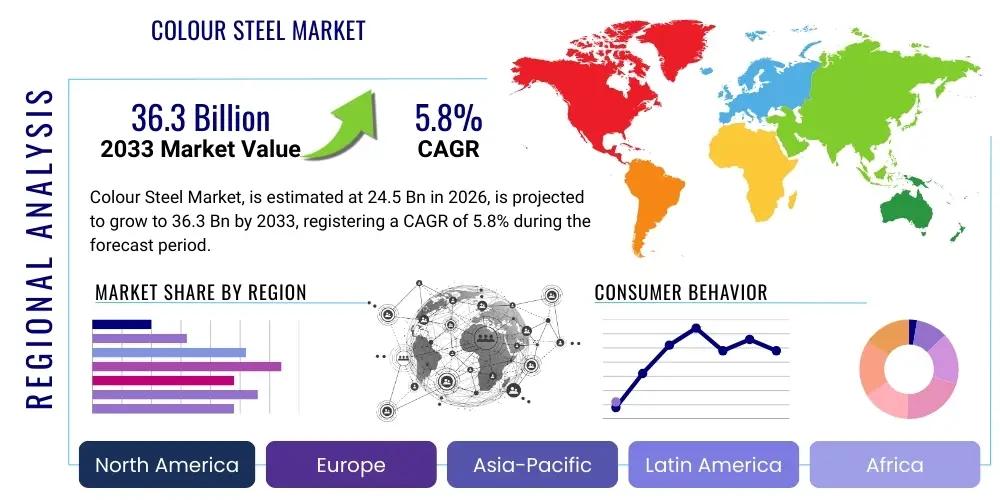

Colour Steel Market Size, By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 439911 | Date : Jan, 2026 | Pages : 258 | Region : Global | Publisher : MRU

Colour Steel Market Size

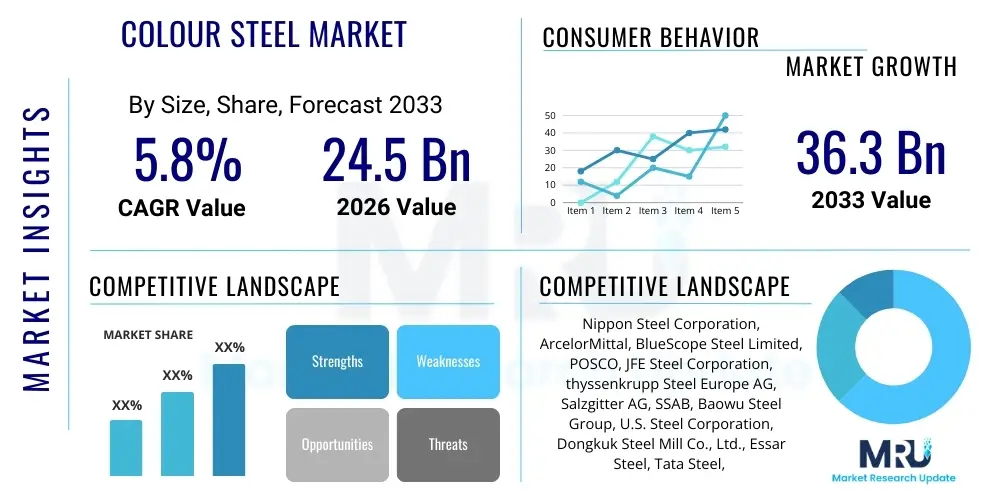

The Colour Steel Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at USD 24.5 Billion in 2026 and is projected to reach USD 36.3 Billion by the end of the forecast period in 2033.

Colour Steel Market introduction

The Colour Steel Market encompasses the production and distribution of pre-painted metal sheets, primarily steel, which are coated with organic paints or films in a continuous coil coating process. These products are widely utilized across various industries due to their superior aesthetics, enhanced corrosion resistance, and excellent formability. The pre-coating process ensures a consistent finish and minimizes environmental impact compared to post-painting.

Major applications for colour steel include roofing, wall cladding, and structural elements in the building and construction sector, where its durability and aesthetic versatility are highly valued. Furthermore, it finds extensive use in the manufacturing of home appliances such as refrigerators, washing machines, and microwave ovens, providing both protective and decorative surfaces. The automotive industry, furniture manufacturing, and general industrial applications also leverage colour steel for its specific properties.

The primary benefits of colour steel include its long lifespan, low maintenance requirements, and a broad spectrum of colors and finishes, allowing for significant design flexibility. Driving factors for market growth include rapid urbanization, increasing investments in infrastructure development, a growing demand for durable and aesthetically pleasing building materials, and the expansion of the consumer electronics and automotive sectors, particularly in emerging economies.

Colour Steel Market Executive Summary

The Colour Steel Market is experiencing robust growth, driven by an escalating demand for pre-finished, durable, and aesthetically versatile construction and manufacturing materials. Key business trends indicate a strong focus on sustainable production practices, including energy-efficient coating processes and the development of eco-friendly paints, alongside an increasing emphasis on customized solutions to meet diverse end-user specifications. Manufacturers are investing in advanced coating technologies to enhance product performance, such as improved weatherability, scratch resistance, and self-cleaning properties, catering to the evolving demands of various industries.

From a regional perspective, the Asia Pacific continues to dominate the market, propelled by extensive urbanization, significant infrastructure development projects, and a booming construction sector in countries like China and India. Europe and North America demonstrate mature but steady growth, driven by renovation activities, demand for premium and specialized colour steel products, and stringent energy efficiency regulations influencing building material choices. Emerging markets in Latin America and the Middle East & Africa are also showing considerable potential due to industrialization and infrastructure expansion initiatives.

Segmentation trends highlight the enduring dominance of the building and construction sector as the largest application area, with strong growth observed in both residential and commercial segments. The home appliance sector is also a significant contributor, benefiting from increasing consumer disposable income and technological advancements leading to new appliance designs. In terms of coating types, Polyester (PE) and Silicone Modified Polyester (SMP) remain popular for their cost-effectiveness and versatility, while high-performance coatings like Polyvinylidene Fluoride (PVDF) are gaining traction in demanding applications requiring superior durability and color retention. The market is characterized by intense competition among global and regional players, with a strategic focus on product innovation, capacity expansion, and supply chain optimization.

AI Impact Analysis on Colour Steel Market

The integration of Artificial Intelligence (AI) within the Colour Steel Market is emerging as a transformative force, addressing key themes such as operational efficiency, quality control, product innovation, and supply chain optimization. Users and industry stakeholders are primarily concerned with how AI can mitigate production inefficiencies, reduce material waste, and ensure consistent product quality across large-scale manufacturing operations. There is also significant interest in AI's potential to accelerate the development of new, advanced coatings and to enable greater customization in product offerings. Expectations are high for AI to provide predictive insights, enhance decision-making, and contribute to more sustainable and cost-effective production models.

- AI-driven predictive maintenance optimizes machinery uptime and reduces unforeseen breakdowns on coil coating lines.

- Enhanced quality control through AI-powered vision systems for real-time defect detection during the coating process.

- AI algorithms improve material utilization and minimize waste by optimizing cutting patterns and production schedules.

- Advanced analytics and machine learning facilitate demand forecasting, leading to more efficient inventory management and supply chain logistics.

- AI supports the rapid development and testing of new coating formulations, accelerating innovation in terms of durability, aesthetics, and functionality.

- Energy consumption optimization in curing ovens and other production stages through AI-based process control.

- Personalized product design and customization capabilities can be enhanced by AI-driven analysis of customer preferences and design trends.

DRO & Impact Forces Of Colour Steel Market

The Colour Steel Market is shaped by a dynamic interplay of drivers, restraints, and opportunities, collectively forming the impact forces that dictate its trajectory. Primary drivers include the global surge in urbanization and industrialization, leading to increased demand for robust and aesthetically pleasing construction materials for both new infrastructure projects and renovation activities. The rapid growth of the building and construction sector, particularly in emerging economies, alongside the expanding home appliance and automotive manufacturing industries, significantly propels market expansion. Moreover, the emphasis on sustainable building practices and the inherent recyclability and long-life cycle benefits of colour steel further stimulate its adoption.

However, the market faces significant restraints that could impede its growth. Fluctuations in the prices of raw materials, such as steel coils, zinc, and various paint ingredients (resins, pigments), introduce volatility and impact profit margins. Stringent environmental regulations concerning volatile organic compounds (VOCs) emitted during the coating process and the disposal of industrial waste compel manufacturers to invest in costly compliance measures and cleaner technologies. Additionally, intense competition from alternative building materials like aluminum, glass, and composites, combined with potential economic slowdowns in key regions, poses challenges to market stability and growth.

Despite these restraints, substantial opportunities exist for market players. The rising demand for specialty coatings with enhanced functionalities such as self-cleaning, anti-bacterial, thermal insulation, and anti-graffiti properties presents avenues for product innovation and differentiation. Emerging economies offer untapped potential due to their rapid infrastructure development and growing consumer bases. Furthermore, technological advancements in coating application techniques, sustainable paint formulations, and process automation (including AI integration) are expected to open new markets and applications, driving future growth and offering a competitive edge to innovators.

Segmentation Analysis

The Colour Steel Market is comprehensively segmented by various parameters, providing a detailed understanding of its diverse landscape and enabling strategic market analysis. These segmentations allow for a granular view of market dynamics, identifying key areas of demand, technological preferences, and application-specific trends across different industries and geographical regions. Understanding these segments is crucial for manufacturers, suppliers, and investors to tailor products, marketing strategies, and R&D efforts effectively.

- By Type

- Pre-painted Galvanized Steel (PPGI)

- Pre-painted Galvalume Steel (PPGL)

- Pre-painted Aluminum Coil

- Pre-painted Aluzinc Steel

- Other Pre-painted Metals

- By Coating Type

- Polyester (PE)

- Silicone Modified Polyester (SMP)

- Polyvinylidene Fluoride (PVDF)

- Polyurethane (PU)

- Plastisol

- Acrylic

- Epoxy

- Others (e.g., Super Durable Polyester)

- By Application

- Building and Construction

- Roofing

- Wall Cladding

- Doors and Windows

- Interior Panels

- Other Architectural Applications

- Home Appliances

- Refrigerators

- Washing Machines

- Microwave Ovens

- Air Conditioners

- Water Heaters

- Other White Goods

- Automotive

- Interior Components

- Exterior Panels

- Structural Parts

- Furniture

- General Industrial

- Electrical Cabinets

- Storage Systems

- HVAC Ducts

- Agricultural Equipment

- Road Signs

- Packaging

- Others

- Building and Construction

- By End-Use Industry

- Construction

- Appliance Manufacturing

- Automotive Industry

- Furniture Industry

- Electrical & Electronics

- Industrial Manufacturing

- Agriculture

- Signage

Value Chain Analysis For Colour Steel Market

The value chain for the Colour Steel Market begins with the upstream procurement of raw materials, primarily steel coils from steel manufacturers, and various organic coatings from chemical and paint suppliers. Steel manufacturers produce hot-rolled and cold-rolled steel, which then undergo galvanization or galvalumization processes to impart corrosion resistance. Simultaneously, specialized chemical companies develop and supply the advanced paints and primers, which are critical for the aesthetic and functional properties of the final colour steel product. The efficiency and cost-effectiveness at this stage are heavily reliant on stable supply agreements and quality control from these upstream providers.

The core manufacturing process involves coil coating lines, where the base steel substrate is cleaned, pre-treated, primed, painted (often multiple layers), and then cured in ovens. This sophisticated process requires significant capital investment in machinery and expertise to ensure uniform coating thickness, consistent color, and adherence to performance specifications. After coating, the colour steel coils are packaged and prepared for distribution. This midstream segment is characterized by advanced technological processes and stringent quality checks to meet diverse customer demands.

Downstream activities involve the distribution channel, which can be direct or indirect. Major colour steel manufacturers often engage in direct sales to large-scale end-users such as prominent construction companies, architectural firms, and large appliance manufacturers, fostering close relationships and offering customized solutions. Indirect channels involve a network of distributors, wholesalers, and fabricators who process the colour steel coils into specific forms like roofing sheets, wall panels, or appliance components, before supplying them to smaller contractors, retailers, or directly to consumers. The effectiveness of this distribution network is crucial for market penetration and customer reach, particularly in fragmented markets.

Colour Steel Market Potential Customers

The Colour Steel Market caters to a diverse range of end-users and buyers across multiple industrial sectors, each seeking the unique combination of durability, aesthetic appeal, and cost-effectiveness offered by these pre-finished materials. The largest segment of potential customers resides within the building and construction industry, encompassing both commercial and residential developers, contractors, and architectural firms. These buyers utilize colour steel extensively for roofing, wall cladding, facades, interior partitions, and structural components, driven by the need for long-lasting, low-maintenance, and visually appealing building envelopes that meet modern design and sustainability standards.

Another significant customer base includes manufacturers of home appliances, such as refrigerators, washing machines, freezers, and microwave ovens. These companies are primary buyers of colour steel for outer casings and interior linings, valuing its smooth finish, corrosion resistance, and the wide array of colors that allow for brand differentiation and aesthetic integration into contemporary kitchens and homes. The automotive sector also represents a growing segment, with manufacturers using colour steel for interior panels, body parts, and specialized components where lightweight, durability, and a pre-finished surface are advantageous.

Beyond these major sectors, potential customers extend to the furniture manufacturing industry for cabinets, shelving, and office furniture; the HVAC industry for ductwork and casing; and various general industrial applications including electrical cabinets, storage solutions, and agricultural equipment. These buyers are continuously seeking materials that reduce manufacturing complexity, enhance product longevity, and offer design versatility, making colour steel a preferred choice for a wide array of industrial and consumer goods.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 24.5 Billion |

| Market Forecast in 2033 | USD 36.3 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Nippon Steel Corporation, ArcelorMittal, BlueScope Steel Limited, POSCO, JFE Steel Corporation, thyssenkrupp Steel Europe AG, Salzgitter AG, SSAB, Baowu Steel Group, U.S. Steel Corporation, Dongkuk Steel Mill Co., Ltd., Essar Steel, Tata Steel, Severstal, JSW Steel, Metal One Corporation, Curtis Steel Co. Inc., Yieh Phui Enterprise Co., Ltd., China Steel Corporation, Novolipetsk Steel (NLMK) |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Colour Steel Market Key Technology Landscape

The technological landscape of the Colour Steel Market is characterized by continuous innovation aimed at enhancing product performance, sustainability, and manufacturing efficiency. At the heart of production are advanced continuous coil coating lines, which integrate sophisticated pre-treatment processes like cleaning and phosphating to ensure optimal adhesion of coatings. These lines feature multiple coating heads for applying primers and topcoats, followed by high-efficiency curing ovens (both thermal and increasingly UV-curing systems) that ensure rapid and complete polymerization of the paint layers, thereby improving throughput and reducing energy consumption. Precision control systems regulate coating thickness and temperature, crucial for consistent quality.

Significant technological advancements are also evident in paint and coating formulations. Modern coatings are engineered to provide superior weathering resistance, preventing fading and chalking, and enhanced scratch and abrasion resistance, crucial for handling and installation. Innovations include self-cleaning coatings that utilize photocatalytic effects, anti-bacterial coatings for hygienic applications, and specialized thermal reflective coatings that contribute to energy efficiency in buildings. The development of low-VOC (Volatile Organic Compound) and chrome-free pre-treatment chemicals reflects the industry's commitment to environmental sustainability and compliance with stringent regulations, driving R&D into more eco-friendly solutions.

Furthermore, the integration of automation and digitalization technologies is transforming manufacturing operations. Robotic systems are increasingly used for inspection and material handling, while advanced sensor technologies and data analytics enable real-time monitoring and control of the entire production process. This leads to improved quality consistency, reduced waste, and optimized production schedules. Future technological developments are expected to focus on smart coatings with embedded functionalities, AI-driven process optimization, and additive manufacturing techniques to create highly customized and specialized colour steel products, further expanding the market's capabilities and applications.

Regional Highlights

- Asia Pacific (APAC): Dominates the global market due to extensive urbanization, rapid industrialization, and massive infrastructure development projects, particularly in China, India, and Southeast Asian nations. High demand from the booming construction, automotive, and appliance manufacturing sectors fuels significant growth.

- North America: Characterized by a mature market with steady growth driven by renovation activities, demand for high-performance and aesthetic building materials, and a strong automotive industry. Emphasis on sustainable construction and energy-efficient solutions boosts demand for advanced colour steel products in the United States and Canada.

- Europe: Exhibits consistent growth, primarily led by demand from Western European countries for both new construction and refurbishment projects, along with a robust automotive sector. Strict environmental regulations and a focus on premium, sustainable, and energy-efficient building solutions shape market trends in Germany, France, and the UK.

- Latin America: Emerging market with substantial growth potential due to increasing investments in infrastructure, rising construction activities, and expanding industrial sectors. Brazil and Mexico are key contributors, driven by urbanization and economic development.

- Middle East & Africa (MEA): Demonstrates significant opportunities, especially with large-scale construction projects and diversification efforts away from oil economies in countries like Saudi Arabia, UAE, and Qatar. Growing demand for durable and aesthetically pleasing materials for residential, commercial, and industrial developments.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Colour Steel Market.- Nippon Steel Corporation

- ArcelorMittal

- BlueScope Steel Limited

- POSCO

- JFE Steel Corporation

- thyssenkrupp Steel Europe AG

- Salzgitter AG

- SSAB

- Baowu Steel Group

- U.S. Steel Corporation

- Dongkuk Steel Mill Co., Ltd.

- Essar Steel

- Tata Steel

- Severstal

- JSW Steel

- Metal One Corporation

- Curtis Steel Co. Inc.

- Yieh Phui Enterprise Co., Ltd.

- China Steel Corporation

- Novolipetsk Steel (NLMK)

Frequently Asked Questions

What is colour steel?

Colour steel, also known as pre-painted steel or coil-coated steel, is a steel sheet that has been continuously coated with multiple layers of organic paint or film in a factory setting. This process provides enhanced corrosion resistance, durability, and a wide range of aesthetic finishes, eliminating the need for post-painting after installation.

What are the primary applications of colour steel?

The main applications of colour steel are in the building and construction industry for roofing, wall cladding, and facades. It is also extensively used in the manufacturing of home appliances (e.g., refrigerators, washing machines), automotive components, and various general industrial applications.

What factors are driving the growth of the colour steel market?

Key drivers include rapid urbanization, global infrastructure development, increasing demand for durable and aesthetically pleasing building materials, growth in the home appliance and automotive sectors, and a rising focus on sustainable and energy-efficient construction practices worldwide.

What are the common types of coatings used on colour steel?

Common coating types include Polyester (PE) for general use, Silicone Modified Polyester (SMP) for enhanced durability, Polyvinylidene Fluoride (PVDF) for superior weatherability in harsh environments, Polyurethane (PU) for abrasion resistance, and Plastisol for thick, textured finishes.

Which region holds the largest share in the colour steel market?

The Asia Pacific region currently holds the largest market share for colour steel, primarily driven by massive construction and infrastructure projects, rapid industrialization, and strong demand from the manufacturing sectors in countries like China and India.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

- Colour Steel Market Size Report By Type (PE Coated Steel, HDP Coated Steel, SMP Coated Steel, PVDF Coated Steel), By Application (Construction, Home Appliance, Automotive), By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Share, Trends, Outlook and Forecast 2025-2032

- Colour Steel Market Statistics 2025 Analysis By Application (Construction, Home Appliance, Automotive), By Type (PE Coated Steel, HDP Coated Steel, SMP Coated Steel, PVDF Coated Steel), and By Region (North America, Latin America, Europe, Asia Pacific, Middle East, and Africa) - Size, Share, Outlook, and Forecast 2025 to 2032

- Prefabricated House Market Size, Share, Trends, & Covid-19 Impact Analysis By Type (Polystyrene Colour Steel Sandwich Plate, Rock Wool Color Steel Sandwich Plate, Polyurethane Colour Steel Sandwich Plate, Single Colored Steel Plate), By Application (Government, Building, Medical, Commercial, Other), By Region - North America, Latin America, Europe, Asia Pacific, Middle East, and Africa | In-depth Analysis of all factors and Forecast 2023-2030

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager