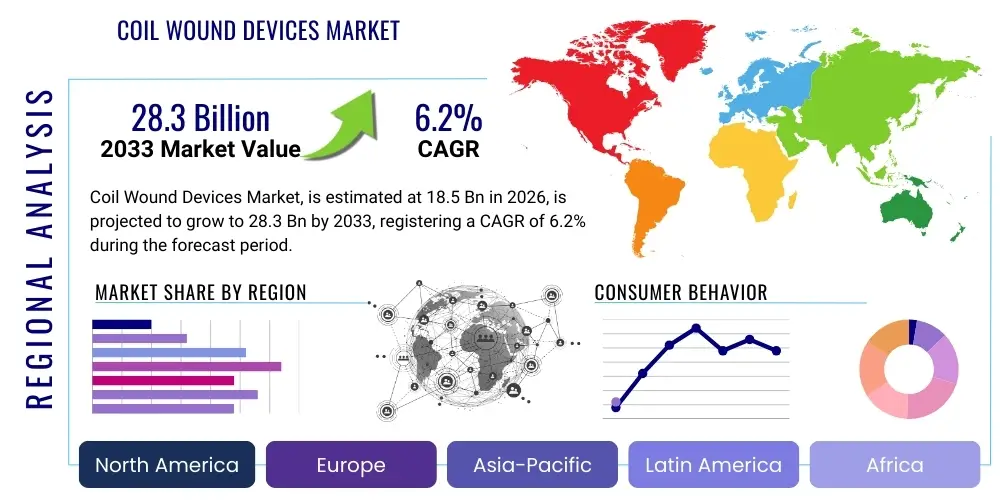

Coil Wound Devices Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 440531 | Date : Jan, 2026 | Pages : 246 | Region : Global | Publisher : MRU

Coil Wound Devices Market Size

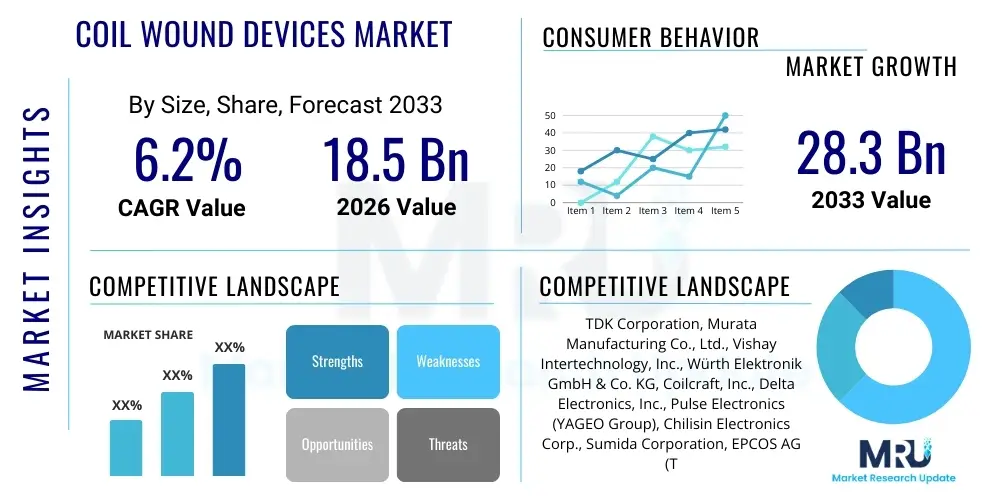

The Coil Wound Devices Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.2% between 2026 and 2033. The market is estimated at USD 18.5 Billion in 2026 and is projected to reach USD 28.3 Billion by the end of the forecast period in 2033.

Coil Wound Devices Market introduction

Coil wound devices are fundamental electromagnetic components, including inductors, transformers, chokes, solenoids, and various types of coils, critical for energy storage, signal filtering, impedance matching, and magnetic field generation across a vast array of electronic and electrical systems. These devices leverage the principle of electromagnetic induction to perform their functions, acting as indispensable elements in power conversion, communication, sensing, and control applications. Their robust design, reliable performance, and adaptability to specific electrical parameters make them ubiquitous in modern technology, facilitating efficient and stable operation of countless devices.

Major applications span diverse industries such as consumer electronics, automotive (especially electric vehicles), industrial automation, telecommunications (including 5G infrastructure), healthcare (medical imaging, diagnostic equipment), and renewable energy systems (solar inverters, wind power converters). The benefits derived from these devices include enhanced power efficiency, improved signal integrity, effective noise suppression, and robust magnetic field generation, all essential for sophisticated electronic functionalities. Key driving factors for market growth include the increasing demand for miniaturized and high-performance electronic components, the global push towards electrification and automation, the expansion of IoT ecosystems, and significant investments in smart grid and renewable energy infrastructure, all demanding reliable power management and signal processing solutions.

Coil Wound Devices Market Executive Summary

The Coil Wound Devices Market is currently experiencing robust growth, driven by an accelerating pace of technological innovation and increasing integration across various end-use industries. Key business trends include a strong focus on developing compact, high-frequency, and highly efficient devices to meet the stringent demands of modern electronics, alongside significant investments in automation and advanced manufacturing techniques to improve production scalability and reduce costs. The market is also witnessing strategic collaborations and mergers aimed at expanding product portfolios and enhancing competitive positioning, while sustainability considerations are influencing material selection and design processes for environmentally friendly solutions. Companies are continuously exploring new materials and winding technologies to push performance boundaries.

Regionally, the Asia Pacific (APAC) continues to dominate the market due to its robust manufacturing base for consumer electronics and automotive industries, coupled with rapid urbanization and industrialization. North America and Europe are mature markets, characterized by significant R&D investments, a strong presence in high-reliability applications like aerospace and medical, and increasing adoption of electric vehicles and industrial automation. Emerging economies in Latin America, the Middle East, and Africa are showing promising growth potential, fueled by infrastructure development, rising disposable incomes, and increasing technological adoption. These regions represent future growth pockets as industrial and electronic manufacturing capabilities expand.

In terms of segment trends, the automotive sector, particularly the electric vehicle (EV) segment, is a prominent growth driver, demanding advanced inductors and transformers for charging systems, powertrain electronics, and ADAS. The industrial sector also shows strong demand for high-power and robust devices for automation equipment, power supplies, and motor drives. Furthermore, the burgeoning Internet of Things (IoT) and 5G telecommunications infrastructure are driving demand for miniature, high-frequency coil wound devices for compact and efficient communication modules. Specialized applications in medical and aerospace & defense sectors continue to require custom-designed, high-precision, and ultra-reliable components, fostering innovation in niche areas.

AI Impact Analysis on Coil Wound Devices Market

Users frequently inquire about how Artificial Intelligence (AI) can revolutionize the design, manufacturing, and application of coil wound devices. Common themes revolve around AI's potential to optimize device performance, streamline production processes, and enable new functionalities in smart systems. Key concerns include the initial investment in AI infrastructure, data privacy, and the need for a skilled workforce capable of integrating and managing AI-driven systems. There is also significant interest in AI's role in predictive maintenance, quality control, and the development of intelligent coil wound devices that can adapt to changing operational conditions, ultimately leading to more efficient, reliable, and cost-effective solutions for various industries.

- AI-driven design optimization: Utilizing machine learning algorithms to rapidly iterate and optimize coil geometries, core materials, and winding patterns for enhanced efficiency, reduced size, and improved thermal management.

- Predictive maintenance: AI models analyzing operational data from coil wound devices to predict potential failures, enabling proactive maintenance and extending device lifespan, particularly in critical industrial or automotive applications.

- Automated quality inspection: Implementing AI-powered vision systems and anomaly detection algorithms for real-time, high-precision quality control during manufacturing, identifying defects that human inspection might miss.

- Smart manufacturing and process control: AI integrating into production lines to optimize winding speed, tension, and other parameters, leading to higher yields, reduced waste, and improved consistency.

- Enhanced demand forecasting and supply chain management: AI algorithms analyzing market trends, customer orders, and historical data to more accurately predict demand for specific coil wound devices, optimizing inventory and production schedules.

- New smart device integrations: AI enabling coil wound devices to become 'smarter' by embedding sensing capabilities and processing units, allowing them to adapt their performance or provide diagnostic data autonomously within larger AI-driven systems.

DRO & Impact Forces Of Coil Wound Devices Market

The Coil Wound Devices Market is propelled by several robust drivers, primarily the rapid electrification of the automotive sector, particularly the surge in electric vehicles (EVs) requiring advanced inductors and transformers for power conversion and charging infrastructure. Furthermore, the pervasive expansion of IoT devices, coupled with the global rollout of 5G networks, is fueling demand for miniaturized, high-frequency, and highly efficient coils for communication modules and compact electronic systems. The increasing adoption of industrial automation and robotics across manufacturing sectors also necessitates reliable and high-performance coil wound components for motor control, power supplies, and sensing applications, ensuring precise and efficient operation of automated machinery. Lastly, significant investments in renewable energy infrastructure, such as solar power inverters and wind turbine generators, continue to drive demand for robust power inductors and transformers capable of handling high power levels and extreme environmental conditions.

However, the market faces notable restraints, including the inherent volatility in raw material prices, particularly for copper, magnetic alloys, and specialized core materials, which can directly impact manufacturing costs and profit margins. The complex and precise manufacturing processes involved in producing high-quality coil wound devices, especially for miniaturized or high-frequency applications, require significant capital investment in advanced machinery and skilled labor, posing a barrier to entry for new players and challenging existing manufacturers. Moreover, the increasing stringency of regulatory standards for electromagnetic compatibility (EMC) and energy efficiency mandates continuous R&D and design adjustments, adding to product development costs and time. The persistent issue of counterfeit products also poses a threat, eroding market share and potentially jeopardizing the performance and safety of end-user applications.

Opportunities for growth are abundant, particularly in the expanding electric vehicle charging infrastructure, which demands high-power, high-reliability coil wound devices for both AC and DC charging stations. The development of advanced medical devices, including implantable electronics and sophisticated diagnostic equipment, presents a niche but high-value market requiring ultra-compact, precise, and biocompatible coil solutions. The global transition towards smart grids and modernized power distribution systems offers substantial opportunities for power transformers and inductors integrated with smart sensing and control capabilities. Additionally, continued innovation in aerospace and defense applications, coupled with the integration of AI into smart industrial devices, opens avenues for specialized, high-performance, and resilient coil wound components capable of operating in extreme environments and contributing to intelligent system functionalities. These opportunities underscore the market's dynamic nature and potential for diversified growth.

Segmentation Analysis

The Coil Wound Devices Market is comprehensively segmented to provide granular insights into its diverse components and applications. This segmentation allows for a detailed analysis of market dynamics across different product types, end-use industries, and specific technological characteristics, enabling stakeholders to identify key growth areas and understand competitive landscapes. The market is primarily broken down by the fundamental type of device, reflecting distinct design principles and functional attributes. Further segmentation considers the myriad of end-use industries, highlighting specific demands and growth trajectories driven by sector-specific technological advancements and market needs. Additionally, categorizations based on frequency range and power rating delineate performance capabilities and suitability for various applications, from low-power consumer electronics to high-power industrial and energy systems.

- By Type

- Inductors (Power Inductors, RF Inductors, Choke Coils, Ferrite Beads)

- Transformers (Power Transformers, Signal Transformers, Flyback Transformers, Current Sense Transformers, Pulse Transformers)

- Solenoids (Linear Solenoids, Rotary Solenoids, Latching Solenoids)

- Coils (Voice Coils, Antenna Coils, Sensor Coils, Ignition Coils)

- Actuators

- Electromagnets

- By Application

- Power Conversion & Management

- Signal Processing & Filtering

- Energy Storage

- Electromagnetic Sensing

- Motor Control

- Wireless Charging

- By End-Use Industry

- Automotive (EVs, ADAS, Infotainment, Engine Control)

- Consumer Electronics (Smartphones, Laptops, Wearables, Home Appliances)

- Industrial (Automation & Robotics, Power Supplies, Motor Drives, Test & Measurement)

- Telecommunications (5G Infrastructure, Network Equipment, IoT Devices)

- Healthcare (Medical Imaging, Diagnostic Equipment, Implantable Devices)

- Aerospace & Defense (Avionics, Radar Systems, Weaponry)

- Renewable Energy (Solar Inverters, Wind Turbine Systems, Energy Storage)

- Other Industries (Lighting, Security, Building Automation)

- By Frequency Range

- Low Frequency (below 1 MHz)

- High Frequency (1 MHz to 1 GHz)

- Radio Frequency (above 1 GHz)

- By Power Rating

- Low Power (up to 10W)

- Medium Power (10W to 1kW)

- High Power (above 1kW)

Value Chain Analysis For Coil Wound Devices Market

The value chain for the Coil Wound Devices Market begins with upstream activities, primarily involving the sourcing and processing of critical raw materials. This includes suppliers of magnetic materials such as ferrite powders, amorphous metals, and silicon steel laminations, as well as providers of high-purity copper wire, specialized insulating materials (e.g., enamel coatings, insulation tapes), and various core formers. These raw material providers are fundamental to the quality and performance of the final coil wound device, and their supply stability and pricing significantly influence the entire value chain. Research and development also play a crucial upstream role, focusing on new material sciences and advanced design methodologies to enhance device efficiency and miniaturization.

Moving downstream, the value chain encompasses the manufacturing and assembly of the coil wound devices, where raw materials are transformed into finished components through processes like precision winding, core assembly, encapsulation, and testing. Device manufacturers, ranging from large multinational corporations to specialized niche players, engage in product design, engineering, and mass production. These manufacturers then supply their products directly to Original Equipment Manufacturers (OEMs) across various end-use industries, such as automotive, consumer electronics, industrial automation, and telecommunications. This direct channel facilitates customization and technical support, catering to the specific requirements of large-volume buyers and complex system integrators.

In parallel, an extensive network of distribution channels supports the wider market reach of coil wound devices. Indirect distribution involves a robust ecosystem of authorized distributors, wholesalers, and electronics component retailers who stock and supply a broad range of standard and semi-custom devices to a diverse customer base, including smaller manufacturers, R&D labs, and aftermarket service providers. These distributors often provide value-added services such as inventory management, technical assistance, and logistics, bridging the gap between manufacturers and a fragmented customer base. Both direct and indirect channels are critical for market penetration, ensuring that coil wound devices are readily available to meet the varied demands of the global electronics and electrical industries.

Coil Wound Devices Market Potential Customers

The potential customers for coil wound devices are remarkably diverse, spanning nearly every sector that relies on electronic and electrical systems for their operation. Foremost among these are automotive Original Equipment Manufacturers (OEMs), especially those heavily invested in electric vehicles (EVs), hybrid vehicles, and advanced driver-assistance systems (ADAS), where high-performance inductors and transformers are essential for power conversion, battery management, and sensor integration. Manufacturers of consumer electronics represent another massive customer base, requiring miniaturized and efficient coils for smartphones, laptops, wearables, home appliances, and various smart devices to manage power, filter signals, and enable wireless charging functionalities.

The industrial sector constitutes a significant segment of potential customers, including companies engaged in industrial automation, robotics, power supply manufacturing, and motor drive systems. These customers demand robust, high-power, and reliable coil wound devices for their machinery, control panels, and energy management solutions, ensuring operational efficiency and durability in demanding environments. Telecommunications equipment providers, especially those deploying 5G infrastructure, data centers, and Internet of Things (IoT) devices, are also key buyers, seeking high-frequency and compact components for network modules, base stations, and communication peripherals to facilitate high-speed data transmission and connectivity.

Furthermore, the healthcare industry presents a specialized customer segment, encompassing manufacturers of medical imaging equipment (e.g., MRI, ultrasound), diagnostic devices, and implantable electronics. These applications require extremely precise, often custom-designed, and highly reliable coil wound devices that meet stringent regulatory standards. Lastly, companies in the renewable energy sector, such as manufacturers of solar inverters, wind turbine systems, and energy storage solutions, are critical customers, relying on high-power transformers and inductors to efficiently convert and manage energy generated from sustainable sources, thereby contributing to global decarbonization efforts.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 18.5 Billion |

| Market Forecast in 2033 | USD 28.3 Billion |

| Growth Rate | 6.2% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | TDK Corporation, Murata Manufacturing Co., Ltd., Vishay Intertechnology, Inc., Würth Elektronik GmbH & Co. KG, Coilcraft, Inc., Delta Electronics, Inc., Pulse Electronics (YAGEO Group), Chilisin Electronics Corp., Sumida Corporation, EPCOS AG (TDK Group), Gowanda Components Group, Vacuumschmelze GmbH & Co. KG, Laird Performance Materials (DuPont), Panasonic Corporation, TT Electronics plc, Bourns, Inc., Kemet Corporation (YAGEO Group), Schaffner Holding AG, Standex Electronics, Inc., Eaton Corporation |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Coil Wound Devices Market Key Technology Landscape

The Coil Wound Devices Market is continuously evolving through advancements in materials science, manufacturing techniques, and integration technologies. A primary technological focus is on the development of advanced magnetic core materials, such as high-permeability ferrites, amorphous metals, and nano-crystalline alloys. These materials enable devices to operate more efficiently at higher frequencies, reduce core losses, and achieve greater power density, which is crucial for miniaturization and enhanced performance in compact electronic systems. Innovations in winding technologies, including automated precision winding and new geometric configurations, are also critical for optimizing inductance, reducing parasitic effects, and improving thermal dissipation, ensuring reliability under demanding operational conditions.

Furthermore, significant technological progress is being made in simulation and design software, leveraging advanced Finite Element Analysis (FEA) and multiphysics modeling tools. These sophisticated software platforms allow engineers to accurately predict device performance, optimize designs for specific applications, and conduct virtual prototyping, significantly reducing development cycles and costs. The integration of coil wound devices with surface mount technology (SMT) and miniaturization techniques, such as low-profile designs and stacked architectures, is essential for meeting the stringent space constraints in modern consumer electronics and automotive applications. This push towards smaller form factors without compromising performance is a constant driver of innovation in packaging and manufacturing processes.

Another key aspect of the technology landscape involves improved thermal management solutions, as increasing power density in smaller packages generates more heat, which can degrade performance and reliability. This includes advancements in potting compounds, heat sinks, and integrated cooling channels within the device structure. Moreover, the emergence of smart coil wound devices with embedded sensors and connectivity features is enabling real-time monitoring of operational parameters like temperature and current, facilitating predictive maintenance and integration into IoT ecosystems. High-frequency design expertise, particularly for applications in 5G and wireless power transfer, is also paramount, driving research into specialized materials and resonant structures to minimize energy loss and maximize efficiency.

Regional Highlights

- North America: Characterized by a robust market for high-performance and specialty coil wound devices, driven by significant investments in aerospace and defense, advanced medical technology, and the burgeoning electric vehicle sector. The region benefits from strong R&D capabilities and early adoption of new technologies.

- Europe: A mature market with strong demand from the automotive industry, particularly for EVs and industrial automation. Strict environmental regulations and a focus on energy efficiency drive innovation in high-efficiency and compact coil wound devices. Germany, France, and the UK are key contributors.

- Asia Pacific (APAC): The largest and fastest-growing market, primarily fueled by the presence of major electronics manufacturing hubs in China, Japan, South Korea, and Taiwan. Rapid growth in consumer electronics, automotive production, telecommunications infrastructure (5G), and renewable energy contributes to its dominance.

- Latin America: An emerging market experiencing growth due to increasing industrialization, infrastructure development, and growing foreign investments in manufacturing. Countries like Brazil and Mexico are showing increasing demand for coil wound devices in automotive and industrial applications.

- Middle East & Africa (MEA): A developing market with increasing demand driven by investments in energy infrastructure, telecommunications expansion, and economic diversification initiatives. Opportunities are emerging in industrial, automotive, and renewable energy projects, though market size remains comparatively smaller than other regions.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Coil Wound Devices Market.- TDK Corporation

- Murata Manufacturing Co., Ltd.

- Vishay Intertechnology, Inc.

- Würth Elektronik GmbH & Co. KG

- Coilcraft, Inc.

- Delta Electronics, Inc.

- Pulse Electronics (YAGEO Group)

- Chilisin Electronics Corp.

- Sumida Corporation

- EPCOS AG (TDK Group)

- Gowanda Components Group

- Vacuumschmelze GmbH & Co. KG

- Laird Performance Materials (DuPont)

- Panasonic Corporation

- TT Electronics plc

- Bourns, Inc.

- Kemet Corporation (YAGEO Group)

- Schaffner Holding AG

- Standex Electronics, Inc.

- Eaton Corporation

Frequently Asked Questions

What are coil wound devices?

Coil wound devices are essential electromagnetic components like inductors, transformers, and solenoids that use coiled wires to store energy, filter signals, or generate magnetic fields, vital for various electronic and electrical systems.

What are the key drivers for the Coil Wound Devices Market growth?

The market's growth is primarily driven by the electrification of the automotive sector (especially EVs), the expansion of IoT and 5G networks, increasing industrial automation, and significant investments in renewable energy infrastructure.

How does AI impact the Coil Wound Devices Market?

AI significantly impacts the market by optimizing device design, enabling predictive maintenance, automating quality inspection in manufacturing, enhancing supply chain management, and facilitating new integrations into smart, adaptive systems.

Which industries are the primary end-users of coil wound devices?

Key end-user industries include automotive (EVs, ADAS), consumer electronics (smartphones, wearables), industrial automation, telecommunications (5G, IoT), healthcare (medical imaging), and renewable energy (inverters).

What are the main challenges faced by the Coil Wound Devices Market?

Major challenges include the volatility of raw material prices (copper, magnetic materials), the complexity of precision manufacturing processes, stringent regulatory compliance for efficiency and EMC, and the ongoing threat of counterfeit products.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager