Commercial Multifunctional Food Slicer Market Size By Region (North America, Europe, Asia-Pacific, Latin America, Middle East and Africa), By Statistics, Trends, Outlook and Forecast 2026 to 2033 (Financial Impact Analysis)

ID : MRU_ 431986 | Date : Dec, 2025 | Pages : 243 | Region : Global | Publisher : MRU

Commercial Multifunctional Food Slicer Market Size

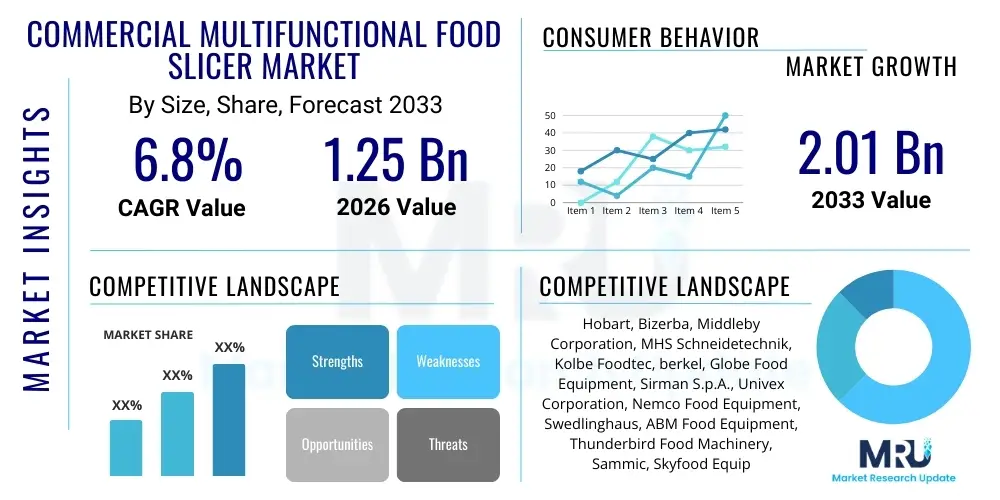

The Commercial Multifunctional Food Slicer Market is projected to grow at a Compound Annual Growth Rate (CAGR) of 6.8% between 2026 and 2033. The market is estimated at USD 1.25 billion in 2026 and is projected to reach USD 2.01 billion by the end of the forecast period in 2033.

Commercial Multifunctional Food Slicer Market introduction

The Commercial Multifunctional Food Slicer Market encompasses high-capacity, precision-engineered machinery designed for use in professional food service environments, catering facilities, large institutional kitchens, and industrial food processing plants. These advanced appliances are distinguished by their capability to perform multiple functions beyond standard slicing, often including shredding, dicing, cubing, and specialized cuts, enabling kitchens to process diverse raw ingredients efficiently and consistently. Product differentiation in this highly competitive space is driven by factors such as blade technology, material composition (often stainless steel for hygiene and durability), safety features, and integration capabilities with other automated kitchen systems. The core function of these slicers is to ensure uniform product presentation, which is critical for portion control, aesthetic appeal, and cooking consistency in high-volume settings, thereby directly impacting operational profitability and customer satisfaction across the hospitality sector.

Major applications for commercial multifunctional food slicers span deli counters, institutional cafeterias, fine dining establishments, and dedicated meat and vegetable preparation areas within central kitchens. These machines handle an extensive range of food items, including cured meats, cheeses, raw vegetables, and specialized breads, providing versatility that single-purpose machines lack. The integration of powerful motors, adjustable thickness controls, and easy-to-clean designs positions these slicers as indispensable assets for businesses prioritizing speed and food safety compliance. Furthermore, the modern multifunctional slicer incorporates ergonomic designs and intuitive user interfaces, minimizing training time and maximizing throughput, addressing the persistent operational challenge of labor scarcity in the commercial food industry.

Key market drivers fueling expansion include the increasing global demand for prepared and semi-prepared foods, the rigorous enforcement of hygiene and food safety standards requiring stainless steel and easily sanitized equipment, and the perpetual necessity for operational efficiency improvements in the hospitality and food processing sectors. The core benefits derived from adopting these systems include substantial labor cost reduction, enhanced food quality consistency, minimization of food waste through precise cutting, and compliance with strict regulatory body guidelines regarding cross-contamination and cleanliness. Continuous innovation focusing on automatic feeding mechanisms and specialized blade geometries is further reinforcing the market's trajectory towards higher automation and specialized preparation tasks, particularly as restaurants seek equipment capable of adapting quickly to changing menu trends and dietary preferences.

Commercial Multifunctional Food Slicer Market Executive Summary

The Commercial Multifunctional Food Slicer Market is currently undergoing significant transformation, characterized by a robust shift towards automation and integration with IoT technologies, positioning efficiency and connectivity as paramount business trends. Leading manufacturers are investing heavily in developing smart slicers capable of monitoring performance metrics, predicting maintenance needs, and communicating directly with inventory management systems, optimizing supply chain operations for commercial users. A notable trend is the escalating consumer and regulatory focus on food safety, driving demand for slicers with advanced sanitation features, including antimicrobial surface coatings and simplified disassembly processes for deep cleaning, thereby mitigating bacterial risks inherent in high-volume food preparation. Furthermore, the market is responding to sustainability pressures by introducing energy-efficient motors and materials that reduce the overall carbon footprint associated with commercial kitchen operations.

Regionally, the market exhibits divergent growth patterns. North America and Europe maintain dominance, driven by stringent food safety regulations, high labor costs necessitating automation, and the widespread presence of large supermarket chains and institutional catering services demanding standardized equipment. However, the Asia Pacific (APAC) region is projected to register the highest Compound Annual Growth Rate (CAGR) throughout the forecast period. This accelerated growth is primarily attributed to rapid urbanization, increasing disposable incomes leading to greater reliance on organized food service sectors (including QSRs and central kitchens), and significant investments in modernizing food processing infrastructure across emerging economies like China and India. Latin America and the Middle East & Africa (MEA) present burgeoning opportunities, particularly as global hospitality chains expand their footprints, demanding professional-grade kitchen equipment that meets international operational benchmarks.

Segment-wise, automatic and semi-automatic slicers continue to capture the largest market share, though the fully automatic segment is experiencing the fastest growth, propelled by large-scale processing facilities seeking minimal human intervention. Based on application, the segment covering meat and poultry processing remains central to market valuation, yet the rising popularity of plant-based diets and complex salads is rapidly boosting the segment for vegetable and fruit preparation slicers, particularly those optimized for delicate ingredients. Materially, high-grade stainless steel construction dominates due to its hygiene properties, essential for compliance, while technology trends emphasize precision mechanisms such as servo motors and laser-guided cutting systems to achieve micron-level thickness consistency, crucial for premium food products and portion control.

AI Impact Analysis on Commercial Multifunctional Food Slicer Market

User queries regarding the impact of Artificial Intelligence (AI) on the Commercial Multifunctional Food Slicer Market primarily center on three themes: enhanced operational safety, predictive maintenance capabilities, and the potential for hyper-precise, adaptive slicing based on real-time ingredient analysis. Users are highly interested in how AI vision systems might revolutionize sorting and quality control by identifying defects or inconsistencies in raw food items before slicing, automatically adjusting cutting parameters to minimize waste. Concerns often revolve around the initial investment costs associated with integrating complex AI hardware and software, and the necessary expertise required to maintain these smart systems within existing kitchen infrastructures. The overarching expectation is that AI will move the commercial slicer beyond basic automation toward intelligent processing units capable of autonomous decision-making regarding optimal slicing angles, speeds, and thickness settings based on the specific texture and type of food being handled, significantly improving both throughput and consistency without human oversight.

- AI-driven computer vision systems analyze ingredient texture and density in real-time, optimizing blade speed and thickness automatically to ensure perfect cuts and reduce food breakage.

- Predictive maintenance algorithms monitor motor vibrations, blade wear, and operational temperature, scheduling necessary service automatically before component failure occurs, maximizing uptime.

- Integration of machine learning allows slicers to adapt slicing protocols based on historical performance data and quality metrics, leading to continuous efficiency improvement and consistent product output.

- AI facilitates enhanced safety protocols by detecting foreign objects or incorrect human interaction patterns, instantly shutting down the machine to prevent injury or equipment damage.

- Automated quality control checks utilize deep learning to identify slice irregularities, discarding non-compliant cuts and providing instant feedback to kitchen managers regarding material quality input.

DRO & Impact Forces Of Commercial Multifunctional Food Slicer Market

The market dynamics of commercial multifunctional food slicers are heavily influenced by a complex interplay of Drivers, Restraints, and Opportunities (DRO), which collectively shape the competitive landscape and investment decisions. The primary driver remains the compelling necessity for optimizing labor costs in the foodservice industry, where automation of complex cutting tasks provides significant long-term operational savings compared to manual preparation. This is augmented by the global trend towards mass customization in food production, requiring flexible equipment capable of rapidly switching between different product types and precision cuts. Opportunities lie predominantly in integrating advanced robotics for automated loading and unloading, bridging the gap between current semi-automatic operations and fully integrated processing lines. These forces compel manufacturers to prioritize technological innovation while addressing market resistance related to high capital expenditures and training complexities associated with advanced machinery.

Restraints primarily revolve around the initial substantial capital investment required to acquire high-end, multifunctional slicers, which can be prohibitive for small and medium-sized enterprises (SMEs). Furthermore, the maintenance and repair of highly specialized, digitally controlled commercial equipment require specialized technicians, adding complexity and cost to ownership. The market also faces the impact force of rapidly evolving food safety regulations; while these regulations drive demand for compliance-focused features, they simultaneously require manufacturers to continuously redesign equipment, potentially increasing production costs and time-to-market. The rapid obsolescence of digital control interfaces, driven by advancements in smart kitchen technology, is also a concern for end-users worried about long-term equipment viability.

Impact forces currently shaping the market include technological advancements, where continuous improvement in blade metallurgy and motor efficiency provides better cutting quality and lower energy consumption, creating a strong pull factor for equipment replacement cycles. Economic volatility, particularly rising costs of raw materials (like stainless steel) and global supply chain disruptions, exerts pressure on manufacturing margins and final product pricing. However, the demographic shift towards convenient, ready-to-eat meals, coupled with expansion of cloud kitchens and centralized catering hubs globally, acts as a powerful enabling force, guaranteeing consistent demand for high-throughput, reliable slicing solutions. Successfully navigating these forces requires manufacturers to focus on modular designs that offer scalability and easier maintenance, mitigating the risks associated with high upfront costs and technical complexity.

Segmentation Analysis

The Commercial Multifunctional Food Slicer Market is segmented primarily based on operational type, application, material, and distribution channel, providing a clear framework for understanding market dynamics and targeted strategies. Operational type segmentation distinguishes between manual, semi-automatic, and fully automatic machines, reflecting varying degrees of automation and suitability for different throughput volumes, from small deli operations to industrial processing plants. Application segmentation highlights the diverse end-uses, including meat, cheese, vegetable, and bakery item slicing, each requiring specific blade geometries and motor specifications. Material segmentation underscores the industry standard of stainless steel versus other composites, driven heavily by hygiene and longevity requirements. Analyzing these segments is essential for stakeholders looking to optimize product portfolios and address the specific needs of commercial buyers across the global food service ecosystem.

- By Operational Type:

- Manual Slicers

- Semi-Automatic Slicers

- Fully Automatic Slicers (High-throughput industrial models)

- By Application:

- Meat and Poultry Processing

- Cheese and Dairy Processing

- Vegetable and Fruit Preparation

- Deli and Catering Services

- Bakery and Confectionery

- By Material:

- Stainless Steel Construction (Dominant)

- Aluminum Alloy and Composite Materials

- By Distribution Channel:

- Direct Sales (Major processing plants)

- Indirect Sales (Distributors, Retailers, E-commerce Platforms)

- By End-User:

- Restaurants and Hotels (HORECA)

- Catering and Institutional Food Services

- Supermarkets and Hypermarkets

- Food Processing Facilities

Value Chain Analysis For Commercial Multifunctional Food Slicer Market

The value chain for the Commercial Multifunctional Food Slicer Market begins with Upstream Analysis, focusing on the sourcing of critical raw materials, predominantly high-grade stainless steel, specialized alloys for blades, and sophisticated electronic components (motors, sensors, control boards). Manufacturers often face supply chain volatility, particularly concerning critical components, making strategic sourcing and long-term contracts vital for maintaining stable production costs and quality. Efficiency in the manufacturing stage, including precision machining and assembly, dictates the final quality and durability of the slicer, with leading players utilizing advanced robotic assembly lines to ensure compliance with strict regulatory standards and design specifications. Intellectual property, particularly relating to specialized blade technology and automated cutting mechanisms, forms a significant competitive advantage at this stage.

The Downstream Analysis involves the distribution and final sale of the equipment to commercial end-users. The distribution channel is bifurcated into direct and indirect routes. Direct sales are often utilized for large, high-value, fully automatic industrial slicers, where manufacturers deploy dedicated sales teams offering technical consultation, customized installation, and comprehensive post-sale maintenance contracts to major food processing companies. Indirect channels, involving authorized distributors, equipment dealers, and specialized catering equipment suppliers, handle the majority of semi-automatic and mid-range slicers sold to restaurants, delis, and smaller institutional buyers. E-commerce platforms are increasingly gaining traction, particularly for replacement parts and standard counter-top models, although the heavy weight and complexity of commercial units necessitate specialized logistics.

Service and support constitute a crucial segment of the downstream value chain, differentiating market leaders through rapid response times, availability of genuine spare parts, and specialized technical training for client staff. The profitability across the chain is often highest in the upstream innovation stage and the downstream aftermarket services. Successful market participants strategically manage the balance between manufacturing efficiency and the robust support necessary to maintain the high operational demands of commercial kitchen environments. Emphasis is placed on streamlining inventory management for replacement blades and critical mechanical assemblies to minimize client operational downtime, which is a major purchasing criterion for high-volume customers.

Commercial Multifunctional Food Slicer Market Potential Customers

Potential customers for Commercial Multifunctional Food Slicers are highly diversified, encompassing any establishment requiring precise, high-volume processing of food materials for consumption or further industrial preparation. The primary end-users are large centralized food production facilities, known as central kitchens or commissaries, which supply numerous restaurant outlets or institutional clients. These facilities prioritize fully automatic, high-throughput models integrated with robotic loading systems to maximize efficiency and maintain stringent quality controls across millions of product units annually. The inherent need for consistent product specifications across all output makes these customers the most significant buyers of high-value equipment.

Another major segment includes the entire spectrum of the Hospitality (HORECA) sector, ranging from fast-casual restaurant chains and hotels to fine dining establishments and catering companies. For HORECA users, the primary buying criteria include versatility, ease of cleaning (to meet immediate hygiene standards), and footprint efficiency, often leaning towards semi-automatic or advanced counter-top models that can handle a variety of items like charcuterie, bulk cheese, and produce. Supermarkets, hypermarkets, and specialized deli counters form a third key customer group, relying on these slicers for in-store preparation of meats, cheeses, and prepared meal components, where durability, speed, and safety features for daily public-facing use are paramount considerations.

The institutional sector, including hospitals, schools, military bases, and corporate cafeterias, represents a stable and growing customer base. These entities require robust, easy-to-operate slicers that can manage large batches under strict portion control guidelines and dietary requirements. Their purchasing decisions are often influenced by government procurement regulations, prioritizing equipment longevity, compliance certifications (such as NSF or CE), and proven reliability. The expanding demand for specialized food items, like gluten-free or artisanal products, also necessitates slicer models that offer highly specialized blade and carriage configurations, driving purchases among specialized food producers and niche caterers.

| Report Attributes | Report Details |

|---|---|

| Market Size in 2026 | USD 1.25 billion |

| Market Forecast in 2033 | USD 2.01 billion |

| Growth Rate | 6.8% CAGR |

| Historical Year | 2019 to 2024 |

| Base Year | 2025 |

| Forecast Year | 2026 - 2033 |

| DRO & Impact Forces |

|

| Segments Covered |

|

| Key Companies Covered | Hobart, Bizerba, Middleby Corporation, MHS Schneidetechnik, Kolbe Foodtec, berkel, Globe Food Equipment, Sirman S.p.A., Univex Corporation, Nemco Food Equipment, Swedlinghaus, ABM Food Equipment, Thunderbird Food Machinery, Sammic, Skyfood Equipment, Vollrath Company, Nella Cutlery, Berkel S.p.A., Robot Coupe, and Graef. |

| Regions Covered | North America, Europe, Asia Pacific (APAC), Latin America, Middle East, and Africa (MEA) |

| Enquiry Before Buy | Have specific requirements? Send us your enquiry before purchase to get customized research options. Request For Enquiry Before Buy |

Commercial Multifunctional Food Slicer Market Key Technology Landscape

The commercial multifunctional food slicer market is undergoing substantial technological evolution, moving far beyond basic mechanical cutting mechanisms toward highly sophisticated, integrated digital systems. One of the paramount technological advancements is the deployment of high-precision servo motors and magnetic levitation drives, replacing traditional gearing systems. These motors offer instantaneous and precise control over blade speed and carriage movement, essential for maintaining exact thickness consistency across different product densities and temperatures, thereby improving yield and reducing waste. Furthermore, advanced blade materials, incorporating ceramic coatings or specialized hardened steels, are becoming standard to enhance cutting edge retention and reduce the frequency of sharpening, directly impacting operational efficiency in high-throughput environments. The integration of sensors capable of detecting product temperature and resistance allows the machine's control unit to dynamically adjust cutting parameters, ensuring optimal performance across a wide spectrum of food items.

Connectivity and smart functionality define the modern slicer landscape, primarily through the adoption of Internet of Things (IoT) sensors. These sensors collect real-time operational data, including usage patterns, motor load, and hygiene status, transmitting it to cloud-based platforms for predictive maintenance analysis and remote diagnostics. This shift from reactive to proactive maintenance minimizes costly downtime, a critical factor in large-scale food processing. Another significant innovation is the implementation of Hygienic Design principles, utilizing smooth, crevice-free surfaces, easily removable components, and often incorporating automated wash cycles (Clean-In-Place or CIP systems) to drastically reduce the labor associated with sanitation and maximize adherence to HACCP guidelines. This technological focus on safety and cleanliness is non-negotiable and drives much of the replacement demand across highly regulated markets.

Furthermore, human-machine interface (HMI) advancements, utilizing intuitive touch screens and programmable memory settings, enable operators to quickly recall complex cutting programs for diverse products, improving versatility and reducing human error. Robotic automation, particularly in the fully automatic segment, is leveraging collaborative robots (cobots) for automated product loading and stacking, which significantly enhances line speed and further reduces manual handling risks. These technological shifts—precision mechanics, IoT connectivity, advanced hygiene features, and enhanced robotics—are collectively pushing the envelope of what commercial slicers can achieve, positioning them as essential components of the modern, digitally optimized food processing ecosystem.

Regional Highlights

Geographic analysis reveals distinct consumption patterns and growth drivers across the major global regions, reflecting economic maturity, regulatory environments, and prevailing culinary trends. North America, characterized by high labor costs and stringent USDA and FDA regulations, maintains a strong demand for fully automated, high-safety slicers, particularly within large supermarket chains and high-volume deli operations. The replacement cycle for equipment is relatively stable, driven primarily by technological upgrades focused on integrated connectivity (IoT) and efficiency gains, reinforcing its position as a major revenue generator. Europe follows a similar trajectory, with Germany, the UK, and France leading the market due to robust food processing sectors and a cultural emphasis on high-quality, processed meats and cheeses, necessitating extremely precise slicing equipment that adheres to rigorous EU machinery directives and hygiene standards.

The Asia Pacific (APAC) region is forecasted to experience the most dynamic growth, fueled by demographic shifts and massive infrastructure investments in modernizing the food supply chain. Countries like China and India are seeing a rapid proliferation of organized retail, quick-service restaurants (QSRs), and centralized food production hubs, creating unprecedented demand for commercial kitchen equipment. Although the market initially favored semi-automatic and lower-cost models, there is an accelerating transition towards high-end, multifunctional equipment as operational efficiency and safety standards become paramount, particularly in export-focused processing facilities. Government initiatives supporting food security and processing modernization further amplify the market potential in Southeast Asia and surrounding economies.

Latin America and the Middle East & Africa (MEA) represent significant emerging opportunities. In Latin America, economic stabilization in key markets like Brazil and Mexico, coupled with the expansion of international hotel chains and franchise restaurants, is driving the adoption of professional-grade slicers. The MEA region, particularly the Gulf Cooperation Council (GCC) countries, is experiencing booming tourism and hospitality sectors, necessitating large volumes of imported, professional kitchen equipment to service luxury hotels and institutional catering required for major events and growing expat populations. While these regions may lag in immediate adoption of the very latest AI-integrated models, demand for reliable, durable, and standard-compliant semi-automatic and automatic slicers is expanding rapidly, positioning them as strategic targets for global manufacturers looking for long-term growth.

- North America: Market leader driven by high labor costs, demanding strict automation, and continuous investment in smart, IoT-enabled slicers for efficiency and advanced data logging in large deli chains and institutional settings.

- Europe: Mature market characterized by robust regulatory compliance (CE marking, HACCP), strong demand from specialty meat and cheese processors, and preference for highly precise, durable German and Italian manufactured equipment.

- Asia Pacific (APAC): Highest projected CAGR, propelled by rapid urbanization, massive expansion of central kitchens, growing organized retail, and increasing emphasis on global food safety standards in emerging economies.

- Latin America (LATAM): Growing market driven by globalization of the hospitality industry and need for reliable equipment to support local restaurant and hotel expansion under improved operational standards.

- Middle East & Africa (MEA): Market growth linked directly to soaring tourism infrastructure, large-scale catering projects, and institutional demand requiring durable, professional equipment compliant with international certifications.

Top Key Players

The market research report includes a detailed profile of leading stakeholders in the Commercial Multifunctional Food Slicer Market.- Hobart (ITW Food Equipment Group)

- Bizerba SE & Co. KG

- Middleby Corporation (Pitco, Blodgett)

- MHS Schneidetechnik GmbH

- Kolbe Foodtec GmbH

- Berkel S.p.A.

- Globe Food Equipment Company

- Sirman S.p.A.

- Univex Corporation

- Nemco Food Equipment

- Swedlinghaus

- ABM Food Equipment

- Thunderbird Food Machinery

- Sammic S.L.

- Skyfood Equipment LLC

- Vollrath Company

- Nella Cutlery

- Graef GmbH

- Dito Sama (Electrolux Professional)

- Robot Coupe

Frequently Asked Questions

Analyze common user questions about the Commercial Multifunctional Food Slicer market and generate a concise list of summarized FAQs reflecting key topics and concerns.What is the primary difference between automatic and semi-automatic commercial food slicers?

Automatic slicers feature motorized carriages and feeding systems requiring minimal operator interaction, ideal for high-volume, standardized processing in industrial settings. Semi-automatic models utilize motorized blades but require the operator to manually load and push the food carriage, commonly used in delis and restaurants prioritizing versatility over maximum throughput.

How do food safety regulations influence the design of modern commercial slicers?

Regulations necessitate designs that prevent cross-contamination and ensure ease of sanitation. This drives the use of high-grade, corrosion-resistant stainless steel, seamless construction, fully enclosed components, and quick-release mechanisms for easy, tool-free cleaning, directly addressing HACCP and NSF compliance requirements for commercial kitchens.

Which technological trends are currently driving innovation in the slicing market?

Key technological innovations include the integration of IoT sensors for predictive maintenance and performance monitoring, the use of advanced servo motors for micron-level slicing precision, and AI vision systems to automatically assess food quality and adjust cutting parameters in real-time to optimize yield.

What is the expected CAGR for the Commercial Multifunctional Food Slicer Market between 2026 and 2033?

The Commercial Multifunctional Food Slicer Market is projected to grow at a steady Compound Annual Growth Rate (CAGR) of 6.8% during the forecast period of 2026 to 2033, driven by increasing automation adoption globally and expanding food processing infrastructure in emerging markets.

Which region presents the strongest growth opportunities for new market entrants?

The Asia Pacific (APAC) region offers the strongest growth opportunities, fueled by rapid expansion of the centralized kitchen model, significant investments in modernizing food service supply chains, and an escalating need for high-throughput, safety-compliant processing equipment across diverse economies like China, India, and Southeast Asia.

To check our Table of Contents, please mail us at: sales@marketresearchupdate.com

Research Methodology

The Market Research Update offers technology-driven solutions and its full integration in the research process to be skilled at every step. We use diverse assets to produce the best results for our clients. The success of a research project is completely reliant on the research process adopted by the company. Market Research Update assists its clients to recognize opportunities by examining the global market and offering economic insights. We are proud of our extensive coverage that encompasses the understanding of numerous major industry domains.

Market Research Update provide consistency in our research report, also we provide on the part of the analysis of forecast across a gamut of coverage geographies and coverage. The research teams carry out primary and secondary research to implement and design the data collection procedure. The research team then analyzes data about the latest trends and major issues in reference to each industry and country. This helps to determine the anticipated market-related procedures in the future. The company offers technology-driven solutions and its full incorporation in the research method to be skilled at each step.

The Company's Research Process Has the Following Advantages:

- Information Procurement

The step comprises the procurement of market-related information or data via different methodologies & sources.

- Information Investigation

This step comprises the mapping and investigation of all the information procured from the earlier step. It also includes the analysis of data differences observed across numerous data sources.

- Highly Authentic Source

We offer highly authentic information from numerous sources. To fulfills the client’s requirement.

- Market Formulation

This step entails the placement of data points at suitable market spaces in an effort to assume possible conclusions. Analyst viewpoint and subject matter specialist based examining the form of market sizing also plays an essential role in this step.

- Validation & Publishing of Information

Validation is a significant step in the procedure. Validation via an intricately designed procedure assists us to conclude data-points to be used for final calculations.

×

Request Free Sample:

Related Reports

Select License

Why Choose Us

We're cost-effective and Offered Best services:

We are flexible and responsive startup research firm. We adapt as your research requires change, with cost-effectiveness and highly researched report that larger companies can't match.

Information Safety

Market Research Update ensure that we deliver best reports. We care about the confidential and personal information quality, safety, of reports. We use Authorize secure payment process.

We Are Committed to Quality and Deadlines

We offer quality of reports within deadlines. We've worked hard to find the best ways to offer our customers results-oriented and process driven consulting services.

Our Remarkable Track Record

We concentrate on developing lasting and strong client relationship. At present, we hold numerous preferred relationships with industry leading firms that have relied on us constantly for their research requirements.

Best Service Assured

Buy reports from our executives that best suits your need and helps you stay ahead of the competition.

Customized Research Reports

Our research services are custom-made especially to you and your firm in order to discover practical growth recommendations and strategies. We don't stick to a one size fits all strategy. We appreciate that your business has particular research necessities.

Service Assurance

At Market Research Update, we are dedicated to offer the best probable recommendations and service to all our clients. You will be able to speak to experienced analyst who will be aware of your research requirements precisely.

Contact With Our Sales Team

Customer Testimonials

The content of the report is always up to the mark. Good to see speakers from expertise authorities.

Privacy requested , Managing Director

A lot of unique and interesting topics which are described in good manner.

Privacy requested, President

Well researched, expertise analysts, well organized, concrete and current topics delivered in time.

Privacy requested, Development Manager