CNC Machine Monitoring Software Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 436624 | Date : Dec, 2025 | Pages : 251 | Region : Global | Publisher : MRU

CNC Machine Monitoring Software Market Size

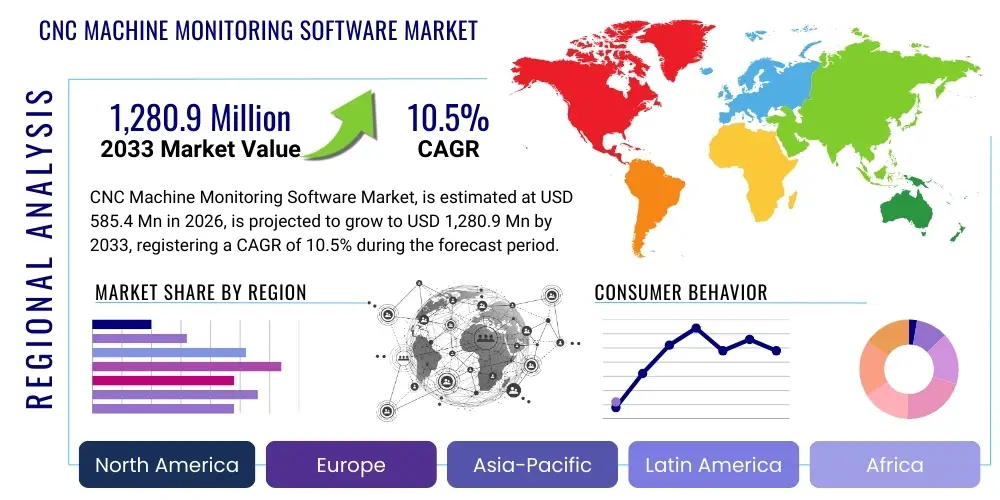

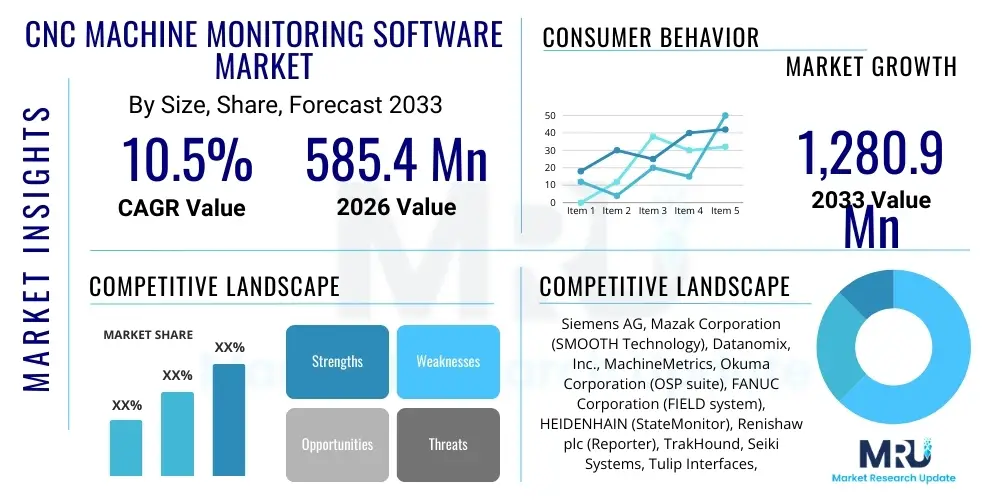

The CNC Machine Monitoring Software Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 10.5% between 2026 and 2033. The market is estimated at $585.4 Million in 2026 and is projected to reach $1,280.9 Million by the end of the forecast period in 2033. This substantial expansion is fundamentally driven by the global imperative across manufacturing sectors to enhance operational efficiency, minimize downtime, and accelerate the adoption of Industry 4.0 principles, which mandate comprehensive real-time data collection and analysis from shop floor assets. The shift towards automated production processes, especially in high-value industries like aerospace and automotive, necessitates sophisticated monitoring tools capable of providing actionable insights derived from machine performance data.

Market growth is further supported by technological advancements, particularly in integrating Industrial Internet of Things (IIoT) sensors and edge computing capabilities directly into Computer Numerical Control (CNC) machine infrastructure. These innovations allow manufacturers to move beyond simple fault detection to true predictive maintenance, thereby optimizing tool life, managing energy consumption, and achieving higher Overall Equipment Effectiveness (OEE). The capital expenditure required for sophisticated CNC machinery often justifies the investment in monitoring software, as the potential returns from reduced unplanned downtime significantly outweigh the initial implementation costs.

Geographically, expansion is accelerating in regions undergoing rapid industrialization and modernization, notably in Asia Pacific (APAC), alongside established manufacturing hubs in North America and Europe. The increasing complexity of supply chains and the stringent quality standards demanded by global markets compel small and medium-sized enterprises (SMEs) to adopt monitoring solutions previously reserved for large multinational corporations. This broadening user base, coupled with the rising availability of subscription-based, cloud-deployed software models, ensures sustained market buoyancy throughout the forecast period.

CNC Machine Monitoring Software Market introduction

The CNC Machine Monitoring Software Market encompasses solutions designed to connect to, collect data from, and analyze the operational status of Computer Numerical Control (CNC) machines in real time. These software platforms translate raw machine data—such as spindle utilization, cutting feed rates, power consumption, program status, and alarm codes—into meaningful, actionable Key Performance Indicators (KPIs), primarily focusing on Overall Equipment Effectiveness (OEE). The core product involves dedicated software platforms, often IIoT-enabled, that facilitate connectivity between disparate machine tools, regardless of their manufacturer or age, and provide centralized visibility through dashboards and reporting modules.

Major applications of these monitoring systems span across critical industrial sectors including automotive component manufacturing, aerospace and defense, precision medical device production, heavy equipment fabrication, and general metalworking. Key benefits realized by end-users include significant reductions in unplanned downtime through predictive maintenance alerts, optimization of production schedules, improved quality control by correlating machine parameters with part defects, and enhanced labor productivity by minimizing time spent manually tracking machine status. Furthermore, these systems are crucial for compliance reporting and continuous process improvement initiatives, supporting lean manufacturing methodologies.

Driving factors for this market are the intensifying push towards Industry 4.0 adoption, mandating the digital transformation of manufacturing floor operations, and the continuous pressure on manufacturing firms worldwide to achieve higher asset utilization rates in highly competitive global environments. The declining cost of sensors and connectivity hardware, coupled with the increasing sophistication of analytical algorithms, makes these solutions increasingly accessible and powerful, solidifying their role as indispensable tools in modern manufacturing management.

CNC Machine Monitoring Software Market Executive Summary

The CNC Machine Monitoring Software Market is experiencing robust growth fueled by several converging business and technological trends. Business trends highlight a clear pivot toward cloud-based deployment models, driven by lower total cost of ownership (TCO), scalability, and ease of integration, particularly appealing to SMEs. Furthermore, the market is shifting from reactive monitoring to proactive predictive maintenance, significantly enhancing the value proposition for large enterprises seeking to minimize high costs associated with catastrophic equipment failure. Key vendors are strategically focusing on developing highly interoperable platforms capable of connecting legacy equipment alongside new purchases, addressing a major challenge in brownfield manufacturing environments.

Regionally, North America and Europe currently hold significant market shares due to high industrial automation levels and stringent regulatory environments pushing for operational transparency and sustainability. However, the Asia Pacific region, particularly China, Japan, and India, is projected to exhibit the fastest Compound Annual Growth Rate (CAGR) due to rapid infrastructure development, large-scale government initiatives promoting smart manufacturing, and the establishment of new, highly automated production facilities. Regional strategies involve customized solutions addressing specific local manufacturing complexities and language barriers to foster deeper penetration.

Segmentation trends indicate that the Software component segment dominates the market by value, while the Cloud Deployment segment is anticipated to witness the highest growth rate, reflecting the overall industry preference for flexible, subscription-based services. Within end-use segments, the Automotive and Aerospace industries remain the primary revenue generators, driven by high production volumes, complex quality requirements, and the substantial cost consequences of production stoppages. The integration of advanced analytics, including Machine Learning (ML) algorithms, is becoming a standard offering across all segments, moving the industry standard beyond simple data visualization.

AI Impact Analysis on CNC Machine Monitoring Software Market

Common user questions regarding the impact of Artificial Intelligence (AI) on CNC Machine Monitoring Software frequently revolve around the reliability and practicality of autonomous decision-making capabilities, particularly concerns about false positive error predictions disrupting production schedules. Users often inquire about the expected Return on Investment (ROI) derived from AI-enhanced predictive maintenance versus traditional threshold monitoring, questioning the complexity and resources required for training the ML models on proprietary machine data. Additionally, cybersecurity implications of allowing AI systems to access and potentially control machine parameters—either locally or via cloud connectivity—represent a significant area of user concern, focusing on data privacy and operational integrity.

The market consensus is that AI is fundamentally transforming the monitoring landscape, shifting the focus from historical reporting to deep prescriptive analytics. AI algorithms, particularly those based on deep learning, are vastly superior at detecting subtle anomalies and complex multi-parameter correlations that precede machine failure, a task impossible for traditional statistical methods. This enables genuinely optimized maintenance scheduling, tool wear compensation, and process parameter adjustments in real time. The integration of AI also facilitates automated root cause analysis, drastically reducing the time required for engineering teams to diagnose and resolve persistent performance bottlenecks, making manufacturing processes significantly more resilient and self-optimizing.

Key themes emerging from user expectations include the desire for fully automated process optimization loops where the software not only predicts failure but also suggests or executes remedial actions (e.g., adjusting cutting speeds or alerting specific personnel). Users expect AI integration to lower energy consumption by identifying and correcting inefficient operational patterns. Furthermore, there is strong demand for AI tools that can perform automatic analysis across fleets of machines from different vendors, standardizing performance benchmarks and identifying best practices transferable across the entire organization, ensuring knowledge capitalization throughout the manufacturing network.

- AI enables highly accurate predictive maintenance, shifting from scheduled or reactive repairs to condition-based servicing.

- Integration of Machine Learning (ML) algorithms optimizes cutting parameters in real time, enhancing part quality and tool life.

- AI facilitates automated fault diagnosis and root cause analysis, significantly reducing mean time to repair (MTTR).

- Deployment of computer vision and AI for automated quality inspection integrated with machine operation data.

- Utilization of reinforcement learning for dynamic production scheduling and resource allocation on the shop floor.

- Enhanced cybersecurity measures provided by AI-driven anomaly detection in machine network traffic patterns.

DRO & Impact Forces Of CNC Machine Monitoring Software Market

The CNC Machine Monitoring Software Market is primarily driven by the mandatory shift toward Industry 4.0 adoption and the critical need for manufacturing organizations to boost Overall Equipment Effectiveness (OEE) in a competitive global environment. Restraints primarily center around the high initial capital investment required for integration, particularly in environments with older, legacy CNC machinery, and persistent concerns regarding data security and connectivity complexity across large, heterogeneous machine fleets. Opportunities are abundant, especially concerning the penetration into the vast small and medium-sized enterprise (SME) sector through accessible, subscription-based cloud solutions and the integration of advanced features such as Digital Twin technology for comprehensive process simulation and validation. These dynamic factors collectively generate significant impact forces, compelling rapid digital transformation across industrial sectors.

Key drivers include the advancements in Industrial IoT (IIoT) infrastructure, which simplifies the data acquisition process, making previously inaccessible machine operational data available for analysis. Furthermore, the stringent quality requirements in high-precision industries such as aerospace and medical devices necessitate real-time monitoring to ensure compliance and traceability for every manufactured component. Governments globally are also promoting smart factory initiatives through incentives and subsidies, accelerating the adoption curve for these monitoring solutions. This market dynamism is essential for manufacturers striving to maintain cost leadership and operational excellence.

Impact forces are strongly influenced by the rapid obsolescence of non-connected manufacturing methods; companies that fail to adopt real-time monitoring face significant competitive disadvantages due to higher maintenance costs and less predictable production output. The ongoing convergence of Operational Technology (OT) and Information Technology (IT) networks is another powerful force, driving standardization and facilitating deeper integration of shop floor data with Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES). Successfully navigating these drivers, mitigating the restraints related to cybersecurity, and capitalizing on opportunities through scalable cloud offerings will define market leadership in the coming decade.

Segmentation Analysis

The CNC Machine Monitoring Software Market is extensively segmented based on key criteria including component, deployment model, enterprise size, and end-use industry, providing a granular view of market dynamics and adoption patterns. Segmentation by component separates the market into the core Software Platform, which includes the analytical and visualization tools, and the associated Services (implementation, consulting, and maintenance), both essential for successful deployment. Analyzing these segments helps in understanding where the core value creation lies and how supporting services contribute to the overall customer life cycle management.

The segmentation by deployment is critical, distinguishing between On-Premise solutions, favored by large enterprises with high data security requirements or proprietary manufacturing processes, and Cloud-Based solutions, which offer greater flexibility, lower upfront costs, and superior scalability, making them highly attractive to SMEs. Further segmentation by enterprise size—Large Enterprises versus Small and Medium Enterprises (SMEs)—shows differing adoption speeds and feature requirements, with SMEs often prioritizing ease of use and rapid ROI, while Large Enterprises focus on deep customization and seamless integration with existing IT infrastructure. These distinctions are crucial for vendors developing targeted product strategies.

The most defining segmentation occurs across the End-Use Industry, reflecting the diverse applications and intensity of use across sectors such as Automotive, Aerospace & Defense, Medical Devices, Electronics & Semiconductor, and General Manufacturing. Each sector presents unique challenges, from the high volume and speed demands of the automotive industry to the extreme precision and traceability requirements of the aerospace sector. Understanding these vertical nuances allows market participants to tailor their software functionalities, such as specific compliance features or specialized analytics modules, maximizing relevance and market penetration within high-value target industries.

- By Component:

- Software Platform (Analytics, Visualization, Reporting Modules)

- Services (Implementation, Consulting, Training, Maintenance, Support)

- By Deployment Type:

- On-Premise

- Cloud-Based

- By Enterprise Size:

- Large Enterprises

- Small and Medium Enterprises (SMEs)

- By End-Use Industry:

- Automotive

- Aerospace and Defense

- Medical Devices and Equipment

- Electronics and Semiconductor

- Heavy Equipment Manufacturing

- Oil and Gas

- General Manufacturing and Job Shops

Value Chain Analysis For CNC Machine Monitoring Software Market

The value chain for the CNC Machine Monitoring Software Market begins with the upstream segment, which is dominated by hardware manufacturers and foundational technology providers. This includes providers of sensors (e.g., vibration, current, temperature), IoT gateways, connectivity modules, and specialized data acquisition devices (DAQ). Also critical in the upstream are the core software technology providers supplying operating systems, database management systems, and specialized industrial protocols (like MTConnect and OPC UA) necessary for effective machine communication. Efficiency and cost optimization in this initial stage directly impact the final product cost and its interoperability capabilities, emphasizing the importance of robust industrial hardware standards.

The midstream segment involves the core activities of the software vendors, including product development, integration, and platform deployment. This stage involves writing the monitoring application software, developing the analytics engine (including AI/ML modules), creating intuitive user interfaces (dashboards), and ensuring seamless integration capabilities with various CNC machine brands and existing Enterprise Resource Planning (ERP) and Manufacturing Execution Systems (MES). Distribution channels play a vital role here, with direct sales models often utilized for large enterprise accounts requiring deep customization and indirect channels, such as authorized system integrators and distributors, essential for reaching the geographically dispersed SME market.

The downstream activities focus on the delivery, adoption, and ongoing servicing of the software platform to the end-users. Direct distribution provides vendors with greater control over customer relationships and feedback loops, allowing for faster product iteration. Indirect channels, through specialized system integrators, offer local expertise in deployment and maintenance, often bundled with other smart factory solutions. Potential customers (end-users) include a wide array of discrete and process manufacturing facilities. The sustained value is delivered through ongoing technical support, software updates, and consulting services focused on optimizing manufacturing processes based on the continuous flow of machine data.

CNC Machine Monitoring Software Market Potential Customers

The primary customers for CNC Machine Monitoring Software are manufacturing organizations across virtually all industrial sectors that rely on high-precision machining operations, aiming to maximize asset utilization and maintain strict quality standards. This customer base spans from large, multi-site multinational corporations to small, independent job shops. Large enterprises, particularly those in the automotive, aerospace, and medical device sectors, are key buyers due to their extensive machine fleets, high volume production demands, and the necessity for comprehensive data traceability to comply with rigorous industry regulations. These customers typically require highly customized, on-premise solutions integrated deeply into their existing SAP or Oracle systems.

Small and Medium Enterprises (SMEs) represent a rapidly expanding customer segment. Historically constrained by high capital costs, SMEs are increasingly adopting cloud-based, subscription-model monitoring solutions due to their affordability, rapid deployment timeframes, and scalable nature. Job shops and smaller component manufacturers recognize that monitoring is essential for maintaining competitiveness, especially when bidding for contracts requiring proof of efficiency and predictable delivery schedules. For these customers, the immediate visibility into OEE and labor productivity provides a clear and fast Return on Investment (ROI), often necessitating user-friendly, non-technical interfaces.

Other significant potential customers include specialized educational and research institutions that utilize CNC machinery for prototyping and advanced material science projects, where detailed data logging is crucial for process experimentation and academic documentation. Furthermore, machine tool builders themselves are increasingly bundling monitoring software as a standard feature or value-added service with new machine sales, expanding the base of potential users by integrating the software into the initial purchase decision. The diversity of the customer landscape requires vendors to offer flexible pricing and modular feature sets tailored to operational scale and complexity.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $585.4 Million |

| Market Forecast in 2033 | $1,280.9 Million |

| Growth Rate | 10.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Siemens AG, Mazak Corporation (SMOOTH Technology), Datanomix, Inc., MachineMetrics, Okuma Corporation (OSP suite), FANUC Corporation (FIELD system), HEIDENHAIN (StateMonitor), Renishaw plc (Reporter), TrakHound, Seiki Systems, Tulip Interfaces, Predikto, Senseye (Siemens), Forcam GmbH, Eyelit Inc., Oelheld GmbH, Capstone Connected, Prolink, Nexas America, Fastems. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

CNC Machine Monitoring Software Market Key Technology Landscape

The technological landscape of the CNC Machine Monitoring Software Market is defined by the integration of core Industrial IoT (IIoT) capabilities with advanced computational techniques. The foundation relies heavily on standardized communication protocols such as MTConnect and OPC UA, which facilitate vendor-agnostic data extraction from diverse machine tools, enabling a unified data stream regardless of the machine's age or manufacturer. Edge computing is a critical technology, allowing for preliminary data processing and filtering to occur directly at the machine level (the "edge"), which reduces latency, minimizes network traffic congestion, and ensures that immediate, localized alarms can be triggered even if the central network connection is temporarily lost. This architecture improves reliability and supports rapid local decision-making processes.

The analytical backbone of modern monitoring solutions is increasingly reliant on Artificial Intelligence (AI) and Machine Learning (ML) algorithms. These technologies move beyond simple rule-based alarming to analyze complex patterns in vibration, temperature, and power consumption data, enabling highly accurate predictive maintenance models. Furthermore, Digital Twin technology is emerging as a critical differentiator. A Digital Twin is a virtual replica of a physical CNC machine or an entire production line, created using monitoring data. This twin allows manufacturers to simulate changes in process parameters, test new production schedules, and predict the impact of various maintenance strategies without disrupting live production, providing a safe, robust environment for optimization.

Cloud infrastructure providers (AWS, Azure, Google Cloud) are essential partners, offering the scalable computing resources necessary to store, manage, and analyze the massive datasets generated by modern manufacturing facilities. The continuous evolution of user interface (UI) and user experience (UX) design, often leveraging mobile accessibility and augmented reality (AR) overlays for maintenance instruction, further enhances the utility of the software. The key technological direction remains the seamless integration of real-time machine data with enterprise-level systems (MES/ERP) through robust Application Programming Interfaces (APIs), creating a fully transparent and interconnected manufacturing ecosystem.

Regional Highlights

- North America: North America, particularly the United States, holds a dominant position in the CNC Machine Monitoring Software Market, primarily driven by the early and widespread adoption of smart factory initiatives and robust investment in digital transformation across the automotive and aerospace manufacturing sectors. The region benefits from a high concentration of technologically advanced manufacturers and leading software vendors who actively collaborate to set industry standards, such as the MTConnect protocol. High labor costs act as a significant driver, compelling manufacturers to invest heavily in efficiency-enhancing automation and monitoring solutions to maintain global competitiveness. The mature industrial infrastructure and strong venture capital investment in IIoT startups ensure continuous innovation and market growth, focusing heavily on cloud-based deployment and sophisticated AI-driven predictive analytics.

- Europe: Europe represents another established and substantial market, spearheaded by countries like Germany, recognized globally for its high-precision engineering and the government-backed Industry 4.0 strategy (Industrie 4.0). The European market is characterized by a strong demand for integrated solutions that meet rigorous environmental and sustainability standards, prompting a focus on energy consumption monitoring and optimization features within the software. While adoption is high among large conglomerates, the market is also driven by thousands of specialized SMEs that form complex supply chains, requiring interoperable and scalable monitoring solutions. Stringent regulatory requirements for product traceability and quality control further solidify the need for sophisticated, real-time data capture systems across the continent.

- Asia Pacific (APAC): The Asia Pacific region is projected to be the fastest-growing market throughout the forecast period. This rapid expansion is primarily fueled by accelerated industrialization in countries like China, India, and South Korea, coupled with significant government spending on manufacturing modernization programs. The region is characterized by high volume manufacturing, especially in the electronics and general machinery sectors. While initial adoption may be driven by on-premise solutions due to data sovereignty concerns and large-scale factory setups, there is a clear and accelerating trend toward adopting advanced cloud solutions to manage newly established greenfield smart factories. The influx of foreign direct investment in manufacturing also brings in best practices regarding efficiency and monitoring, driving overall regional market maturity.

- Latin America (LATAM): The LATAM market is in an emerging phase, exhibiting moderate growth potential driven by increasing foreign investment and the modernization of key industrial sectors, notably automotive assembly and natural resources processing in countries like Brazil and Mexico. Market adoption is often linked to the subsidiaries of multinational companies that mandate global monitoring standards. Challenges include fragmented industrial infrastructure and fluctuating economic conditions, often leading to a preference for lower-cost, scalable solutions, making SaaS models particularly appealing for initial digital transformation steps.

- Middle East and Africa (MEA): The MEA region is developing rapidly, largely influenced by high-value investments in sectors like oil and gas, defense, and localized automotive production (Turkey and South Africa). The market demand for CNC monitoring software is tied to capital projects aimed at diversification away from resource-dependent economies. Adoption rates are lower compared to NA and APAC, but significant potential exists, driven by large state-owned enterprises focused on achieving global benchmarks for operational excellence and asset longevity, particularly through advanced condition monitoring techniques.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the CNC Machine Monitoring Software Market.- Siemens AG (Sinumerik CNC Monitoring Solutions)

- Datanomix, Inc.

- MachineMetrics, Inc.

- FANUC Corporation (FIELD system)

- Mazak Corporation (SMOOTH Technology)

- Okuma Corporation (OSP Suite)

- HEIDENHAIN GmbH (StateMonitor)

- Renishaw plc (Reporter and Equator solutions)

- GE Digital (Predix Manufacturing Data Suite)

- Forcam GmbH (FORCAM FORCE)

- Tulip Interfaces

- Seiki Systems (Seiki Scheduler & Monitoring)

- TrakHound

- VIMANA (HCL Technologies)

- Predikto

- Senseye (now part of Siemens)

- Eyelit Inc. (MES/Monitoring Integration)

- PROLINK, a Division of Fastems LLC

- Nexus America Inc.

- Micronor Inc.

Frequently Asked Questions

Analyze common user questions about the CNC Machine Monitoring Software market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary function and measurable benefit of CNC machine monitoring software?

The primary function is the real-time collection and analysis of operational data (spindle speed, alarms, cycle time) from CNC machines. The measurable benefit is a significant increase in Overall Equipment Effectiveness (OEE), typically realized through reduced unplanned downtime, optimized machine utilization rates, and enhanced process control, leading directly to lower operational costs and higher production throughput.

How does the integration of AI change traditional machine monitoring practices?

AI integration transforms monitoring from reactive reporting to prescriptive analytics. Traditional monitoring relies on fixed thresholds, whereas AI/ML algorithms analyze complex, multivariate datasets to detect subtle anomalies indicative of impending failure far earlier. This enables true predictive maintenance, optimizing maintenance schedules based on actual machine condition rather than fixed timelines, maximizing asset lifespan.

Is it possible to monitor old or legacy CNC machines without modern network interfaces?

Yes, it is possible and highly common. Legacy CNC machines can be monitored using specialized Industrial IoT (IIoT) gateway devices and non-intrusive sensors (such as power consumption meters, vibration sensors, or current clamps). These external hardware components translate analog signals into digital data compatible with modern monitoring software, bridging the technological gap and providing connectivity for brownfield environments.

What are the key differences between On-Premise and Cloud-Based CNC monitoring solutions?

On-Premise solutions are installed and maintained on the client's local servers, offering maximum data security, proprietary control, and deep integration with local ERP/MES systems, favored by large enterprises. Cloud-Based (SaaS) solutions require lower upfront capital expenditure, offer superior scalability and accessibility (mobile), and are generally preferred by Small and Medium Enterprises (SMEs) seeking rapid deployment and reduced IT overhead.

Which industrial sectors are driving the highest demand for CNC machine monitoring software?

The highest demand is driven by high-value, high-precision manufacturing sectors, predominantly the Automotive and Aerospace & Defense industries. These sectors require rigorous quality control, high asset utilization due to expensive machinery, and mandatory data traceability to meet stringent safety and regulatory standards, making real-time monitoring an essential operational requirement.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager