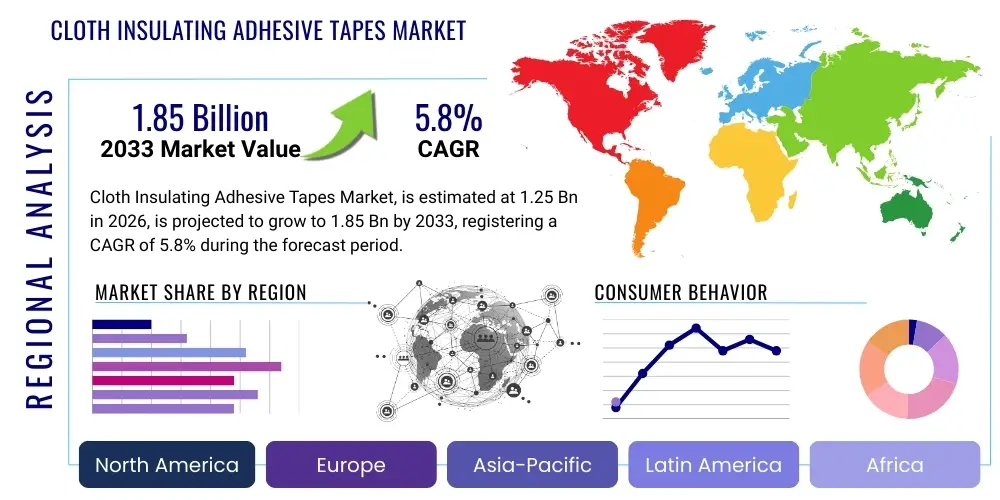

Cloth Insulating Adhesive Tapes Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439805 | Date : Jan, 2026 | Pages : 249 | Region : Global | Publisher : MRU

Cloth Insulating Adhesive Tapes Market Size

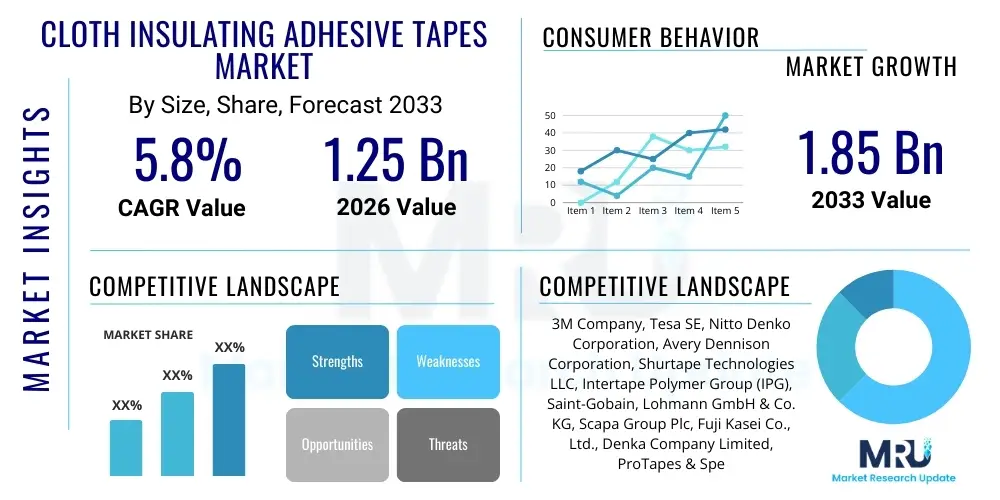

The Cloth Insulating Adhesive Tapes Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 1.25 billion in 2026 and is projected to reach USD 1.85 billion by the end of the forecast period in 2033. This steady growth is underpinned by escalating demand across various industrial sectors, particularly in electrical and electronics manufacturing, where these tapes are indispensable for ensuring safety, efficiency, and longevity of components. The continuous evolution of electrical systems and the increasing adoption of advanced materials contribute significantly to this market expansion.

The market's valuation reflects its critical role in modern infrastructure and product development. From insulating sensitive electronic circuits to providing robust mechanical protection in heavy industrial machinery, cloth insulating adhesive tapes offer versatile solutions that meet stringent performance requirements. The projected increase in market size underscores a global trend towards greater electrification, industrial automation, and the widespread integration of electronic components into everyday life and complex systems, driving consistent demand for high-quality insulation materials.

Cloth Insulating Adhesive Tapes Market introduction

The Cloth Insulating Adhesive Tapes Market encompasses a specialized segment within the broader adhesive tape industry, focusing on products designed for electrical insulation, thermal management, and mechanical protection. These tapes typically feature a fabric backing, such as cotton, fiberglass, polyester, or acetate, coated with various adhesive types including rubber, acrylic, or silicone. The primary function of these tapes is to provide reliable electrical isolation in wires, cables, motors, transformers, and electronic components, thereby preventing short circuits, enhancing safety, and optimizing operational efficiency. Beyond their insulative properties, they also offer critical mechanical strength, abrasion resistance, and often thermal stability, making them versatile solutions in demanding environments.

Major applications for cloth insulating adhesive tapes span across diverse industries including electrical and electronics manufacturing, automotive, aerospace, construction, and industrial maintenance. In electrical systems, they are used for coil wrapping, cable bundling, harnessing, and primary insulation. In the automotive sector, they contribute to wiring harness protection and component insulation, especially with the rising demand for electric vehicles. Their ability to withstand varying temperatures, resist chemicals, and offer robust adhesion makes them an indispensable component in critical applications where reliability is paramount.

The benefits derived from using these tapes are extensive, ranging from superior dielectric strength and high temperature resistance to excellent conformability and ease of application. These characteristics are crucial for ensuring the long-term performance and safety of electrical installations and electronic devices. Key driving factors for market growth include rapid industrialization, global infrastructure development, the expansion of the electronics manufacturing sector, the increasing complexity and miniaturization of electronic devices, and the burgeoning demand for renewable energy systems that require robust and efficient electrical insulation solutions. Furthermore, advancements in material science leading to improved tape performance continue to fuel market innovation and adoption.

Cloth Insulating Adhesive Tapes Market Executive Summary

The Cloth Insulating Adhesive Tapes Market is experiencing dynamic shifts driven by evolving technological landscapes and industrial demands. Current business trends indicate a strong emphasis on developing high-performance tapes with enhanced thermal resistance, superior dielectric strength, and eco-friendly formulations to meet stringent industry standards and sustainability goals. Manufacturers are increasingly investing in research and development to innovate new material combinations and adhesive technologies that cater to specialized applications, such as high-voltage insulation in renewable energy infrastructure and miniaturized components in advanced electronics. Furthermore, the push for automation in manufacturing processes is creating a demand for tapes that are compatible with automated application systems, thereby improving production efficiency and reducing labor costs across various end-use sectors.

Regional trends reveal Asia-Pacific as the leading market, primarily propelled by its robust manufacturing base in electrical and electronics, automotive, and general industrial sectors, particularly in countries like China, India, Japan, and South Korea. North America and Europe also hold significant market shares, driven by high demand for premium, high-specification tapes in aerospace, defense, and advanced industrial applications, alongside strong regulatory frameworks promoting safety and efficiency. Emerging economies in Latin America, the Middle East, and Africa are showing promising growth, attributed to increasing infrastructure development, urbanization, and industrial expansion, which directly translate into a greater need for reliable electrical insulation products. These regions are becoming attractive markets for global manufacturers seeking to expand their geographical footprint and tap into new growth opportunities.

Segmentation trends highlight the increasing prominence of specific material types and end-use applications. Fiberglass-backed tapes are gaining traction due to their excellent high-temperature resistance and mechanical strength, making them ideal for heavy-duty electrical insulation and motor winding. Polyester and polyimide tapes are witnessing increased adoption in electronic applications where thinness, high dielectric strength, and resistance to harsh environments are critical. In terms of end-use, the electrical and electronics industry remains the largest consumer, driven by continuous innovation in consumer electronics, industrial electronics, and power distribution systems. The automotive sector, particularly with the transition towards electric vehicles (EVs) and advanced driver-assistance systems (ADAS), is a rapidly expanding segment, demanding tapes with superior insulation, vibration damping, and thermal management capabilities. This dynamic interplay of material science advancements and application-specific requirements is continually shaping the market's trajectory.

AI Impact Analysis on Cloth Insulating Adhesive Tapes Market

Common user questions regarding the impact of AI on the Cloth Insulating Adhesive Tapes Market frequently revolve around how artificial intelligence can enhance manufacturing efficiency, improve product quality, and accelerate material innovation. Users are particularly interested in AI's role in optimizing production processes, predicting equipment failures, and developing new tape formulations with superior performance characteristics. There are also concerns about the potential for AI to streamline supply chain logistics and personalize product offerings. Key themes include the transformation of quality control from reactive to predictive, the potential for AI-driven automation to reduce waste and energy consumption, and how machine learning can aid in the discovery of novel materials that meet increasingly stringent insulation and thermal management requirements in advanced electrical and electronic systems.

- Enhanced quality control through AI-driven vision systems for defect detection.

- Optimized production processes via machine learning algorithms for parameter tuning.

- Predictive maintenance for manufacturing equipment, minimizing downtime and costs.

- Accelerated material R&D using AI for property prediction and formulation discovery.

- Improved supply chain management and logistics through demand forecasting and route optimization.

- Customization and smart manufacturing solutions for tailored tape specifications.

- Real-time monitoring and analysis of performance data for continuous product improvement.

- Automated testing and inspection reducing human error and increasing throughput.

DRO & Impact Forces Of Cloth Insulating Adhesive Tapes Market

The Cloth Insulating Adhesive Tapes Market is significantly shaped by a confluence of drivers, restraints, opportunities, and broader impact forces. Key drivers include the robust growth of the electrical and electronics industry, fueled by increasing consumer electronics adoption, industrial automation, and the expansion of data centers. The global push for renewable energy sources, such as solar and wind power, creates a substantial demand for high-performance insulating tapes in their complex electrical systems. Furthermore, the rapid advancements in automotive electrification, particularly the proliferation of electric vehicles (EVs), necessitate specialized tapes for battery pack insulation, wiring harnesses, and motor components. Urbanization and infrastructure development projects worldwide also contribute to the demand for reliable electrical insulation solutions in construction and utility sectors.

Despite these strong drivers, the market faces several restraints. Volatility in the prices of raw materials, such as polymers, adhesives, and fabric backings, can significantly impact manufacturing costs and profit margins. Stringent environmental regulations concerning volatile organic compounds (VOCs) in adhesives and waste disposal practices push manufacturers to invest in more sustainable, yet often more expensive, formulations. Intense competition from alternative insulation materials, including liquid resins, heat shrink tubing, and various films, also poses a challenge, requiring continuous innovation to maintain market share. Moreover, the complexity of managing global supply chains, particularly in times of geopolitical instability or pandemics, can lead to disruptions in material availability and production schedules.

Opportunities for growth are abundant within the market. Emerging economies in Asia-Pacific, Latin America, and Africa present untapped potential due to their rapidly expanding industrial bases and infrastructure projects. The development of advanced material science offers avenues for creating next-generation tapes with enhanced properties like higher dielectric strength, improved thermal conductivity, and greater resistance to extreme environmental conditions, catering to niche and high-value applications. The expansion of smart grid technologies and the modernization of existing electrical infrastructure globally also represent significant growth prospects. Furthermore, increasing demand for customized tape solutions tailored to specific industrial needs and the adoption of automation-friendly tape formats present lucrative opportunities for specialized manufacturers.

Impact forces acting on the market include the accelerating pace of technological advancements, which continuously redefine performance expectations and manufacturing capabilities. Environmental regulations and global sustainability initiatives are compelling a shift towards greener production processes and recyclable materials, influencing product development strategies. Global economic shifts, trade policies, and geopolitical events can directly affect market dynamics, influencing raw material availability, manufacturing locations, and consumer demand. Lastly, the imperative for supply chain resilience, highlighted by recent global disruptions, is encouraging regionalized manufacturing and diversified sourcing strategies, which in turn impact the competitive landscape and operational models of tape manufacturers.

Segmentation Analysis

The Cloth Insulating Adhesive Tapes Market is intricately segmented across various dimensions to reflect the diverse applications and material specifications demanded by different industries. This segmentation provides a granular view of market dynamics, revealing specific growth pockets and competitive landscapes within specialized niches. The market's complexity is driven by the need for tapes with tailored properties, such as specific dielectric strength, thermal resistance, mechanical durability, and adhesive characteristics, to perform optimally in distinct operational environments. Understanding these segments is crucial for manufacturers to align their product development and marketing strategies with prevailing industry requirements and technological advancements, ensuring that a comprehensive range of solutions is available to meet the evolving needs of end-users.

The primary segmentation often includes categories based on the material composition of the backing and adhesive, the specific application areas where the tapes are utilized, and the end-use industries that primarily consume these products. Each segment presents unique challenges and opportunities, influenced by factors such as material innovation, regulatory standards, and technological integration. For instance, the demand for high-performance tapes in electronics often prioritizes thinness and high dielectric strength, while industrial applications may emphasize mechanical robustness and thermal stability. This layered approach to market analysis allows stakeholders to identify key trends, evaluate competitive positioning, and forecast future growth trajectories within the specialized field of cloth insulating adhesive tapes, enabling more informed strategic decisions across the value chain.

- By Backing Material:

- Cotton

- Fiberglass

- Polyester

- Acetate

- Polyimide

- PTFE

- Aramid

- Others (e.g., Nylon, Rayon)

- By Adhesive Type:

- Rubber-based (Natural Rubber, Synthetic Rubber)

- Acrylic-based (Solvent Acrylic, Water-based Acrylic, UV Cured Acrylic)

- Silicone-based

- Others (e.g., Urethane)

- By Application:

- Electrical Insulation

- Masking

- Bundling and Harnessing

- Repair and Reinforcement

- Thermal Management

- High-Temperature Applications

- Mechanical Protection

- Die-Cutting and Converting

- By End-Use Industry:

- Electrical & Electronics (Consumer Electronics, Industrial Electronics, Power Distribution)

- Automotive (Wiring Harnesses, Battery Insulation, Motor Insulation)

- Aerospace & Defense

- Industrial Manufacturing (Motors, Transformers, Generators)

- Construction

- Energy (Renewable Energy, Utilities)

- Healthcare

- Others (e.g., Marine, Appliance)

Value Chain Analysis For Cloth Insulating Adhesive Tapes Market

The value chain for the Cloth Insulating Adhesive Tapes Market is a complex network involving several key stages, beginning from raw material sourcing and extending to the end-user. Upstream analysis focuses on the suppliers of fundamental components, which include manufacturers of various fabric backings (such as cotton, fiberglass, polyester, and polyimide films), producers of specialized adhesives (rubber, acrylic, silicone polymers, and their chemical precursors), and suppliers of release liners and other additives. The quality, consistency, and cost-effectiveness of these raw materials are paramount as they directly influence the performance characteristics and final price of the insulating tapes. Relationships with these suppliers are critical, often involving long-term contracts and strategic partnerships to ensure a stable supply of high-grade inputs, especially for specialized high-performance materials.

Midstream activities involve the tape manufacturers themselves, who transform these raw materials into finished products through sophisticated coating, laminating, slitting, and packaging processes. This stage adds significant value through proprietary adhesive formulations, precision coating technologies, and quality control systems that ensure the tapes meet stringent electrical, thermal, and mechanical specifications. Manufacturers often specialize in certain types of tapes or applications, leveraging their technical expertise and production capabilities to create differentiated products. The efficiency of these manufacturing processes, along with continuous investment in research and development for new material combinations and production techniques, determines a manufacturer's competitive edge in the market.

Downstream analysis encompasses the distribution channels and the ultimate end-users. Distribution primarily occurs through a mix of direct sales to large original equipment manufacturers (OEMs) and major industrial clients, as well as indirect channels via a network of industrial distributors, electrical wholesalers, and specialized material suppliers. Direct distribution allows for tailored solutions and stronger customer relationships, while indirect channels provide broader market reach and cater to smaller businesses or MRO (Maintenance, Repair, and Operations) demands. The effectiveness of these channels in reaching diverse customer bases, coupled with efficient logistics and warehousing, plays a crucial role in market penetration and customer satisfaction. The end-users span a wide array of industries, each with unique requirements for insulating tapes, from electrical and electronics to automotive, aerospace, and construction, driving the need for diverse product portfolios and targeted marketing efforts.

Cloth Insulating Adhesive Tapes Market Potential Customers

The potential customer base for Cloth Insulating Adhesive Tapes is remarkably diverse, reflecting the critical and ubiquitous nature of electrical insulation and mechanical protection across numerous industries. At the core, end-users are primarily entities that design, manufacture, install, or maintain electrical and electronic systems and components. This includes major electrical equipment manufacturers who produce motors, transformers, generators, and power distribution units, where these tapes are essential for winding, insulation, and general assembly. The electronics assembly plants, responsible for everything from consumer gadgets to sophisticated industrial control systems, rely heavily on these tapes for circuit board insulation, component fastening, and thermal management within compact devices. The constant drive towards miniaturization and higher performance in electronics continuously fuels demand for advanced tape solutions.

Another significant segment of potential customers resides within the automotive industry, particularly with the rapid global transition towards electric vehicles (EVs) and hybrid electric vehicles (HEVs). Automotive OEMs and their tier-one suppliers are major consumers, utilizing cloth insulating adhesive tapes for crucial applications such as wiring harness construction, battery pack insulation, sensor protection, and motor winding in propulsion systems. The demands here are stringent, requiring tapes that can withstand extreme temperatures, vibrations, chemicals, and offer superior dielectric strength for high-voltage systems. Similarly, aerospace component manufacturers and defense contractors constitute a high-value customer group, requiring tapes that meet extremely rigorous specifications for performance, reliability, and safety in aircraft, spacecraft, and military equipment, often in environments with extreme temperatures and harsh conditions.

Beyond these manufacturing-intensive sectors, the market extends to the construction industry, where electrical contractors and infrastructure developers use these tapes for wiring installations, cable bundling, and conduit repairs in buildings and large-scale projects. Utility companies and power generation sectors, including those focused on traditional fossil fuels and renewable energy sources like wind and solar, are vital customers for maintaining and upgrading their vast electrical grids and equipment. Furthermore, a broad range of industrial manufacturing operations, encompassing general machinery, appliances, and HVAC systems, consistently require cloth insulating adhesive tapes for various assembly, repair, and maintenance tasks, highlighting the product's widespread utility across the industrial landscape. The growing complexity of industrial automation further underscores the increasing need for reliable and durable insulation solutions.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 billion |

| Market Forecast in 2033 | USD 1.85 billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | 3M Company, Tesa SE, Nitto Denko Corporation, Avery Dennison Corporation, Shurtape Technologies LLC, Intertape Polymer Group (IPG), Saint-Gobain, Lohmann GmbH & Co. KG, Scapa Group Plc, Fuji Kasei Co., Ltd., Denka Company Limited, ProTapes & Specialties, Inc., Stokvis Tapes, Sekisui Chemical Co., Ltd., Teraoka Seisakusho Co., Ltd., Yongle Tape Co., Ltd., Wuxi Huadong Insulation Material Co., Ltd., Shanghai Yongguan Adhesive Products Corp., Ltd., Wuhan Huagong Insulation Material Co., Ltd., Suzhou Industrial Tape Co., Ltd. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Cloth Insulating Adhesive Tapes Market Key Technology Landscape

The Cloth Insulating Adhesive Tapes Market is characterized by a dynamic and evolving technological landscape, driven by the continuous demand for enhanced performance, durability, and specialized functionalities. A crucial area of innovation lies in advanced coating techniques, which enable manufacturers to apply adhesives with greater precision and uniformity, leading to improved adhesion strength, consistency, and reduced waste. These techniques often involve multi-layer coating systems to impart specific properties such as flame retardancy, chemical resistance, or anti-static characteristics. Furthermore, the development of solvent-free adhesive formulations is a significant technological trend, addressing environmental concerns and increasingly stringent regulations regarding volatile organic compounds (VOCs). UV-cured acrylics and water-based adhesives are examples of these eco-friendlier alternatives that offer comparable or superior performance to traditional solvent-based systems, while also improving worker safety in manufacturing facilities.

Another pivotal technological advancement involves the synthesis and utilization of high-performance backing materials. Innovations in polymer science have led to the widespread adoption of specialized backings like polyimide and PTFE derivatives, which offer exceptional thermal stability, dielectric strength, and chemical inertness, making them ideal for high-temperature and harsh-environment applications. The incorporation of nanotechnology is also emerging as a frontier in this field, with research focusing on embedding nanoparticles to enhance dielectric properties, thermal conductivity, or mechanical strength of the tapes without significantly increasing thickness. This allows for the creation of thinner, yet more robust, insulation solutions critical for miniaturized electronic components and high-density wiring systems, pushing the boundaries of what these tapes can achieve in terms of performance and reliability.

Beyond material science, manufacturing processes are benefiting from increased automation and sophisticated quality control systems. Automated production lines improve efficiency, reduce labor costs, and ensure consistent product quality, which is vital for high-volume production. Integrated vision systems and real-time sensor technologies are being deployed to detect minute defects, measure coating thickness, and verify product specifications with unparalleled accuracy. This technological integration not only enhances product reliability but also contributes to lean manufacturing principles by minimizing scrap and optimizing resource utilization. Furthermore, the application of data analytics and machine learning in R&D processes is accelerating the discovery and development of new tape formulations, allowing manufacturers to quickly respond to market demands and create bespoke solutions for highly specialized applications, thereby reinforcing the technological leadership within the market.

Regional Highlights

- Asia Pacific (APAC): Dominates the market due to its robust electronics manufacturing base, rapid industrialization, and significant infrastructure development in countries like China, India, Japan, and South Korea. High production volumes and increasing demand for consumer electronics and automotive components drive substantial market growth.

- North America: A mature market characterized by demand for high-performance and specialized tapes in aerospace, defense, automotive (especially EVs), and advanced industrial sectors. Strong emphasis on innovation and adherence to stringent safety standards.

- Europe: Exhibits steady growth, driven by a strong automotive industry (including EV production), industrial automation, and stringent environmental regulations promoting sustainable tape solutions. Germany, the UK, and France are key contributors.

- Latin America: Emerging market with growing industrialization and infrastructure projects, particularly in Brazil and Mexico. Increasing manufacturing activities and urban development contribute to rising demand for electrical insulation products.

- Middle East and Africa (MEA): Shows promising growth fueled by significant investments in energy infrastructure, construction, and industrial expansion. Demand is rising from oil & gas, utilities, and general manufacturing sectors.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Cloth Insulating Adhesive Tapes Market.- 3M Company

- Tesa SE

- Nitto Denko Corporation

- Avery Dennison Corporation

- Shurtape Technologies LLC

- Intertape Polymer Group (IPG)

- Saint-Gobain

- Lohmann GmbH & Co. KG

- Scapa Group Plc

- Fuji Kasei Co., Ltd.

- Denka Company Limited

- ProTapes & Specialties, Inc.

- Stokvis Tapes

- Sekisui Chemical Co., Ltd.

- Teraoka Seisakusho Co., Ltd.

- Yongle Tape Co., Ltd.

- Wuxi Huadong Insulation Material Co., Ltd.

- Shanghai Yongguan Adhesive Products Corp., Ltd.

- Wuhan Huagong Insulation Material Co., Ltd.

- Suzhou Industrial Tape Co., Ltd.

Frequently Asked Questions

What are cloth insulating adhesive tapes primarily used for?

Cloth insulating adhesive tapes are predominantly used for electrical insulation in components like wires, cables, motors, and transformers. They also provide mechanical protection, thermal management, bundling, and harnessing in various industrial and electronic applications, ensuring safety and optimal performance.

How do different backing materials influence tape performance?

Backing materials like cotton, fiberglass, polyester, or polyimide significantly dictate tape performance. Cotton offers conformability; fiberglass provides high-temperature resistance and strength; polyester balances strength and electrical properties; while polyimide excels in extreme temperatures and thinness for high-tech electronics.

What are the key advantages of using these tapes over other insulation methods?

Key advantages include superior dielectric strength, high temperature resistance, excellent conformability to irregular surfaces, mechanical protection against abrasion and punctures, ease of application, and versatile adhesion properties, making them reliable for diverse and critical insulation needs compared to liquid resins or heat shrink.

What market trends are currently shaping the cloth insulating adhesive tapes industry?

Current market trends include the increasing demand for high-performance tapes in electric vehicles and renewable energy, the development of eco-friendly and solvent-free adhesive formulations, the adoption of automation-compatible tapes, and a growing focus on advanced materials for enhanced thermal and dielectric properties.

How does environmental sustainability factor into the production of these tapes?

Environmental sustainability is increasingly important, driving manufacturers to develop solvent-free adhesives, use recyclable backing materials, and implement energy-efficient production processes. The focus is on reducing VOC emissions, minimizing waste, and offering products that meet global environmental standards for a greener supply chain.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager