Chopping Block Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 431794 | Date : Dec, 2025 | Pages : 246 | Region : Global | Publisher : MRU

Chopping Block Market Size

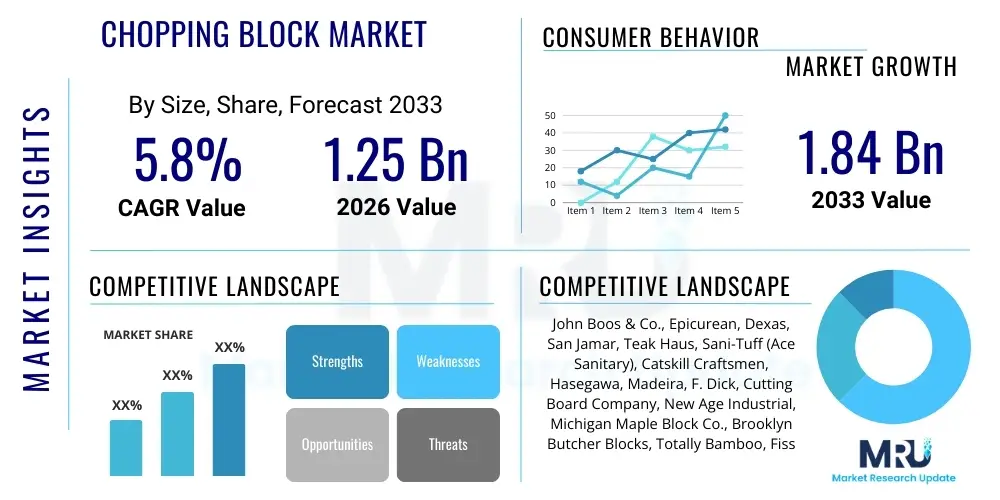

The Chopping Block Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 1.25 Billion in 2026 and is projected to reach USD 1.84 Billion by the end of the forecast period in 2033. This growth is primarily fueled by stringent global food safety regulations, increasing professionalism in commercial culinary operations, and rising consumer demand for premium, durable kitchen equipment designed for specialized tasks like butchery and heavy-duty vegetable preparation.

Chopping Block Market introduction

The Chopping Block Market encompasses the manufacturing, distribution, and sale of heavy-duty cutting surfaces used predominantly in food preparation environments where durability, stability, and hygiene are paramount. Unlike standard cutting boards, chopping blocks are characterized by their thickness, weight, and often specialized construction—such as end-grain wood or high-density polyethylene—designed to withstand intensive use, particularly in meat processing and high-volume commercial kitchens. The core products range from traditional maple or oak butcher blocks, prized for their resilience and self-healing properties, to advanced synthetic materials offering superior resistance to moisture and bacteria absorption, catering to diverse industry needs and regulatory requirements across the globe.

Major applications of chopping blocks span the entire food value chain, from industrial meat packing plants requiring massive, durable processing surfaces to small-scale artisanal bakeries and professional culinary schools. Driving factors for market expansion include the continuous global proliferation of the HoReCa (Hotel, Restaurant, Catering) sector, alongside increasing investments in optimizing food processing efficiency and sanitation standards. Furthermore, the growing trend of gourmet home cooking and specialized meat preparation in affluent households has created a niche but significant demand for high-quality, aesthetically pleasing chopping blocks, viewed often as a statement piece in modern kitchens. Benefits associated with these products, such as improved knife edge retention and the reduced risk of cross-contamination when standard sanitation protocols are followed, solidify their essential role in safe food handling.

The market faces constant innovation pressures, particularly concerning material science and ergonomic design. Manufacturers are continuously exploring hybrid materials and incorporating features like integrated juice grooves, non-slip feet, and modular designs to enhance usability and compliance with health codes. The shift towards sustainable sourcing, notably utilizing fast-growing hardwoods like bamboo or recycled food-grade plastics, is another crucial trend influencing product development and consumer choice. This continuous refinement ensures that chopping blocks remain foundational tools, essential for maintaining operational flow and hygienic integrity in professional settings, thereby securing sustained market relevance through the forecast period.

Chopping Block Market Executive Summary

The Chopping Block Market is experiencing robust expansion, fundamentally driven by sustained growth in the global foodservice and meat processing industries, paired with stringent government mandates regarding food hygiene and sanitation. Key business trends indicate a distinct shift towards premiumization, where end-users prioritize high initial investment in durable, specialized materials—such as end-grain wood blocks or proprietary antimicrobial polymer compounds—over cheaper, less resilient alternatives. This trend reflects the long-term cost-saving benefits associated with superior knife maintenance and reduced replacement frequency in intensive commercial environments. Furthermore, vertical integration among leading suppliers, combining material sourcing, manufacturing, and direct distribution, is optimizing supply chains and ensuring quality control across diverse product lines, stabilizing pricing in competitive regional markets.

Regionally, Asia Pacific (APAC) stands out as the highest growth potential area, propelled by rapid urbanization, significant expansion of the middle-class population, and the corresponding explosive growth in organized retail and food service chains across countries like China, India, and Southeast Asia. North America and Europe, while mature, maintain strong market shares driven by established regulatory frameworks and high demand for specialized, custom-designed chopping solutions required by large-scale institutional kitchens and meat processing facilities. These mature markets are focusing heavily on product innovation geared towards environmental sustainability and integration of smart features, such as embedded sensors for temperature and hygiene monitoring, reflecting sophisticated buyer requirements.

Segmentation trends highlight the increasing dominance of high-density polyethylene (HDPE) blocks in large industrial and institutional settings due to their ease of cleaning and compliance with HACCP color-coding standards, crucial for preventing cross-contamination. Conversely, the high-end residential and artisanal commercial segments continue to favor wood chopping blocks, specifically end-grain constructions, valued for their aesthetic appeal, perceived longevity, and ability to minimize impact on expensive culinary knives. Overall, the market's trajectory is characterized by a dual focus: regulatory compliance and industrial efficiency driving the large-scale segment, and quality, craftsmanship, and sustainability influencing the premium commercial and consumer sectors, ensuring balanced growth across all segments.

AI Impact Analysis on Chopping Block Market

User inquiries regarding AI's impact on the Chopping Block Market primarily revolve around how automation and smart technology can enhance traditional manufacturing processes and improve product utility. Common questions address the role of AI in optimizing raw material utilization (minimizing waste in expensive wood sourcing), predicting material stress failures, automating precision cutting using robotic arms guided by computer vision, and ensuring end-product quality control through defect detection. Users are also concerned about AI’s potential to revolutionize kitchen management, specifically questioning how smart chopping surfaces might interface with inventory systems or automatically monitor and log surface hygiene status to comply with stringent food safety standards, signaling a desire for 'smart kitchen' integration and predictive maintenance functionalities for industrial-grade blocks.

The application of Artificial Intelligence within the chopping block value chain is currently most transformative in the manufacturing and supply chain management phases. AI-driven vision systems coupled with advanced robotics are enabling hyper-precise milling and bonding processes, especially critical for end-grain construction where minuscule alignment errors can compromise structural integrity. These systems analyze wood grain patterns in real-time, optimizing the cutting path to maximize yield from expensive hardwoods while simultaneously identifying and isolating structural flaws before assembly, leading to significantly reduced manufacturing waste and enhanced product uniformity. This precision is difficult to achieve reliably through traditional manual or conventional CNC processes, positioning AI as a critical enabler for high-volume, premium production.

Furthermore, AI models are increasingly utilized in predictive demand forecasting and inventory management, particularly for custom and specialized large-format blocks required by industrial meat processors. By analyzing historical order patterns, seasonal culinary trends, and macroeconomic indicators, AI algorithms allow manufacturers to optimize raw material stock levels and production schedules, mitigating supply chain bottlenecks associated with sourcing specific, high-quality timber or specialized plastics. While the physical product itself remains analog, the processes supporting its creation, distribution, and long-term performance are being significantly optimized by AI, promising reduced operational costs and improved responsiveness to dynamic market demands, ultimately providing a competitive edge to companies that successfully integrate these advanced analytical capabilities.

- AI-Optimized Material Sourcing: Predictive modeling for purchasing and harvesting premium hardwoods based on quality, availability, and future demand, reducing procurement risk.

- Precision Manufacturing: Utilizing computer vision and machine learning algorithms to guide CNC machinery for flawless end-grain alignment and minimal waste generation during cutting and bonding.

- Quality Assurance Automation: AI-driven defect detection systems scanning finished blocks for cracks, voids, or bonding failures that compromise food safety and durability.

- Smart Kitchen Integration: Potential integration of RFID tags or non-intrusive sensors coupled with AI processing for automatic hygiene logging and tracking usage cycles in commercial settings.

- Supply Chain Resilience: Predictive logistics utilizing AI to forecast transport constraints and optimize inventory placement for heavy and bulky products like chopping blocks.

DRO & Impact Forces Of Chopping Block Market

The dynamics of the Chopping Block Market are fundamentally shaped by a confluence of driving factors, persistent restraints, and significant opportunities, which collectively exert powerful impact forces on market growth and direction. Key drivers include increasingly rigorous global food safety legislation (such as HACCP principles) necessitating dedicated, easy-to-sanitize cutting surfaces, alongside the expansion of professional culinary training and the associated demand for high-quality, specialized tools. However, market expansion is constrained by several factors, including the high initial cost and weight of premium materials (like thick maple or specialized composites), which complicates logistics and inventory management, as well as the ongoing requirement for strict maintenance and sanitation procedures, especially for wood blocks which require oiling and careful cleaning to prevent warping and bacterial harborages. Opportunities for growth are significantly present in the development of innovative, low-maintenance materials that meet both durability and hygiene requirements, coupled with market expansion through customization and direct-to-consumer digital sales channels offering unique, artisanal products.

Among the critical driving forces, the continuous growth and internationalization of the quick-service restaurant (QSR) and industrial meat processing sectors provide reliable, high-volume demand for standard, compliant chopping surfaces, predominantly utilizing high-density polyethylene (HDPE) for color-coding and durability. Simultaneously, the premiumization trend among independent gourmet restaurants and artisanal butcher shops drives demand for aesthetically superior, specialized wood blocks, capable of enhancing the presentation of food preparation while offering unmatched durability. These drivers create a bifurcated market structure where efficiency and compliance guide industrial purchases, and quality and aesthetic appeal guide the premium commercial segment, maintaining high baseline demand across different material types and price points. The commitment to minimizing foodborne illnesses across all jurisdictions acts as a powerful, non-negotiable motivator for investment in high-standard equipment.

Restraints, particularly those related to sustainability and raw material sourcing, exert considerable pressure. High-quality hardwoods required for butcher blocks face sourcing restrictions and environmental certifications, increasing material costs and complicating supply chain traceability. Furthermore, while plastic blocks are durable, concerns over microplastic shedding and end-of-life disposal are prompting buyers to look for more sustainable composite or recycled options, adding complexity to product development. The impact forces manifest strongly in material innovation; successful market players are those who can navigate these restraints by capitalizing on opportunities through research and development into highly durable, fully recyclable polymers or sustainably certified, fast-growing wood alternatives. The ultimate impact force remains regulatory compliance, compelling all market participants to prioritize hygiene-focused features and certifications, fundamentally shaping product specifications and market acceptance.

Segmentation Analysis

The Chopping Block Market is comprehensively segmented based on material type, end-user application, and manufacturing method, reflecting the diverse requirements across the professional and residential culinary landscapes. Understanding these segmentations is crucial for manufacturers and marketers aiming to target specific niches—ranging from institutional kitchens requiring robust, color-coded synthetic solutions to high-end domestic consumers seeking artisanal, specialized wooden blocks. The material segmentation (Wood, Plastic/Polyethylene, Composite/Other) dictates key performance characteristics such as hygiene level, knife friendliness, maintenance requirements, and overall cost, representing the foundational determinant of market viability for different applications.

Application segmentation categorizes demand based on the environment of use, primarily differentiating between the high-volume, regulated demands of Commercial Food Service (restaurants, catering), the massive scale and unique hygiene needs of Industrial Meat Processing (slaughterhouses, packing plants), and the aesthetic and durability preferences of the Residential/Gourmet segment. Each end-user category dictates different purchase volumes, specification tolerances, and logistical needs. For instance, industrial users prioritize large, seamless surfaces and chemical resistance, whereas residential users prioritize design, wood species (e.g., walnut vs. maple), and manageability, leading to highly specific product offerings tailored to these distinct user groups.

The complexity of market demand is further highlighted by manufacturing method segmentation, distinguishing traditional solid wood slabs, edge-grain construction (more economical, standard cutting boards), and the high-performance, complex end-grain construction (superior durability, self-healing, often higher cost). The convergence of these segment variables dictates overall market growth dynamics. For example, growth in the plastic segment is tied directly to expansion in commercial food service due to regulatory compliance, while growth in the end-grain wood segment is fueled by premiumization in both residential and high-end commercial kitchens, demonstrating the multi-faceted nature of market demand and the necessity for diversified product portfolios.

- By Material:

- Wood (Maple, Walnut, Bamboo, Oak)

- High-Density Polyethylene (HDPE)

- Rubber/Composite Materials

- By Application/End-User:

- Commercial Food Service (Restaurants, Cafeterias)

- Industrial Meat Processing and Butchery

- Institutional (Hospitals, Schools, Military)

- Residential/Home Use

- By Construction Type:

- Edge Grain

- End Grain

- Solid Slab/Plastic Sheet

- By Size/Format:

- Standard Commercial Sizes

- Industrial Custom Large Format

- Residential Portable/Small Format

Value Chain Analysis For Chopping Block Market

The value chain for the Chopping Block Market begins with the upstream analysis, which is critically dependent on the sourcing of high-quality raw materials, predominantly certified timber and food-grade polymers. For wood blocks, the upstream phase involves sustainable forestry, careful lumber selection, kiln drying, and initial milling to ensure stability and prevent warping—a crucial step given the product's function in wet environments. Suppliers must adhere to strict quality standards regarding wood species (e.g., North American Hard Maple is highly sought after) and certification (e.g., FSC). For plastic blocks, upstream activities involve petrochemical processing to produce food-grade HDPE or similar polymers, where material purity and color consistency (for HACCP compliance) are the primary concerns. The costs and availability of these raw inputs heavily influence the final manufacturing cost and time-to-market, making strong supplier relationships vital.

The midstream phase focuses on manufacturing and processing, where the raw materials are converted into the final product. This stage involves sophisticated processes such as CNC routing, precise cutting for end-grain construction, lamination using food-safe adhesives, sanding, and finishing with specialized food-safe oils or waxes. Quality control is paramount here, ensuring structural integrity and surface smoothness meet professional standards. Downstream analysis covers the distribution channel, which is highly specialized. Industrial and commercial blocks are typically sold B2B through specialized kitchen equipment distributors, institutional suppliers, or direct contracts with large food processing facilities. These channels require expertise in logistics for heavy items, installation services, and compliance consulting (e.g., ensuring block dimensions meet facility codes).

The distribution network is bifurcated into direct and indirect channels. Direct channels are increasingly utilized by premium and artisanal block manufacturers who leverage e-commerce platforms to reach residential and specialized commercial buyers globally, offering high margins and direct customer feedback. Indirect channels, which dominate the industrial market, involve wholesalers and large retail chains (for residential products). Success in the distribution phase hinges on efficient inventory management for bulky items and effective marketing that highlights product durability, hygiene certifications, and aesthetic value. The complexity of handling heavy, fragile-in-transit (if wood) products requires highly specialized packaging and freight solutions to minimize damage before the product reaches the end-user.

Chopping Block Market Potential Customers

The potential customer base for the Chopping Block Market is highly diversified, spanning heavy industrial processing facilities to individual domestic users, yet all segments share a common requirement for durable, stable, and hygienic cutting surfaces. The largest volumetric buyers are typically industrial end-users, including commercial meat packers, poultry processing plants, and large-scale institutional kitchens (e.g., military bases, large universities, and centralized catering operations). These buyers prioritize bulk quantity, resistance to harsh cleaning chemicals, compliance with large-format regulatory standards (often requiring custom dimensions), and material that can withstand high-pressure washing and continuous usage cycles, making high-quality HDPE the material of choice.

A secondary, high-value customer segment comprises the commercial foodservice sector, encompassing independent fine-dining restaurants, specialized butcher shops, high-volume casual dining chains, and culinary schools. These users often purchase a mix of materials: durable HDPE for prep work requiring HACCP color-coding, and premium end-grain wood blocks for presentation areas, bread stations, or heavy-duty butchery requiring superior knife care. These customers often seek specialized features such as custom thickness, specific edge geometry, and aesthetically appealing wood finishes, leading to higher average selling prices and a strong preference for brands known for craftsmanship and reliability.

Finally, the growing segment of affluent home cooks and gourmet enthusiasts represents a crucial driver for the premium residential market. These buyers, often influenced by culinary media and professional trends, seek smaller, high-quality, artisanal wood blocks that serve both functional and decorative purposes. Purchase drivers in this segment include exotic wood species (walnut, teak), personalized engraving, and specialized maintenance kits. Effective targeting of this consumer group relies heavily on digital marketing, direct-to-consumer models, and strong brand association with professional culinary excellence, ensuring that the market successfully taps into both high-volume industrial demand and high-margin specialized consumer demand.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 Billion |

| Market Forecast in 2033 | USD 1.84 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | John Boos & Co., Epicurean, Dexas, San Jamar, Teak Haus, Sani-Tuff (Ace Sanitary), Catskill Craftsmen, Hasegawa, Madeira, F. Dick, Cutting Board Company, New Age Industrial, Michigan Maple Block Co., Brooklyn Butcher Blocks, Totally Bamboo, Fissler, Victorinox, Taylor Woodcraft, Larch Wood Canada, Proteak Renewable Resources. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Chopping Block Market Key Technology Landscape

The technology landscape in the Chopping Block Market, while seemingly simple, is highly reliant on advanced manufacturing precision, material science, and automation to achieve the necessary standards of durability and hygiene. A critical technology is the application of Computerized Numerical Control (CNC) machining, particularly for the production of end-grain wood blocks. Modern CNC equipment ensures micro-level precision in cutting and alignment of wood pieces, which is essential for creating the tight bonds and structural integrity that characterize premium chopping blocks. This precision minimizes voids and gaps where bacteria could accumulate, directly addressing hygiene concerns and extending the product lifecycle. Furthermore, the use of industrial-grade, food-safe adhesives and advanced lamination techniques is a key technological differentiator, ensuring bonds withstand high temperature and moisture fluctuations typical in commercial kitchen environments without delamination.

In the synthetic materials segment, the key technological focus is on polymer science, specifically developing high-molecular-weight, food-grade polyethylene (HDPE) with superior performance characteristics. This includes specialized blending techniques to enhance surface hardness while maintaining knife-friendliness, and integrating permanent, non-leaching antimicrobial additives directly into the polymer matrix. These advanced plastic blocks often undergo specialized surface treatments to reduce porosity, making them highly resistant to staining and bacterial penetration, offering a distinct hygienic advantage in regulated environments like healthcare food service or meat packaging. Color-coding technology, while simple in concept, is technically refined to ensure consistent, durable pigmentation essential for strict adherence to HACCP cross-contamination prevention protocols.

Beyond material composition, packaging and logistics technologies are increasingly important due to the bulk and weight of the products. Specialized shock-absorption packaging systems are utilized to prevent cracking or separation of wooden blocks during freight. Furthermore, the integration of traceability technologies, such as embedded RFID chips or QR codes linked to material sourcing and manufacturing batch records, is emerging as a critical feature for industrial buyers who require complete supply chain transparency for auditing and regulatory compliance. These seemingly disparate technologies—from precision CNC cutting to advanced material compounding and digital traceability—collectively define the modern, competitive edge in the highly regulated and demanding Chopping Block Market.

Regional Highlights

North America (NA): North America represents a mature yet highly dynamic market segment, characterized by stringent federal and state food safety regulations (such as those enforced by the FDA and USDA) which drive consistent demand for compliant, high-quality chopping blocks, particularly in the industrial meat and poultry processing sectors. The US is a major consumer, dominated by large chain restaurants and institutional kitchens that favor HDPE blocks due to their high durability, ease of cleaning, and compliance with HACCP standards requiring specific color-coding. Simultaneously, the region boasts a substantial market for high-end, artisanal wood blocks, fueled by a strong culture of gourmet cooking, specialization in craft butchery, and a willingness among affluent consumers to invest heavily in premium kitchenware. Market growth in NA is heavily dependent on product innovation focused on sustainability, such as incorporating certified sustainable hardwoods and offering recycling programs for industrial plastic blocks, thereby catering to the environmental consciousness of the modern American consumer and commercial buyer.

Europe: The European Chopping Block Market is defined by a strong emphasis on tradition, quality craftsmanship, and extremely high regulatory standards mandated by the European Union (EU) Food Safety Authority. Countries like Germany, France, and Italy exhibit robust demand for both industrial plastic blocks and traditionally crafted, high-quality wood blocks, particularly in the fine-dining sector where aesthetics and performance are critical. The trend toward farm-to-table cuisine and artisanal preparation further bolsters the demand for specialized wood blocks, often sourced locally within Europe (e.g., beech or oak) and emphasizing local certifications and traceable materials. Challenges in Europe include managing the diverse regulatory landscape across member states and navigating high labor costs, which incentivize automation in the manufacturing process. Manufacturers focus on providing highly durable, certified products that meet strict chemical migration limits and offer certified bacteriostatic properties, essential for penetrating the competitive institutional and healthcare foodservice segments.

Asia Pacific (APAC): APAC is projected to be the fastest-growing region during the forecast period, primarily driven by explosive growth in the foodservice sector resulting from rapid urbanization, rising disposable incomes, and the proliferation of international restaurant chains across China, India, and Southeast Asia. This region is witnessing a rapid adoption of professional kitchen standards, moving away from traditional or less hygienic surfaces towards certified HDPE and composite blocks to meet global safety standards. While price sensitivity remains a factor in developing APAC economies, the sheer scale of the food processing industry—especially in meat and seafood—creates massive volumetric demand for standardized industrial chopping solutions. Furthermore, increasing Westernization of culinary trends in urban centers is creating emerging niche markets for premium imported wood blocks. Successful market penetration in APAC relies on scalable manufacturing, competitive pricing, and efficient logistics networks to serve the geographically diverse and rapidly expanding commercial user base.

Latin America (LATAM) and Middle East & Africa (MEA): These regions represent emerging markets with high growth potential, though currently exhibiting smaller market sizes compared to NA and APAC. In LATAM, growth is tied to the expansion of organized retail and the development of modern food processing infrastructure, particularly in countries like Brazil and Mexico. Demand is price-sensitive, often favoring economical yet functional HDPE blocks, though there is a developing market for specialized equipment linked to the region's strong meat consumption culture. The MEA region is heavily influenced by large-scale institutional catering—driven by tourism, massive urban development projects, and military/government contracts—which generates high demand for durable, volume-purchase plastic blocks compliant with international hygiene standards. Political and economic stability can impact large infrastructure projects, making demand somewhat volatile. Both regions require local partnerships and tailored distribution strategies to overcome logistical challenges and penetrate fragmented regional markets effectively.

- North America: Strong regulatory compliance drives HDPE demand; high disposable income fuels premium, artisanal wood block sales.

- Europe: High focus on certified quality, traditional craftsmanship, and sustainability; demanding institutional and fine-dining sectors.

- Asia Pacific: Highest growth rate driven by rapid urbanization and massive expansion of organized food service and industrial meat processing facilities.

- Latin America and MEA: Emerging markets characterized by price sensitivity and volume purchases for large catering and processing projects, dependent on economic development stability.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Chopping Block Market.- John Boos & Co.

- Epicurean

- Dexas

- San Jamar

- Teak Haus

- Sani-Tuff (Ace Sanitary)

- Catskill Craftsmen

- Hasegawa

- Madeira

- F. Dick

- Cutting Board Company

- New Age Industrial

- Michigan Maple Block Co.

- Brooklyn Butcher Blocks

- Totally Bamboo

- Fissler

- Victorinox

- Taylor Woodcraft

- Larch Wood Canada

- Proteak Renewable Resources

Frequently Asked Questions

Analyze common user questions about the Chopping Block market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between end-grain and edge-grain chopping blocks, and which is better for professional use?

End-grain blocks display the wood fibers vertically, allowing them to absorb knife impacts, providing a "self-healing" surface that preserves the knife edge better and resists deep scratches. Edge-grain blocks display fibers horizontally and are generally more economical. For heavy professional use, the superior knife maintenance and durability of end-grain construction make it the preferred choice, despite the higher cost.

How do global food safety regulations, such as HACCP, influence the demand for different chopping block materials?

HACCP principles strongly drive the demand for high-density polyethylene (HDPE) blocks, particularly those that are color-coded (e.g., red for raw meat, blue for fish) to prevent cross-contamination in commercial kitchens. Regulations prioritize materials that are non-porous, easily sanitized with industrial-strength cleaners, and resistant to microbial growth, giving synthetic options a strong competitive edge in institutional settings.

What are the main growth drivers for the Chopping Block Market in the Asia Pacific region?

The primary growth drivers in APAC are the rapid expansion and formalization of the commercial foodservice sector (restaurants, catering chains) due to urbanization and rising middle-class consumption. This growth necessitates investments in standardized, hygienic kitchen equipment that meets international safety standards, leading to high volumetric demand for industrial and commercial-grade chopping blocks.

Are sustainable and eco-friendly chopping block materials gaining market traction?

Yes, sustainability is a key trend, particularly in North America and Europe. Consumers and commercial buyers are increasingly seeking blocks made from rapidly renewable resources like bamboo or teak (if sustainably harvested), as well as products utilizing high-quality recycled food-grade plastics. Manufacturers are investing in certifications (e.g., FSC) and low-VOC finishes to meet this rising environmental demand.

What technological advancements are optimizing the manufacturing process for high-end wood chopping blocks?

Advanced manufacturing is optimized through the use of high-precision Computerized Numerical Control (CNC) machinery guided by AI vision systems. This technology ensures flawless alignment and lamination of wood pieces in end-grain construction, minimizes material waste by optimizing cutting paths, and guarantees the structural integrity required for long-term commercial use, ultimately enhancing product consistency and durability.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager