Chlorine Dioxide Generator Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 433315 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Chlorine Dioxide Generator Market Size

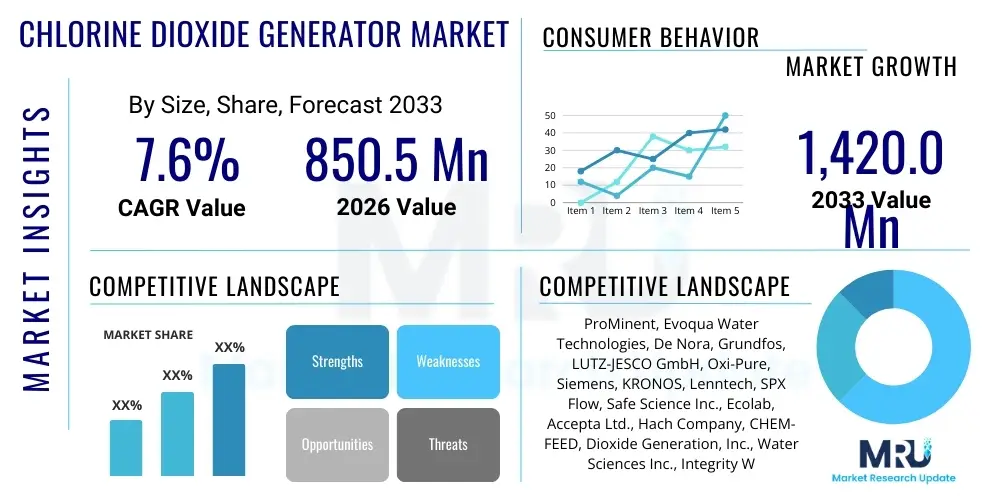

The Chlorine Dioxide Generator Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.6% between 2026 and 2033. The market is estimated at USD 850.5 Million in 2026 and is projected to reach USD 1,420.0 Million by the end of the forecast period in 2033.

Chlorine Dioxide Generator Market introduction

The Chlorine Dioxide Generator Market encompasses equipment designed to safely and efficiently produce chlorine dioxide (ClO₂) solution, primarily for use as a powerful antimicrobial agent and disinfectant. Chlorine dioxide is preferred over traditional chlorine in many critical applications due to its superior oxidizing capabilities, effectiveness across a wider pH range, and its inability to form harmful trihalomethanes (THMs) and other disinfection byproducts (DBPs). These generators utilize various chemical precursors, typically sodium chlorite and hydrochloric acid or chlorine, reacting them under controlled conditions to produce ClO₂ gas dissolved in water. The systems are highly specialized, requiring precise dosing and monitoring capabilities to ensure safety, efficacy, and compliance with stringent environmental and health regulations. The increasing global focus on water safety and stringent regulatory mandates regarding water quality, particularly in municipal and industrial settings, underpin the fundamental demand for advanced ClO₂ generation technologies.

The product portfolio within this market spans across different generator types, categorized mainly by the purity and concentration of the ClO₂ generated, such as high-purity (often used in pharmaceutical or semiconductor clean water systems), medium-purity (common in food and beverage processing), and low-purity generators (frequently deployed in large-scale municipal water treatment). Major applications driving market growth include the disinfection of potable water, wastewater treatment, industrial process water sterilization, biofouling control in cooling towers and heat exchangers, and sanitation within the food and beverage industry to extend shelf life and ensure microbial safety. Furthermore, its efficacy in combating emerging pathogens and mitigating legionella risks in building water systems has cemented its importance in public health infrastructure globally. These systems offer significant operational benefits, including minimized chemical storage footprint, on-site, on-demand generation capabilities, which greatly enhance safety compared to storing large quantities of pre-made hazardous chemicals.

Key driving factors propelling the market forward include rapid urbanization, which strains existing municipal water infrastructure and necessitates advanced treatment solutions, and the escalating demand for highly pure water across diverse industrial sectors, especially electronics manufacturing and pharmaceuticals. The stringent enforcement of environmental protection laws across North America and Europe, requiring reduced DBP formation, favors the adoption of ClO₂ over conventional chlorination. Furthermore, technological advancements leading to safer, more automated, and more efficient generator designs—including systems incorporating remote monitoring and predictive maintenance features—are making ClO₂ generation more accessible and appealing to a broader range of end-users. The continuous threat of waterborne diseases and the necessity for robust disinfection protocols in agricultural irrigation and healthcare settings further contribute to sustained market expansion.

Chlorine Dioxide Generator Market Executive Summary

The Chlorine Dioxide Generator Market is characterized by robust growth, primarily fueled by global mandates for improved water quality and the shift away from less efficient or environmentally problematic disinfection methods. Business trends indicate a strong move toward advanced, high-purity generation systems and modular, scalable designs that cater to both large metropolitan utilities and smaller, decentralized industrial operations. Key companies are focusing on integrating smart technologies, such as IoT sensors and cloud-based monitoring platforms, to offer enhanced operational visibility and predictive maintenance capabilities, thereby reducing downtime and chemical consumption. Furthermore, strategic mergers, acquisitions, and partnerships aimed at expanding geographical reach, particularly in high-growth Asia Pacific economies, and diversifying application expertise (e.g., integrating into advanced oil and gas water management solutions) are defining the competitive landscape.

Regionally, North America and Europe maintain dominance, driven by established regulatory frameworks and high industrial uptake in food processing and pharmaceuticals. However, the Asia Pacific (APAC) region is projected to register the highest CAGR during the forecast period due to rapid industrialization, massive infrastructure investment in water and wastewater treatment, and increased awareness regarding waterborne diseases in populous nations like China and India. Latin America and the Middle East & Africa (MEA) are also emerging as crucial growth pockets, particularly in areas requiring effective biofouling control in industrial cooling systems and enhanced oil recovery (EOR) operations, which are significant consumers of ClO₂ for sulfate-reducing bacteria mitigation. The dynamic regulatory landscape in developing economies, though sometimes fragmented, is progressively aligning with global standards, accelerating the adoption of certified ClO₂ solutions.

In terms of segment trends, the Water Treatment application segment, encompassing both municipal and industrial water treatment, remains the largest market shareholder, driven by necessity and scale. Within this segment, the demand for medium and high-purity generators is rising, reflecting the need for precision in disinfection for sophisticated processes. The Food & Beverage segment is exhibiting rapid growth, leveraging ClO₂’s effectiveness as a non-corrosive disinfectant for surface sanitation and produce washing, ensuring compliance with global food safety standards. Technology-wise, generators utilizing the two-chemical precursor method (sodium chlorite and acid) are the most commercially prevalent, favored for their balance of purity, efficiency, and operational simplicity. The increasing focus on sustainability is also pushing manufacturers to innovate systems that reduce chemical waste and optimize energy consumption, aligning with broader corporate social responsibility (CSR) goals.

AI Impact Analysis on Chlorine Dioxide Generator Market

User queries regarding AI's influence on the Chlorine Dioxide Generator Market predominantly revolve around three key themes: optimization, automation, and predictive capabilities. Users are frequently asking how Artificial Intelligence (AI) and Machine Learning (ML) can optimize chemical dosing to reduce reagent costs and minimize waste, a critical operational expenditure for end-users. There is significant interest in the automation potential, specifically concerning autonomous generator operation, fault detection, and real-time adjustment of output based on fluctuating water quality parameters (e.g., turbidity, pH, microbial load). Furthermore, users seek clarity on how predictive maintenance, powered by AI analyzing sensor data (IoT integration), can forecast component failure, schedule necessary servicing, and ultimately increase the lifespan and reliability of high-cost generator units. The summary indicates a strong user expectation that AI will transition ClO₂ generation from a reactive process to a highly proactive, self-regulating system, ensuring optimal disinfection efficacy with minimal human intervention and chemical overuse.

AI is set to revolutionize the operational efficiency and reliability of Chlorine Dioxide generators by integrating advanced algorithms that process vast amounts of real-time operational data. By analyzing variables such as precursor feed rates, reaction temperatures, flow rates, residual ClO₂ concentrations, and external water quality metrics, AI models can establish highly precise dosing profiles tailored to dynamic environmental conditions. This ability to continuously learn and adjust chemical usage not only ensures disinfection effectiveness under various loads but also dramatically reduces the consumption of expensive precursors, leading to substantial cost savings for water utilities and industrial plants. Furthermore, ML techniques are being applied to analyze historical performance data to fine-tune the reaction process, ensuring maximum yield and purity of the ClO₂ solution, which is paramount in sensitive applications like beverage manufacturing or healthcare.

Beyond optimization, AI facilitates significant advancements in safety and compliance monitoring. AI-powered systems can instantaneously detect anomalies in the generation process—such as unusual pressure drops, temperature spikes, or deviations in precursor ratios—and automatically initiate shutdown procedures or alerts, minimizing the risk of hazardous chemical exposure or equipment damage. This enhanced monitoring capability is crucial for meeting stringent regulatory standards globally. Moreover, AI integration allows for seamless connectivity with centralized water management systems (SCADA), enabling remote diagnostics and comprehensive reporting. The implementation of digital twins, generated and refined through ML, allows operators to simulate changes in operational parameters virtually before implementation, ensuring predictable performance and facilitating advanced troubleshooting, thereby setting new benchmarks for generator reliability and operational excellence.

- Enhanced chemical dosing optimization using machine learning algorithms based on real-time water quality data.

- Predictive maintenance schedules enabled by AI analyzing sensor data (IoT integration) to forecast component failure and minimize unplanned downtime.

- Automated fault detection and diagnostic systems ensuring immediate response to operational anomalies, improving safety and compliance.

- Integration with centralized SCADA systems for autonomous generator control and remote performance monitoring.

- Development of digital twins to simulate operational changes, optimizing reaction efficiency and ClO₂ yield.

- Reduced operational costs through minimized precursor chemical consumption and optimized energy usage during the generation cycle.

DRO & Impact Forces Of Chlorine Dioxide Generator Market

The Chlorine Dioxide Generator Market is significantly influenced by a powerful combination of legislative drivers, chemical safety constraints, technological innovation, and application-specific demands. The primary drivers revolve around the non-formation of carcinogenic disinfection byproducts (DBPs) like THMs and HAAs, making ClO₂ a superior alternative to traditional chlorine, especially in densely populated areas. Regulatory bodies, particularly the EPA in North America and equivalent agencies in Europe, are continuously tightening DBP limits, forcefully encouraging the shift towards ClO₂. Restraints, however, include the relatively high capital expenditure required for purchasing and installing high-purity generation equipment compared to basic chlorination systems, alongside the perceived complexity and necessity for specialized training for operating and maintaining these precise chemical systems. Furthermore, concerns regarding the storage and handling of precursor chemicals, though less volatile than elemental chlorine, necessitate strict safety protocols, which can deter smaller operators.

Opportunities for market expansion are vast, centering on underserved segments such as agricultural irrigation water treatment, where the need for non-persistent, broad-spectrum disinfection is rising, and the integration of ClO₂ into advanced water reuse and recycling facilities, crucial for addressing global water scarcity. Significant opportunities also exist in developing portable or mobile ClO₂ generation units tailored for disaster relief or temporary industrial sites. The impact forces shaping the market trajectory include the accelerating growth of the food and beverage industry, demanding highly sterile environments, and the increasing global focus on battling infectious diseases, driving adoption in institutional settings like hospitals and long-term care facilities for legionella control. The continuous drive towards decentralized water treatment also favors modular, on-site ClO₂ generation solutions over centralized chemical supply chains.

The market faces impact forces related to technological advancements that lower the barriers to entry, such as the development of simplified, cassette-based systems requiring minimal manual intervention, thus addressing the restraint concerning operational complexity. Competitive pricing pressure, particularly from manufacturers based in Asia, is forcing established Western players to innovate continuously on efficiency and automation to maintain market share. Environmentally, the push for green chemistry and sustainable practices acts as a catalyst; generators that produce fewer waste streams or utilize less energy intensive reaction pathways gain a significant competitive edge. Overall, the market dynamics reflect a continuous trade-off between the undeniable benefits of superior disinfection efficacy and the initial investment and operational training requirements, with global regulatory pressure acting as the strongest long-term positive driver.

Segmentation Analysis

The Chlorine Dioxide Generator market is strategically segmented based on several critical factors, including the type of generator technology utilized, the required purity level of the ClO₂ produced, and the diverse range of end-user applications. This segmentation allows manufacturers to tailor generator specifications—such as capacity, reaction method (e.g., chemical, electrochemical), and control sophistication—to meet the specific safety and regulatory requirements of different industries. Understanding these segments is crucial for accurate market forecasting, as demand elasticity and adoption rates vary significantly between highly regulated sectors like pharmaceuticals, demanding high-purity, and high-volume sectors like municipal water treatment, prioritizing cost-efficiency and scale.

- By Type:

- High Purity Generators (typically >98% yield, often used in CIP/SIP, pharmaceutical)

- Medium Purity Generators (common for municipal water, food processing)

- Low Purity Generators (larger scale, non-critical industrial water treatment)

- By Application:

- Water Treatment (Municipal Water Disinfection, Wastewater Treatment)

- Industrial Process Water (Cooling Towers, Boiler Feed Water, Pulp & Paper)

- Oil & Gas (Enhanced Oil Recovery, Frac Water Treatment, Sulfate-Reducing Bacteria Control)

- Food & Beverage Processing (Washing Produce, Surface Sanitation, Bottling Water)

- Healthcare and Pharmaceuticals (Disinfection, Cleanroom Sterilization)

- Others (Agriculture, Aquaculture, Odor Control)

- By End-Use Industry:

- Industrial

- Commercial

- Institutional (Hospitals, Schools)

- Municipal

Value Chain Analysis For Chlorine Dioxide Generator Market

The value chain for the Chlorine Dioxide Generator Market begins with the upstream sourcing and supply of critical raw materials, primarily sodium chlorite (NaClO₂) and hydrochloric acid (HCl), or sulfuric acid (H₂SO₄), which serve as the chemical precursors. The efficiency and reliability of this upstream supply chain are paramount, as the quality and concentration of these reagents directly impact the purity and yield of the final ClO₂ solution and the operational cost for the end-user. Key activities at this stage include the manufacturing and refining of these commodity chemicals, ensuring compliance with purity standards, specialized hazardous material logistics, and establishing robust supply contracts to buffer against chemical price volatility. Relationships between generator manufacturers and major chemical suppliers are often strategic, aiming to ensure consistent, timely delivery, especially for large municipal contracts.

Midstream activities involve the design, engineering, and manufacturing of the generator systems themselves. This stage is characterized by intense intellectual property development focused on improving reaction efficiency, enhancing safety features (e.g., containment, venting, pressure regulation), and integrating advanced control electronics. Manufacturers must adhere to stringent quality standards (like ISO certifications and regulatory approvals from bodies such as NSF or various national water safety organizations). The integration of IoT capabilities, sensors, and robust materials capable of handling corrosive chemicals constitutes a significant portion of the value added at the manufacturing level. Distribution channels are bifurcated: direct sales channels are typically used for large-scale, custom-engineered industrial or municipal projects, allowing for specialized technical consultation and post-installation support. Indirect channels, involving authorized distributors, chemical service providers, and specialized water technology integrators, handle smaller commercial and institutional applications, leveraging their local presence and service networks.

The downstream component of the value chain focuses heavily on installation, commissioning, maintenance, and the crucial provision of ongoing technical support and chemical resupply. This after-market service segment often represents a significant, high-margin revenue stream for generator providers, as these specialized units require regular calibration and maintenance to operate safely and effectively. Customer relations at the downstream level focus on long-term partnership, ensuring compliance, optimizing chemical usage, and providing emergency response. Potential customers, including municipal water utilities and large industrial plants, prioritize generators with robust service contracts and proven longevity. The seamless integration of the generator into the overall water treatment process (e.g., compatibility with existing pumps, mixers, and monitoring equipment) is a key determinant of value capture at this final stage.

Chlorine Dioxide Generator Market Potential Customers

Potential customers for the Chlorine Dioxide Generator Market span a wide array of sectors fundamentally reliant on high-quality, safe, and reliably disinfected water or sterilized surfaces. Municipal water utilities represent the largest buying cohort globally, utilizing ClO₂ generators to ensure the safety of potable water supply chains, driven by their superior performance over chlorine in mitigating DBPs and effectively treating source water high in organic material. These large-scale buyers prioritize durability, high capacity, automation, and total cost of ownership (TCO) over a multi-decade operational lifespan, often requiring bespoke engineering solutions to integrate with existing plant infrastructure and meet stringent local regulatory requirements.

The industrial sector constitutes the most diversified group of potential customers, with specific needs varying greatly. The Food & Beverage industry (including breweries, dairies, and soft drink producers) seeks ClO₂ for high-level disinfection of process water, bottle washing, and cleaning-in-place (CIP) systems, valuing its low-corrosion properties and effectiveness against biofilm formation. The Oil & Gas sector, particularly in hydraulic fracturing and enhanced oil recovery (EOR), utilizes ClO₂ to control sulfide and iron precipitation and mitigate sulfate-reducing bacteria (SRB) that cause reservoir souring and pipeline corrosion, demanding high-flow, robust, and often mobile generation solutions capable of handling challenging feedwater sources. Pharmaceutical and healthcare facilities require ultra-high-purity ClO₂ for sterilization of process water, cleanrooms, and medical devices, prioritizing generators that offer verifiable purity and validated performance protocols to comply with GMP standards.

Other significant end-users include commercial facilities with large cooling tower installations, where ClO₂ is critical for controlling biofouling and preventing the proliferation of Legionella bacteria, a major public health concern. Agricultural operations are increasingly adopting ClO₂ for irrigation water disinfection and post-harvest produce washes to minimize microbial spoilage and extend the marketability of crops. These diverse customer needs underscore the necessity for generator manufacturers to offer a versatile product line, ranging from small, cost-effective commercial units to large, complex industrial systems, supported by specialized application expertise and comprehensive safety documentation tailored to the regulatory environment of each sector.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 850.5 Million |

| Market Forecast in 2033 | USD 1,420.0 Million |

| Growth Rate | 7.6% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | ProMinent, Evoqua Water Technologies, De Nora, Grundfos, LUTZ-JESCO GmbH, Oxi-Pure, Siemens, KRONOS, Lenntech, SPX Flow, Safe Science Inc., Ecolab, Accepta Ltd., Hach Company, CHEM-FEED, Dioxide Generation, Inc., Water Sciences Inc., Integrity Water, SUEZ Water Technologies & Solutions, Severn Trent Services. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Chlorine Dioxide Generator Market Key Technology Landscape

The technological landscape of the Chlorine Dioxide Generator Market is dominated by chemical reaction methodologies, primarily categorized into three main approaches: the two-chemical method, the three-chemical method, and electrochemical generation. The two-chemical method, typically reacting sodium chlorite (NaClO₂) with a strong mineral acid such as hydrochloric acid (HCl), is the most widely adopted due to its balance of reliable yield, relatively high purity, and manageable operational complexity. Recent innovations in this established technology focus on kinetic enhancement—using optimized reaction chambers, precise metering pumps, and temperature control—to increase conversion efficiency and minimize the residual precursor chemicals in the final solution, thereby adhering to stricter municipal and industrial standards for residual chemical discharge.

The three-chemical method, utilizing sodium chlorite, chlorine gas, and water, offers extremely high purity and large-scale capacity, making it preferred for expansive municipal water treatment facilities where chlorine gas handling infrastructure is already in place. However, the stringent safety regulations associated with chlorine gas storage and handling present a significant operational constraint, driving some large users towards modernized two-chemical or advanced electrochemical systems. Electrochemical generation represents a significant emerging technology, producing ClO₂ through the electrolysis of a sodium chlorite solution. This method eliminates the need for storing or handling strong mineral acids, drastically improving site safety and simplifying logistics. While electrochemical generators currently possess a higher initial capital cost, their smaller footprint, lower operational complexity, and ability to generate extremely high-purity ClO₂ are making them increasingly attractive for applications requiring high precision, such as pharmaceuticals and specialized food processing.

Beyond the core generation chemistry, modern ClO₂ generators are defined by their advanced monitoring and control systems. Key technological differentiators include the integration of sophisticated proportional-integral-derivative (PID) controllers and HMI (Human-Machine Interface) touch screens for intuitive operation, real-time diagnostic reporting, and secure remote access via cloud-based platforms. Spectrophotometric or amperometric sensors are critical components, providing instantaneous feedback on ClO₂ residual concentration, allowing the system to dynamically adjust precursor dosing. Furthermore, the incorporation of highly resistant, non-metallic materials (e.g., PVDF, PTFE) in wetted components has significantly extended the lifespan and reliability of the generators when dealing with corrosive precursors and the final ClO₂ solution, driving down long-term maintenance costs and improving the overall value proposition of these essential disinfection systems.

Regional Highlights

The global market for Chlorine Dioxide Generators exhibits distinct adoption patterns and growth drivers across major geographic regions, influenced heavily by regional water quality standards, industrial density, and infrastructure maturity.

North America: This region holds a significant market share, driven primarily by strict regulatory enforcement, particularly concerning the formation of disinfection byproducts (DBPs) under the US Environmental Protection Agency (EPA) rules. The mature industrial sectors, including sophisticated food and beverage, pharmaceuticals, and a robust oil and gas sector (EOR operations), are major consumers of high and medium-purity generators. The market here is characterized by high investment in automated, high-reliability systems and a focus on minimizing operational risk. Innovation often centers on remote diagnostics and compliance reporting integration.

Europe: Europe is another dominant region, spurred by the implementation of the EU Water Framework Directive and strict national regulations regarding potable water quality and legionella control in buildings and public spaces. Germany, the UK, and France are key contributors, favoring continuous, high-efficiency generation systems. There is a strong emphasis on sustainability, leading to increased adoption of advanced electrochemical systems that reduce chemical footprint and improve overall safety protocols.

Asia Pacific (APAC): APAC is projected to be the fastest-growing region. Rapid urbanization and massive government investments in water and wastewater infrastructure across China, India, and Southeast Asia are the main catalysts. While cost sensitivity remains a factor, the escalating need for clean water, combined with increasing industrial activity (especially textile, pulp, and paper, and electronics manufacturing), is accelerating the adoption of ClO₂ solutions for scaling capacity and meeting emerging international quality standards. The market here demands scalable, cost-effective, and robust generator designs.

Latin America (LATAM): Growth in LATAM is steady, particularly in Brazil and Mexico, driven by industrial process water needs in mining, brewing, and agricultural sectors. Challenges include variable regulatory environments and infrastructure deficiencies, leading to demand for robust, easy-to-maintain systems suitable for remote installations. The shift towards modernization in municipal utilities is gradually opening up new avenues for larger ClO₂ projects.

Middle East & Africa (MEA): This region is emerging due to intense water scarcity issues and massive infrastructure projects, particularly in the Gulf Cooperation Council (GCC) states. Applications are concentrated in desalination pretreatment, industrial cooling water, and petrochemical operations, where biofouling control is critical due to high ambient temperatures. The demand is often for large-capacity, resilient generators capable of handling high-salinity source water, coupled with comprehensive service agreements.

- North America (USA, Canada): Market leader driven by DBP regulations (EPA) and strong industrial adoption (O&G, F&B).

- Europe (Germany, UK, France): Focus on sustainability, legionella control, and adherence to EU directives, favoring safer electrochemical technologies.

- Asia Pacific (China, India, Japan, South Korea): Fastest growth attributed to massive infrastructure development, industrialization, and improving water treatment standards.

- Latin America (Brazil, Mexico): Steady growth in mining, agriculture, and urban water modernization projects.

- Middle East and Africa (UAE, Saudi Arabia, South Africa): Demand concentrated in desalination, petrochemical, and high-temperature cooling applications requiring robust biofouling control.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Chlorine Dioxide Generator Market.- ProMinent GmbH

- Evoqua Water Technologies LLC

- De Nora S.p.A.

- Grundfos Holding A/S

- LUTZ-JESCO GmbH

- Oxi-Pure Inc.

- Siemens AG (Water Technologies)

- KRONOS Worldwide, Inc.

- Lenntech B.V.

- SPX Flow, Inc.

- Safe Science Inc.

- Ecolab Inc.

- Accepta Ltd.

- Hach Company (a Danaher Company)

- CHEM-FEED Corporation

- Dioxide Generation, Inc.

- Water Sciences Inc.

- Integrity Water Treatment

- SUEZ Water Technologies & Solutions

- Severn Trent Services (part of Severn Trent PLC)

Frequently Asked Questions

Analyze common user questions about the Chlorine Dioxide Generator market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is Chlorine Dioxide (ClO₂) and why is it preferred over traditional chlorine for disinfection?

Chlorine Dioxide (ClO₂) is a highly effective, broad-spectrum oxidant and disinfectant used in water treatment and sanitation. It is preferred over elemental chlorine because it does not react with organic matter to form harmful, carcinogenic disinfection byproducts (DBPs) such as trihalomethanes (THMs). ClO₂ maintains its efficacy over a wider pH range, effectively penetrates biofilms, and requires lower doses to achieve microbial kill, ensuring superior overall water safety.

What are the primary generator technologies used in the market?

The market primarily utilizes three technologies: the two-chemical method (sodium chlorite and acid) for reliable, medium-to-high purity generation; the three-chemical method (using chlorine gas) for large-scale, high-purity municipal applications; and advanced electrochemical generation, which uses electrolysis to produce ClO₂ on-site without strong mineral acids, prioritizing safety and ultra-high purity.

How does the high capital cost of ClO₂ generators impact their adoption in developing regions?

The initial high capital expenditure (CAPEX) for sophisticated ClO₂ generators can restrain adoption in developing regions compared to cheaper alternatives. However, the long-term operational savings resulting from lower chemical consumption, reduced risk of regulatory penalties, and the superior public health outcomes often justify the investment, particularly as modular and standardized generator designs become more cost-effective and accessible.

Which industry applications drive the highest demand for Chlorine Dioxide generation systems?

The highest demand is driven by the Municipal Water Treatment sector for potable water disinfection. Rapidly growing industrial demand stems from the Food & Beverage industry (for sanitation and biofilm control) and the Oil & Gas sector, specifically for water management in Enhanced Oil Recovery (EOR) and hydraulic fracturing, where ClO₂ effectively controls corrosive bacteria and ensures process efficiency.

What role does automation and IoT play in modern Chlorine Dioxide generators?

Modern generators integrate advanced automation, including PLC control systems and IoT connectivity, to allow for precise, real-time dosing adjustments based on continuous water quality monitoring. This integration ensures optimal efficiency, minimizes chemical waste, provides remote diagnostic capabilities, and enables predictive maintenance planning, drastically improving operational safety, compliance, and reliability.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager