Cleaning Nozzles Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436432 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Cleaning Nozzles Market Size

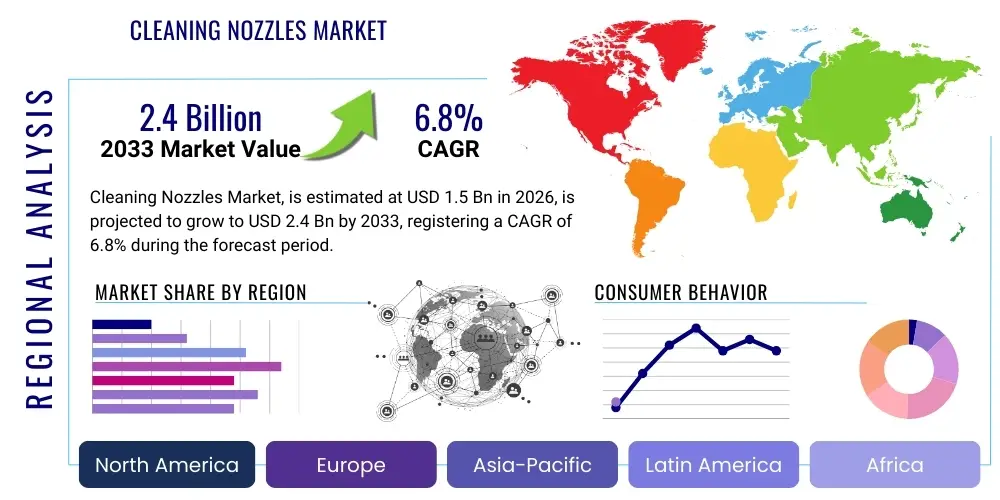

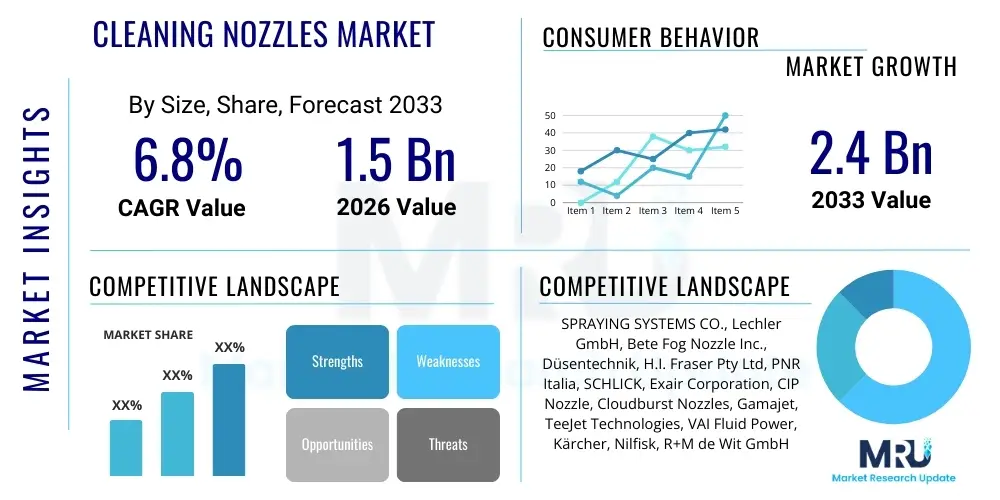

The Cleaning Nozzles Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.5 Billion in 2026 and is projected to reach USD 2.4 Billion by the end of the forecast period in 2033.

Cleaning Nozzles Market introduction

The Cleaning Nozzles Market encompasses a vast range of precision-engineered components designed to optimize fluid dynamics for surface preparation, sanitation, rinsing, and debris removal across diverse industrial and commercial settings. These devices are critical for efficiency, water conservation, and ensuring adherence to stringent cleanliness standards, particularly in regulated industries like food and beverage, pharmaceuticals, and automotive manufacturing. Modern cleaning nozzles are characterized by sophisticated spray patterns—ranging from solid stream and flat fan to hollow cone and specialized rotating jets—tailored to specific application requirements concerning impact force, coverage uniformity, and flow rate control.

Product descriptions typically emphasize material compatibility (e.g., stainless steel for corrosive environments, plastics for lightweight applications), operational pressure ranges (low, medium, or high), and self-cleaning mechanisms (such as Clean-In-Place or CIP systems). Major applications span vessel cleaning (tanks, reactors), parts washing, surface degreasing, spray drying, and dust suppression. The primary benefits derived from using specialized cleaning nozzles include significantly reduced cycle times, lower consumption of water and chemicals, improved cleaning quality consistency, and enhanced operator safety by minimizing manual intervention in hazardous processes. The market’s growth is fundamentally driven by escalating automation trends in industrial cleaning, increasing global focus on hygiene standards, and continuous technological advancements improving nozzle efficiency and durability.

Cleaning Nozzles Market Executive Summary

The Cleaning Nozzles Market is experiencing robust expansion, primarily fueled by global industry movements toward advanced automation and the non-negotiable requirement for high-standard hygiene across manufacturing and processing sectors. Business trends indicate a strong pivot toward high-pressure, low-flow rate nozzles that offer superior impact force while maximizing water efficiency, aligning with corporate sustainability mandates. Furthermore, the integration of smart nozzle technology, featuring sensors and actuators for real-time spray monitoring and pattern adjustment, is transforming operational effectiveness and predictive maintenance schedules within complex industrial cleaning systems.

Regional trends highlight Asia Pacific (APAC) as the fastest-growing market, driven by rapid industrialization, particularly in the chemical, pharmaceutical, and automotive industries in China and India, necessitating bulk procurement of specialized cleaning equipment. North America and Europe maintain dominance in terms of technological adoption and market value, characterized by mature regulatory frameworks that enforce strict sanitation protocols, thereby driving demand for premium, stainless steel, and certified CIP nozzles. Segmentation trends reveal that the rotating nozzle and specialized tank cleaning segment (CIP nozzles) are witnessing accelerated growth due to the expansion of large-scale processing facilities requiring automated internal vessel sanitation.

AI Impact Analysis on Cleaning Nozzles Market

User inquiries regarding the impact of Artificial Intelligence (AI) on the Cleaning Nozzles Market typically center on how AI can optimize cleaning processes, minimize resource consumption, and enhance predictive maintenance capabilities. Key concerns revolve around the cost of integrating AI-driven sensor technology into traditional nozzle systems and the reliability of machine learning algorithms in varying operational conditions (e.g., high heat, chemical exposure). Users often express expectations for AI to facilitate 'smart cleaning,' where the system dynamically adjusts spray patterns, pressure, and flow rates based on real-time contamination levels detected by integrated sensors, leading to quantifiable improvements in efficiency and reduced waste. The overarching theme is the transition from scheduled cleaning cycles to condition-based, intelligent cleaning operations, improving both product yield and equipment longevity.

AI's primary influence will manifest through advanced data analytics applied to nozzle performance, enabling automated diagnostics that predict spray degradation, blockage, or uneven coverage before operational failure occurs. This shift supports a preventive maintenance model, significantly reducing unplanned downtime, a critical factor in capital-intensive industries. Furthermore, machine learning algorithms can analyze historical cleaning data—including water usage, chemical concentrations, and microbial counts—to generate optimized cleaning recipes specific to each batch or product changeover, ensuring compliance while cutting utility costs. This level of optimization requires the adoption of sensor-equipped nozzles (IoT-enabled) capable of feeding precise data into the cloud-based AI platforms.

- AI enables predictive maintenance by analyzing flow rate and pressure data to identify potential nozzle clogging or wear.

- Machine learning optimizes cleaning cycles, reducing water and energy consumption based on real-time cleanliness validation.

- AI-driven sensor integration facilitates dynamic spray pattern adjustments for complex geometries, ensuring complete surface coverage.

- Automated diagnostics improve system uptime by alerting operators to required nozzle replacement before performance degradation.

- Data synthesis allows for customized chemical and water usage protocols based on contamination severity, enhancing sustainability.

DRO & Impact Forces Of Cleaning Nozzles Market

The dynamics of the Cleaning Nozzles Market are primarily driven by stringent regulatory pressures mandating high levels of hygiene in processing environments, particularly within the Food & Beverage and Pharmaceutical sectors, globally known as market Drivers. These requirements necessitate the frequent replacement and upgrading of cleaning equipment to meet current standards. Coupled with this is the opportunity presented by the increasing adoption of automated cleaning systems (such as CIP and COP systems), which require specialized, high-performance nozzles designed for integration into complex mechanized setups. However, the market faces significant restraints, including the high initial capital investment required for high-end, precise nozzle systems and the vulnerability of certain materials (like brass or plastic) to harsh chemicals or extreme temperatures, limiting their application scope and longevity.

Impact forces currently shaping the market include technological advancements in materials science, leading to the development of highly durable and chemical-resistant nozzles (e.g., those made from specialized ceramics or engineered polymers), extending operational lifespans and reducing maintenance downtime. Furthermore, the push for environmental sustainability acts as a crucial driver, compelling manufacturers to develop low-flow, high-impact nozzle designs that significantly reduce water and energy consumption without compromising cleaning efficacy. This technological pressure ensures that innovation remains central to market competition, particularly in mature economies where operational efficiency dictates profitability.

Opportunities abound in emerging economies where industrial infrastructure is rapidly modernizing and installing standardized automated cleaning processes for the first time. Market players are focused on penetrating these developing regions by offering scalable and cost-effective nozzle solutions suitable for varied manufacturing capacities. Addressing the restraint of high cost through value engineering and manufacturing standardization, especially for replacement parts, remains a core strategy for achieving wider market penetration and sustained growth throughout the forecast period. The combined effects of regulatory push, efficiency demands, and emerging market adoption create a strong positive impact trajectory.

Segmentation Analysis

The Cleaning Nozzles Market is meticulously segmented based on critical factors such as Type, Material, Pressure Range, and End-User Industry, reflecting the diverse application needs across the industrial spectrum. Type segmentation is crucial as it dictates the physical impact and coverage area of the cleaning medium, with segments like flat fan nozzles being highly common for general surface washing, while solid stream nozzles are preferred for high-impact spot cleaning. The Material segment determines the nozzle's durability and chemical compatibility, with stainless steel dominating high-demand sectors due to its resistance to corrosion and high-temperature environments. Understanding these segmentation nuances is vital for manufacturers to tailor product offerings and for end-users to select the optimal nozzle for their specific cleaning challenges, ensuring both efficiency and system longevity.

The Pressure Range segmentation (Low, Medium, High) directly correlates with the intensity and specific application: high-pressure nozzles are essential for heavy-duty applications like paint stripping or stubborn debris removal in the automotive sector, while low-to-medium pressure nozzles suffice for rinsing and general maintenance in the food processing industry. The End-User Industry segmentation provides insight into demand volume and regulatory standards, highlighting that sectors like Pharmaceuticals and Chemical Processing often require complex, validated CIP nozzles, driving premium price points and stringent quality control. This multi-faceted segmentation structure allows for precise market sizing and strategic targeting by regional and product line managers.

- By Type:

- Flat Fan Nozzles

- Solid Cone Nozzles

- Hollow Cone Nozzles

- Stream/Jet Nozzles

- Rotating/CIP Nozzles

- By Material:

- Stainless Steel

- Brass

- Plastics (PP, PVDF, PTFE)

- Ceramics/Carbide

- By Pressure Range:

- Low Pressure (Up to 100 psi)

- Medium Pressure (100 to 1,000 psi)

- High Pressure (Above 1,000 psi)

- By End-User:

- Industrial Manufacturing

- Chemical Processing

- Food & Beverage (F&B)

- Automotive & Transportation

- Pharmaceutical & Biotechnology

- Water Treatment & Municipal

Value Chain Analysis For Cleaning Nozzles Market

The value chain for the Cleaning Nozzles Market begins with the upstream activities centered on raw material procurement, focusing heavily on high-grade metals (especially stainless steel 304 and 316) and specialized engineering plastics, sourced from global commodity markets. Key upstream analyses include managing price volatility of raw materials and ensuring consistent supply of specialized components like precision bearings used in rotating nozzles. Manufacturers must establish strong relationships with material suppliers to ensure compliance with quality certifications, particularly for components used in hygienic and high-pressure applications, where material integrity is non-negotiable for system safety and performance.

Midstream processes involve core manufacturing, including CNC machining, precision molding, and assembly, where intellectual property related to spray pattern design and flow optimization is critical. Companies invest significantly in R&D to enhance nozzle efficiency (maximizing impact force while minimizing water usage) and developing modular designs for easier maintenance and replacement. Downstream activities involve distribution and end-user engagement. Direct distribution channels are often favored for complex, custom-engineered solutions required by large industrial clients (e.g., pharmaceutical companies), allowing for specialized consultation and integration support provided by the manufacturer or authorized distributors.

Indirect distribution channels, utilizing industrial supply houses, MRO (Maintenance, Repair, and Operations) suppliers, and e-commerce platforms, are crucial for standard, high-volume replacement parts and for reaching smaller industrial consumers. The effectiveness of the value chain relies heavily on logistics efficiency, inventory management (stocking high-demand replacement models), and post-sales service, including training on optimal nozzle selection and preventative maintenance schedules. The overall profitability of the market segment is often determined by the ability to maintain manufacturing precision and control the material input costs while delivering specialized, certified products through efficient distribution networks.

Cleaning Nozzles Market Potential Customers

Potential customers, or end-users, of cleaning nozzles are spread across virtually every sector that requires industrial-scale sanitation, surface preparation, or debris removal. These buyers range from large, multinational food and beverage corporations that require daily automated tank cleaning (CIP systems) to specialized automotive paint shops needing ultra-precise surface pretreatment nozzles. The common denominator among these buyers is the need for reliable, performance-driven fluid delivery systems that ensure process consistency, adhere to regulatory compliance (such as FDA or GMP standards), and maximize operational uptime. Procurement decisions are typically driven by total cost of ownership (TCO), efficiency metrics (water and chemical savings), and nozzle longevity in harsh operating environments.

Key buying centers within these organizations include MRO departments, process engineering teams, and quality assurance divisions. For instance, in pharmaceutical facilities, the emphasis is heavily placed on sterile, verifiable cleaning performance, making certified stainless steel rotating nozzles (CIP) the default choice. In contrast, municipal water treatment facilities prioritize robust, high-impact nozzles capable of handling scale and sludge removal over long operational periods. Therefore, product differentiation based on material robustness, spray pattern accuracy, and industry-specific certifications is essential for capturing and retaining these varied customer segments. Strategic marketing must align product features directly with specific regulatory or operational pain points unique to each end-user group.

Beyond traditional manufacturing, emerging high-growth customer segments include data center operators utilizing specialized misting nozzles for dust control and fire suppression, and renewable energy providers requiring efficient cleaning solutions for solar panels and wind turbine blades. These new applications demand innovations in non-contact or ultra-low flow cleaning technologies. Consequently, manufacturers must continually update their product portfolios to address these niche, yet technologically demanding, buyer groups. The core value proposition delivered to all potential customers remains centered on optimizing cleaning performance, minimizing environmental impact, and securing process integrity.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.5 Billion |

| Market Forecast in 2033 | USD 2.4 Billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | SPRAYING SYSTEMS CO., Lechler GmbH, Bete Fog Nozzle Inc., Düsentechnik, H.I. Fraser Pty Ltd, PNR Italia, SCHLICK, Exair Corporation, CIP Nozzle, Cloudburst Nozzles, Gamajet, TeeJet Technologies, VAI Fluid Power, Kärcher, Nilfisk, R+M de Wit GmbH, Parker Hannifin, Graco Inc., WEMCO, Aqua-Jet |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Cleaning Nozzles Market Key Technology Landscape

The technology landscape of the Cleaning Nozzles Market is shifting rapidly towards high-precision fluid dynamics and digital integration. Traditional nozzle technology focused primarily on material selection and fixed spray geometry; however, modern innovation centers on optimizing impact uniformity and minimizing overspray losses. A core technological trend is the advancement of rotating and indexing tank cleaning nozzles (CIP technology). These systems utilize gear-driven or fluid-driven mechanisms to generate predictable, comprehensive 3D cleaning patterns inside vessels, ensuring 100% surface coverage using minimal fluid volumes, critical for maintaining sterilization protocols in pharmaceutical and F&B applications.

Another pivotal technological development involves the integration of micro-sensor technology and IoT (Internet of Things) capabilities directly into the nozzle or the manifold system. These smart components monitor crucial performance indicators such as flow rate, pressure, temperature, and vibration in real time. This data is essential for implementing the predictive maintenance strategies discussed previously, enabling early detection of clogs or wear, thereby transitioning maintenance from reactive to proactive. Furthermore, manufacturers are employing Computational Fluid Dynamics (CFD) simulation software extensively during the design phase to accurately model and refine spray patterns, ensuring optimal droplet size and velocity for specific cleaning tasks before physical prototyping, accelerating the product development cycle.

Material innovation remains foundational, with increased utilization of highly durable materials like ceramics, specialty carbides, and advanced polymers (e.g., PTFE, PVDF) that resist aggressive chemicals, high temperatures, and abrasive media. This focus on material engineering enhances nozzle lifespan and reduces downtime associated with component failure. Furthermore, the push for environmentally friendly solutions has spurred the development of air-assisted atomization nozzles and fogging systems, which use significantly less water by mixing cleaning agents with compressed air to generate fine mist for specialized surface treatment, particularly favored in sensitive electronics manufacturing and dust suppression applications.

Regional Highlights

The global cleaning nozzles market exhibits distinct growth patterns and maturity levels across key geographical regions. North America and Europe currently represent the largest revenue generators, primarily due to established industrial sectors, rigorous regulatory environments (e.g., FDA, HACCP), and high adoption rates of automated CIP and high-pressure cleaning systems. In these regions, market growth is fueled less by new installation volumes and more by replacement demand for advanced, water-efficient, and digitally integrated smart nozzles that offer superior operational data and resource optimization. The presence of major manufacturing hubs for pharmaceuticals, aerospace, and high-value chemicals sustains demand for premium-grade stainless steel and precision-engineered nozzles.

Asia Pacific (APAC) is projected to register the highest Compound Annual Growth Rate (CAGR) during the forecast period. This rapid expansion is attributed to unprecedented infrastructure development, expansion of manufacturing capacity across China, India, and Southeast Asian nations, and increasing Westernization of consumer standards, which elevates the requirement for hygiene in local food processing and bottling plants. The APAC market is characterized by a strong demand for cost-effective, durable nozzles suitable for large-scale, often manual, industrial cleaning, though the shift toward automated systems is accelerating, driving specialized demand for rotating and self-cleaning nozzles.

Latin America (LATAM), and the Middle East and Africa (MEA) demonstrate potential, primarily driven by investments in water treatment infrastructure and expansion of the oil & gas and chemical processing industries, necessitating robust, explosion-proof, and corrosion-resistant nozzles for complex industrial cleaning and safety applications. While these regions currently hold smaller market shares, focused government investments in industrial standardization and foreign direct investment into manufacturing capabilities are expected to boost the consumption of industrial cleaning nozzles over the medium to long term, making them critical targets for global market expansion strategies.

- North America: Dominant market share driven by advanced manufacturing (Automotive, Aerospace) and strict food safety regulations; focus on high-pressure and sensor-enabled systems.

- Europe: High adoption of hygienic and resource-efficient (low-flow) nozzles, strongly influenced by EU environmental policies and GMP compliance in Pharma/Biotech.

- Asia Pacific (APAC): Fastest growing region due to rapid industrialization, expansion of F&B processing, and increasing adoption of CIP technology in developing manufacturing sectors.

- Latin America (LATAM): Emerging demand fueled by modernization of chemical and agricultural processing industries; need for robust and easily maintainable equipment.

- Middle East and Africa (MEA): Growth driven by large-scale water management projects, oil & gas refining facilities, and infrastructural construction requiring heavy-duty cleaning systems.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Cleaning Nozzles Market.- SPRAYING SYSTEMS CO.

- Lechler GmbH

- Bete Fog Nozzle Inc.

- Düsentechnik

- H.I. Fraser Pty Ltd

- PNR Italia

- SCHLICK

- Exair Corporation

- CIP Nozzle

- Cloudburst Nozzles

- Gamajet

- TeeJet Technologies

- VAI Fluid Power

- Kärcher

- Nilfisk

- R+M de Wit GmbH

- Parker Hannifin

- Graco Inc.

- WEMCO

- Aqua-Jet

Frequently Asked Questions

Analyze common user questions about the Cleaning Nozzles market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving demand for high-pressure cleaning nozzles?

The primary driver is the need for efficient removal of stubborn contaminants, scale, and heavy debris in industrial settings such as automotive component cleaning, heavy machinery maintenance, and tank stripping. High-pressure nozzles ensure maximum kinetic energy transfer, reducing cleaning time and chemical usage, thereby improving operational efficiency.

How are Clean-In-Place (CIP) nozzles different from standard industrial nozzles?

CIP nozzles are specialized, often rotating or indexing nozzles designed specifically for automated internal cleaning of tanks, vessels, and pipelines without disassembly. Unlike standard nozzles, CIP models must ensure 360-degree coverage, maintain hygienic design standards (typically stainless steel), and operate reliably within fully automated, validated sanitation cycles required by the pharmaceutical and food industries.

Which material segment holds the largest market share, and why?

Stainless steel holds the largest market share, particularly grades 304 and 316. This is due to its superior resistance to corrosion, high temperatures, and chemical degradation, making it suitable for rigorous use in regulated environments like chemical processing and food manufacturing where non-contamination and durability are critical requirements.

What role does the adoption of IoT and smart technology play in the future growth of the cleaning nozzles market?

IoT and smart technology facilitate the shift toward condition-based maintenance and resource optimization. By embedding sensors that monitor flow and pressure, users can preemptively identify nozzle wear or clogging, minimizing unplanned downtime and reducing water and energy consumption through dynamic, data-driven adjustment of cleaning protocols, essential for achieving sustainability goals.

Which regional market is expected to demonstrate the fastest growth rate through 2033?

The Asia Pacific (APAC) region is forecasted to experience the highest CAGR. This accelerated growth is attributed to rapid urbanization, significant government and private investment in industrial infrastructure modernization, and the increasing regional demand for high-standard hygiene solutions across the rapidly expanding chemical and food processing sectors in countries like China and India.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager