Commercial Combi Ovens Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 431439 | Date : Dec, 2025 | Pages : 255 | Region : Global | Publisher : MRU

Commercial Combi Ovens Market Size

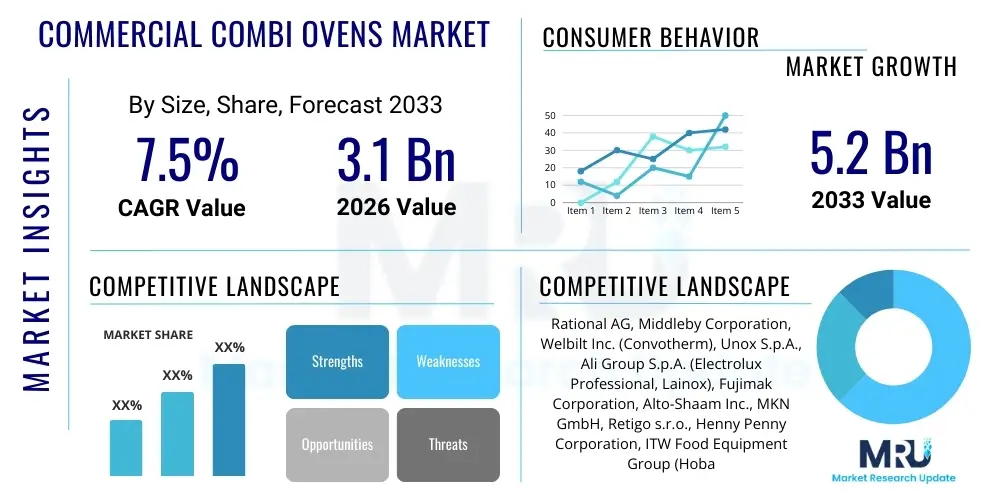

The Commercial Combi Ovens Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 7.5% between 2026 and 2033. The market is estimated at USD 3.1 Billion in 2026 and is projected to reach USD 5.2 Billion by the end of the forecast period in 2033.

Commercial Combi Ovens Market introduction

The Commercial Combi Ovens Market encompasses specialized cooking equipment used in professional kitchens that combines three modes of cooking: convection (dry heat), steam (moist heat), and a combination of both. These multi-functional appliances are designed to enhance cooking efficiency, consistency, and speed across various culinary applications, making them indispensable in high-volume foodservice operations. Product description centers on their advanced programming capabilities, self-cleaning features, and precision temperature control, distinguishing them from conventional commercial ovens. Modern combi ovens are critical assets in optimizing kitchen labor and minimizing food waste.

Major applications of commercial combi ovens span across the entire foodservice spectrum, including fast-casual restaurants, fine dining establishments, large-scale catering operations, hotels, institutional facilities like hospitals and schools, and cruise ships. They are particularly valued for their versatility, allowing operators to bake, roast, steam, blanch, grill, and even proof within a single unit. This versatility reduces the need for multiple pieces of equipment, conserving valuable kitchen space and energy.

The primary benefits driving market adoption include significant improvements in food quality and consistency due to precise humidity and temperature management, reduced cooking times, and lower utility consumption compared to traditional methods. Key driving factors involve the global expansion of the hospitality and tourism sectors, the increasing demand for high-quality, pre-cooked, and prepared meals, and the persistent shortage of skilled kitchen labor, which combi ovens help mitigate through automation and ease of use. Additionally, stringent food safety regulations are encouraging the adoption of controlled cooking environments provided by advanced combi ovens.

Commercial Combi Ovens Market Executive Summary

The Commercial Combi Ovens Market is experiencing robust expansion driven by technological advancements focused on connectivity, automation, and sustainability. Key business trends include the strong push towards boilerless technology, which reduces maintenance and water usage, and the integration of IoT sensors for remote monitoring and predictive maintenance. Manufacturers are heavily investing in user-friendly interfaces and recipe management systems to cater to varied skill levels across the globe. Regional trends show rapid adoption in the Asia Pacific due to burgeoning tourism and the proliferation of organized Quick Service Restaurants (QSRs), while North America and Europe remain mature markets focusing on replacement cycles and high-efficiency models. Segment trends indicate that the boilerless segment is gaining momentum due to lower operational costs, and the 11-to-20 rack capacity segment is dominant, catering efficiently to medium-to-large-scale foodservice operations seeking optimal space utilization and throughput.

AI Impact Analysis on Commercial Combi Ovens Market

User inquiries regarding AI's influence in the Commercial Combi Ovens Market frequently center on automation, recipe optimization, predictive maintenance, and energy efficiency. Users are keenly interested in how AI can move beyond simple pre-set programs to offer dynamic, real-time adjustments based on food characteristics, loading capacity, and desired outcome, thus reducing errors and reliance on expert chefs. Concerns revolve around the initial high cost of AI-enabled systems and the security implications of network-connected equipment. The overriding expectation is that AI will eventually create 'autonomous kitchens,' where ovens self-diagnose maintenance needs, optimize cooking parameters for maximum flavor and energy saving, and even manage inventory integration by tracking food usage and depletion during the cooking process.

- AI-driven Predictive Maintenance: Analyzing usage patterns and sensor data to forecast component failure, minimizing downtime and maintenance costs.

- Dynamic Recipe Optimization: Adjusting temperature, humidity, and fan speed in real-time based on the internal conditions of the food (e.g., core temperature, browning level).

- Enhanced Energy Management: Utilizing machine learning algorithms to schedule operations and manage heating elements for peak energy efficiency during high and low usage periods.

- Automated Quality Control: Employing computer vision and AI to assess the consistency and readiness of cooked items, ensuring adherence to quality standards without manual intervention.

- Supply Chain Integration: Connecting cooking cycle data with inventory management systems to streamline ordering and reduce food waste.

DRO & Impact Forces Of Commercial Combi Ovens Market

The market is primarily driven by the expanding global foodservice industry, the necessity for high labor efficiency, and technological innovations enhancing energy efficiency. Restraints include the high initial capital investment required for high-end combi oven models and the complexity of installation, especially in older kitchens with limited utility infrastructure. Significant opportunities lie in emerging markets adopting professional kitchen equipment rapidly and the development of compact, smaller-capacity units tailored for convenience stores and small-scale operations. The competitive intensity among existing manufacturers, coupled with buyer power driven by standardization demands, dictates the impact forces. The threat of substitutes, while low due to the unique multifunctionality of combi ovens, still exists from specialized equipment like dedicated industrial steamers or convection ovens.

The most compelling driver is the increasing focus on operational costs, particularly labor. A single combi oven can replace multiple pieces of equipment and perform the tasks of several specialized personnel simultaneously, offering an attractive return on investment (ROI) for operators facing escalating wage pressures. Furthermore, advancements in self-cleaning systems and remote diagnostics significantly reduce ongoing maintenance burdens, further sweetening the investment case. Environmental regulations are also impacting the market, pushing manufacturers to innovate on water consumption and gas efficiency, which positively reinforces the 'opportunity' side of the market dynamic.

Conversely, the primary restraint remains the significant initial price point. While the long-term ROI is clear, securing the initial capital outlay can be challenging for independent restaurants or small chain operators. Market entry barriers for new technologies, particularly in integrating AI and IoT capabilities, necessitate substantial R&D expenditure, which translates to higher consumer costs. The impact forces are characterized by strong rivalry, as key players continually introduce incremental technological improvements and aggressive pricing strategies to secure large chain contracts, keeping competitive pressure exceptionally high.

Segmentation Analysis

The Commercial Combi Ovens market segmentation offers granular insight into market dynamics based on cooking technology, capacity, energy source, and end-user applications. Understanding these segments is crucial for manufacturers to tailor their product offerings and marketing strategies to meet specific operational requirements across the diverse foodservice landscape. The segmentation highlights the migration towards boilerless technology due to reduced maintenance costs and the dominance of the institutional catering sector in driving demand for high-capacity units. Geographical distribution also plays a critical role, influencing preferences for gas versus electric models depending on regional energy costs and infrastructure availability.

- By Product Type: Boiler-based, Boilerless

- By Capacity: 6-10 Racks, 11-20 Racks, >20 Racks (Large Capacity)

- By Energy Source: Electric, Gas

- By End-User: Full-Service Restaurants, Quick Service Restaurants (QSR) & Fast Casual, Hotels & Catering, Institutional Catering (Hospitals, Schools, Military), Retail & Convenience Stores

Value Chain Analysis For Commercial Combi Ovens Market

The value chain for the Commercial Combi Ovens Market begins with upstream activities centered on raw material procurement, specifically high-grade stainless steel, advanced electronic components, and specialized heating elements. This stage is characterized by careful sourcing to ensure durability and adherence to strict food safety standards. Midstream activities involve the core manufacturing process, focusing on precision engineering, integrating complex software and control systems, and assembly. Manufacturers often engage in heavy R&D to optimize insulation, steam generation methods, and energy consumption, creating intellectual property that forms a significant competitive advantage.

Downstream analysis focuses on product distribution, installation, and post-sale service. Given the technical complexity of combi ovens, specialized distribution channels are preferred, often utilizing authorized dealers and foodservice equipment providers who can also offer initial setup and training. Direct sales channels are common for large institutional or global chain contracts, where manufacturers negotiate directly with the corporate purchasing departments. The crucial element in the downstream segment is after-sales support, including maintenance contracts and prompt access to certified technicians, as uptime is critical for commercial kitchens.

The distribution channel involves both direct and indirect methods. Indirect channels, through specialized kitchen equipment distributors and catering suppliers, handle the bulk of sales to independent restaurants and smaller chains. These distributors provide localized stock, credit facilities, and essential market access. Direct channels are deployed when engaging with high-volume buyers such as international hotel groups, large institutional buyers (e.g., government contracts), or global QSR franchises, allowing for customized specifications and volume pricing. Effective service networks are a necessity, influencing purchasing decisions significantly due to the high replacement cost and reliance on the equipment.

Commercial Combi Ovens Market Potential Customers

The primary consumers and end-users of commercial combi ovens are diverse organizations operating within the expansive foodservice and hospitality sectors, prioritizing efficiency, volume consistency, and high-quality output. These buyers are typically characterized by high operational intensity and stringent hygiene requirements. Hotels and large catering operations represent a substantial customer base due to their need to prepare vast quantities of diverse menu items simultaneously for banquets and room service. Institutional buyers, such as hospital kitchens, military bases, and university cafeterias, demand durable, high-capacity ovens that adhere to strict nutritional and safety guidelines, often favoring gas or electric models based on utility access.

Furthermore, the rapidly expanding Quick Service Restaurant (QSR) and Fast Casual segments are increasingly adopting compact and smart combi ovens. Although QSRs traditionally relied on fryers and specific cooking units, modern combi ovens enable them to introduce healthier, steamed, or roasted menu items while maintaining rapid service times and standardized product quality across multiple locations. Full-service restaurants and fine dining establishments are also key buyers, utilizing the precise temperature and humidity controls offered by combi ovens to execute complex culinary techniques that demand absolute consistency, often favoring the premium boiler-based models for superior steaming capabilities.

The emerging customer demographic includes convenience stores and retail food operations that offer prepared, hot meals. These smaller enterprises require benchtop or low-capacity combi units that offer flexibility in preparing snacks, baked goods, and hot entrees with minimal staff training. The purchasing decisions across all these customer groups are heavily influenced by total cost of ownership (TCO), energy efficiency ratings, localized service availability, and the simplicity of integrated control systems that streamline workflow for diverse kitchen staff.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 3.1 Billion |

| Market Forecast in 2033 | USD 5.2 Billion |

| Growth Rate | 7.5% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Rational AG, Middleby Corporation, Welbilt Inc. (Convotherm), Unox S.p.A., Ali Group S.p.A. (Electrolux Professional, Lainox), Fujimak Corporation, Alto-Shaam Inc., MKN GmbH, Retigo s.r.o., Henny Penny Corporation, ITW Food Equipment Group (Hobart), Duke Manufacturing Co., Pratica Klimatizaçao e Refrigeração, Fagor Professional, E-Combi. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Commercial Combi Ovens Market Key Technology Landscape

The technology landscape of the Commercial Combi Ovens Market is dominated by advancements in steam generation, control interface sophistication, and connectivity features. Key innovations revolve around differentiating between boiler-based systems, which produce high-quality, saturated steam ideal for sensitive cooking processes, and boilerless (or injection) systems, which spray water directly onto heating elements, offering reduced maintenance and faster heat-up times. Modern control panels utilize large, intuitive touchscreen interfaces (often capacitive) that support multi-step programming, cloud-based recipe management, and language localization, drastically lowering the learning curve for kitchen staff.

The increasing integration of Internet of Things (IoT) technology is transforming operational management. Combi ovens are now frequently equipped with Wi-Fi or Ethernet connectivity, enabling remote monitoring of cooking cycles, energy usage, and operational status. This connectivity facilitates firmware updates, remote diagnostics by service technicians, and integration with broader kitchen management systems (KMS). Furthermore, manufacturers are focusing heavily on sensors that provide granular control over the cooking environment, including multi-point core temperature probes and humidity sensors that adjust steam injection precisely, optimizing texture and flavor profiles.

Sustainability and efficiency technologies are also paramount. This includes advanced heat recovery systems that recapture waste heat from exhaust to preheat incoming water, reducing overall energy consumption. Sophisticated self-cleaning systems, requiring minimal manual intervention and utilizing highly concentrated, specialized cleaning agents, represent a significant technological draw, improving kitchen hygiene and reducing labor hours. The future landscape is moving toward AI-driven self-correction mechanisms that learn from previous cooking cycles to consistently deliver specified results, regardless of variations in initial load or product consistency.

Regional Highlights

The global Commercial Combi Ovens Market exhibits varied growth patterns and technology adoption rates across major geographies, driven by differences in disposable income, regulatory environments, and the maturity of the foodservice infrastructure. North America and Europe collectively represent the largest share of the market, characterized by high automation levels and a strong focus on energy-efficient replacement models. In these regions, high labor costs necessitate investment in equipment that maximizes output per employee, reinforcing the demand for high-capacity, fully automated, and networked combi ovens that minimize operational variance.

North America is dominated by large QSR chains, institutional catering providers, and high-end hospitality sectors. The market here is highly receptive to technological upgrades, including advanced IoT integration, predictive maintenance solutions, and seamless integration with existing kitchen hardware. Europe, particularly Western Europe, shows a strong preference for durable, high-quality, German and Italian manufactured units. Strict European Union regulations regarding energy consumption and hygiene standards drive innovation towards eco-friendly and easily sanitizable designs. The high saturation rate means growth primarily stems from replacing older, less efficient units with smarter, more connected models.

The Asia Pacific (APAC) region is projected to register the fastest growth rate during the forecast period. This acceleration is attributed to massive urbanization, rising disposable incomes, and the rapid westernization of diets, leading to explosive growth in organized foodservice, including domestic and international QSRs, hotels, and tourist resorts. Countries such as China, India, and Southeast Asian nations are heavily investing in modern kitchen infrastructure to support this expansion. Demand in APAC often favors models offering versatility and reliability under challenging conditions (e.g., fluctuating power supply), making mid-range, robust boilerless systems highly popular for their low maintenance overhead. The Middle East and Africa (MEA), particularly the GCC states, show robust demand fueled by large infrastructure projects, tourism, and governmental investment in institutional facilities, often importing high-end European models.

- North America: Focus on high capacity, advanced automation, and IoT connectivity; mature market driven by replacement cycles and labor cost mitigation.

- Europe: Leading adoption of sustainability features (low water use, heat recovery) and stringent hygiene standards; dominance of boiler-based systems in gourmet segments.

- Asia Pacific (APAC): Fastest-growing region driven by QSR expansion, rising tourism, and rapid adoption of professional equipment in developing economies; high demand for robust, easy-to-maintain boilerless ovens.

- Latin America: Characterized by fragmented distribution networks; increasing adoption of combi ovens in major metropolitan areas for efficient hotel and institutional catering.

- Middle East & Africa (MEA): Growth linked closely to tourism investment and large hospitality projects; preference for high-end, reliable models imported from established global leaders.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Commercial Combi Ovens Market.- Rational AG

- Middleby Corporation

- Welbilt Inc. (Convotherm)

- Unox S.p.A.

- Ali Group S.p.A. (Electrolux Professional, Lainox)

- Fujimak Corporation

- Alto-Shaam Inc.

- MKN GmbH

- Retigo s.r.o.

- Henny Penny Corporation

- ITW Food Equipment Group (Hobart)

- Duke Manufacturing Co.

- Pratica Klimatizaçao e Refrigeração

- Fagor Professional

- E-Combi

- Groupe SEB (associated professional brands)

- Cleveland Range, LLC

- Vulcan (ITW FEG subsidiary)

- RATIONAL International AG

- Electrolux Professional AB

Frequently Asked Questions

Analyze common user questions about the Commercial Combi Ovens market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the fundamental difference between boiler-based and boilerless combi ovens?

Boiler-based combi ovens use an external steam generator (boiler) to produce high volumes of saturated, highly precise steam, which is critical for consistent texture in delicate foods like pastries or seafood. Boilerless ovens (also called injection or self-generating) inject water directly onto a hot heating element inside the cavity. Boilerless models are generally preferred for lower maintenance, faster heat-up times, and reduced water consumption, making them popular in QSR and general catering settings where operational simplicity outweighs the need for absolute steam precision.

How do commercial combi ovens contribute to reducing labor costs in a professional kitchen?

Combi ovens significantly reduce labor costs by consolidating the functions of multiple traditional appliances, such as steamers, fryers, and convection ovens, into a single unit. Their advanced programming capabilities allow complex, multi-stage recipes to be executed automatically and consistently, minimizing the need for constant monitoring by highly skilled chefs. Furthermore, integrated self-cleaning cycles drastically reduce the time and effort spent on end-of-day cleaning tasks, allowing staff to focus on food preparation and service, thereby maximizing labor efficiency.

Which capacity segment is projected to show the highest growth in the global market?

The 11-to-20 Racks capacity segment is generally projected to show stable, robust growth, primarily driven by the expansion of large institutional kitchens (hospitals, schools, corporate catering) and mid-to-large hotel chains globally. However, the 6-10 Racks segment, including compact countertop models, is exhibiting the fastest incremental growth, fueled by the rapid expansion of QSRs, fast-casual restaurants, and convenience stores looking for versatile, high-throughput equipment that fits smaller footprints in high-rent urban areas.

What are the key sustainability features driving purchase decisions in mature markets like Europe?

In mature markets, sustainability features are critical determinants of procurement. Key technologies include advanced heat recovery systems that capture thermal energy from exhaust air to pre-warm incoming water, leading to significant energy savings. Furthermore, innovations in water conservation, particularly in boilerless models and smart water management systems that adjust usage based on need, are highly valued. Certification marks related to energy efficiency (like Energy Star ratings, where applicable) and reduced chemical usage in automated cleaning cycles are increasingly mandatory requirements for major institutional buyers.

How is IoT and AI technology fundamentally changing the functionality of new combi oven models?

IoT and AI are transforming combi ovens into networked intelligent appliances. Connectivity enables manufacturers and operators to utilize predictive maintenance algorithms that analyze sensor data to anticipate equipment failure, thereby maximizing uptime. AI functionality facilitates dynamic cooking adjustments, meaning the oven can automatically modify humidity and time based on real-time feedback from internal food probes and ambient cavity conditions, ensuring perfect, consistent results and enabling remote diagnostics and cloud-based management of recipes and operational data across multiple store locations.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager