Colorimeters Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 435989 | Date : Dec, 2025 | Pages : 245 | Region : Global | Publisher : MRU

Colorimeters Market Size

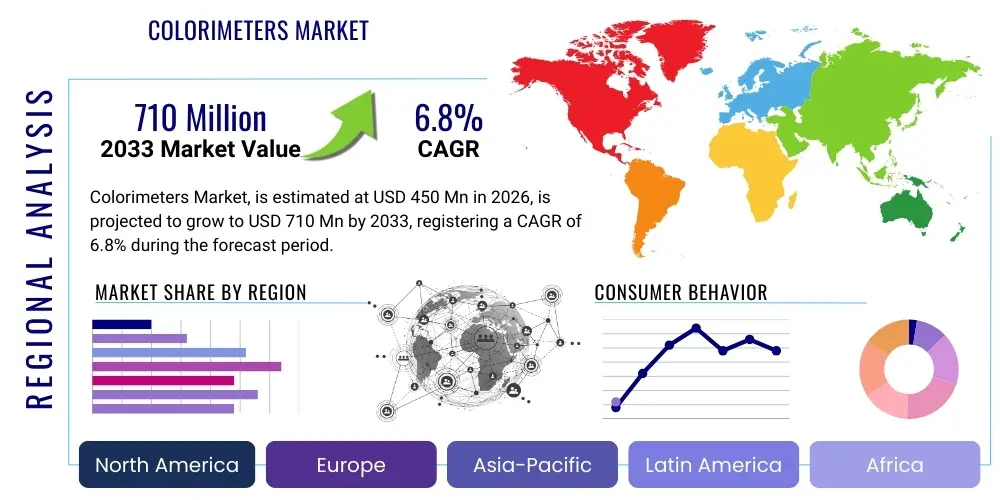

The Colorimeters Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 450 Million in 2026 and is projected to reach USD 710 Million by the end of the forecast period in 2033.

Colorimeters Market introduction

The Colorimeters Market encompasses the global trade and utilization of devices designed to measure color, specifically quantifying the spectral characteristics of light transmitted or reflected by a sample. These instruments operate based on the principles of tristimulus colorimetry, simulating human eye response using filtered photodetectors calibrated to the CIE standard observer functions (X, Y, Z). The core objective is to provide objective, standardized color measurement, moving beyond subjective visual assessment. Colorimeters are critical quality control tools, ensuring product consistency, identifying deviations from acceptable color tolerances, and facilitating regulatory compliance across multiple industrial sectors. Their operational simplicity, portability, and relatively lower cost compared to spectrophotometers make them the preferred choice for routine, high-throughput color measurement tasks in various manufacturing and production environments globally. The increasing stringency of quality standards, particularly in consumer-facing industries, significantly drives the deployment of these measurement technologies.

Colorimeters find major applications across sectors such as food and beverage, where color indicates freshness, ripeness, or concentration; textiles, where dye consistency is paramount; pharmaceuticals, utilized for tablet coating and packaging verification; and paints and coatings, ensuring batch-to-batch consistency. The fundamental benefit of adopting colorimetric technology lies in minimizing human error, accelerating quality assurance processes, and creating a globally transferable standard for color communication. Furthermore, advancements in sensor technology and microelectronics have led to the proliferation of highly accurate and compact handheld colorimeters, broadening their accessibility and utility in field applications, environmental monitoring, and retail environments where immediate assessment is necessary. These devices transform physical color attributes into measurable, repeatable numerical values, typically expressed in L*a*b* or L*C*h coordinates, which are easily integrated into digital quality management systems.

Driving factors for sustained market growth include the robust expansion of the global manufacturing sector, particularly in emerging economies focused on export quality standards, and the escalating consumer demand for aesthetically consistent products. Furthermore, legislative mandates and industry certifications requiring documented proof of color conformity, such as those in the automotive or construction materials industries, necessitate the systematic use of certified color measurement equipment. The continuous innovation leading to improved user interfaces, integration with wireless connectivity (IoT), and enhanced data processing capabilities further cements the colorimeter's role as an indispensable analytical instrument in modern industrial quality control pipelines. These technological enhancements are crucial for meeting the demands of high-precision applications requiring rapid and accurate chromaticity data.

Colorimeters Market Executive Summary

The global Colorimeters Market is characterized by steady technological evolution, transitioning towards smart, interconnected devices that offer enhanced spectral accuracy and portability. Current business trends indicate a strong competitive focus on providing integrated software solutions that facilitate seamless data management, reporting, and cloud-based calibration services, rather than solely hardware sales. Key industry players are increasingly engaging in strategic mergers and acquisitions to consolidate market share and acquire specialized intellectual property related to miniaturization and advanced spectral analysis algorithms. Furthermore, the push towards sustainability in industries like textiles and paints necessitates more precise color management to minimize material waste and optimize resource utilization, positioning high-performance colorimeters as essential tools for achieving green manufacturing goals. This shift in focus emphasizes workflow integration and analytical efficiency, ensuring that color data directly supports operational decisions and supply chain transparency.

Regionally, Asia Pacific (APAC) stands out as the primary growth engine, fueled by massive industrial expansion, particularly in China, India, and Southeast Asian nations, where stringent export quality standards are increasingly being adopted. North America and Europe maintain leading positions in terms of technological adoption and value consumption, driven by highly regulated industries such as pharmaceuticals and high-end automotive coatings, demanding superior instrument precision and regulatory compliance features. Emerging markets in Latin America and the Middle East & Africa (MEA) are showing promising growth trajectories, stimulated by infrastructure development and the localization of manufacturing capabilities. These regions are prioritizing cost-effective yet reliable color measurement solutions, favoring portable and affordable models for initial adoption and widespread deployment across smaller enterprises and new production facilities.

Segment trends highlight the dominance of portable colorimeters, which cater to on-site testing needs and flexible quality assurance protocols, often preferred for their rugged design and ease of use in diverse environmental conditions. However, the benchtop segment maintains high relevance in research and high-precision laboratory settings where maximum accuracy and stability are non-negotiable for critical reference measurements. Application-wise, the food and beverage sector, alongside the automotive coatings industry, represents significant growth areas due to the high volume of production requiring continuous, automated quality checks. Furthermore, there is a distinct trend towards instruments incorporating non-contact measurement capabilities to analyze sensitive or liquid samples without contamination risk, addressing evolving needs in chemical and biopharmaceutical processing.

AI Impact Analysis on Colorimeters Market

Analysis of common user questions regarding AI's impact on the Colorimeters Market reveals key themes centered around automation, predictive maintenance, and enhanced color formulation accuracy. Users frequently inquire: "How can AI algorithms reduce color matching time?" and "Will AI integration make dedicated color specialists redundant?" There is a strong expectation that AI will primarily optimize data interpretation, moving beyond simple L*a*b* comparisons to predicting material degradation or identifying the root cause of color shifts in complex manufacturing processes. Concerns often revolve around the initial investment required for AI-ready instrumentation and the necessity of massive, high-quality data sets for training effective spectral learning models. Users are keenly interested in predictive quality control systems where AI analyzes real-time color drift data from colorimeters and autonomously adjusts machine parameters, thereby dramatically improving first-pass yield rates and minimizing material waste in sectors like plastic molding and textile dyeing.

The immediate influence of Artificial Intelligence (AI) algorithms on the Colorimeters Market involves revolutionizing data processing and decision support systems. AI facilitates advanced spectral curve matching, which is significantly more complex than standard tristimulus comparisons. By applying machine learning models to vast archives of color measurement data, AI can swiftly identify subtle, non-linear relationships between color attributes, raw material input variability, and environmental conditions. This capability allows manufacturers to achieve superior color consistency, especially across different substrates or under varying lighting conditions, a task traditionally requiring highly skilled, subjective human expertise. Moreover, AI models are being trained to predict the required adjustments in dye or pigment concentration based on real-time readings from colorimeters, significantly accelerating the iterative process of color formulation correction and reducing production cycle times, contributing directly to operational efficiency gains.

In the domain of maintenance and operational efficiency, AI integrated with colorimeters supports highly sophisticated predictive maintenance protocols. By analyzing deviations and noise patterns in measurement data over time, AI can forecast potential sensor drift or calibration issues before they lead to inaccurate readings or production errors. This proactive approach minimizes downtime and ensures that the colorimeters maintain optimal performance throughout their lifecycle. Furthermore, for market research and competitive analysis, AI analyzes aggregated color data trends across supply chains, providing unparalleled insights into consumer color preferences, regional trends, and the performance stability of competitive products. This high-level analytical capability transforms colorimeter data from simple quality assurance metrics into strategic business intelligence assets, justifying the higher investment in next-generation smart colorimetric platforms that feature integrated AI capabilities for enhanced operational longevity and strategic planning.

- AI enables automated color formulation adjustment, predicting dye or pigment quantities needed to hit target chromaticity.

- Machine learning algorithms enhance spectral data interpretation, moving beyond standard L*a*b* values to understand subtle color shifts.

- Predictive maintenance utilizes AI to monitor sensor degradation and forecast necessary recalibration, maximizing instrument uptime.

- AI integration supports non-linear color matching, critical for complex materials like metallic paints or textured surfaces.

- Autonomous quality control systems leverage AI to analyze real-time color deviation and trigger corrective actions in the manufacturing process.

- Natural Language Processing (NLP) combined with AI assists users in querying and generating comprehensive color conformity reports from historical data.

DRO & Impact Forces Of Colorimeters Market

The Colorimeters Market is shaped by a powerful confluence of driving forces, inherent structural restraints, and evolving opportunities, collectively dictating the direction and pace of technological adoption. Key drivers include the global mandate for stringent quality assurance, particularly in export-oriented industries where standardized color measurement is non-negotiable for trade. Regulatory bodies in pharmaceuticals, food safety, and automotive industries continuously impose stricter compliance requirements, forcing manufacturers to invest in verifiable, reliable color measurement instruments. Counterbalancing these drivers are significant restraints, primarily the substantial initial capital expenditure required for high-accuracy benchtop models and the complexity associated with precise calibration and training of technical personnel. The critical impact forces stem from technological convergence, where advancements in optics, sensing technology, and microprocessors allow for the creation of smaller, yet more accurate, portable devices, broadening the market scope beyond traditional laboratory settings into field inspection and consumer-grade applications, effectively democratizing precise color measurement.

A primary market driver is the proliferation of complex, multi-material products, such as layered electronics or specialized medical devices, where color consistency across disparate components is essential for both functionality and brand perception. This complexity mandates the use of advanced colorimeters capable of handling different geometries and surface finishes, often requiring instruments equipped with sophisticated algorithms to compensate for gloss and texture effects. Furthermore, the global expansion of high-speed manufacturing lines increases the need for automation and rapid, non-destructive testing (NDT), which colorimeters efficiently fulfill by providing instantaneous, quantifiable feedback. Conversely, a major constraint impeding faster growth is the pervasive, yet often false, perception among smaller enterprises that visual inspection remains sufficient, coupled with the difficulty of maintaining consistent inter-instrument agreement (IIA) across different sites or suppliers, leading to supply chain discrepancies and resistance to adopting digital color standards.

Significant opportunities for market penetration emerge from the nascent integration of colorimeters into the Internet of Things (IoT) ecosystems. Connecting color measurement devices to cloud platforms allows for centralized monitoring, remote diagnostics, and standardized data comparison across globally distributed manufacturing sites. This capability offers unprecedented efficiency in global supply chain management, ensuring that all suppliers adhere to the identical color specification in real-time. Another crucial opportunity lies in the development of specialized colorimeters for niche markets, such as the cosmetics industry (analyzing skin tone and makeup blendability) or environmental science (monitoring water quality and pollutant concentration based on color changes). Addressing the restraint of calibration complexity through AI-driven self-diagnosis and automated calibration verification presents a compelling value proposition that will accelerate the replacement cycle for older, less sophisticated instrumentation and significantly expand the market size in developing regions.

Segmentation Analysis

The Colorimeters Market segmentation provides a granular view of market dynamics based on the product type, the underlying technology used for measurement, and the diverse applications across various end-use industries. Product type segmentation distinguishes between highly mobile, battery-operated devices and stationary, high-precision laboratory equipment, catering to differing needs for flexibility versus accuracy. The market is also strategically segmented by technology, recognizing the fundamental differences between simple tristimulus filtered systems and more sophisticated spectrophotometry-based colorimeters which offer full spectral analysis but often at a higher cost. Understanding these segments is crucial for manufacturers to tailor their R&D investments and marketing strategies, focusing on the specific price points, robustness requirements, and data complexity demanded by each respective user group within the global industrial landscape.

The application segment remains the largest determinant of market volume, driven primarily by high-volume manufacturing sectors such as packaging, printing, and textiles, where color is an intrinsic quality metric. Within the technology sphere, while traditional tristimulus colorimeters maintain market share due to their affordability and simplicity for basic quality checks, the increasing need for absolute color definition and metamerism analysis pushes adoption toward full spectral colorimetry, even in traditionally price-sensitive application areas. Geographic segmentation highlights divergent investment priorities; established markets focus on advanced, connected systems and software integration, while emerging economies prioritize rugged, cost-effective handheld units for immediate field deployment and rapid expansion of quality control protocols across decentralized facilities, optimizing deployment strategies.

Furthermore, segmentation by end-user industry demonstrates specific requirements for color measurement complexity. The pharmaceutical and automotive sectors demand instruments with ultra-high repeatability and rigorous validation documentation, fueling demand for premium benchtop models. In contrast, the food and agriculture sectors often require instruments with specialized fixtures for irregular sample handling (e.g., fruit ripeness measurement or liquid turbidity), necessitating customized optical geometries and robust, easy-to-clean designs. The interplay between product type and application segments defines the competitive landscape, compelling leading vendors to offer diverse product portfolios capable of addressing the wide spectrum of color management challenges encountered across the modern supply chain, from raw material inspection to final product verification.

- By Product Type:

- Portable/Handheld Colorimeters

- Benchtop Colorimeters

- By Technology:

- Tristimulus Colorimetry

- Spectrophotometry-based Colorimetry (often utilized but distinct in capability)

- By Application/End-Use Industry:

- Food and Beverage Industry

- Textiles and Apparel

- Paints, Coatings, and Dyes

- Plastics and Packaging

- Pharmaceuticals and Cosmetics

- Chemicals and Petrochemicals

- Academic Research and Education

- Environmental Testing and Water Treatment

- By Measurement Geometry:

- 45/0 and 0/45 Geometry (Directional measurement)

- d/8 Sphere Geometry (Diffuse measurement)

Value Chain Analysis For Colorimeters Market

The value chain for the Colorimeters Market begins with highly specialized upstream activities centered around raw material procurement and advanced component manufacturing. This upstream segment is dominated by suppliers of high-quality optical components, including precision lenses, robust filtered photodetectors calibrated to CIE standards, and high-performance light sources (e.g., Xenon flash or pulsed LEDs). The dependency on a limited number of specialized sensor and optics manufacturers creates potential supply chain vulnerabilities, emphasizing the strategic importance of secure sourcing and long-term contracts. Integration of advanced microprocessors and memory components, crucial for executing complex color algorithms and storing extensive measurement profiles, also constitutes a significant part of the upstream cost structure, driving the final price point of sophisticated instruments. Success in this stage requires rigorous quality control of components to ensure the ultimate measurement accuracy and inter-instrument agreement (IIA) of the final product.

Midstream activities involve the design, assembly, and rigorous calibration of the colorimetric instruments. This manufacturing phase includes the core R&D investment focused on developing proprietary color matching algorithms, ergonomic housing designs for portable units, and robust mechanical structures for benchtop stability. Calibration is arguably the most critical midstream step, ensuring that the instrument accurately simulates the human eye response under defined illuminants and is traceable to international metrology standards. The distribution channel, the subsequent downstream segment, is characterized by a mix of direct sales channels for large industrial accounts demanding bespoke integration services and indirect channels utilizing specialized laboratory equipment distributors and regional resellers. These distributors often provide local technical support, application training, and essential post-sale calibration and repair services, acting as a crucial interface between the manufacturer and the end-user.

Downstream market dynamics are highly influenced by the service and support infrastructure. Direct engagement allows manufacturers to gather detailed customer feedback, fostering rapid product iteration and optimization. Indirect channels, though broader in reach, require tight management to ensure consistent quality of technical service and accurate representation of complex product specifications. Furthermore, the market relies heavily on the provision of standardized color standards (e.g., traceable white tiles and calibration standards) and specialized software for data analysis and reporting, which are often sold as recurring revenue accessories or subscription services. The overall chain efficiency is increasingly being optimized through digital platforms that connect colorimeter data directly to enterprise resource planning (ERP) systems, reducing manual data entry and speeding up quality release decisions in high-volume production environments.

Colorimeters Market Potential Customers

The potential customer base for the Colorimeters Market is exceptionally broad, spanning nearly all industrial and research sectors where quantifiable color quality is a prerequisite for success. End-users, or buyers of the product, include quality control departments in major manufacturing organizations, R&D laboratories, and academic institutions dedicated to materials science and chemistry. Within the manufacturing realm, key customers are companies operating in high-volume, color-sensitive production environments such as automotive original equipment manufacturers (OEMs) and their Tier 1 suppliers, who use colorimeters to ensure exterior paint, interior fabrics, and plastic components match precisely under diverse lighting conditions. Similarly, major players in the fast-moving consumer goods (FMCG) sector, particularly those involved in cosmetics, food processing, and packaging, are vital customers requiring rapid and reliable measurement tools to uphold brand integrity and comply with labeling regulations related to consistency and appearance.

The textile and printing industries constitute a foundational customer group, utilizing colorimeters to manage dye recipes, verify colorfastness, and ensure conformity across different batches and materials, which is critical for minimizing costly material waste and rework. Chemical and pharmaceutical industries also represent significant end-users, employing these instruments not only for verifying product appearance but also for detecting chemical degradation or assessing the purity of compounds based on subtle color changes in liquid or powder form. Furthermore, the increasing focus on environmental stewardship has expanded the customer base to include environmental agencies and water treatment facilities, which use colorimeters to perform rapid analyses of effluent clarity and concentration of certain chemical indicators, providing immediate feedback essential for regulatory compliance and operational safety.

In addition to large corporations, the burgeoning market for specialized and portable colorimeters has created a substantial customer segment among small and medium-sized enterprises (SMEs) that previously relied solely on subjective visual checks. These smaller entities, driven by demands from their larger supply chain partners to adhere to digital color standards, are adopting entry-level portable units to formalize their quality control processes. Academic and research laboratories continuously invest in high-precision benchtop units for fundamental research in material science, optics, and perception studies, acting as critical early adopters of advanced spectroscopic technology. The diversity of the customer needs—ranging from rapid field assessment to ultra-high laboratory precision—necessitates specialized product offerings and dedicated application support across all geographical regions, maintaining a high level of market fragmentation in terms of end-user requirements.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 450 Million |

| Market Forecast in 2033 | USD 710 Million |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Konica Minolta Sensing Americas, X-Rite (Danaher), HunterLab, Datacolor, PCE Instruments, BYK-Gardner, Lovibond, 3nh, Elcometer, AMETEK, Techkon, Admesy, Kett Electric Laboratory, Shimadzu, Hitachi High-Tech, Hach, Hanna Instruments, Vernier Software & Technology, Taylor Technologies, VWR International, Merck KGaA, Endress+Hauser, Testo SE & Co. KGaA, Thermo Fisher Scientific. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Colorimeters Market Key Technology Landscape

The technological landscape of the Colorimeters Market is rapidly evolving, driven by the shift from basic filtered measurement to advanced spectral analysis and digital integration. Historically, colorimeters relied solely on the tristimulus method, using three broad-band filters to mimic the human eye's response to color (X, Y, Z coordinates). While this method remains cost-effective and suitable for basic quality checks, the industry is increasingly adopting hybrid systems that incorporate aspects of spectrophotometry. Modern colorimeters often utilize pulsed LED light sources combined with enhanced digital signal processing (DSP) to achieve greater stability and longevity than older Xenon lamp systems. The critical technological advancement is the focus on improving Inter-Instrument Agreement (IIA) and reducing measurement variance, which requires highly stable optical benches and sophisticated calibration routines integrated directly into the firmware of the device, ensuring reliable data transfer across global supply chains that use multiple instruments.

Miniaturization and portability are central technological trends, fueled by advancements in microelectronics and battery life. Handheld colorimeters now possess spectral performance capabilities that were previously exclusive to benchtop laboratory instruments. This shift enables quality control checks to be performed directly on the factory floor, minimizing the time lag between production and assessment. Furthermore, the integration of wireless communication standards, such as Wi-Fi and Bluetooth, is now standard, facilitating seamless data transmission to centralized color management software and cloud services. This connectivity is foundational for realizing the benefits of IoT in manufacturing, allowing for remote diagnostics, automated software updates, and centralized control over color standards across disparate production facilities, which is crucial for multinational corporations aiming for global color consistency and reducing the reliance on localized physical calibration.

Another area of intense technological focus is the development of non-contact and specialized measurement geometries. Traditional colorimeters require direct contact with the sample, which is problematic for wet paints, delicate textiles, or powdered substances. Non-contact colorimeters utilizing advanced laser ranging and precise focus systems mitigate this issue, enhancing application scope in areas like inline process control during continuous manufacturing runs. Furthermore, specialized instruments are being developed to handle complex materials, such as those exhibiting high gloss, texture (e.g., textiles), or fluorescence. Technologies like sphere-based spectrophotometers (d/8 geometry) are essential for accurately measuring textured or diffuse samples, while 45/0 geometry remains standard for measuring surface color that replicates human viewing conditions. These technological enhancements ensure that colorimetric instruments can accurately characterize the visual appearance of complex industrial materials under highly specific regulatory and aesthetic requirements.

Regional Highlights

- Asia Pacific (APAC): The APAC region is poised for the most rapid growth in the Colorimeters Market, driven primarily by the colossal expansion of the manufacturing sector across China, India, South Korea, and Southeast Asian nations. This growth is intrinsically linked to these countries becoming global manufacturing hubs for textiles, consumer electronics, plastics, and automotive components. Increasing emphasis on export quality control, coupled with rising labor costs necessitating automation in quality assurance, pushes manufacturers to invest heavily in modern colorimetric solutions. Furthermore, domestic regulatory pressures regarding food safety and environmental monitoring are intensifying, creating a strong localized demand for both basic, cost-effective portable units and advanced laboratory equipment. Japan and South Korea, being technologically mature economies, lead in the adoption of high-precision, AI-integrated colorimetry for high-end applications like display manufacturing and advanced materials research, setting the standard for regional innovation.

- North America: North America holds a substantial market share, characterized by high adoption rates of advanced, often spectrophotometry-based, colorimeters in highly regulated industries such as pharmaceuticals, aerospace, and high-performance coatings. The market here is driven less by volume expansion and more by the replacement of older systems with smart, IoT-enabled devices that facilitate seamless data integration and compliance tracking. Manufacturers in the U.S. and Canada prioritize software integration, comprehensive service contracts, and robust instruments that offer superior Inter-Instrument Agreement (IIA). The strong presence of leading market players and a mature R&D ecosystem ensures continuous innovation, focusing on specialized solutions for niche applications, including forensic science and precision agriculture, reinforcing its position as a market leader in value consumption and technological sophistication.

- Europe: The European market is stable and mature, driven by rigorous quality standards imposed by regulatory bodies such as the European Union (EU), particularly in the automotive, textile, and chemical sectors. European manufacturers are strong proponents of digital color standards and are early adopters of centralized color management systems connecting their European and global manufacturing sites. Germany, France, and the UK are key contributors, investing heavily in benchtop and inline color measurement systems to ensure production consistency and reduce material waste, aligning with strict environmental and sustainability targets. The focus in Europe is heavily skewed towards high-precision, long-life instruments, and service-intensive contracts, emphasizing operational excellence and the minimization of tolerance deviations across complex production environments.

- Latin America: The Latin American market exhibits moderate growth, stimulated by increasing industrialization and foreign direct investment into manufacturing capabilities, particularly in Brazil and Mexico. The demand is currently concentrated in the food processing, packaging, and basic materials sectors, where colorimeters are deployed to meet basic quality and import/export requirements. The market remains somewhat price-sensitive, favoring portable and affordable tristimulus colorimeters, although investment in advanced spectral instruments is growing alongside the regional expansion of global automotive and pharmaceutical multinationals seeking to standardize quality control practices across their regional subsidiaries and supply chains. Infrastructure improvement and increasing access to localized technical support are key to unlocking faster market growth in this region.

- Middle East and Africa (MEA): The MEA region is an emerging market with specialized growth drivers, primarily linked to significant infrastructure projects, the expansion of the petrochemical industry, and the development of local pharmaceutical manufacturing capabilities (especially in the Gulf Cooperation Council countries). Investment in colorimeters is driven by the need to maintain quality standards for construction materials (paints, coatings), textiles, and water quality monitoring. Adoption rates are currently lower than in other regions, constrained by limited technical expertise and reliance on imports. However, the push for economic diversification and local content requirements is expected to accelerate the acquisition of modern colorimetric equipment for quality assurance protocols and technology transfer initiatives, particularly in large industrial zones and newly established free trade areas requiring strict adherence to international product standards.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Colorimeters Market.- Konica Minolta Sensing Americas

- X-Rite (Danaher)

- HunterLab

- Datacolor

- PCE Instruments

- BYK-Gardner

- Lovibond

- 3nh

- Elcometer

- AMETEK

- Techkon

- Admesy

- Kett Electric Laboratory

- Shimadzu Corporation

- Hitachi High-Tech Corporation

- Hach (Danaher Corporation)

- Hanna Instruments

- Vernier Software & Technology

- Taylor Technologies

- VWR International (Avantor)

- Merck KGaA

- Endress+Hauser Group Services AG

- Testo SE & Co. KGaA

- Thermo Fisher Scientific Inc.

- Opto-Line International

Frequently Asked Questions

Analyze common user questions about the Colorimeters market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the fundamental difference between a colorimeter and a spectrophotometer?

A colorimeter measures color based on the tristimulus model (X, Y, Z), simulating the human eye’s response using three broadband filters, providing L*a*b* values sufficient for quality control within tolerance limits. A spectrophotometer, conversely, measures the full spectrum of reflected or transmitted light across the visible wavelengths, offering more precise data for color formulation, metamerism detection, and absolute color definition, though typically at a higher cost and complexity. Colorimeters are generally preferred for quick, routine quality checks, while spectrophotometers are used for highly accurate reference measurements and advanced R&D tasks.

How does the integration of IoT impact the workflow of color measurement in manufacturing?

IoT integration allows colorimeters to wirelessly connect to cloud-based color management systems, enabling real-time centralized monitoring, remote diagnostics, and automated data logging across geographically dispersed manufacturing sites. This connectivity standardizes color communication, improves Inter-Instrument Agreement (IIA), and allows for instantaneous corrective actions based on real-time data analysis, significantly accelerating quality assurance processes and ensuring supply chain consistency without manual data transfer or localized calibration challenges.

Which measurement geometry (45/0 vs. d/8 Sphere) is most suitable for industrial quality control?

The suitability depends on the sample surface characteristics. The 45/0 geometry is ideal for measuring color as the human eye perceives it, excluding gloss (specular component excluded), and is typically used for measuring smooth, opaque surfaces like plastic casings and finished prints. The d/8 (Diffuse/8 degree) sphere geometry measures total reflected light, including the specular component, making it essential for accurately measuring textured, highly reflective, or translucent materials such as metallic paints, rough textiles, or powdered substances, providing a more comprehensive color characterization irrespective of sample surface orientation or texture variation.

What are the primary challenges limiting the widespread adoption of colorimeters in small and medium-sized enterprises (SMEs)?

The main challenges for SMEs include the high initial capital investment required for high-precision models and the perceived complexity of calibration and technical training necessary to operate the instruments reliably. Furthermore, establishing and maintaining consistent digital color standards (Inter-Instrument Agreement) across multiple sites or suppliers can be difficult without robust centralized software and dedicated technical support, leading many smaller businesses to rely on less reliable visual inspection methods instead of transitioning to objective color measurement techniques.

How do advancements in sensor technology contribute to the enhanced performance of portable colorimeters?

Advancements in sensor technology, specifically the use of highly stable silicon photodiode arrays and advanced microprocessors, allow portable colorimeters to achieve accuracy levels previously restricted to benchtop models. This miniaturization, combined with improved filters calibrated to tighter tolerances and powerful digital signal processing (DSP) capabilities, enhances the instrument’s stability, longevity, and repeatability, making handheld devices reliable for critical on-site quality checks in demanding industrial environments, democratizing high-precision color measurement capabilities for field use.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Colorimeters Market Statistics 2025 Analysis By Application (Military, Scientific Research, Sewage Detection, Chemical), By Type (Portable Type, Stationary Type), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Imaging Colorimeters and Photometers Market Statistics 2025 Analysis By Application (Electronic Displays, Lighting, Automotive), By Type (CCD-based Imaging Colorimeters & Photometers, CMOS-based Imaging Colorimeters & Photometers), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager