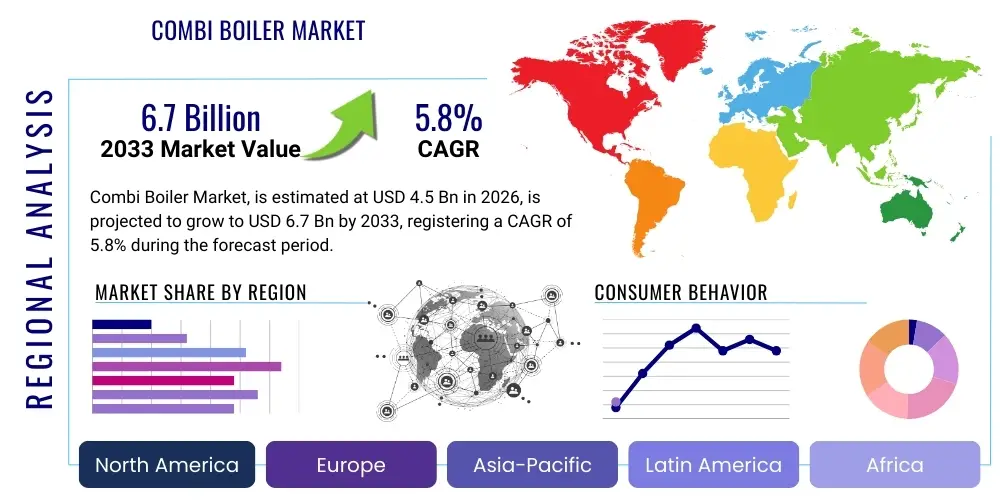

Combi Boiler Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 438400 | Date : Dec, 2025 | Pages : 251 | Region : Global | Publisher : MRU

Combi Boiler Market Size

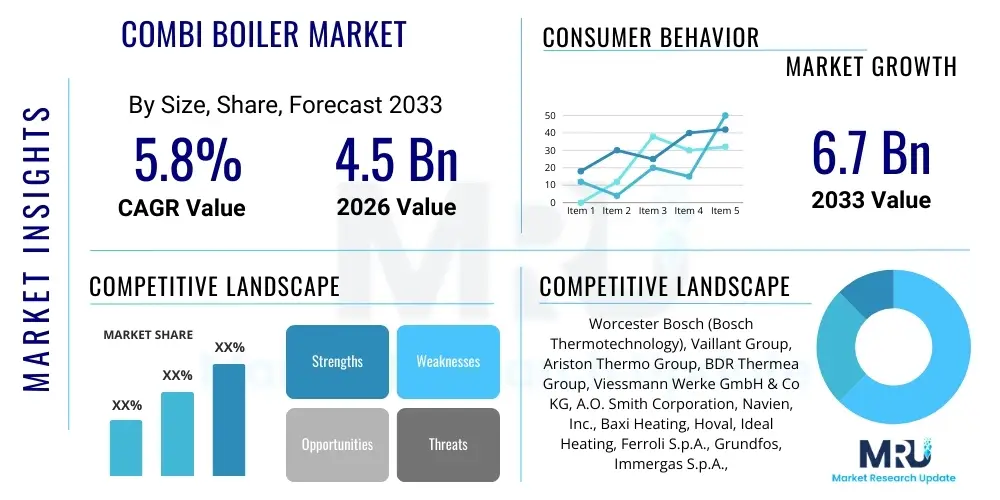

The Combi Boiler Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $4.5 billion in 2026 and is projected to reach $6.7 billion by the end of the forecast period in 2033.

Combi Boiler Market introduction

The Combi Boiler Market encompasses heating appliances that efficiently combine a high-efficiency water heater and a central heating boiler into a single compact unit. These systems, predominantly condensing models utilizing natural gas or liquefied petroleum gas (LPG), are highly favored in residential settings, especially in Europe and North America, due to their ability to provide instant hot water on demand without the need for a separate hot water storage tank. The product design emphasizes space saving, reduced installation complexity, and superior energy efficiency compared to traditional heating systems, aligning with global trends toward sustainable building technologies and reduced carbon emissions. Key applications primarily include new residential constructions and retrofitting projects aimed at upgrading older, less efficient heating infrastructure across developed economies.

The core benefit driving market penetration is the enhanced energy efficiency achieved through condensing technology, which recovers heat typically lost through the flue gases. This process significantly lowers operating costs for end-users and reduces the overall environmental impact. Furthermore, regulatory mandates, such as the European Union’s Energy related Products (ErP) directive and similar efficiency standards in North America, increasingly necessitate the adoption of high-efficiency heating solutions, positioning combi boilers as a compliant and cost-effective replacement option. The market is characterized by continuous innovation focused on improved modulation ratios, reduced noise levels, and integration with smart home ecosystems for optimized energy management.

Major driving factors include the aging residential infrastructure in established markets requiring mandatory upgrades, consistent government incentives promoting energy-efficient appliances, and rapid urbanization in emerging economies leading to smaller dwelling sizes where space-saving heating solutions are highly valued. The transition towards hybrid heating systems, where combi boilers are integrated with heat pumps, further solidifies their relevance in a decarbonizing energy landscape. Consequently, manufacturers are investing heavily in research and development to produce hydrogen-ready combi boilers, anticipating future shifts in fuel sources and ensuring product longevity in line with long-term climate targets.

Combi Boiler Market Executive Summary

The Combi Boiler Market is experiencing robust growth driven primarily by stringent environmental regulations and the rising cost of energy globally, making energy efficiency a paramount consumer concern. Key business trends indicate a strong shift towards advanced condensing models featuring IoT connectivity for remote diagnostics and predictive maintenance, alongside growing investment in hydrogen-ready boiler technology to future-proof heating infrastructure. Regional trends show Europe maintaining its dominance due to high penetration rates and replacement cycles mandated by the Ecodesign Directive, while the Asia Pacific region, particularly China and India, exhibits the fastest growth fueled by rapid construction activities and increasing consumer awareness regarding energy savings. Segmentation trends highlight the natural gas segment retaining the largest market share, but the emergence of hybrid systems combining gas combi boilers with renewable sources like solar thermal or air source heat pumps represents a critical area for expansion, catering to the residential sector's need for flexible and sustainable heating solutions.

Macroeconomic factors such as fluctuating material costs (e.g., copper and steel) and unstable geopolitical environments impact manufacturing margins and supply chain stability. However, continuous innovation in manufacturing processes, including automation and modular design, helps mitigate some of these pressures. Strategic acquisitions and partnerships among key players are common, aimed at expanding geographic reach and integrating complementary technologies, particularly in the realm of smart thermostats and energy management platforms. The competitive landscape is intensely focused on product durability, after-sales service quality, and achieving the highest Seasonal Space Heating Energy Efficiency (SSHEE) ratings, ensuring that market leaders maintain a premium position based on long-term value and reliability rather than just initial cost.

Furthermore, the transition within the residential heating sector is moving beyond mere efficiency to total system optimization. This involves integrating the boiler not just into the home network but also into local utility load management programs, optimizing consumption based on grid conditions and pricing. This sophisticated approach transforms the combi boiler from a simple heating appliance into a crucial component of a smart, efficient home energy system. This integration requires manufacturers to collaborate closely with software developers and utility providers, accelerating the convergence of traditional heating engineering with digital technology. This trend is particularly vital in densely populated urban areas where collective energy management can yield significant grid stability benefits and further drive the adoption of digitally-enabled combi boilers over conventional units.

AI Impact Analysis on Combi Boiler Market

User queries regarding AI's influence in the Combi Boiler Market predominantly revolve around three critical areas: enhanced operational efficiency, predictive failure analysis, and personalized energy consumption optimization. Users are keen to understand how AI-driven algorithms can monitor boiler performance in real-time, predict component failure before breakdown occurs, and ultimately reduce maintenance costs and downtime. Concerns often focus on data security, the privacy implications of connectivity, and the complexity of integrating advanced AI features into existing plumbing infrastructure. The expectations center on AI facilitating the next generation of smart diagnostics and personalized climate control, ensuring the boiler adapts dynamically to occupant behavior and external weather conditions, maximizing comfort while minimizing energy waste. The consensus expectation is that AI will move the market from reactive maintenance to proactive, automated management.

The application of Artificial Intelligence is fundamentally transforming the lifecycle of combi boilers, from design to end-of-life maintenance. During the design phase, AI-powered simulations optimize heat exchanger geometry and combustion processes for maximum thermal output and reduced emissions. In operation, Machine Learning (ML) models analyze vast datasets derived from installed units—including usage patterns, water pressure fluctuations, and internal temperature readings—to establish baseline performance parameters. Any deviation from this baseline triggers an alert, allowing maintenance providers to dispatch technicians with the correct parts preemptively. This dramatically increases the Mean Time Between Failures (MTBF) and elevates customer satisfaction, offering a significant competitive advantage to manufacturers embracing these digital capabilities.

AI also plays a crucial role in optimizing the boiler’s runtime and modulating its output based on household occupancy schedules derived from connected smart home devices and even hyperlocal weather forecasts. This level of granular control ensures that the boiler only generates the necessary heat, avoiding standby losses and unnecessary cycling. Furthermore, in commercial applications, AI algorithms manage large banks of combi boilers within multifamily housing or commercial buildings, balancing load requirements across the network to maintain efficiency and reliability across the entire heating system. This advanced energy management capability is vital for meeting carbon neutrality goals and positioning combi boilers as key assets in future smart grid systems.

- AI enables predictive maintenance, drastically reducing unexpected breakdowns and minimizing costly emergency call-outs.

- Machine Learning algorithms optimize combustion and gas modulation ratios, ensuring peak fuel efficiency under varying load conditions.

- Integration with smart home AI platforms allows for personalized heating schedules based on learning occupant behaviors and external factors.

- Automated fault diagnostics utilize AI to accurately identify root causes of operational issues, streamlining repair processes for technicians.

- AI supports supply chain resilience by forecasting demand fluctuations for components based on aggregate installed base performance data.

DRO & Impact Forces Of Combi Boiler Market

The Combi Boiler Market is propelled by stringent energy efficiency regulations, consumer demand for compact heating solutions, and high replacement rates of outdated non-condensing systems (Drivers). Growth, however, is moderated by significant upfront investment costs, technical complexities in retrofitting older properties, and stiff competition from alternative low-carbon technologies like heat pumps (Restraints). Opportunities abound in the development of hybrid heating systems, integration with smart grid technologies, and the commercialization of hydrogen-ready boilers, addressing future energy security concerns. These dynamics are intensely influenced by the volatile pricing of key raw materials (copper, steel) and the unpredictable trajectory of natural gas prices, constituting the primary Impact Forces determining market profitability and end-user adoption rates.

Drivers: The most significant driver is the global legislative shift towards energy conservation, exemplified by mandatory minimum efficiency standards in industrialized nations. The push for decarbonization requires residential heating systems to meet stringent performance benchmarks, making high-efficiency condensing combi boilers essential replacements. Furthermore, demographic shifts toward smaller, urbanized living spaces elevate the value of the combi boiler’s compact, tankless design. Government rebates and subsidies, particularly active in key European markets, further incentivize consumers to discard old, inefficient units for modern combi systems, accelerating the replacement cycle and providing consistent demand stability for manufacturers.

Restraints: Despite long-term cost savings, the high initial purchase and installation cost of premium condensing combi boilers remains a barrier for low-income households, particularly in price-sensitive emerging markets. Moreover, installation complexity, especially when upgrading pipework and venting systems in older buildings, requires specialized labor, contributing to higher installation fees and potential delays. A growing restraint is the increasing market prominence of renewable heating alternatives, particularly air source and ground source heat pumps, which, supported by massive governmental push towards electrification, pose a significant long-term competitive threat to gas-fired technologies, even high-efficiency ones.

Opportunities: The greatest potential lies in technological adaptation, specifically the development and scaling of combi boilers capable of utilizing blended hydrogen (up to 20%) or pure hydrogen (100%). This development positions the product favorably in future energy scenarios where natural gas infrastructure is repurposed for hydrogen distribution. Further opportunities exist in integrating combi boilers into sophisticated hybrid systems alongside heat pumps, creating highly efficient, flexible solutions that maximize the benefits of both fossil fuels and electricity, adapting seamlessly to fluctuating energy market conditions and regulatory demands.

Segmentation Analysis

The Combi Boiler Market is meticulously segmented based on essential product attributes, energy sources, and end-user applications to provide a detailed view of market dynamics and adoption patterns. Key segmentations include categorization by Technology (Condensing vs. Non-condensing, with condensing dominating), Fuel Type (Natural Gas, LPG, Oil, and Hybrid), and Application (Residential and Commercial). The residential segment accounts for the vast majority of demand due to the boiler’s suitability for single-family homes and apartments, while the commercial sector, primarily utilizing larger capacity units, represents a high-value niche focused on reliability and durability. Understanding these segments is crucial for strategic planning, enabling manufacturers to tailor their product offerings—such as highly efficient, compact natural gas models for urban residential retrofits or high-capacity hybrid solutions for light commercial applications—to specific regional and legislative requirements.

The distinction between condensing and non-condensing technology is fundamental, with condensing models now mandated in many developed economies due to their superior efficiency (typically 90% or higher). Non-condensing boilers are rapidly being phased out, remaining primarily relevant in specific replacement scenarios in regions with less strict regulatory oversight or challenging flue conditions. Among fuel types, natural gas remains the dominant choice due to existing extensive infrastructure and lower operational costs compared to LPG or oil. However, the LPG segment retains strong relevance in rural or off-grid areas lacking natural gas access, offering manufacturers a targeted market opportunity. The increasing focus on sustainability is driving rapid expansion within the Hybrid segment, which typically combines a gas combi boiler with an electrically powered heat pump, offering the best balance of efficiency, environmental performance, and reliable heating capacity during peak demand periods.

Analyzing segmentation by capacity is also vital for understanding the market landscape. Low-capacity units (under 25 kW) are essential for apartments and small homes, representing high-volume sales. Medium-capacity units (25 kW to 35 kW) cater to standard single-family homes and are the most common installation. High-capacity units (over 35 kW) serve larger residential properties or light commercial facilities like small offices or retail spaces. Manufacturers optimize production lines based on these capacity needs, focusing on miniaturization and high energy density for low-capacity units, and robust, durable components for the higher-capacity commercial applications, ensuring that product development efforts align directly with defined end-user needs and consumption patterns across various dwelling sizes and building types.

- By Technology: Condensing, Non-condensing

- By Fuel Type: Natural Gas, LPG (Liquefied Petroleum Gas), Oil, Hybrid

- By Capacity: Less than 25 kW, 25 kW to 35 kW, Greater than 35 kW

- By Application: Residential, Commercial (Light Commercial, Multi-family Housing)

Value Chain Analysis For Combi Boiler Market

The Value Chain for the Combi Boiler Market begins with the Upstream analysis, focusing on the sourcing and procurement of critical raw materials, primarily specialized alloys (stainless steel, copper) for heat exchangers and high-precision electronic components for control boards and sensors. Manufacturing involves complex assembly processes, rigorous testing, and quality control to ensure compliance with international safety and efficiency standards (e.g., ISO, CE markings). The Midstream segment is dominated by distribution channels, which are typically indirect, relying heavily on professional plumbing and heating wholesalers, dedicated heating merchants, and national distributors who manage large inventories and logistics. Direct sales channels, though less common, are utilized by key players primarily for large commercial contracts or direct-to-installer schemes, often bypassing the traditional wholesaler layer to enhance margin control and direct market feedback.

The Downstream aspect of the value chain is critical and involves professional installation by certified engineers and ongoing maintenance services. Due to the technical complexity and safety requirements associated with gas appliances, the installer network acts as the primary gatekeeper and influencer of purchasing decisions. Manufacturers invest heavily in installer training and certification programs, often offering exclusive warranties or support schemes to build loyalty within this crucial segment. The profitability of the downstream sector is heavily reliant on the recurrent revenue generated from routine servicing, replacement parts, and the provision of annual maintenance contracts, ensuring the long-term operational efficiency and compliance of the installed base.

The efficiency of the value chain is increasingly being optimized through digital tools. Upstream suppliers are adopting IoT sensors to track component quality and delivery times. Midstream distributors leverage advanced inventory management software and regional hubs to minimize lead times and logistical costs. Crucially, the after-sales service (downstream) is being transformed by AI and connectivity, allowing manufacturers to remotely diagnose issues, ensuring technicians arrive on-site with the necessary parts, significantly reducing service visit duration and enhancing first-time fix rates. This digital integration across the value chain not only improves efficiency but also establishes stronger feedback loops between product performance and future design iterations, ensuring continuous improvement in product reliability and market alignment.

Combi Boiler Market Potential Customers

Potential customers for the Combi Boiler Market primarily consist of end-users involved in three key sectors: new residential construction, residential replacement/retrofit projects, and light commercial facilities. In the residential sector, the primary buyers are homeowners (directly or via architects/developers) seeking highly efficient, space-saving heating solutions for apartments, townhouses, and standard single-family homes. The decision to purchase is frequently influenced by local regulatory requirements mandating high efficiency, the availability of government subsidies, and the advice of trusted plumbing and heating engineers who specify the unit. This customer base is highly focused on long-term operational cost savings and product reliability, making condensing technology a necessity rather than an option.

The replacement market forms the largest and most consistent demand pool, comprising homeowners or property management companies looking to replace aging, inefficient non-condensing boilers that have reached their end-of-life or no longer meet modern efficiency standards. These buyers prioritize minimal disruption during installation and proven track record reliability, often selecting brands with strong local service networks. Furthermore, property developers specializing in sustainable or green buildings are increasingly specified to use hybrid combi boiler systems, appealing to environmentally conscious consumers willing to pay a premium for reduced carbon footprint and future-proofed energy solutions.

The light commercial sector includes buyers such as owners or facility managers of small offices, retail outlets, schools, and multi-tenant residential complexes. For these applications, the focus shifts slightly towards higher capacity, robust commercial-grade combi units that offer redundancy and rapid heat recovery, ensuring continuous service for multiple demand points. Purchasing decisions in this segment are highly analytical, driven by total cost of ownership (TCO), energy consumption projections, and compliance with commercial building energy codes. These professional buyers require detailed performance data and often negotiate service contracts directly with manufacturers or specialized commercial installers, seeking scalable solutions that can manage varying load requirements efficiently across the operational year.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $4.5 Billion |

| Market Forecast in 2033 | $6.7 Billion |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Worcester Bosch (Bosch Thermotechnology), Vaillant Group, Ariston Thermo Group, BDR Thermea Group, Viessmann Werke GmbH & Co KG, A.O. Smith Corporation, Navien, Inc., Baxi Heating, Hoval, Ideal Heating, Ferroli S.p.A., Grundfos, Immergas S.p.A., E.ON SE, Daikin Industries, Ltd., Mitsubishi Electric, Rinnai Corporation, Rheem Manufacturing Company, Glow-worm Boilers, and Alpha Heating Innovation. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Combi Boiler Market Key Technology Landscape

The Combi Boiler Market technology landscape is rapidly evolving, driven by the mandate for higher energy efficiency, lower emissions, and seamless smart home integration. A critical technological shift is the transition to hydrogen-ready combustion technology. Manufacturers are engineering burners and internal components to safely and efficiently handle hydrogen blends, ensuring product viability in a future decarbonized gas network. This involves advanced materials science to prevent hydrogen embrittlement and sophisticated burner design to manage the higher flame speed and lower energy density of hydrogen compared to natural gas. Furthermore, the incorporation of advanced modulating gas valves allows the boiler to operate efficiently over a wider range of heat outputs, minimizing system cycling and maximizing fuel utilization, which is crucial for maximizing Seasonal Space Heating Energy Efficiency (SSHEE).

Connectivity and smart control systems represent another pivotal area of technological innovation. Modern combi boilers are equipped with integrated IoT sensors and Wi-Fi modules, enabling remote monitoring, real-time performance diagnostics, and Over-the-Air (OTA) software updates. This connectivity facilitates predictive maintenance driven by AI, allowing installers and manufacturers to address potential faults proactively. The proliferation of OpenTherm and similar protocols ensures compatibility with sophisticated smart thermostats and zonal control systems, allowing users to precisely manage heating in different areas of the home, leading to significant energy savings and enhanced user comfort. These sophisticated controls manage system integration, especially in hybrid setups where the combi boiler must seamlessly coordinate with an air source heat pump to determine the most energy-efficient heat source at any given moment based on external temperature and energy tariffs.

Another area of focus is on improving the heat exchanger design and material composition to enhance durability and maximize heat transfer efficiency. Developments include proprietary aluminum or stainless steel alloys that resist corrosion and scaling, extending the operational life of the unit, particularly in areas with hard water. Furthermore, advancements in flue gas heat recovery systems are pushing efficiencies close to the theoretical maximum. Beyond efficiency, noise reduction technology, utilizing advanced insulation and variable speed pumps and fans, is becoming standard, addressing consumer demands for quieter operation, especially relevant in high-density urban housing. These technological improvements collectively position the combi boiler as a sophisticated, digitally-enabled appliance essential for modern energy infrastructure.

Regional Highlights

- Europe: Europe represents the largest and most mature market for combi boilers globally, heavily influenced by the EU’s Ecodesign Directive (ErP) which mandates high energy efficiency standards. The UK, Germany, and Italy are key markets characterized by high replacement demand and strong government support for condensing technology adoption. The transition towards mandatory hydrogen blending and the growing popularity of hybrid heating systems, particularly in Germany and the Netherlands, are defining current regional investment and regulatory landscapes.

- North America: The market here, particularly in the US and Canada, is growing steadily, though generally favors forced air furnaces; however, combi boilers are gaining traction, especially in the Northeast and Pacific Northwest, driven by space constraints in multifamily housing and increasing utility incentives for high-efficiency systems. Adoption is higher for models that combine space heating and domestic hot water preparation efficiently, often competing with high-efficiency tankless water heaters.

- Asia Pacific (APAC): APAC is projected to be the fastest-growing region, fueled by rapid urbanization, significant residential construction across China, South Korea, and Japan, and rising disposable incomes. While market penetration is lower than in Europe, the regulatory push for air quality improvement, particularly in cities like Beijing and Seoul, drives demand for clean-burning, efficient gas heating solutions. The market here focuses heavily on compact design suitable for smaller apartment complexes.

- Latin America (LATAM): Growth in LATAM is concentrated in urban centers, primarily due to increasing construction activities and middle-class expansion, notably in Brazil and Mexico. The market often utilizes LPG boilers due to less developed natural gas infrastructure in certain regions. The demand is currently sensitive to initial pricing, but efficiency and reliability are becoming more important purchasing factors as energy costs rise.

- Middle East & Africa (MEA): This region exhibits mixed dynamics. The Middle East sees specific demand in cooler inland areas, with high reliance on robust units capable of operating reliably in diverse climatic conditions. In Africa, the market is nascent, focused mainly on high-end residential and commercial developments, often relying on imported European technology and prioritizing durability over digital features in many instances due to infrastructure limitations.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Combi Boiler Market.- Worcester Bosch (Bosch Thermotechnology)

- Vaillant Group

- Ariston Thermo Group

- BDR Thermea Group

- Viessmann Werke GmbH & Co KG

- A.O. Smith Corporation

- Navien, Inc.

- Baxi Heating

- Hoval

- Ideal Heating

- Ferroli S.p.A.

- Grundfos (Component Supplier Influence)

- Immergas S.p.A.

- E.ON SE (Energy Service Provider Integration)

- Daikin Industries, Ltd.

- Mitsubishi Electric

- Rinnai Corporation

- Rheem Manufacturing Company

- Glow-worm Boilers

- Alpha Heating Innovation

Frequently Asked Questions

Analyze common user questions about the Combi Boiler market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary factor driving the current growth of the Combi Boiler Market?

The primary driver is the implementation of global energy efficiency mandates, such as the European Union’s Ecodesign Directive, which necessitates the replacement of older, low-efficiency heating systems with high-efficiency condensing combi boilers that reduce both carbon emissions and consumer energy bills.

Are Combi Boilers compatible with future low-carbon energy sources, such as hydrogen?

Yes, significant technological advancements are focused on developing hydrogen-ready combi boilers, capable of operating efficiently with up to 20% blended hydrogen immediately, and with many manufacturers targeting 100% hydrogen compatibility to align with long-term national decarbonization strategies.

How does the integration of AI impact the operational lifespan and maintenance costs of modern combi boilers?

AI integration utilizes IoT connectivity to enable predictive maintenance by continuously analyzing performance data. This proactive approach allows technicians to address potential failures before they occur, drastically reducing unexpected downtime, minimizing service costs, and extending the overall operational lifespan of the unit.

Which geographical region holds the largest market share for Combi Boilers?

Europe currently holds the largest market share, predominantly driven by high penetration rates in the residential sector, established regulatory replacement cycles, and widespread consumer acceptance of gas-fired condensing technology, especially in the United Kingdom and Germany.

What are the key differences between standard Combi Boilers and Hybrid Combi Systems?

A standard combi boiler exclusively uses a fuel source (like natural gas) for heat. A hybrid combi system integrates the gas boiler unit with a renewable source, typically an air source heat pump, utilizing smart controls to automatically switch between sources to maximize energy efficiency and minimize operational costs based on weather conditions and electricity pricing.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager