Clamping Vise Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435493 | Date : Dec, 2025 | Pages : 241 | Region : Global | Publisher : MRU

Clamping Vise Market Size

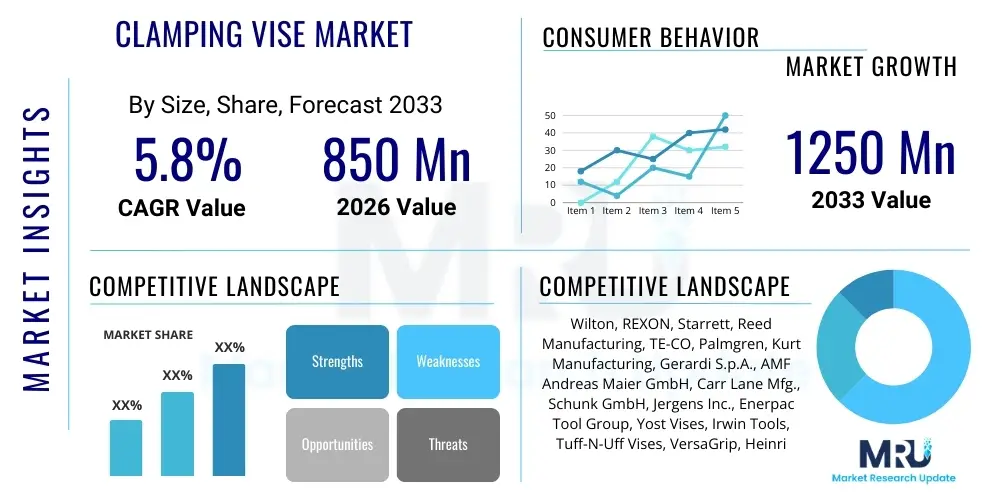

The Clamping Vise Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 850 million in 2026 and is projected to reach USD 1250 million by the end of the forecast period in 2033. This growth trajectory is fundamentally supported by the sustained expansion of the global manufacturing sector, particularly within high-precision industries such as aerospace, automotive, and medical device manufacturing. The necessity for high-tolerance workholding solutions that guarantee repeatability and stability drives demand across key industrialized regions. Furthermore, the increasing adoption of automated CNC machining centers globally necessitates specialized clamping vises capable of integration with automated loading systems and sophisticated control protocols, thereby influencing market valuation positively.

Market expansion is also significantly influenced by the rapid modernization of fabrication workshops and the persistent growth of the Do-It-Yourself (DIY) and woodworking segments, especially in developed economies. While industrial vises command higher Average Selling Prices (ASPs) due to complex mechanical features and material science requirements, the sheer volume demand stemming from hobbyists and smaller workshops for general-purpose bench vises contributes substantially to the overall market size. Technological advancements focused on ergonomics, quick-change systems, and modular clamping solutions are concurrently enhancing product utility and replacing legacy equipment, offering a consistent revenue stream for manufacturers.

Clamping Vise Market introduction

The Clamping Vise Market encompasses the production, distribution, and sale of mechanical apparatuses designed to securely hold workpieces during machining, fabrication, or assembly operations. Clamping vises are essential workholding tools, providing stability and precision crucial for maintaining dimensional accuracy and ensuring worker safety. Products range from heavy-duty hydraulic vises used in CNC milling centers to specialized woodworking vises and compact precision vises required for micro-machining tasks. The core function of a vise—to apply substantial, controlled clamping force—remains universal, but modern iterations incorporate features such as quick-release mechanisms, swivel bases, and enhanced jaw materials to cater to diverse industrial needs.

Major applications of clamping vises span critical sectors including industrial manufacturing (milling, grinding, drilling), automotive component production, aerospace fabrication requiring tight tolerances, and the furniture and construction industries. Key benefits derived from utilizing high-quality vises include improved machining precision, reduction in setup time, enhanced operational safety by preventing workpiece shifting, and overall boosting of manufacturing throughput. These tools are indispensable for any operation requiring stable fixturing of raw materials or semi-finished goods.

Driving factors propelling market growth include the escalating trend of industrial automation, which requires vises capable of interfacing seamlessly with robotics and FMS (Flexible Manufacturing Systems). Furthermore, the persistent demand for lightweight yet strong materials, such as specialized aluminum alloys and carbon composites in end-use industries, mandates advanced vise technology that can grip these materials without deformation or damage. The global infrastructure push, particularly in emerging economies, further catalyzes demand for robust fabrication tools, positioning the clamping vise market for sustainable expansion throughout the forecast period.

Clamping Vise Market Executive Summary

The Clamping Vise Market is characterized by steady technological evolution toward higher precision and integration, reflecting broader business trends in the industrial machinery sector focused on efficiency and repeatability. Key business trends include the consolidation of niche manufacturers to leverage specialized technologies, an increased focus on developing intelligent vises equipped with force sensors and digital readouts for quality control, and the growing prominence of e-commerce channels for the distribution of standard models, particularly targeting the robust DIY and small-to-medium enterprise (SME) segments. Manufacturers are heavily investing in materials science to create lighter yet more rigid vise bodies and jaws, enhancing performance in high-vibration machining environments.

Regional trends indicate that Asia Pacific (APAC), particularly China and India, maintains the highest growth momentum, driven by massive investments in domestic manufacturing capabilities and the establishment of global supply chain hubs. North America and Europe, while being mature markets, exhibit strong demand for premium, high-precision hydraulic and pneumatic vises necessary for advanced aerospace and automotive production lines, where the focus is on automation integration and reduced manual intervention. Political stability and industrial policy support, such as incentives for re-shoring manufacturing, further influence regional market buoyancy and procurement patterns.

Segmentation trends highlight the increasing demand for Machine Vises, particularly those designed for 5-axis machining, reflecting the industry's move toward complex geometry production. Although traditional Bench Vises maintain significant market share by volume, the highest revenue growth is observed in highly engineered, modular clamping systems that offer versatility and quick changeover capabilities, critical factors in high-mix, low-volume manufacturing environments. Sustainability is also emerging as a segment trend, with manufacturers exploring environmentally friendlier materials and longer-lasting product designs to meet evolving corporate environmental responsibility targets.

AI Impact Analysis on Clamping Vise Market

User queries regarding AI's influence on the Clamping Vise Market predominantly revolve around how automation and machine learning can enhance workholding precision, predict maintenance needs, and optimize production setup times. Users seek understanding on topics like ‘smart vises,’ ‘sensor integration for clamping force feedback,’ and ‘AI-driven fixture design optimization.’ The key themes emerging from this analysis are focused on predictive capabilities (e.g., preventing slippage), integration with Computer Numerical Control (CNC) systems, and the expectation that AI will transition vises from passive workholding tools to active, communicative components within the Industry 4.0 ecosystem. Users are keen to know if AI can compensate for material variations or thermal expansion in real-time.

The implementation of AI and related technologies primarily impacts the design phase and the operational efficiency of manufacturing processes where vises are deployed. AI algorithms analyze data streams from embedded sensors (monitoring clamping force, temperature, and vibration) to adjust parameters dynamically, ensuring optimal grip and minimizing scrap rates. This shift transforms high-end vises into 'intelligent' peripheral devices, drastically improving repeatability and reducing the dependency on manual operator expertise for complex setups. Furthermore, predictive maintenance powered by machine learning analyzes wear patterns in the vise screw, jaws, and hydraulic systems, scheduling maintenance before critical failures occur, thereby maximizing uptime.

The long-term influence of AI suggests a market polarization: mass-produced, low-cost vises remain largely untouched, while the premium segment rapidly integrates digital and AI capabilities. This integration necessitates specialized software, training, and maintenance contracts, creating new revenue streams for market players and substantially increasing the value proposition of high-end clamping solutions. AI supports the move towards customized, highly agile manufacturing lines, making clamping vises more adaptable to rapid changes in product specifications.

- AI facilitates real-time clamping force optimization based on material properties.

- Machine learning algorithms enable predictive maintenance for mechanical components of the vise.

- AI integrates smart vises with CNC machine control systems for automated setup verification (fixture recognition).

- Data analysis drives improved ergonomic design and operator feedback mechanisms.

- Optimization of jaw configuration and customized fixturing solutions using generative design driven by AI.

DRO & Impact Forces Of Clamping Vise Market

The Clamping Vise Market is shaped by powerful Drivers such as the global push for manufacturing precision and automation, particularly in sectors like aerospace and medical devices, necessitating complex, high-rigidity workholding. Restraints include the volatility of raw material prices (steel and cast iron), which directly impacts manufacturing costs and profit margins, and the significant capital expenditure required for automated, hydraulic, or pneumatic vises, posing a barrier for small workshops. Opportunities primarily lie in developing smart vises with IoT capabilities, expanding into emerging markets with rapidly industrializing economies, and creating modular clamping systems that minimize machine downtime. Impact Forces dictate the market's direction, balancing the urgent need for enhanced manufacturing efficiency against cost constraints and competitive pressures.

Key drivers include the technological advancements in CNC machinery, which demand equally advanced clamping vises to maximize machine potential. The growth in 5-axis machining complexity explicitly drives the need for low-profile, high-clamping-force vises that provide greater tool clearance and accessibility. Furthermore, stringent quality control standards across numerous industries necessitate clamping solutions that offer verifiable, consistent force application, often through hydraulic or digital systems, thus boosting the premium segment of the market.

Conversely, significant restraints hinder growth, notably the long product life cycle of traditional mechanical vises, which often discourages frequent replacement unless a major technology upgrade is necessary. Counterfeit and low-quality vises, predominantly originating from uncontrolled markets, undermine the established market players by offering lower-priced alternatives, compromising quality and safety standards. Opportunities, however, abound in developing countries, where government initiatives to boost local manufacturing create a massive untapped demand for reliable, foundational workholding tools. The shift towards specialized materials like composites also opens up a distinct opportunity for non-marring, specialized clamping jaws and systems.

Segmentation Analysis

The Clamping Vise Market is extensively segmented across several dimensions, including product type, operational technology, application, and distribution channel, reflecting the highly specialized nature of workholding requirements across the industrial landscape. Segmentation based on type, such as Machine Vises versus Bench Vises, addresses the fundamental operational environment—high-precision machining versus general workshop assembly. Analysis reveals that the Machine Vises segment, particularly hydraulic and pneumatic variants, commands the highest average revenue due to their integration into capital-intensive automated systems, while the Bench Vises segment accounts for the largest volume sales driven by workshops and DIY consumers. The segmentation structure provides manufacturers with targeted strategies for product development and market penetration.

- By Type:

- Machine Vises (Milling, Grinding, 5-Axis)

- Bench Vises (Engineers' Vises, Workshop Vises)

- Woodworking Vises (Front Vises, Tail Vises)

- Drill Press Vises

- Precision/Inspection Vises

- Modular Clamping Systems

- By Operation:

- Manual Vises (Screw-based)

- Hydraulic Vises

- Pneumatic Vises

- Mechanical Vises (Lever/Cam-Lock)

- By Application/End-Use Industry:

- Industrial Manufacturing (General Engineering)

- Automotive and Transportation

- Aerospace and Defense

- Woodworking and Furniture

- DIY and Home Improvement

- Tool & Die Making

- By Distribution Channel:

- Offline (Direct Sales, Distributors, Retail Stores)

- Online (E-commerce Platforms)

Value Chain Analysis For Clamping Vise Market

The value chain for the Clamping Vise Market begins with the upstream procurement of essential raw materials, primarily high-grade cast iron, forged steel, and specialized aluminum alloys, requiring stringent quality control due to the critical performance requirements of the final product regarding rigidity and durability. Manufacturers often face challenges in securing consistent pricing and supply of specialized alloys necessary for high-precision components like jaws and lead screws. The core manufacturing stage involves complex processes such as precision casting, forging, heat treatment, and meticulous CNC grinding to achieve the necessary tolerances, representing the highest value-add activity in the chain. Differentiation at this stage relies heavily on intellectual property regarding clamping mechanisms and hydraulic system design.

Downstream activities focus on effective distribution and after-sales support. Distribution channels are bifurcated: high-end industrial vises are typically sold through specialized industrial distributors or direct sales teams who provide technical consulting and integration services to large manufacturers (OEMs and Tier-1 suppliers). This direct/specialized approach ensures proper application match and installation. Conversely, general-purpose bench and woodworking vises are increasingly sold through mass retail channels, industrial supply catalogs, and rapidly expanding e-commerce platforms, optimizing for volume and broad reach.

Direct sales offer manufacturers maximum control over pricing and customer feedback but require significant investment in a skilled sales force. Indirect channels, primarily utilizing distributors and value-added resellers (VARs), provide essential market penetration, warehousing, and local support, proving crucial for reaching diverse geographical and SME customer bases. Effective management of the distribution channel, balancing direct technical support for complex systems with efficient, cost-effective distribution for standard products, is paramount for maintaining profitability and market share.

Clamping Vise Market Potential Customers

The primary consumers and end-users of clamping vises span a wide spectrum, ranging from multinational aerospace giants operating advanced multi-axis machining centers to independent carpentry workshops and home hobbyists. High-value potential customers include manufacturers within the automotive, aerospace, and medical device sectors, who necessitate premium, automated, hydraulic, or pneumatic vises capable of holding expensive, complex components with micron-level precision. These large industrial consumers prioritize features like high clamping force consistency, fast setup times, integration capability with automation, and certified quality assurance, often leading to large-volume contracts for specialized models.

A crucial secondary customer group consists of educational institutions, vocational training centers, and government maintenance facilities, which maintain consistent demand for standard, durable manual vises for training and general repair work. While individual unit cost might be lower, the cumulative demand from this sector provides a stable base revenue stream. The growth of the global SME manufacturing sector, specializing in subcontracted general engineering and tool-and-die making, represents a significant growth vector for mid-range precision vises, balancing cost-effectiveness with performance requirements suitable for smaller batch production.

The fastest-growing segment in terms of customer volume is the DIY and home improvement market, accessible through consumer retail and online marketplaces. These customers prioritize affordability, ease of use, and versatility, typically opting for smaller, manually operated bench vises. Strategic targeting of professional trade workers, such as plumbers, electricians, and mechanics, through specialized tool distributors also forms a substantial part of the potential customer base, emphasizing durability and portability in product selection.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 850 Million |

| Market Forecast in 2033 | USD 1250 Million |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Wilton, REXON, Starrett, Reed Manufacturing, TE-CO, Palmgren, Kurt Manufacturing, Gerardi S.p.A., AMF Andreas Maier GmbH, Carr Lane Mfg., Schunk GmbH, Jergens Inc., Enerpac Tool Group, Yost Vises, Irwin Tools, Tuff-N-Uff Vises, VersaGrip, Heinrich Inc., Columbian Vises, Dawn Vises, WEN. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Clamping Vise Market Key Technology Landscape

The technological landscape of the Clamping Vise Market is rapidly evolving beyond simple mechanical clamping, focusing heavily on enhancing precision, automation capability, and system integration. Modern advancements center on hydraulic and pneumatic actuation systems that offer consistent, measurable, and repeatable clamping force, essential for high-volume CNC machining where slight variations can lead to costly scrap. Furthermore, the development of modular clamping platforms, such as zero-point systems, allows for faster fixture changeovers and reduced non-productive time, leveraging sophisticated indexing and locating technologies to ensure repeatability between setups. Specialized jaw technology, including interchangeable soft jaws made from engineered plastics or aluminum, protects delicate workpieces and adapts the vise for unconventional shapes, extending its functional utility.

Material science plays a critical role, with leading manufacturers utilizing stress-relieved high-tensile cast iron or precision-ground alloy steel to maintain rigidity and dimensional stability under extreme clamping pressure and high-speed machining vibrations. This focus on material integrity is vital to prevent lifting or distortion of the workpiece. More recent innovations include the incorporation of sensors (piezoelectric and strain gauges) into vise bodies. These sensors monitor and digitally display the actual clamping force applied, providing closed-loop feedback to the machine operator or the automated system, thereby ensuring compliance with stringent process control specifications required in regulated industries like medical and aerospace. These technological upgrades position the vise as a core component of the quality control loop.

The convergence of mechatronics has led to the emergence of 'smart vises' that can communicate their status and parameters via industrial networking protocols (e.g., EtherCAT or PROFINET). This integration facilitates seamless synchronization with robot loading systems and overall factory management software, which is a significant factor in promoting lights-out manufacturing environments. Manufacturers are also exploring advanced surface coatings and treatments, such as nitride or black oxide finishes, to enhance corrosion resistance and reduce friction in moving parts, extending the operational lifespan and maintaining long-term accuracy, thereby reducing the Total Cost of Ownership (TCO) for end-users.

Regional Highlights

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, driven primarily by extensive infrastructure development, massive expansion of the automotive sector (especially electric vehicle manufacturing), and government initiatives supporting high-tech manufacturing in countries like China, India, South Korea, and Southeast Asian nations. The region demands a mix of high-volume, cost-effective standard vises and specialized high-precision vises required for electronics and advanced machinery production. Investment in automation systems significantly accelerates demand for hydraulic and pneumatic workholding solutions.

- North America: Characterized by a strong focus on high-value, low-volume production in aerospace, defense, and medical devices. The US and Canada are major consumers of premium, technologically advanced vises, particularly 5-axis and automated clamping systems. Market demand is driven by the necessity for extreme precision, rapid changeover capabilities, and robust integration with existing CNC infrastructure. Strict quality standards mandate the use of vises with integrated force monitoring and digital feedback systems.

- Europe: Europe represents a mature but highly sophisticated market, led by Germany, Italy, and Switzerland, which are global hubs for machine tool manufacturing and high-quality engineering. The emphasis here is on precision, energy efficiency, and modularity. European manufacturers highly value durability and compliance with strict safety and ergonomic standards (CE certification), favoring specialized suppliers offering customized clamping solutions tailored for complex, multi-sided machining tasks.

- Latin America (LATAM): Growth in LATAM is moderate but steady, centered around automotive assembly, mining equipment maintenance, and basic fabrication in countries like Brazil and Mexico. The market generally prioritizes durable, mid-range mechanical vises, with increasing adoption of basic hydraulic systems as industrial automation slowly expands, particularly in large manufacturing clusters near international borders.

- Middle East and Africa (MEA): This region is heavily influenced by oil and gas infrastructure, construction, and emerging localized industrialization efforts (e.g., Saudi Arabia’s Vision 2030). Demand is concentrated in robust, heavy-duty vises suitable for maintenance, repair, and overhaul (MRO) activities in harsh environments, alongside a nascent, high-end demand for precision vises related to technological diversification projects.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Clamping Vise Market.- Kurt Manufacturing

- Wilton (A division of JPW Industries)

- Starrett

- Reed Manufacturing

- Palmgren

- TE-CO

- Gerardi S.p.A.

- Schunk GmbH & Co. KG

- Jergens Inc.

- Enerpac Tool Group

- Yost Vises

- Irwin Tools

- Carr Lane Manufacturing Co.

- AMF Andreas Maier GmbH & Co. KG

- Heinrich Inc.

- Tuff-N-Uff Vises

- VersaGrip Vises

- Columbian Vises

- Dawn Vises

- WEN Products

Frequently Asked Questions

Analyze common user questions about the Clamping Vise market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between a hydraulic and a manual clamping vise?

A manual vise utilizes a lead screw and handle for force application, relying on operator effort. A hydraulic vise uses pressurized fluid to generate significantly higher, highly repeatable, and adjustable clamping forces, making it essential for precision CNC machining and automation where consistent grip is non-negotiable.

How does the integration of 5-axis machining influence the design requirements for modern vises?

5-axis machining requires low-profile vises with maximum jaw opening and minimal obstruction to allow the spindle and cutting tools access to five sides of the workpiece. Modern 5-axis vises often feature modular components and specialized wedge-style mechanisms to ensure strong grip with reduced clamping height.

Which geographical region exhibits the highest growth rate for clamping vises, and why?

Asia Pacific (APAC) exhibits the highest growth rate due to rapid industrialization, massive government investments in manufacturing capabilities (e.g., automotive and electronics production), and the widespread adoption of automation technologies replacing older, manual machining setups across China and India.

What are 'smart vises,' and what key technology enables their functionality in the industrial setting?

Smart vises are advanced clamping systems integrated with force sensors and digital readouts. Their functionality is enabled by IoT connectivity, allowing them to communicate real-time clamping data to CNC controllers or quality management systems, optimizing machining processes and enabling predictive maintenance.

What are the key materials used in high-precision machine vises, and why is material selection critical?

High-precision vises utilize high-tensile strength cast iron (Ductile Iron) or precision-ground alloy steel, often stress-relieved. Material selection is critical because the vise body must maintain exceptional rigidity and resist deflection or vibration under high machining loads to ensure geometric accuracy and repeatability of the workpiece.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager