, typically a dielectric barrier discharge (DBD) cell, where oxygen or air is passed through a gap between a high-voltage electrode and a ground electrode, separated by a ceramic dielectric material (the tube). This high-voltage discharge splits the oxygen molecules (O2) into atomic oxygen (O), which then recombines with O2 to form ozone (O3). The inherent stability and thermal management capabilities of ceramic components ensure minimized ozone decay and increased power efficiency, making them ideal for sustained, high-volume ozone generation required in large-scale sanitation and purification processes.

Major applications of these high-efficiency generators include municipal drinking water treatment, advanced industrial wastewater remediation, medical sterilization, agricultural disinfection, and extensive air purification systems in commercial buildings. The superior performance attributes, such as low maintenance requirements, resistance to chemical corrosion, and high conversion rates of oxygen to ozone, are the principal driving factors compelling their widespread adoption across highly regulated sectors globally. Furthermore, the rising awareness regarding environmental safety and the necessity for chemical-free disinfection alternatives are bolstering market expansion.

Ceramic Tube Ozone Generator Market Executive Summary

The global Ceramic Tube Ozone Generator Market is experiencing robust growth driven by stringent environmental regulations, particularly concerning wastewater discharge and public health standards. Current business trends indicate a strong industry focus on miniaturization, enhanced energy efficiency, and the integration of smart monitoring systems to improve operational control and reduce overall power consumption, which is traditionally a major operational cost for ozone systems. Furthermore, manufacturers are increasingly developing modular designs, allowing end-users across diverse sectors—from aquaculture to pulp and paper—to scale ozone generation capacity precisely according to fluctuating demands. The competitive landscape is characterized by established purification technology firms and specialized ozone equipment providers vying for market share through patented ceramic material compositions and sophisticated power supply designs capable of maintaining stable discharge under variable load conditions.

Regional trends highlight the Asia Pacific (APAC) as the fastest-growing market, largely fueled by rapid industrialization, massive infrastructure investment in water and sewage treatment facilities in developing economies like China and India, and pervasive air quality concerns. North America and Europe maintain dominance in terms of technological adoption and market maturity, driven by stringent regulatory frameworks (e.g., EPA and EU Water Framework Directive) that mandate advanced oxidation processes (AOPs) like ozonation for the removal of emerging contaminants, pharmaceuticals, and micropollutants from municipal supplies. The Middle East and Africa (MEA) are also showing promising growth, primarily concentrated around petrochemical refining and desalinization projects where high-purity water is essential, necessitating reliable disinfection methods.

In terms of segmentation, the high-power output segment (above 100 g/h) is projected to command the largest market share due to escalating requirements from large-scale industrial and municipal water treatment plants seeking robust solutions for bulk water disinfection and contaminant destruction. Conversely, the low-to-medium power segment is witnessing significant expansion within the commercial air purification and food and beverage processing sectors, reflecting the growing application of ozonation as a residue-free sanitizing agent. The ceramic dielectric technology segment, specifically, is replacing older glass tube technology owing to its superior thermal management and reduced risk of cracking, ensuring longer operational lifecycles and consistent ozone output quality, which is critical for maintaining regulatory compliance.

AI Impact Analysis on Ceramic Tube Ozone Generator Market

User queries regarding the intersection of Artificial Intelligence (AI) and the Ceramic Tube Ozone Generator Market frequently center on predictive maintenance capabilities, optimization of energy consumption relative to real-time disinfection needs, and the integration of smart sensors for continuous performance monitoring. Users are primarily concerned with how AI algorithms can minimize downtime, extend the lifespan of expensive ceramic components, and dynamically adjust high-frequency power inputs to maximize ozone yield while minimizing electricity usage based on fluctuating water quality metrics or atmospheric contaminant levels. The overarching expectation is that AI will transform these traditionally reactive systems into proactive, highly efficient assets, thereby improving the economic viability and operational reliability of large-scale ozonation installations.

- AI-driven Predictive Maintenance: Utilizing machine learning algorithms to analyze real-time operational data (voltage, temperature, flow rate, ozone concentration) to predict potential failure of ceramic tubes or power supplies before catastrophic malfunction occurs.

- Dynamic Dosage Optimization: Employing AI to correlate input parameters (e.g., water quality indices like TOC, pH, turbidity) with desired ozone output, ensuring optimal dosage for disinfection or oxidation without wastage, leading to substantial chemical and energy savings.

- Energy Efficiency Management: AI systems adjusting the frequency and voltage of the DBD power supply in real-time to maintain target ozone concentration using the least amount of electrical power, maximizing specific energy yield (g O3/kWh).

- Remote Monitoring and Control: Implementation of cloud-based AI platforms for remote diagnostics, performance benchmarking, and autonomous corrective adjustments, significantly reducing the need for on-site technician intervention.

- Supply Chain Optimization: Using AI to forecast demand for high-purity ceramic components and specialized power electronics, ensuring timely stocking and reducing lead times for generator manufacturing and repair.

- Automated Compliance Reporting: Generating automated, detailed operational reports validated by AI analysis, streamlining regulatory compliance procedures for water treatment and industrial facilities.

DRO & Impact Forces Of Ceramic Tube Ozone Generator Market

The Ceramic Tube Ozone Generator Market is profoundly shaped by a combination of strong regulatory drivers, technological advancements, and inherent system limitations. The primary driving force is the global imperative for stringent water quality standards and the resulting shift away from traditional chlorination towards advanced oxidation processes (AOPs) to eliminate recalcitrant micropollutants, which ozone is highly effective at destroying. However, market growth is significantly restrained by the high initial capital investment required for high-capacity ceramic systems and the substantial energy consumption associated with the dielectric barrier discharge process. These restraints often limit adoption in smaller municipalities or enterprises with constrained operational budgets, despite the long-term cost benefits. Nonetheless, the burgeoning opportunity lies in the expanding adoption of ozonation within emerging sectors such as controlled environment agriculture (CEA), extensive food preservation logistics, and pharmaceutical manufacturing, all of which require residue-free, highly reliable sterilization methods. These fundamental market forces collectively determine the pace and direction of technological innovation and market penetration across geographic regions.

Specifically, regulatory mandates are pushing industrial sectors, particularly textiles, pharmaceuticals, and pulp and paper, to implement tertiary treatment steps that utilize ozone for color removal and reduction of chemical oxygen demand (COD) before effluent discharge, providing a continuous tailwind for market demand. Furthermore, growing public awareness regarding the harmful disinfection byproducts (DBPs) generated by chlorine, such as trihalomethanes (THMs), is accelerating the substitution of chlorine with ozone in municipal settings, offering significant health and safety benefits. The impact forces acting on this market include intensifying competitive pressures from alternative disinfection technologies, such as UV irradiation and electrochemical oxidation, which constantly push manufacturers to improve the power efficiency and longevity of ceramic dielectric materials. Furthermore, geopolitical stability and trade policies impacting the supply of rare earth elements and specialized ceramic precursor materials also exert a powerful influence on manufacturing costs and lead times for high-performance ozone systems.

Segmentation Analysis

The Ceramic Tube Ozone Generator Market is systematically segmented based on technological specifications, operational capacity, and application sector, allowing for a detailed analysis of specialized demand curves and targeted technological development. The core segmentation by capacity (low, medium, and high output) directly correlates with the scale of the required purification task, differentiating between small-scale commercial use and large municipal or heavy industrial applications. Further segmentation by application is crucial, highlighting the distinct requirements of sectors such as drinking water treatment, industrial effluent remediation, and food safety, where regulatory requirements and contaminant profiles vary significantly. The continued evolution of the market is defined by continuous innovation in ceramic material composition (e.g., alumina, zirconia) to enhance dielectric strength and cooling efficiency, thereby improving the overall generator performance profile.

- By Capacity/Output (g/h):

- Low Output (< 10 g/h): Primarily used in laboratory settings, small commercial air purifiers, and localized point-of-use water systems.

- Medium Output (10 g/h to 100 g/h): Common in commercial laundries, small-to-medium scale food processing, swimming pool disinfection, and bottled water plants.

- High Output (> 100 g/h): Dominant in municipal drinking water treatment, industrial wastewater treatment, large aquaculture facilities, and chemical manufacturing processes.

- By Feed Gas Type:

- Air-fed Ozone Generators: Suitable for lower concentration needs and applications where complexity and cost must be minimized.

- Oxygen-fed Ozone Generators: Used for high-concentration ozone requirements in critical applications, maximizing efficiency and output purity.

- By Application:

- Water Treatment (Municipal, Industrial Wastewater, Process Water, Desalination Post-treatment).

- Air Treatment (HVAC systems, Odor control, Indoor air quality remediation).

- Food & Beverage (Sanitization of processing equipment, Bottled water production, Cold storage disinfection).

- Medical & Pharmaceutical (Sterilization of equipment, Water for injection (WFI) systems).

- Aquaculture and Agriculture (Fish health management, Crop irrigation water disinfection).

- By End-User Industry:

- Municipal Authorities.

- Manufacturing (Textiles, Chemical, Pulp & Paper).

- Healthcare & Hospitality.

- Food Processing & Agriculture.

Value Chain Analysis For Ceramic Tube Ozone Generator Market

The value chain for the Ceramic Tube Ozone Generator Market commences with the upstream supply of specialized, high-purity raw materials. This includes sophisticated ceramic powders (such as alumina and quartz) necessary for manufacturing the dielectric tubes, high-frequency power semiconductors (IGBTs, MOSFETs) for the power supply units, and precision-machined stainless steel for the housing and reactor assembly. Upstream profitability is often dictated by the ability to secure consistent supplies of these high-specification materials, which demand highly specialized manufacturing expertise and rigorous quality control to ensure uniform dielectric constants and mechanical strength necessary for reliable operation under high-voltage conditions. Manufacturers must maintain strategic relationships with specialized material suppliers to manage risks associated with material scarcity and price volatility, particularly for electronic components.

The midstream involves the core manufacturing process, where integration capabilities are paramount. This stage involves the precision assembly of the ceramic tubes within the ozone reactor housing and the crucial development and integration of the power supply system, which must be precisely matched to the dielectric load of the ceramic tube to optimize ozone generation efficiency. The manufacturing focus is heavily weighted toward achieving maximum specific energy efficiency (g O3/kWh) and thermal management within the reactor cell, often requiring specialized cooling systems (water or air). Differentiation at this stage relies heavily on intellectual property related to electrode design, ceramic coating techniques, and proprietary power electronics control algorithms that govern the dielectric barrier discharge process.

Downstream analysis covers distribution channels and end-user engagement, which are categorized into direct and indirect sales models. Direct sales are common for large-scale municipal or industrial projects, typically involving specialized engineering firms or Environmental, Procurement, and Construction (EPC) contractors who integrate the generator into complex treatment systems. Indirect channels involve regional distributors and value-added resellers (VARs) who cater to small-to-medium enterprises (SMEs) and commercial applications, providing localized installation, maintenance, and system support. The effectiveness of the downstream segment is determined by the quality of after-sales support, spare parts availability (especially ceramic tubes and power modules), and rapid response times for maintenance, given the critical nature of disinfection processes in most applications. Customer relationships are heavily dependent on demonstrated reliability and operational lifespan guarantees.

Ceramic Tube Ozone Generator Market Potential Customers

The primary customers for Ceramic Tube Ozone Generators span a wide array of industries that necessitate high-level, environmentally friendly sterilization and oxidation capabilities. The largest segment of buyers consists of governmental and municipal authorities responsible for public infrastructure, particularly large-scale drinking water treatment plants and wastewater management facilities. These buyers require high-output, continuous-duty generators that offer superior reliability and comply with strict national and international water quality standards, especially concerning the removal of emerging contaminants and pharmaceutical residues. These organizations prioritize system longevity, operational efficiency, and low total cost of ownership (TCO) over the 15-20 year lifespan of the infrastructure.

Another significant customer base resides within the industrial manufacturing sector, including chemical processing plants, textile mills requiring robust color removal from effluent, and pulp and paper companies using ozone for bleaching processes, reducing reliance on chlorine derivatives. In these environments, the generator serves as a vital component in meeting mandated discharge regulations and optimizing industrial processes. These customers emphasize the generator's ability to handle high concentrations of complex organic loads and maintain performance consistency despite variations in inflow quality and operational temperature, leveraging the superior thermal resistance of ceramic components.

The third major segment includes the food and beverage industry, pharmaceutical companies, and the hospitality sector. Food processors utilize ceramic tube generators for sanitizing processing equipment, air, and rinse water, ensuring food safety without leaving chemical residues (as ozone quickly decays back to oxygen). Pharmaceutical manufacturers rely on these generators for producing high-purity water (WFI) and sterilizing cleanrooms, where zero-residue disinfection is critical. These potential customers seek compact, highly reliable systems that meet rigorous GMP (Good Manufacturing Practice) standards and provide precise, measurable ozone dosages for sensitive applications, ensuring regulatory adherence and product integrity.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $850.5 Million |

| Market Forecast in 2033 | $1,525.8 Million |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | OZONIA (Suez), Xylem Inc., Metawater Co., Ltd., De Nora Permelec, WEDECO (Xylem), Mitsubishi Electric Corporation, Pinnacle Ozone Solutions, ClearWater Tech, Ltd., DEL Ozone, Qihong Ozone Technology, Qingdao Guolin Industry Co., Ltd., Korotex Environmental Science Co., Ltd., TTO, Toshiba Corporation, Ebara Corporation, Pacific Ozone Technology, MKS Instruments, Primozone, Teledyne API, Hessaire Products. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Ceramic Tube Ozone Generator Market Key Technology Landscape

The technological landscape of the Ceramic Tube Ozone Generator Market is primarily defined by continuous advancements in dielectric materials, power supply optimization, and thermal management systems, all aimed at enhancing the specific energy yield (SEY) of the ozonation process. The use of high-purity ceramic materials, typically sintered alumina or quartz derivatives, is central, offering superior thermal stability and higher dielectric constants compared to traditional borosilicate glass, allowing for operation at higher frequencies and voltages without thermal degradation. This advancement facilitates more compact reactor designs capable of generating higher ozone concentrations (up to 15-20% by weight) while minimizing the loss of electrical energy as heat. Innovations are focused on creating proprietary ceramic coatings and internal electrode configurations that reduce discharge irregularities and enhance the uniformity of the dielectric barrier discharge (DBD) gap, which is crucial for maximizing conversion efficiency and extending the maintenance interval.

A critical area of technological focus is the high-frequency power supply unit, which drives the DBD process. Modern ceramic generators rely on sophisticated solid-state electronics, including Insulated Gate Bipolar Transistors (IGBTs) and high-speed Pulse Width Modulation (PWM) techniques, to precisely control the frequency (often 1 kHz to 20 kHz) and voltage (10 kV to 20 kV) delivered to the ceramic cell. The shift toward intelligent, digitally controlled power supplies allows for dynamic adjustment of power input based on real-time ozone demand and feed gas conditions, which is essential for integration with AI-driven optimization systems. Furthermore, developments in cooling technology, including advanced water-cooling jackets and specialized heat exchange designs integrated directly into the ceramic modules, are paramount for managing the significant thermal load generated during high-power operation, ensuring the longevity and stability of the ceramic dielectric components.

The integration of advanced sensing and monitoring technologies is also transforming the market. Generators are increasingly equipped with real-time ozone analyzers, humidity sensors, and dew point monitors to ensure optimal feed gas quality, alongside sensors embedded within the ceramic tube array to track voltage, current, and temperature distribution. This influx of operational data supports remote diagnostics and predictive maintenance models. Future technological developments are anticipated to center on utilizing novel composite ceramics that offer even higher thermal conductivity and dielectric strength, potentially allowing for even higher density ozone generation, and further reducing the physical footprint and operational energy requirements for industrial-scale ozonation facilities, thereby lowering the total cost of ownership significantly and making ozone technology competitive across more varied application scales.

Regional Highlights

The regional dynamics of the Ceramic Tube Ozone Generator Market are highly polarized, reflecting varying levels of industrial development, regulatory rigor, and water stress. Asia Pacific (APAC) is currently the epicenter of market expansion, driven primarily by massive investments in environmental protection infrastructure, particularly in China and India. Rapid urbanization and industrial expansion have placed immense pressure on existing water resources, compelling governments to implement stringent pollution controls and invest heavily in advanced wastewater treatment technologies, favoring high-efficiency ceramic ozone systems for tertiary purification and recycling. Japan and South Korea lead in technological adoption and possess mature markets driven by high environmental consciousness and advanced municipal utility operations.

North America (NA) and Europe remain vital markets characterized by technological maturity and high regulatory compliance. In these regions, growth is steady, focusing less on capacity expansion and more on system optimization, energy efficiency, and replacing older, less efficient ozonation systems. European regulations, specifically the revised Drinking Water Directive and stringent industrial effluent standards, mandate the removal of trace contaminants, making ceramic tube generators essential components for advanced oxidation processes (AOPs). The US market is driven by increasing concern over pharmaceutical residues and per- and polyfluoroalkyl substances (PFAS) in water supplies, positioning ozone as a key technology for emerging contaminant remediation.

Latin America (LATAM) and the Middle East and Africa (MEA) represent emerging high-potential markets. LATAM's growth is tied to modernization of outdated water infrastructure and expansion in food processing and agricultural exports, requiring reliable sanitation. The MEA region, characterized by severe water scarcity, sees significant demand stemming from oil and gas industry wastewater treatment, and large-scale desalination plants, where ozonation is often used for pre-treatment (biofouling control) and post-treatment disinfection. The high reliability and low maintenance profile of ceramic technology are particularly appealing in remote and challenging operational environments found across the MEA region.

- Asia Pacific (APAC): Characterized by the highest growth rate, fueled by urgent environmental infrastructure needs, rapid industrialization, and major governmental initiatives in China (e.g., Water Ten Plan) aimed at cleaning major waterways and urban air quality improvement, leading to massive demand for high-capacity ozone generators for industrial effluent treatment.

- North America: Market maturity focused on replacing aging infrastructure and adopting ozone for specialized applications, including removal of microplastics, endocrine disruptors, and chemical residues, with a strong emphasis on energy-efficient designs and remote monitoring capabilities driven by EPA standards.

- Europe: Driven by strict EU directives governing drinking water quality and industrial discharge limits. Strong adoption in the food and beverage industry for sanitation and a focus on integrating ozonation into sustainable, circular economy water management strategies, utilizing high-quality, long-lifecycle ceramic systems.

- Middle East & Africa (MEA): Growth concentrated around desalination projects, oil and gas processing water treatment, and municipal upgrades in urban centers. Demand is driven by the need for robust, reliable purification systems capable of operating efficiently in high-temperature environments.

- Latin America (LATAM): Developing market exhibiting growth in agricultural sectors for irrigation water sanitation and in the mining industry for process water recycling, requiring durable, scalable ozone solutions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Ceramic Tube Ozone Generator Market.- OZONIA (Suez)

- Xylem Inc.

- Metawater Co., Ltd.

- De Nora Permelec

- WEDECO (Xylem)

- Mitsubishi Electric Corporation

- Pinnacle Ozone Solutions

- ClearWater Tech, Ltd.

- DEL Ozone

- Qihong Ozone Technology

- Qingdao Guolin Industry Co., Ltd.

- Korotex Environmental Science Co., Ltd.

- TTO

- Toshiba Corporation

- Ebara Corporation

- Pacific Ozone Technology

- MKS Instruments

- Primozone

- Teledyne API

- Hessaire Products

Frequently Asked Questions

Analyze common user questions about the Ceramic Tube Ozone Generator market and generate a concise list of summarized FAQs reflecting key topics and concerns.What are the primary advantages of ceramic tube technology over traditional glass tube ozone generators?

Ceramic tubes offer superior thermal dissipation and higher dielectric strength, enabling operation at higher frequencies and temperatures. This results in greater ozone output concentration, improved energy efficiency (grams of ozone per kilowatt-hour), enhanced corrosion resistance, and significantly longer operational lifecycles with reduced risk of catastrophic failure compared to glass systems. Ceramic technology supports highly stable, industrial-scale ozone production.

In which applications does the High Output (>100 g/h) segment show the most significant growth?

The High Output segment exhibits the most significant growth in large-scale municipal drinking water treatment and heavy industrial wastewater remediation, particularly in sectors such as pulp and paper, textile manufacturing, and petrochemical processing. This growth is directly driven by stringent environmental regulations necessitating tertiary treatment for chemical oxygen demand (COD) reduction and micropollutant removal, requiring continuous high-volume ozone supply.

How does Artificial Intelligence (AI) enhance the efficiency and lifespan of ceramic tube ozone systems?

AI enhances efficiency through dynamic dosage optimization, where algorithms adjust the generator's power input in real-time based on fluctuating input water quality, ensuring only the necessary amount of ozone is produced, saving energy. AI also improves lifespan by providing predictive maintenance alerts derived from continuous analysis of operating parameters, preventing thermal stress and component failure in the ceramic tubes and power supply.

What is the main restraining factor limiting the faster adoption of ceramic ozone generators globally?

The primary restraining factor is the high initial capital expenditure (CapEx) associated with purchasing high-capacity, sophisticated ceramic ozone systems, including the specialized power electronics and comprehensive peripheral equipment such as oxygen concentrators and cooling systems. This high upfront cost presents a significant barrier to entry, particularly for small-to-medium scale enterprises and municipalities with limited initial investment budgets.

Which geographical region is leading the current market growth and why?

The Asia Pacific (APAC) region, specifically driven by countries like China and India, is leading current market growth. This acceleration is due to rapid industrial expansion, widespread water scarcity issues, and aggressive governmental investment in modernizing water and sewage infrastructure to comply with newly enforced, stringent environmental protection standards, resulting in massive demand for reliable purification technologies like ceramic ozone generators.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager