CNC Video Measuring Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 431855 | Date : Dec, 2025 | Pages : 253 | Region : Global | Publisher : MRU

CNC Video Measuring Market Size

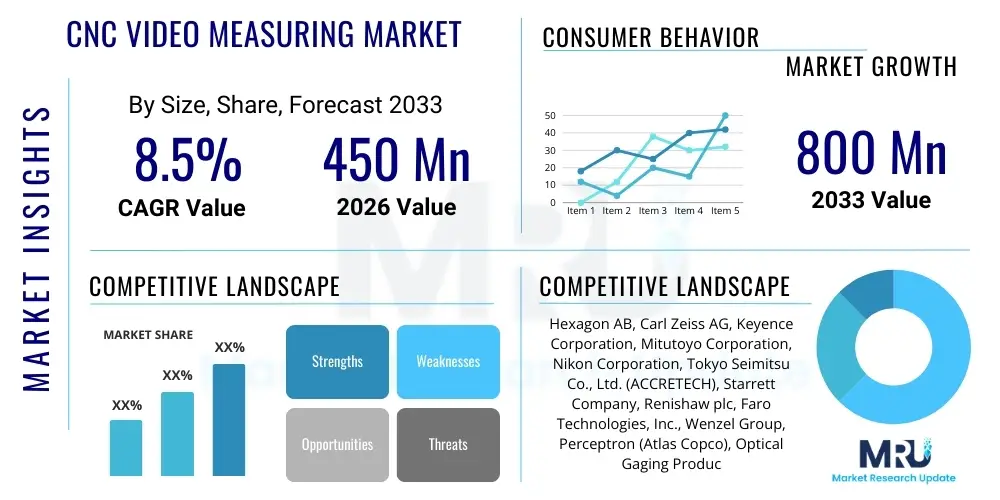

The CNC Video Measuring Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 8.5% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 800 Million by the end of the forecast period in 2033.

CNC Video Measuring Market introduction

The CNC Video Measuring Machine (VMM) market centers on advanced metrology equipment designed to perform non-contact, high-accuracy dimensional measurements of complex manufactured parts. These systems utilize sophisticated optical components, high-resolution digital cameras, and precision computer numerical control (CNC) stages to automate the measurement process, significantly reducing inspection time while enhancing data integrity. Unlike traditional touch-probe Coordinate Measuring Machines (CMMs), VMMs excel at measuring fine features, delicate components, and 2D geometries, making them indispensable in quality control loops across numerous high-precision industries.

Product sophistication involves the seamless integration of hardware—including high-magnification telecentric lenses, specialized illumination systems (coaxial, contour, and programmable ring lights), and high-precision granite bases—with powerful metrology software. Major applications span critical manufacturing sectors such as aerospace for turbine blades and complex assemblies, automotive for powertrain components and sensor enclosures, electronics for printed circuit boards (PCBs) and micro-components, and medical devices for implants and surgical instruments. The core benefit derived from adopting VMMs is the ability to achieve micron-level accuracy repeatedly and traceably, crucial for adhering to stringent international quality standards (ISO, AS9100).

Key factors driving the expansion of this market include the global push towards miniaturization of electronic and medical components, which necessitates non-destructive and highly accurate inspection methods. Furthermore, the pervasive adoption of Industry 4.0 principles, demanding greater automation in manufacturing and real-time feedback loops for process control, fuels the demand for CNC VMMs capable of high-throughput automated measurement routines. The ability of these systems to integrate seamlessly into automated production lines and provide comprehensive measurement reports accelerates their acceptance, establishing them as essential tools for modern quality assurance environments.

CNC Video Measuring Market Executive Summary

The CNC Video Measuring Market is experiencing robust growth driven primarily by escalating demand for quality control automation across manufacturing ecosystems and the increasing complexity of manufactured components that require non-contact measurement. Business trends indicate a strong shift toward multi-sensor systems that combine optical, laser, and tactile measurement capabilities within a single platform, enhancing versatility and throughput for diverse applications. Strategic mergers and acquisitions among key technology providers are consolidating market expertise, while increased investment in research and development focuses on improving measurement speed, software usability, and integration with enterprise resource planning (ERP) and manufacturing execution systems (MES).

Regionally, the Asia Pacific (APAC) stands as the dominant and fastest-growing market, largely due to its concentrated manufacturing base, particularly in automotive electronics, consumer electronics, and high-volume component production in countries like China, Japan, and South Korea. North America and Europe remain mature markets characterized by high adoption rates of advanced metrology solutions in high-value sectors such as aerospace and medical device manufacturing, focusing on compliance with strict regulatory requirements. The maturity in these regions drives demand for retrofitting and upgrading existing VMM infrastructure with newer, AI-enhanced software features.

Segmentation analysis highlights the high-growth trajectory of fully automated, large-format CNC VMMs, catering to the inspection of large assemblies and complex parts used in electric vehicle batteries and larger aerospace components. By component, the specialized metrology software segment is projected to exhibit the highest CAGR, reflecting the continuous need for sophisticated algorithms for edge detection, pattern recognition, and geometric dimensioning and tolerancing (GD&T) analysis. This software evolution is crucial for unlocking the full potential of the hardware, enabling faster programming and autonomous measurement routines, which are vital for meeting the high-speed requirements of contemporary production lines.

AI Impact Analysis on CNC Video Measuring Market

Common user questions regarding AI's impact on the CNC Video Measuring Market frequently revolve around immediate concerns such as "How much faster can AI make my inspection process?" and "Can AI eliminate human error in programming measurement routines?" Users are also keen to understand the reliability and accuracy implications, asking if AI-driven image processing can handle complex or low-contrast surfaces where traditional algorithms fail, and whether machine learning can truly enable predictive maintenance for VMM calibration. The synthesis of these inquiries reveals a strong expectation that AI will deliver substantial improvements in automation, speed, accuracy, and operational autonomy, thereby reducing the dependency on highly specialized metrology technicians and decreasing overall cost of quality.

- AI-Enhanced Image Processing: Machine learning algorithms significantly improve edge detection and feature extraction, especially on challenging surfaces (e.g., reflective or translucent materials), reducing measurement variability.

- Automated Measurement Planning: AI minimizes setup time by automatically generating optimal measurement paths and illumination settings based on CAD models and historical inspection data.

- Predictive Maintenance and Self-Calibration: Machine learning models analyze sensor data and system performance metrics to predict potential failures or necessary calibration adjustments before they impact measurement accuracy.

- Defect Recognition and Classification: Deep learning models enable highly accurate and fast classification of micro-defects or anomalies, moving beyond simple dimensional checks to comprehensive surface quality assessment.

- Improved Data Interpretation and Reporting: AI assists in analyzing large datasets of inspection results, identifying systematic manufacturing drift, and providing intelligent feedback to the production process upstream.

- Adaptive Inspection Routines: Systems leverage reinforcement learning to dynamically adjust measurement parameters in real-time based on environmental conditions or part variation, optimizing throughput without sacrificing precision.

- Operator Skill Reduction: Intuitive, AI-driven interfaces and automated routine generation lower the threshold for operating complex VMM systems, democratizing access to high-precision metrology.

DRO & Impact Forces Of CNC Video Measuring Market

The dynamics of the CNC Video Measuring Market are shaped by a complex interplay of drivers, restraints, and opportunities, collectively forming the critical impact forces influencing strategic decisions and technological development. A primary driver is the accelerating trend of digital manufacturing and the associated demand for high-speed, verifiable dimensional data required for closed-loop manufacturing systems. This shift is compounded by stringent regulatory requirements, particularly in safety-critical sectors like medical devices and aerospace, where 100% inspection traceability is mandatory. However, growth is tempered by significant restraints, primarily the substantial initial capital investment required for high-end CNC VMM equipment, which can be prohibitive for small and medium-sized enterprises (SMEs). Furthermore, the scarcity of trained metrology specialists capable of programming and maintaining these complex machines remains a structural challenge globally.

Opportunities for market expansion are abundant, particularly through geographical penetration into emerging Asian and Latin American economies that are rapidly industrializing and adopting modern manufacturing standards. Technological opportunities center on the refinement of multi-sensor fusion technology, allowing VMMs to handle an unprecedented range of materials and geometries, effectively blurring the line between traditional optical and tactile CMMs. The ongoing integration of specialized metrology software with simulation tools also presents a major opportunity, allowing manufacturers to predict how tolerances will affect part function earlier in the design cycle. These factors combine to create strong impact forces pushing the market towards greater automation, versatility, and deeper software integration, ensuring that VMMs remain central to the modern quality assurance landscape.

The prevailing impact forces dictate that providers must focus on delivering systems with lower total cost of ownership (TCO), perhaps through subscription-based software models or modular hardware designs, to overcome the restraint of high initial cost. The shift towards non-contact measurement is irreversible due to the complexity and fragility of new materials (e.g., advanced composites and micro-electromechanical systems (MEMS)), solidifying the long-term positive impact force of technological necessity. Successfully addressing the skills gap restraint via user-friendly, AI-driven interfaces will be critical for market penetration into broader industrial applications beyond traditional high-precision domains.

Segmentation Analysis

The CNC Video Measuring Market is strategically segmented based on factors including the type of machine architecture, the end-user application sector, and the core components utilized within the system. Segmentation by machine type often differentiates between standard desktop systems for smaller, high-precision components and large-format gantry or cantilever systems designed for inspecting larger parts and assemblies, providing targeted solutions based on part size and production volume requirements. Application segmentation reveals the diverse utility of VMMs across key industrial verticals, highlighting areas with the most intense demand for high-accuracy non-contact measurement, such as the automotive sector focusing on EV components, and the electronics sector driven by smartphone and semiconductor manufacturing requirements.

- By Type:

- Standard CNC Video Measuring Systems

- Large-Format/Gantry CNC Video Measuring Systems

- Multi-Sensor/Hybrid CNC VMMs

- Portable/Benchtop CNC VMMs

- By Component:

- Hardware (Optics, CNC Stages, Sensors, Illumination)

- Software (Metrology Analysis, Reporting, Programming Interface)

- Service & Support (Calibration, Maintenance, Training)

- By Application/End-User:

- Automotive

- Aerospace and Defense

- Electronics and Semiconductors

- Medical Devices

- Precision Machining and Fabrication

- Plastics and Rubber

Value Chain Analysis For CNC Video Measuring Market

The value chain for the CNC Video Measuring Market initiates with upstream activities involving the sourcing and refinement of highly specialized components. This includes ultra-high-precision granite or ceramic bases for stability, advanced optical components (telecentric lenses, high-resolution CCD/CMOS cameras), motion control systems (linear motors, encoders), and specialized illumination modules. Key upstream suppliers are characterized by stringent quality controls and deep expertise in precision engineering, which directly impacts the ultimate accuracy and stability of the final VMM system. The development of proprietary metrology software, often outsourced to specialized firms or developed in-house, represents another critical upstream element, defining the user experience and analytical capability of the machine.

Midstream activities encompass the manufacturing, integration, and assembly of the VMM systems. This stage involves complex mechanical assembly, meticulous calibration, and system testing, ensuring the seamless communication between the CNC motion control, the optical path, and the analytical software. Manufacturers differentiate themselves here through innovative hardware design, patented sensor fusion techniques, and adherence to strict manufacturing tolerances. The distribution channel analysis reveals a dual structure: direct sales are favored for large, custom installations or strategic accounts requiring deep technical consultancy, while indirect sales via specialized distributors and value-added resellers (VARs) are utilized for geographical reach and supporting entry-level or standardized product lines, particularly in fragmented international markets.

Downstream activities focus on post-sale services, including installation, extensive operator training, routine calibration, and ongoing software updates. This service component is crucial for customer retention and long-term revenue generation, given the required precision maintenance of VMMs. End-users (potential customers) are highly discerning and seek solutions that offer minimal downtime and verifiable measurement traceability. The distribution channel effectiveness is measured by the speed of technical support and the ability of distributors to provide localized application engineering expertise, ensuring that customers can maximize the efficiency and accuracy benefits promised by the advanced CNC metrology equipment.

CNC Video Measuring Market Potential Customers

Potential customers for CNC Video Measuring Machines are predominantly organizations operating in high-precision manufacturing sectors where dimensional accuracy, quality assurance documentation, and non-contact inspection of delicate parts are mandatory requirements. These buyers typically include quality control departments within large original equipment manufacturers (OEMs) who are mandated to comply with industry-specific standards like ISO 13485 (Medical) or AS9100 (Aerospace). Their buying criteria prioritize repeatability, speed of throughput, certification capabilities, and seamless integration into existing quality data management systems.

A significant segment of buyers comprises precision contract manufacturers and job shops that serve multiple high-tech industries. For these customers, the versatility of the VMM—specifically, its ability to quickly switch between measuring different component types (from injection molded plastics to machined metals)—is a critical purchasing driver. Their purchasing decisions are often tied to the total cost of ownership, looking for machines that minimize operator intervention and reduce programming time, justifying the capital expenditure through improved capacity utilization and reduction in scrap material.

Furthermore, academic institutions and industrial research laboratories represent a smaller but highly influential customer base, purchasing VMMs primarily for advanced materials testing, prototype inspection, and developing new metrology techniques. While volume is low, these customers often require the most technologically advanced multi-sensor systems available. Overall, the end-users are concentrated in sectors experiencing rapid technological complexity and miniaturization, ensuring sustained demand for the capabilities unique to CNC video measuring technology.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 800 Million |

| Growth Rate | 8.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Hexagon AB, Carl Zeiss AG, Keyence Corporation, Mitutoyo Corporation, Nikon Corporation, Tokyo Seimitsu Co., Ltd. (ACCRETECH), Starrett Company, Renishaw plc, Faro Technologies, Inc., Wenzel Group, Perceptron (Atlas Copco), Optical Gaging Products (OGP), Vision Engineering Ltd., Micro-Vu Corporation, Shanghai Optical Instrument Factory (SOIF), Serein Optic-Electric, Leader Metrology, Quality Vision International (QVI), Tesa (Hexagon), GOM (Zeiss) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

CNC Video Measuring Market Key Technology Landscape

The technological landscape of the CNC Video Measuring Market is defined by continuous innovation across three main domains: high-precision optics and sensors, advanced motion control systems, and intelligent metrology software. A foundational technology involves telecentric optics, which provide low distortion and consistent magnification across the depth of field, essential for accurate 2D measurement. Complementing this, the shift from traditional CCD sensors to high-resolution, high-frame-rate CMOS sensors allows for faster image acquisition and superior dynamic range, crucial for capturing detailed images of complex surfaces under varying illumination conditions. These optical advancements are inextricably linked to specialized illumination techniques, including programmable LED ring lights and coaxial lighting, which are software-controlled to optimize contrast and edge detection for diverse material properties.

In terms of motion, the reliance on high-speed, non-contact CNC stages, often utilizing linear motor technology and high-resolution glass scales or encoders, is paramount for achieving the necessary speed and repeatability. These stages ensure micron-level positioning accuracy across large measurement volumes, moving far beyond manual systems. The concept of multi-sensor fusion represents a major technological advancement, integrating non-contact video measurement with laser scanning probes (confocal or line scanning) and traditional tactile probes. This fusion allows a single machine to leverage the strengths of different sensor modalities—high speed for optics, 3D profiling for lasers, and high force tolerance for tactile probes—to measure complex geometries that were previously impossible to inspect efficiently.

The most transformative technology currently is the continuous development of metrology software, which now incorporates advanced algorithms for geometric processing, automated feature recognition, and AI integration. Modern software platforms are designed for high compatibility, supporting import of various CAD file formats (e.g., STEP, IGES) and offering powerful tools for GD&T analysis and comprehensive statistical process control (SPC) reporting. Furthermore, networking capabilities allow VMMs to participate fully in the IoT environment of smart factories, enabling remote diagnostics, real-time data streaming, and automated quality loops that drive production efficiency by providing immediate feedback on manufacturing drift.

Regional Highlights

The global CNC Video Measuring market demonstrates heterogeneous growth profiles across major geographic regions, dictated by varying levels of industrial maturity, technological adoption rates, and investment in automated manufacturing. Asia Pacific (APAC) stands out as the primary market engine, driven by massive investments in automotive manufacturing (particularly in electric vehicle components), electronics, and high-volume consumer goods production. Countries like China, which has become a global manufacturing hub, and emerging economies such as India and Southeast Asian nations are rapidly adopting VMM technology to meet escalating export quality demands. North America and Europe, while mature, maintain steady demand due to the highly regulated aerospace, defense, and medical device sectors, where metrology is non-negotiable for safety and compliance.

- North America: Characterized by early adoption of multi-sensor and complex VMM systems, primarily driven by the stringent quality requirements of the aerospace sector (e.g., turbine engine parts, airframe structures) and advanced medical device manufacturing. Focus is on integration robustness and high-level software customization.

- Europe: High demand originates from the precision automotive industry, particularly in Germany and Italy, focusing on high-volume, high-accuracy inspection for internal combustion engine (ICE) and electric vehicle (EV) components. Strong emphasis on traceability standards and compatibility with European manufacturing data initiatives.

- Asia Pacific (APAC): The dominant regional market due to low manufacturing costs, significant industrial expansion, and high production volumes in the electronics and consumer goods industries. China and Japan lead in market size, with aggressive investment in localized VMM manufacturing and integration into smart factories.

- Latin America: An emerging market showing potential, particularly in Mexico and Brazil, driven by expanding automotive supply chains and increasing foreign direct investment in manufacturing. Adoption is generally focused on entry-level and standard CNC VMMs, with rising interest in automated systems.

- Middle East and Africa (MEA): Represents the smallest regional share, though modernization efforts in energy infrastructure and developing automotive sectors are expected to spur demand for high-accuracy metrology equipment in the medium term, particularly systems offering robust performance in varied environmental conditions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the CNC Video Measuring Market.- Hexagon AB

- Carl Zeiss AG

- Keyence Corporation

- Mitutoyo Corporation

- Nikon Corporation

- Tokyo Seimitsu Co., Ltd. (ACCRETECH)

- Starrett Company

- Renishaw plc

- Faro Technologies, Inc.

- Wenzel Group

- Perceptron (Atlas Copco)

- Optical Gaging Products (OGP)

- Vision Engineering Ltd.

- Micro-Vu Corporation

- Shanghai Optical Instrument Factory (SOIF)

- Serein Optic-Electric

- Leader Metrology

- Quality Vision International (QVI)

- Tesa (Hexagon)

- GOM (Zeiss)

Frequently Asked Questions

Analyze common user questions about the CNC Video Measuring market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary advantage of a CNC Video Measuring Machine over a traditional CMM?

The primary advantage is non-contact measurement, which allows for extremely fast and precise inspection of delicate, flexible, or small components, such as micro-electronics and thin films, without the risk of damage or deformation caused by physical probe contact. VMMs excel at 2D measurements and feature analysis.

How does the integration of AI improve the efficiency of VMMs in a manufacturing environment?

AI significantly improves efficiency by automating complex tasks like measurement program generation from CAD files, optimizing illumination settings automatically, and utilizing deep learning for rapid, reliable defect recognition and classification, thereby reducing human intervention and inspection cycle times.

Which industries are the major drivers of demand for large-format CNC VMMs?

Large-format VMM demand is primarily driven by industries requiring inspection of substantial components or assemblies, notably the aerospace sector (for wing and fuselage components), the automotive sector (for EV battery trays and chassis parts), and general heavy precision machining operations.

What is multi-sensor fusion technology in the context of video measuring machines?

Multi-sensor fusion combines the VMM's core optical capabilities with other sensor types, such as tactile probes, white light sensors, or laser scanners, within a single machine. This integration maximizes versatility, allowing the system to accurately measure both 2D features and complex 3D surface profiles efficiently.

What are the key technological restraints limiting the widespread adoption of advanced VMM systems?

The key restraints include the high initial capital investment required for high-accuracy CNC VMMs, which limits accessibility for smaller enterprises, and the persistent shortage of highly skilled metrology engineers required to program, operate, and maintain these sophisticated measurement instruments.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager