Coaxial Profile Projectors Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440571 | Date : Jan, 2026 | Pages : 251 | Region : Global | Publisher : MRU

Coaxial Profile Projectors Market Size

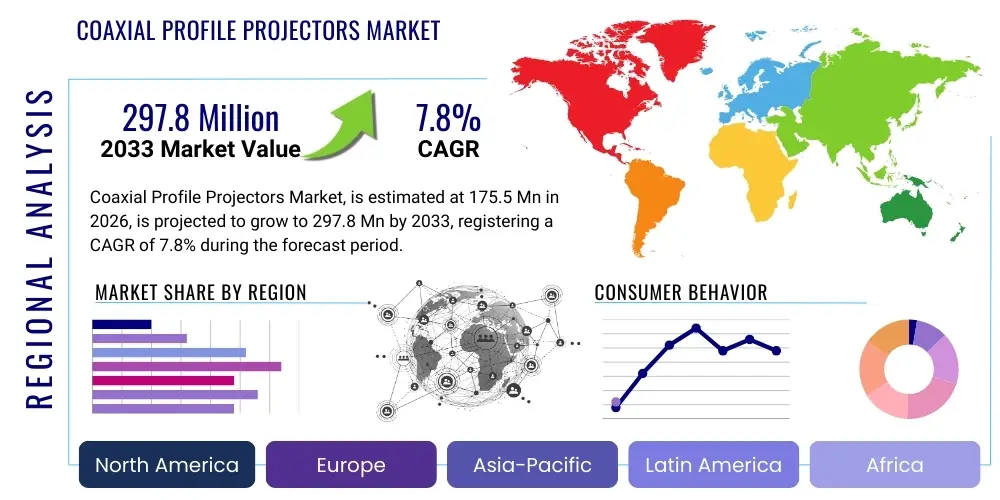

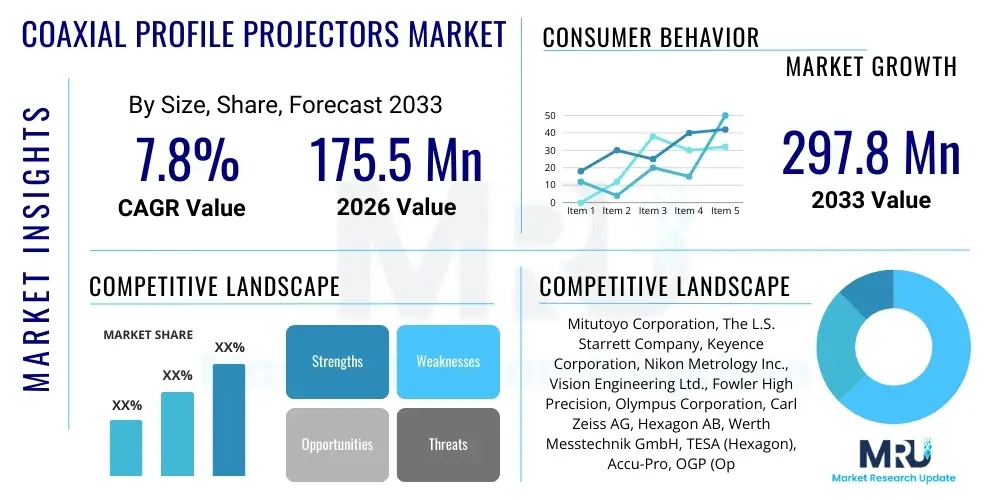

The Coaxial Profile Projectors Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.8% between 2026 and 2033. The market is estimated at USD 175.5 Million in 2026 and is projected to reach USD 297.8 Million by the end of the forecast period in 2033. This growth is driven by the increasing demand for high-precision measurement and inspection solutions across various industrial sectors, alongside the continuous push for enhanced quality control and automation in manufacturing processes globally. The market's expansion is further supported by technological advancements in optical systems, digital readouts, and integrated software, which collectively improve the accuracy, efficiency, and versatility of coaxial profile projectors, making them indispensable tools in modern production environments.

Coaxial Profile Projectors Market introduction

Coaxial profile projectors represent advanced optical metrology instruments designed for the precise two-dimensional measurement and inspection of small to medium-sized components. Unlike traditional profile projectors that use oblique illumination, coaxial profile projectors integrate the light source along the optical axis, providing a clearer, brighter image with enhanced edge detection, especially for complex geometries, blind holes, or features with varying depths. This innovative design minimizes distortion and significantly improves measurement accuracy, making them critical tools for ensuring quality in high-precision manufacturing. Major applications span a wide array of industries, including automotive, aerospace, electronics, medical devices, and general precision engineering, where dimensional accuracy and adherence to strict tolerances are paramount for product performance and safety. The primary benefits of these systems include their non-contact measurement capabilities, high magnification, versatility in inspecting various material types, and the ability to project a magnified silhouette or surface image onto a screen for detailed analysis. Key driving factors propelling the market's growth encompass the global shift towards Industry 4.0, increasing automation in manufacturing processes, the proliferation of miniaturized components requiring precise inspection, and the continuous rise in demand for stringent quality control standards across diverse end-use sectors. The integration of digital readouts (DROs) and advanced software further enhances their functionality, allowing for data analysis, reporting, and seamless integration into quality management systems, thereby improving overall operational efficiency and reducing human error.

Coaxial Profile Projectors Market Executive Summary

The Coaxial Profile Projectors Market is experiencing robust growth driven by accelerating demand for precision metrology solutions in an increasingly complex manufacturing landscape. Current business trends indicate a strong focus on automation, digital integration, and real-time data analysis, with manufacturers investing in advanced inspection equipment to maintain competitive edge and meet stringent quality benchmarks. The market sees considerable innovation in optical technologies, software capabilities, and ergonomic designs, leading to more user-friendly and highly accurate systems. Regional trends highlight Asia Pacific as a dominant and rapidly expanding market, fueled by its extensive manufacturing base and continuous industrialization efforts, particularly in countries like China, Japan, and South Korea. North America and Europe also contribute significantly, driven by aerospace, automotive, and medical device sectors that demand high-precision tools and are early adopters of advanced manufacturing technologies. Meanwhile, emerging economies in Latin America, the Middle East, and Africa are showing promising growth potential as their industrial sectors mature and adopt modern quality control practices. Segment trends reveal a growing preference for models equipped with advanced digital readouts, sophisticated software for analysis and reporting, and automated measurement capabilities. The demand for both vertical and horizontal configurations remains strong, catering to diverse application needs, while a noticeable shift towards systems offering higher magnification, better resolution, and seamless data connectivity is observed across all end-use industries. This collective dynamic positions the market for sustained expansion, with continuous innovation and strategic regional developments shaping its future trajectory.

AI Impact Analysis on Coaxial Profile Projectors Market

Users frequently inquire about how artificial intelligence (AI) will transform the capabilities and applications of coaxial profile projectors, focusing on concerns regarding enhanced automation, improved measurement accuracy, and the potential for predictive maintenance and smart analytics. There is a strong expectation that AI will move these devices beyond simple dimensional checks, enabling more sophisticated defect detection, automated decision-making in quality control, and seamless integration with broader smart factory ecosystems. Common themes revolve around the ability of AI to interpret complex visual data, learn from past inspections to improve future analyses, and provide actionable insights that optimize manufacturing processes, thereby addressing both efficiency and precision challenges currently faced by industries. The primary concerns often relate to the implementation cost, data privacy, the need for specialized training, and the reliability of AI algorithms in critical measurement applications, balancing the desire for innovation with the necessity of trusted accuracy.

- Enhanced Automated Inspection: AI-powered image recognition and processing algorithms can automate defect detection, identify anomalies, and perform complex dimensional measurements with minimal human intervention, significantly increasing throughput and consistency.

- Predictive Maintenance: AI can analyze performance data from coaxial profile projectors to predict potential equipment failures, enabling proactive maintenance and reducing downtime, thereby optimizing operational efficiency.

- Smart Data Analysis and Reporting: AI integrates with software to process vast amounts of measurement data, identify trends, generate comprehensive reports, and provide insights for process improvement, moving beyond raw data collection to actionable intelligence.

- Adaptive Learning for Quality Control: Machine learning algorithms can learn from previous inspection results, improving their accuracy in identifying defects and classifying parts over time, leading to more robust quality control systems.

- Integration with Manufacturing Execution Systems (MES): AI facilitates seamless communication and data exchange between profile projectors and other manufacturing systems, enabling real-time feedback loops and smarter production lines in an Industry 4.0 context.

- Optimized Parameter Settings: AI can suggest or automatically adjust illumination, magnification, and other inspection parameters based on the component being measured and predefined quality standards, reducing setup time and operator variability.

- Augmented Operator Guidance: AI can provide real-time guidance to operators for complex inspection tasks, highlighting areas of interest, suggesting measurement points, and ensuring adherence to inspection protocols, especially for intricate parts.

DRO & Impact Forces Of Coaxial Profile Projectors Market

The Coaxial Profile Projectors Market is primarily driven by the escalating global demand for high-precision measurement and quality control across diverse manufacturing sectors, coupled with the increasing adoption of automation technologies to enhance production efficiency and accuracy. Strict regulatory standards in industries like aerospace, medical devices, and automotive necessitate advanced inspection equipment, thereby propelling market growth. However, this growth is somewhat constrained by the relatively high initial investment costs associated with these sophisticated instruments and the competition from alternative, often more automated, metrology solutions such such as Coordinate Measuring Machines (CMMs) and advanced vision systems that offer multi-axis measurements. Nevertheless, significant opportunities lie in the continuous technological advancements in optical systems, digital readouts, and integrated software, which are making coaxial profile projectors more versatile, precise, and user-friendly, expanding their applicability to new materials and complex geometries. Furthermore, the burgeoning manufacturing sectors in emerging economies present untapped markets for these solutions, as industrialization efforts intensify and demand for quality assurance rises. The overall impact forces shaping this market include the relentless pace of technological innovation, which constantly pushes the boundaries of precision and efficiency, global economic fluctuations affecting capital expenditure in manufacturing, and the evolving landscape of global supply chains which demand robust quality checks at every stage. The increasing complexity and miniaturization of manufactured components worldwide serve as a fundamental driver, ensuring a sustained need for accurate and reliable non-contact measurement tools like coaxial profile projectors.

Segmentation Analysis

The Coaxial Profile Projectors Market is comprehensively segmented to provide a detailed understanding of its diverse applications, technological variations, and end-user adoption patterns. This segmentation helps in identifying specific growth pockets and market dynamics within different product types, illumination technologies, end-use industries, and applications, allowing manufacturers and stakeholders to tailor their strategies effectively. The analysis considers various product configurations that cater to different operational needs, the evolution of illumination techniques for improved clarity and precision, the specific requirements of various industrial sectors, and the distinct purposes for which these projectors are utilized in modern manufacturing and quality assurance environments. Understanding these segments is crucial for market participants to innovate and position their offerings strategically, addressing the unique demands and challenges present across the broad spectrum of potential customers. The market structure reflects a dynamic interplay between technological advancements and evolving industry demands, driving specialization within each segment.

- By Type

- Vertical Coaxial Profile Projectors

- Horizontal Coaxial Profile Projectors

- Benchtop Coaxial Profile Projectors

- Floor-standing Coaxial Profile Projectors

- By Illumination Type

- LED Illumination

- Halogen Illumination

- Fiber Optic Illumination

- By End-Use Industry

- Automotive

- Aerospace & Defense

- Electronics & Semiconductors

- Medical Devices

- Precision Manufacturing

- General Manufacturing

- Research & Development (R&D) and Education

- By Application

- Quality Control & Inspection

- Dimensional Measurement

- Part Comparison & Verification

- Tolerance Analysis

- Reverse Engineering

- Assembly Inspection

Value Chain Analysis For Coaxial Profile Projectors Market

The value chain for the Coaxial Profile Projectors Market commences with the upstream analysis, which primarily involves the procurement of highly specialized raw materials and components critical for manufacturing these precision instruments. This stage includes sourcing high-grade optical lenses, mirrors, light sources (LEDs, halogen lamps), digital cameras, electronic sensors, robust mechanical components for stages and frames, and sophisticated digital readouts and software modules. Key suppliers in this segment are often specialized manufacturers of precision optics and electronics, whose quality directly impacts the performance of the final product. Moving downstream, the value chain encompasses the manufacturing, assembly, testing, and calibration of the coaxial profile projectors. This involves intricate processes to ensure optical alignment, mechanical precision, and software integration. Following production, the finished products are distributed through various channels to reach the end-users. Distribution channels are typically a mix of direct sales, where manufacturers engage directly with large industrial clients for custom solutions and direct support, and indirect sales through a network of specialized distributors, resellers, and system integrators. These intermediaries play a crucial role in providing local sales, technical support, training, and after-sales service to a broader range of customers, including small and medium-sized enterprises. The direct channel allows for closer customer relationships and tailored solutions, while the indirect channel leverages existing sales networks and local presence for wider market penetration. Post-sales activities, including installation, calibration, maintenance, and software updates, form an integral part of the downstream value chain, ensuring customer satisfaction and equipment longevity. The efficiency and quality at each stage of this value chain are vital for delivering high-performance coaxial profile projectors that meet the stringent demands of modern precision industries.

Coaxial Profile Projectors Market Potential Customers

The potential customers for Coaxial Profile Projectors encompass a broad spectrum of industries and organizations that prioritize precision, accuracy, and rigorous quality control in their manufacturing and research processes. The primary end-users and buyers of these sophisticated metrology instruments are typically manufacturing companies across various sectors, ranging from large multinational corporations to specialized small and medium-sized enterprises (SMEs). Specifically, industries such as automotive, aerospace and defense, electronics and semiconductors, and medical devices constitute a significant portion of the customer base due to their stringent requirements for dimensional accuracy and component reliability. Automotive manufacturers utilize these projectors for inspecting engine components, transmission parts, and other critical assemblies, ensuring they meet precise specifications. In aerospace, these systems are indispensable for verifying the dimensional integrity of turbine blades, structural components, and fasteners, where even minor deviations can have catastrophic consequences. The electronics industry relies on them for inspecting miniature components, PCBs, and connectors, where tolerances are often measured in microns. Similarly, the medical device sector employs coaxial profile projectors for examining implants, surgical instruments, and prosthetic components to ensure patient safety and regulatory compliance. Beyond these major manufacturing hubs, general precision engineering workshops, tool and die makers, metal fabrication companies, and plastics manufacturers also represent key customer segments. Furthermore, research and development (R&D) institutions and educational facilities frequently acquire these projectors for material science research, product development, and vocational training in metrology, valuing their ability to provide detailed visual and quantitative analysis of complex geometries. Quality assurance laboratories, both in-house and third-party, also form a crucial customer segment, as they are tasked with certifying product quality and adherence to industry standards, making these projectors an essential part of their inspection arsenal. The demand from these diverse customers is driven by the universal need to reduce scrap rates, improve product functionality, ensure interoperability, and uphold brand reputation in a competitive global market.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 175.5 Million |

| Market Forecast in 2033 | USD 297.8 Million |

| Growth Rate | 7.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Mitutoyo Corporation, The L.S. Starrett Company, Keyence Corporation, Nikon Metrology Inc., Vision Engineering Ltd., Fowler High Precision, Olympus Corporation, Carl Zeiss AG, Hexagon AB, Werth Messtechnik GmbH, TESA (Hexagon), Accu-Pro, OGP (Optical Gaging Products), Shibuya Optical Co., Ltd., Scherr-Tumico, Tokyo Seimitsu Co., Ltd., Micro-Vu Corporation, Aberlink Ltd., Trimos SA, Sylvac SA |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Coaxial Profile Projectors Market Key Technology Landscape

The Coaxial Profile Projectors Market is continuously evolving, driven by significant advancements in optical, digital, and software technologies that enhance precision, functionality, and user experience. At the core of these instruments are sophisticated high-resolution optics, including telecentric lenses, which ensure consistent magnification regardless of the object's position within the field of view, thereby eliminating perspective errors and vastly improving measurement accuracy for complex three-dimensional objects. The integration of advanced digital cameras and image sensors, particularly CCD and CMOS types, allows for high-speed image capture and digital processing, enabling precise edge detection and feature recognition that was not possible with purely optical projection. Digital Readout (DRO) systems have become standard, providing immediate and accurate numerical data on X-Y coordinates, angular measurements, and other critical dimensions, often with sub-micron resolution. Modern coaxial profile projectors are increasingly incorporating powerful software for intricate image analysis, statistical process control (SPC), automated measurement routines, and comprehensive reporting. This software often includes features like CAD file import for part comparison, geometric dimensioning and tolerancing (GD&T) analysis, and multi-sensor integration capabilities. Furthermore, the shift from traditional halogen illumination to advanced LED illumination systems is a significant technological trend. LED light sources offer longer lifespans, lower power consumption, consistent color temperature, and reduced heat generation, contributing to greater measurement stability and component longevity. Many systems now also feature multi-axis motorized stages, enabling semi-automated or fully automated measurement cycles, which are crucial for high-volume inspection. These technological advancements collectively transform coaxial profile projectors from simple inspection tools into integral components of modern quality assurance and smart manufacturing ecosystems, capable of producing highly reliable and repeatable measurement results with enhanced efficiency. The ongoing research in areas such as artificial intelligence and machine vision further promises to revolutionize their capabilities, enabling even smarter, more autonomous inspection processes in the future.

Regional Highlights

- North America: This region represents a mature market for coaxial profile projectors, characterized by high adoption rates in precision manufacturing, aerospace and defense, and medical device industries. The presence of leading technology providers and a strong emphasis on R&D drive innovation, fostering demand for advanced, automated metrology solutions.

- Europe: Driven by robust automotive, precision engineering, and electronics sectors, Europe demonstrates consistent demand for high-accuracy inspection equipment. Countries like Germany, Switzerland, and the UK are at the forefront of adopting advanced manufacturing techniques and stringent quality control standards, ensuring sustained market growth.

- Asia Pacific (APAC): As the largest and fastest-growing market, APAC is fueled by its immense manufacturing base, rapid industrialization, and increasing foreign direct investment in countries such as China, Japan, South Korea, and India. The escalating demand for high-volume, cost-effective, and precise quality control solutions across diverse industries makes this region a crucial growth engine.

- Latin America: This region is an emerging market, with growing industrialization and increasing investments in manufacturing infrastructure, particularly in automotive and electronics sectors in Brazil and Mexico. Demand for coaxial profile projectors is rising as local industries aim to enhance product quality and meet international standards.

- Middle East and Africa (MEA): MEA is a developing market with nascent but growing manufacturing sectors, primarily driven by investments in infrastructure, energy, and localized production capabilities. The market for precision metrology tools is expected to expand as industrial diversification and quality consciousness increase across the region.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Coaxial Profile Projectors Market.- Mitutoyo Corporation

- The L.S. Starrett Company

- Keyence Corporation

- Nikon Metrology Inc.

- Vision Engineering Ltd.

- Fowler High Precision

- Olympus Corporation

- Carl Zeiss AG

- Hexagon AB

- Werth Messtechnik GmbH

- TESA (Hexagon)

- Accu-Pro

- OGP (Optical Gaging Products)

- Shibuya Optical Co., Ltd.

- Scherr-Tumico

- Tokyo Seimitsu Co., Ltd.

- Micro-Vu Corporation

- Aberlink Ltd.

- Trimos SA

- Sylvac SA

Frequently Asked Questions

Analyze common user questions about the Coaxial Profile Projectors market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is a coaxial profile projector and how does it work?

A coaxial profile projector is an optical metrology instrument that projects a magnified silhouette or surface image of a component onto a screen for precise 2D measurement and inspection. It uses a light source aligned with the optical axis, providing superior image clarity and edge detection, especially for complex or recessed features. Users place the part on a measuring stage, and the magnified image allows for accurate dimensional analysis, part comparison, and defect detection.

What are the primary applications of coaxial profile projectors?

Coaxial profile projectors are widely used for quality control, dimensional measurement, inspection, and reverse engineering in industries requiring high precision. Key applications include inspecting components in automotive, aerospace, electronics, medical devices, and general precision manufacturing for critical dimensions, tolerances, thread forms, and surface contours. They are essential for verifying component geometry against design specifications.

How do coaxial profile projectors differ from traditional profile projectors?

The main difference lies in their illumination method. Traditional profile projectors use oblique or diascopic (backlit) illumination, while coaxial profile projectors integrate the light source along the optical axis. This coaxial illumination provides a clearer, brighter image with reduced shadow effects, making them superior for inspecting complex 3D parts, blind holes, and features with varying depths, offering enhanced edge detection and measurement accuracy.

What are the key advantages of using coaxial profile projectors for manufacturing?

The key advantages include highly accurate non-contact measurement, reduced distortion for complex geometries, enhanced edge clarity, and versatility in inspecting various materials. They contribute to improved product quality, reduced scrap rates, faster inspection times, and compliance with stringent industry standards. Modern systems often integrate with digital readouts and software for advanced data analysis and automation.

What technological advancements are impacting the coaxial profile projectors market?

Significant advancements include the integration of high-resolution digital cameras and advanced image processing software for automated measurement and analysis, sophisticated LED illumination for better clarity and longer lifespan, and motorized stages for automated inspection routines. Furthermore, connectivity with manufacturing execution systems (MES) and the incorporation of AI for predictive analytics and smarter quality control are transforming their capabilities, aligning with Industry 4.0 initiatives.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager