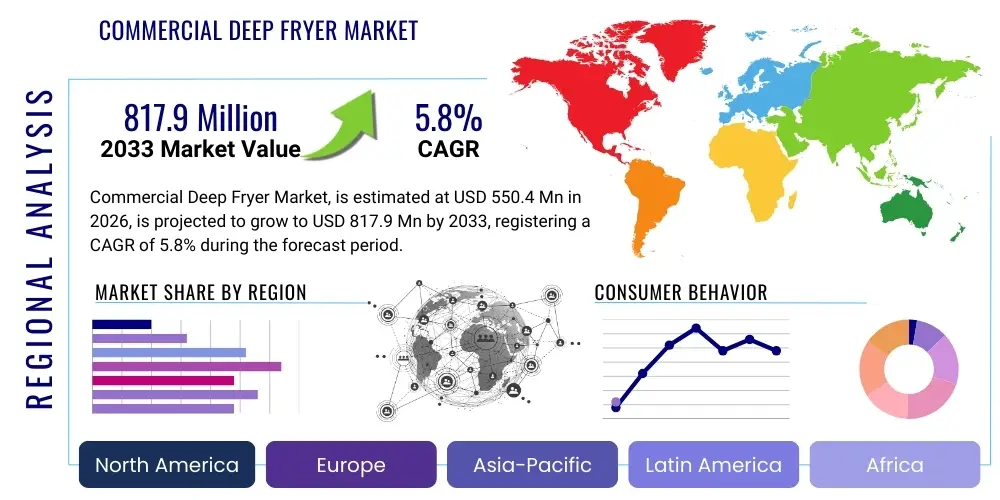

Commercial Deep Fryer Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 437254 | Date : Dec, 2025 | Pages : 242 | Region : Global | Publisher : MRU

Commercial Deep Fryer Market Size

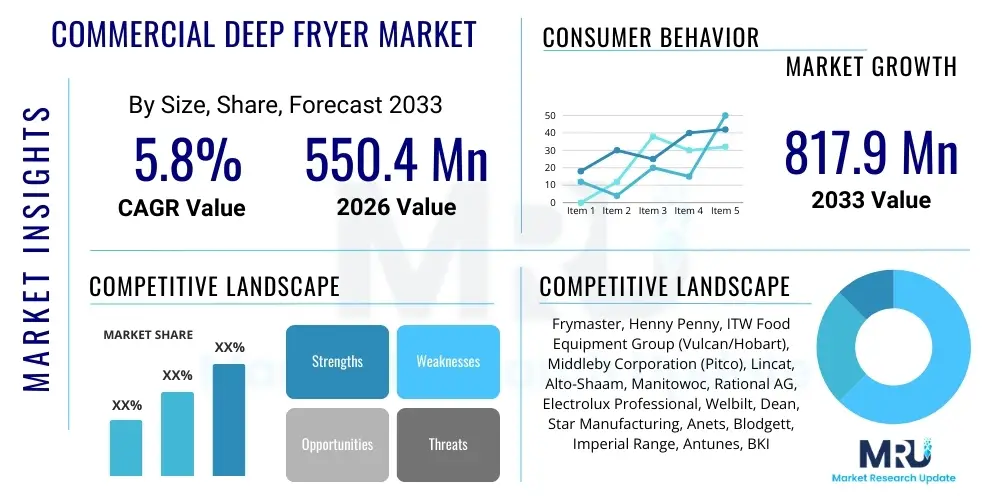

The Commercial Deep Fryer Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 5.8% between 2026 and 2033. The market is estimated at $550.4 Million USD in 2026 and is projected to reach $817.9 Million USD by the end of the forecast period in 2033.

Commercial Deep Fryer Market introduction

The Commercial Deep Fryer Market encompasses the manufacturing, distribution, and sales of heavy-duty equipment designed specifically for deep-frying food items in professional and institutional settings. These units are essential components of commercial kitchens, serving high-volume demands across various foodservice sectors. Products range from small countertop models suitable for independent cafes to large, floor-standing, multi-vat systems utilized by major Quick Service Restaurants (QSRs) and institutional caterers. The core function of these fryers is to provide rapid, consistent, and safe frying capabilities, minimizing oil absorption while maximizing food quality and throughput, which is critical for maintaining operational efficiency in high-traffic environments.

Major applications for commercial deep fryers span the entire spectrum of the hospitality and foodservice industry, including full-service restaurants, hotels, corporate cafeterias, ghost kitchens, and specialized fast-food establishments. The continued global proliferation of fried food items, such as french fries, chicken, donuts, and seafood, acts as a perpetual demand driver. Key benefits associated with modern commercial fryers include enhanced energy efficiency through improved insulation and heating elements, superior oil management systems (like automatic filtration), and integration of digital controls for precise temperature maintenance and programmability. These advancements not only reduce operating costs but also contribute significantly to the consistency and quality of the final food product, meeting increasingly stringent consumer and regulatory expectations.

Driving factors stimulating market expansion include the rapid globalization and expansion of organized foodservice chains, particularly in emerging economies where dining-out culture is accelerating. Furthermore, technological innovation focused on safety and sustainability—such as automated fire suppression systems and high-efficiency heat exchange designs that prolong oil life—is encouraging replacement cycles and new installations. The increasing need for speed and consistency in food preparation, coupled with labor cost pressures, necessitates the adoption of reliable and automated frying equipment, thereby cementing the commercial deep fryer's indispensable role in modern culinary operations globally.

Commercial Deep Fryer Market Executive Summary

The Commercial Deep Fryer Market is experiencing robust growth fueled by continuous expansion in the global Quick Service Restaurant (QSR) sector and a sustained emphasis on operational efficiency within commercial kitchens. Current business trends indicate a strong shift towards equipment offering enhanced connectivity, real-time diagnostics, and superior oil management capabilities, directly addressing concerns related to labor shortages and rising input costs (specifically cooking oil and energy). Key players are focusing intensely on developing smart fryers integrated with IoT functionality to allow remote monitoring and optimization of cooking parameters. Furthermore, regulatory pressures focusing on improved kitchen air quality and reduced emissions are driving the adoption of electric and induction-based fryers over traditional gas models in specific urban environments, contributing to product differentiation and market segmentation.

Regionally, the market dynamics are highly differentiated. Asia Pacific (APAC) stands out as the fastest-growing region, primarily due to the vast expansion of international fast-food chains and the increasing disposable income that supports rapid growth in local organized food services. North America and Europe, representing mature markets, exhibit demand predominantly driven by replacement cycles, upgrades to energy-efficient models (e.g., ENERGY STAR certified units), and the proliferation of virtual kitchens and food delivery services requiring highly consistent, durable equipment. Middle East and Africa (MEA) are witnessing infrastructural development in tourism and hospitality, spurring nascent but significant demand for high-capacity, heavy-duty frying solutions in large hotel and institutional settings.

Segment trends highlight the dominance of floor-standing models due to their high capacity necessary for mass production, especially in high-volume institutional settings. However, the countertop segment is gaining traction, driven by the rise of smaller specialized eateries, food trucks, and ghost kitchen operators prioritizing compact, versatile, and modular equipment. By energy source, while gas fryers remain prevalent due to their low operating cost in specific regions, the electric segment is projected to show the highest CAGR, supported by advancements in heating technology, ease of installation, and growing environmental mandates favoring electric appliances in new commercial building codes. The End-User segment remains heavily weighted towards QSRs, which are the largest volume consumers of commercial deep fryers globally.

AI Impact Analysis on Commercial Deep Fryer Market

User queries regarding the impact of Artificial Intelligence (AI) on the Commercial Deep Fryer Market frequently center on automation potential, predictive maintenance capabilities, and optimization of operational costs. Common questions investigate how AI algorithms can reduce oil degradation, improve cooking consistency across different batches, and automate complex tasks like basket loading/unloading and oil filtration cycles. Users are keenly interested in the feasibility of integrating AI with existing kitchen management systems to predict equipment failure before it occurs (predictive maintenance) and dynamically adjust temperature and cook times based on real-time feedback (e.g., sensor data on food density or moisture content). The key expectation is that AI integration will fundamentally enhance food quality, drastically lower energy and oil consumption, and mitigate the need for constant skilled labor oversight, thereby transforming the traditionally manual frying process into a fully optimized, data-driven operation.

- AI-powered predictive maintenance reduces downtime and maintenance costs by analyzing temperature trends, heating element usage, and component wear indicators.

- Real-time cooking optimization utilizes machine learning models to adjust fry times and temperatures dynamically based on ingredient input and desired crispness, ensuring product consistency.

- Automated oil quality monitoring systems employ AI to analyze oil viscosity and chemical breakdown, triggering filtration or replacement cycles precisely when needed, extending oil life significantly.

- Integration with kitchen management software allows AI to optimize workflow, coordinating fryer output with other cooking stations to minimize waiting times and food waste.

- Advanced safety protocols utilize AI-driven thermal imaging and sensor data to predict and prevent potential oil overheating or fire risks before they become critical.

DRO & Impact Forces Of Commercial Deep Fryer Market

The market for commercial deep fryers is significantly influenced by a complex interplay of demand drivers (D), market restraints (R), and strategic opportunities (O), which collectively define the impact forces shaping its trajectory. The primary driver is the accelerating global preference for convenient, fried food, especially within the rapidly expanding Quick Service Restaurant (QSR) sector, which mandates high-capacity, reliable frying equipment. Simultaneously, technological advancements focusing on reducing energy consumption and enhancing oil longevity are compelling operators to upgrade their existing fleets. However, persistent restraints include the escalating costs associated with cooking oil disposal and replacement, coupled with increasing consumer health consciousness regarding the nutritional profile of deep-fried items. These restraints necessitate innovation towards low-fat or air-frying technologies, although traditional deep fryers remain indispensable for many core menu items.

Opportunities for growth are predominantly centered on the penetration of advanced technologies, such as full automation in oil management and the adoption of IoT-enabled 'smart fryers' that offer remote diagnostics and superior operational control. Furthermore, the rise of specialized ghost kitchens and cloud kitchens—which require modular, highly efficient, and compact equipment optimized for delivery workflows—presents a new, robust avenue for market expansion. The impact forces indicate a competitive environment where differentiation is achieved not merely through capacity but through quantifiable improvements in Total Cost of Ownership (TCO), driven by energy savings, labor reduction, and extended oil service life. Regulatory mandates concerning food safety and worker well-being also act as powerful external forces, pushing manufacturers towards designs that prioritize safer handling and easier cleaning procedures.

The dynamic tension between the demand for high-volume frying (Driver) and the pressure to meet sustainability goals (Restraint/Opportunity) dictates the pace of technological development. Success in this market increasingly depends on providing solutions that offer a sustainable competitive advantage to operators, bridging the gap between high-quality output and minimized environmental footprint. This strategic imperative is visible in the market’s push towards induction heating and advanced filtration systems that recycle oil more effectively than ever before, positioning efficiency and sustainability as central competitive impact forces.

Segmentation Analysis

The Commercial Deep Fryer Market is meticulously segmented based on key criteria including the energy source, capacity, structure, and the ultimate end-user application. This segmentation aids manufacturers and strategists in developing targeted products tailored to the specific operational demands of diverse commercial kitchens. The analysis reveals that while the fundamental need for high-quality frying remains constant, the optimal equipment configuration varies dramatically between a small, independent coffee shop requiring a minimal countertop unit and a large, institutional cafeteria needing multiple floor-standing gas fryers for continuous service. Understanding these segment nuances is crucial for accurate market forecasting and strategic investment in product development, particularly concerning energy efficiency features and automation levels.

- By Type

- Electric Deep Fryers

- Gas Deep Fryers (Natural Gas, Propane)

- Induction Deep Fryers

- By Capacity

- Small Capacity (Less than 10 Liters)

- Medium Capacity (10 to 20 Liters)

- Large Capacity (More than 20 Liters)

- By Structure

- Countertop Deep Fryers

- Floor Standing Deep Fryers

- Built-in/Module Fryers

- By End-User

- Quick Service Restaurants (QSRs)

- Full-Service Restaurants (FSRs)

- Hotels and Cafeterias

- Institutional Food Service (Hospitals, Schools)

- Catering and Others (Food Trucks, Ghost Kitchens)

Value Chain Analysis For Commercial Deep Fryer Market

The Value Chain for the Commercial Deep Fryer Market begins with upstream activities, primarily encompassing the sourcing of critical raw materials such as specialized stainless steel alloys, high-efficiency heating elements (for electric models), and complex control mechanisms. Key upstream suppliers include steel mills, specialized component manufacturers (e.g., thermostats, pressure regulators), and electronic control board providers. Manufacturers must maintain robust relationships with these suppliers to ensure the quality, durability, and compliance of the finished products, given the high-stress environment commercial kitchen equipment operates in. Strategic sourcing and inventory management are paramount in this phase, heavily impacting final manufacturing costs and product lead times, particularly in the current climate of volatile commodity prices.

The manufacturing and assembly stage involves high precision engineering, including welding, assembly of complex filtration systems, and the integration of advanced digital control interfaces. Distribution channels are highly varied, consisting of both direct and indirect routes. Direct sales often target large national and international QSR chains or institutional clients who require specialized, custom-built solutions and comprehensive after-sales support contracts. Indirect distribution relies heavily on an established network of commercial kitchen equipment dealers, wholesalers, and specialized catering equipment distributors, which handle logistics, localized installation, and regional inventory management, particularly for independent restaurants and small regional chains.

Downstream analysis focuses on the end-user interaction, covering installation, operation, maintenance, and eventual replacement. Post-sale services, including warranty provision, spare parts availability, and technical support, are crucial differentiators, significantly influencing brand loyalty and repurchase decisions among professional operators. The increasing complexity of modern fryers, especially those integrated with IoT and advanced filtration, necessitates a highly skilled downstream service network capable of diagnostics and repair. The efficiency of this downstream servicing directly impacts the perceived TCO for the customer, completing the value cycle by ensuring long-term operational viability and customer satisfaction.

Commercial Deep Fryer Market Potential Customers

The primary purchasers and key end-users of commercial deep fryers are broadly categorized as any establishment involved in the high-volume preparation and sale of food. The largest and most influential segment comprises Quick Service Restaurants (QSRs) and global fast-food chains, which depend on these fryers for their core menu offerings, requiring robust, standardized, and highly automated equipment to maintain product consistency across thousands of global outlets. These customers prioritize reliability, speed, and integrated oil management systems to minimize downtime and labor costs, often procuring equipment through large, centralized, multi-year supply contracts negotiated directly with manufacturers or major distributors.

Another significant customer base includes Full-Service Restaurants (FSRs) and high-end hotels, which require flexibility and often smaller, specialized fryers to complement complex menus. Institutional catering, encompassing hospitals, universities, military bases, and corporate cafeterias, represents a distinct segment characterized by predictable, high-volume demand often served by large-capacity, heavy-duty floor models where safety and energy compliance are paramount. Furthermore, the burgeoning ghost kitchen and food truck segments are rapidly emerging as key potential customers, characterized by their demand for compact, modular, and extremely high-efficiency countertop or mobile-specific frying units that maximize output in limited spatial footprints, driving innovation in compact design and energy optimization.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | $550.4 Million USD |

| Market Forecast in 2033 | $817.9 Million USD |

| Growth Rate | 5.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Frymaster, Henny Penny, ITW Food Equipment Group (Vulcan/Hobart), Middleby Corporation (Pitco), Lincat, Alto-Shaam, Manitowoc, Rational AG, Electrolux Professional, Welbilt, Dean, Star Manufacturing, Anets, Blodgett, Imperial Range, Antunes, BKI, Frialator, Garland, Waring. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Commercial Deep Fryer Market Key Technology Landscape

The technology landscape within the Commercial Deep Fryer Market is rapidly evolving, driven primarily by demands for improved energy efficiency, safety, and automation. A foundational technological shift involves the transition toward high-efficiency heating systems, including infrared heating elements and advanced heat exchanger designs in gas models that maximize heat transfer and minimize flue gas temperatures, leading to significant fuel savings. Induction technology is also emerging as a high-potential alternative, offering extremely fast heat-up times, precise temperature control, and cooler kitchen environments, though adoption is still limited by the higher initial capital expenditure required for these systems compared to conventional gas or electric resistance fryers.

The integration of advanced oil management systems represents another crucial technological development. Modern fryers are increasingly equipped with integrated, automatic oil filtration systems that process and return cooking oil to the vat, dramatically extending the oil's lifespan and reducing labor intensity associated with manual filtering. Beyond filtration, many high-end units now feature oil quality sensors (e.g., total polar materials sensors) that provide real-time data on oil degradation, allowing operators to make scientifically informed decisions about oil replacement rather than relying on arbitrary timelines or visual inspection. This technology directly addresses one of the major operating expenses and sustainability concerns in the foodservice industry.

Furthermore, the connectivity and digitalization of commercial fryers are reshaping operations. The advent of IoT (Internet of Things) functionality allows fryers to connect to cloud-based monitoring platforms, providing managers with real-time performance data, usage patterns, and predictive maintenance alerts. These smart features facilitate centralized management of multiple units across various locations, ensuring standardized cooking procedures and enabling remote diagnostics by service technicians. Automated basket lifting and lowering mechanisms, along with programmed recipe settings, further reduce reliance on manual operations, enhancing consistency and worker safety, solidifying the market's move toward highly automated and data-driven equipment solutions.

Regional Highlights

- North America: This region maintains a significant market share, characterized by high penetration of multinational QSR chains and a mature infrastructure for foodservice equipment. Demand is primarily driven by replacement cycles focused on adopting highly energy-efficient models (like ENERGY STAR certified fryers) and those incorporating advanced automation and safety features to combat high labor costs. The US market dominates, showing a strong appetite for large-capacity, floor-standing gas fryers due to the readily available infrastructure.

- Europe: The European market demonstrates robust demand, influenced significantly by stringent regulatory standards concerning energy consumption and environmental impact. There is a noticeable trend towards highly precise, efficient electric and induction fryers, especially in Western European countries, favored for their low emissions and precise temperature control. Germany, the UK, and France are key contributors, with growth often tied to the expansion of casual dining and institutional catering services.

- Asia Pacific (APAC): APAC is positioned as the fastest-growing market globally. This exponential growth is underpinned by the rapid urbanization, rising disposable incomes, and the widespread adoption of Western-style fast food and organized foodservice concepts, particularly in China and India. The market here demands versatile equipment, ranging from high-volume floor models for international chains to compact, durable countertop units for local, independent food vendors, often prioritizing affordability alongside basic reliability.

- Latin America (LATAM): The LATAM market is expanding steadily, driven by increased investment in tourism and hospitality infrastructure in countries like Mexico and Brazil. Market dynamics favor fryers that offer good value and durability, with a growing interest in units that can handle multiple types of cooking oils effectively due to regional supply variations. Standardization efforts across regional foodservice operators are fueling demand for reliable, medium-capacity fryers.

- Middle East and Africa (MEA): Growth in MEA is primarily linked to significant government investments in tourism, mega-hospitality projects, and expansion of global hotel brands and QSR franchises, particularly within the Gulf Cooperation Council (GCC) nations. This region demands high-capacity, heavy-duty frying solutions suitable for large-scale banquet operations and institutional catering, often prioritizing robust construction and high throughput capabilities.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Commercial Deep Fryer Market.- Frymaster (Welbilt, Inc.)

- Henny Penny

- ITW Food Equipment Group (Vulcan/Hobart)

- Middleby Corporation (Pitco Frialator)

- Lincat Group (Middleby Corporation)

- Alto-Shaam

- Manitowoc Foodservice (Welbilt, Inc.)

- Rational AG

- Electrolux Professional

- Dean (Manitowoc Foodservice)

- Star Manufacturing

- Anets (Middleby Corporation)

- Blodgett (Middleby Corporation)

- Imperial Range

- Antunes

- BKI (Standex International)

- Garland (Manitowoc Foodservice)

- Waring Commercial

- Comstock-Castle Stove Co.

- American Range

Frequently Asked Questions

Analyze common user questions about the Commercial Deep Fryer market and generate a concise list of summarized FAQs reflecting key topics and concerns.What factors primarily drive the demand for new commercial deep fryers?

Demand is primarily driven by the expansion of Quick Service Restaurants (QSRs) globally, the need to replace older, inefficient models with energy-efficient units (especially ENERGY STAR certified), and the necessity for advanced oil management systems to reduce operational costs and enhance food quality consistency.

How is the adoption of IoT impacting commercial deep fryer operations?

IoT integration allows for centralized monitoring, real-time performance diagnostics, and automated alerts for predictive maintenance. This technology significantly improves equipment uptime, ensures standardization of cooking parameters across multiple locations, and facilitates remote troubleshooting, optimizing overall kitchen efficiency.

What are the main distinctions between gas and electric commercial fryers?

Gas fryers typically offer faster heat recovery and lower running costs in areas with inexpensive natural gas, often preferred for high-volume, floor-standing applications. Electric fryers, including induction models, provide more precise temperature control, easier installation, and are increasingly favored in urban areas due to zero localized emissions and cooler operation.

Which market segment is projected to grow the fastest in the forecast period?

The Asia Pacific (APAC) region is projected to exhibit the highest Compound Annual Growth Rate (CAGR) due to rapid urbanization, increasing disposable income, and the massive proliferation of organized foodservice chains and institutional catering across key economies like China and India.

What role does oil filtration technology play in modern commercial fryers?

Integrated oil filtration technology is critical for extending the lifespan of cooking oil, thereby significantly reducing one of the highest operational expenditures. Advanced systems automate the cleaning process, ensure consistent oil quality, and contribute directly to better-tasting food and lower oil procurement costs.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager